Introduction: The “Heart” Supporting Energy Transformation

In the grand narrative of the global energy structure’s transformation towards green and low-carbon development, efficient, safe, and clean gas compression technology plays a crucial “heart” role, providing core power for the storage, transportation, and application of new energy sources. As a leading enterprise in this key field, Jiangsu Minnuo Group Co., Ltd. has been deeply involved in the research and development and manufacturing of high-end gas compression equipment since its inception. Its diaphragm compressor series has become an indispensable link in the clean energy industry chain, including hydrogen and natural gas. Minnuo is not just an equipment manufacturer, but a staunch guardian of the safety, efficiency, and purity of energy systems, committed to driving the future of global energy through innovative technology.

I. Technological Leadership: Oil-Free Compression and High-Pressure Precision Control

Diaphragm compressors represent the high-end of gas compression technology. Their core advantage lies in their superior performance when handling high-pressure, high-purity, flammable, explosive, or highly corrosive media. Jiangsu Minnuo’s diaphragm compressors employ a revolutionary multi-layer metal diaphragm design, acting as a robust and reliable barrier to completely isolate the gas chamber from the hydraulic chamber. This structure fundamentally achieves 100% oil-free compression, ensuring the absolute purity of compressed gases (especially high-value hydrogen, electronic gases, or medical gases), and fulfilling the promise of “zero pollution”.

In terms of performance parameters, Minnuo compressors demonstrate industry-leading strength. Their operating pressure range reaches up to 70 MPa, with precise control capability of ±0.1 MPa, a level of accuracy crucial for applications such as hydrogen fuel cell vehicle refueling. The flow rate adjustment range is wide, from 150 to 1000 standard cubic meters per hour, seamlessly adapting to different operating conditions through intelligent frequency conversion control. Whether facing the extreme cold of liquefied natural gas environments or the demanding challenges of high-pressure hydrogen, Minnuo compressors provide stable and reliable power output.

II. Core Advantages: Deep Integration of Materials Science and Intelligent Safety

In the technological realm of diaphragm compressors, true leadership lies not in the simple accumulation of components, but in a profound understanding and deep integration of core material performance and system safety logic. The superior performance of Jiangsu Minnuo diaphragm compressors is built upon the relentless pursuit of materials science and the meticulous design of intelligent safety systems. These two elements work together to form a solid foundation for stable operation under extreme conditions.

Faced with the complex media and harsh environments of the energy industry, the choice of materials directly determines the lifespan and safety of the equipment. Minnuo considers materials science the first line of defense for its products’ lifeline.

Addressing the challenge of “hydrogen embrittlement”: In hydrogen energy applications, hydrogen gas can penetrate the metal lattice under high pressure, leading to material embrittlement and a sharp drop in performance—the so-called “hydrogen embrittlement” effect. Minnuo is well aware of this risk and has carefully selected advanced materials such as nickel-based alloys and Monel alloys for the core pressure-bearing components of hydrogen compressors—such as cylinder heads and chambers. These alloys have a dense austenitic crystal structure, which effectively blocks the intrusion and diffusion of hydrogen atoms, fundamentally eliminating hydrogen embrittlement and ensuring that the equipment maintains the strength and integrity of the materials even under 70MPa high-pressure hydrogen environments.

Resisting multi-component corrosion: In scenarios such as liquefied natural gas (LNG) recovery and shale gas extraction, the medium may contain corrosive components such as hydrogen sulfide, carbon dioxide, and moisture. Minnuo provides a variety of material options for this purpose, including 316L stainless steel and Hastelloy C-276. Hastelloy C-276, known as the “King of Corrosion Resistance,” exhibits exceptional resistance to oxidizing and reducing acids, as well as chloride ion corrosion, ensuring the compressor remains robust and reliable even in acidic gases and humid marine environments.

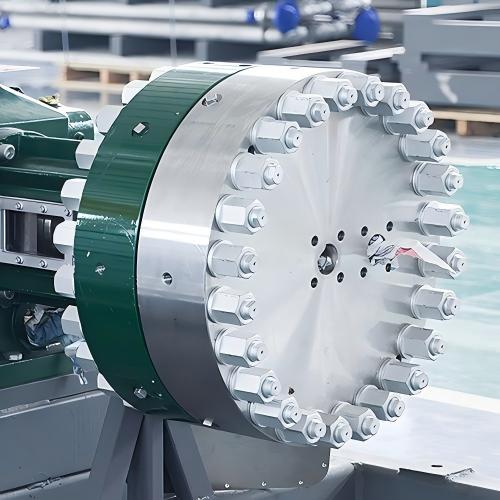

Core Sealing Technology: The “heart” of the equipment—the multi-layer metal diaphragm assembly—is not only crucial for dynamic sealing but also a concentrated embodiment of the material’s mechanical properties. Minnuo employs high-strength stainless steel or nickel-based alloy diaphragms processed with special techniques. Through precise design and molding, these diaphragms possess extremely high fatigue strength and crack propagation resistance, achieving reliable reciprocating motion for tens of thousands of cycles. This core component effectively controls gas leakage at an extremely low level of ≤1×10-6 Pa·m³/s, achieving a physically “zero-leakage” safety and providing ultimate protection for the compression of high-value, high-risk media.

In Minnuo’s design philosophy, safety is not one or more independent functions, but a comprehensive, multi-layered system engineering approach. Minnuo diaphragm compressors, through the deep integration of intelligent control and multiple protection mechanisms, construct a proactive safety defense system encompassing perception, decision-making, and execution.

Intelligent Sensing and Precise Control: The equipment deeply integrates a PLC (Programmable Logic Controller) and DCS (Distributed Control System) monitoring architecture. This not only enables real-time, high-precision monitoring and closed-loop control of key parameters such as output pressure, flow rate, oil pressure, and cylinder temperature, but also transmits equipment operating data in real-time to the central control room or the user’s mobile terminal via a remote IoT module. Operators can monitor the equipment’s health status at any time, perform parameter optimization and energy efficiency management, realizing a transformation from a “passive response” to a “proactive early warning” operation and maintenance model.

Comprehensive Proactive Safety Protection: The core of a safety system lies in anticipating and preventing risks. Minnuo equipment integrates a multi-level overpressure safety interlock system. When the system detects an abnormal increase in pressure, it triggers a tiered response, sequentially activating alarms, automatic adjustments, and ultimately emergency shutdown, avoiding the risks associated with the failure of a single component. Meanwhile, the system comes standard with a gas leak detection sensor. Upon detecting even a trace leak, it immediately issues an alarm and initiates safety procedures.

Intrinsic Safety and Explosion-Proof Certification: In potentially explosive environments, the safety of electrical equipment is paramount. The drive unit and all electrical components of the Minnuo compressor are designed and selected in strict accordance with ATEX II 2G Ex d IIC T4 and IECEx international explosion-proof standards. This means that even if a flammable gas explosion occurs inside the equipment, its robust explosion-proof casing effectively isolates the spread of flames and high temperatures, preventing disasters in the external environment and providing the outermost and most solid intrinsic safety barrier for the entire energy station or process unit.

Through the deep integration of materials science and intelligent safety, Jiangsu Minnuo diaphragm compressors not only provide powerful performance but also give customers the most valuable asset when operating clean energy projects: absolute reliability and unwavering confidence in safety.

III. Application Map: Empowering Diverse Clean Energy Scenarios

Jiangsu Minnuo’s diaphragm compressors, with their excellent adaptability, widely serve multiple key scenarios in the global energy sector, outlining a clear green energy application map.

Hydrogen Energy Storage, Transportation, and Refueling: In the hydrogen energy industry chain, Minnuo compressors are core equipment in 35MPa and 70MPa high-pressure hydrogen refueling stations. Their oil-free design ensures extremely high purity hydrogen fuel, meeting the stringent requirements of fuel cell vehicles, while their hydrogen embrittlement-resistant materials and high-pressure stability provide reliable support for large-scale hydrogen storage and transportation.

Natural Gas Transmission and Distribution & Liquefied Natural Gas (LNG) Processing: In natural gas compression and pressure regulating stations, Minnuo compressors can flexibly handle fluctuations in inlet pressure, ensuring continuous and stable delivery. At LNG receiving terminals, their equipment can withstand extremely low temperatures of 162℃, efficiently and reliably recovering and reliquefying boil-off gas (BOG), significantly reducing energy loss and economic waste.

Unconventional Natural Gas Extraction: In the extraction of unconventional gas fields such as coalbed methane and shale gas, the environment is harsh and the gas composition is complex. Minnuo compressors, with their excellent corrosion resistance and dustproof design, can adapt to the severe challenges of open-field operation and high sulfur content, demonstrating strong environmental adaptability.

Nuclear Power and High-End Industries: In nuclear power plants, helium, used as a coolant or circulating medium, requires an absolutely pure compression environment. Minnuo’s oil-free, zero-leakage design perfectly meets this requirement. Furthermore, in fields with stringent requirements for gas purity, such as semiconductor manufacturing, pharmaceuticals, and aerospace, Minnuo compressors are also key equipment for ensuring process quality.

IV. Corporate Foundation: Thirty-Seven Years of Craftsmanship and Global Trust

A profound corporate foundation is the source of Minnuo’s technological confidence. Founded in 1987, Jiangsu Minnuo Group has, through thirty-seven years of dedicated development, grown into a large-scale modern enterprise group encompassing multiple sectors including gas compression equipment, air compressors, high-end machine tools, and pressure vessels. Through global trade platforms such as Alibaba International Station, Minnuo has accumulated hundreds of millions of US dollars in transactions, and its products are exported to many countries and regions worldwide, including Japan, the UAE, the United States, Europe, Russia, and Chile, establishing a solid international customer trust and an efficient after-sales service system.

Authoritative certifications are the passport for products to enter the global market. Minnuo diaphragm compressors have fully passed multiple authoritative international certifications, including ISO, CE, ATEX, and IECEx. This signifies that its products fully meet or even exceed international standards in terms of quality, safety, and explosion-proof performance, providing strong support for the smooth implementation and safe operation of global projects.

V. Service Support: A Commitment to 24/7 Rapid Response

For energy industry customers, the continuous and stable operation of equipment translates into significant economic benefits. Minnuo deeply understands this and has built a customer-centric, full-cycle service ecosystem. The company has established a localized service network covering multiple regions globally, providing 24/7 technical support. More importantly, Minnuo promises rapid delivery of critical spare parts within 7 days. This measure significantly reduces potential downtime for customers, putting service guarantees into practice and demonstrating Minnuo’s deep sense of responsibility for customer operational efficiency.

VI. Future Outlook: Leading the Industry, Empowering a Zero-Carbon Future

Looking ahead, with the deepening of the global goal of “carbon neutrality,” industries such as hydrogen energy, biomass gas, and carbon capture will experience explosive growth, placing higher and more complex demands on gas compression technology. Jiangsu Minnuo Group is actively targeting this trend, continuously increasing its R&D investment in new materials, intelligent algorithms, energy efficiency optimization, and lifecycle management.

The company is committed not only to being an equipment supplier but also to becoming a strategic partner for its customers throughout the entire process, providing comprehensive solutions from technical consulting and solution design to intelligent operation and maintenance and energy efficiency improvement. Minnuo’s vision is to continuously promote the application of diaphragm compressor technology in broader fields—such as environmental engineering, high-purity material preparation, and cutting-edge scientific research laboratories—constantly expanding technological boundaries, and with a solid “Made in China” core, becoming an indispensable technological force in the global process of moving towards a clean, safe, and efficient energy system.

Email

Email sales:+86 15366749631

sales:+86 15366749631