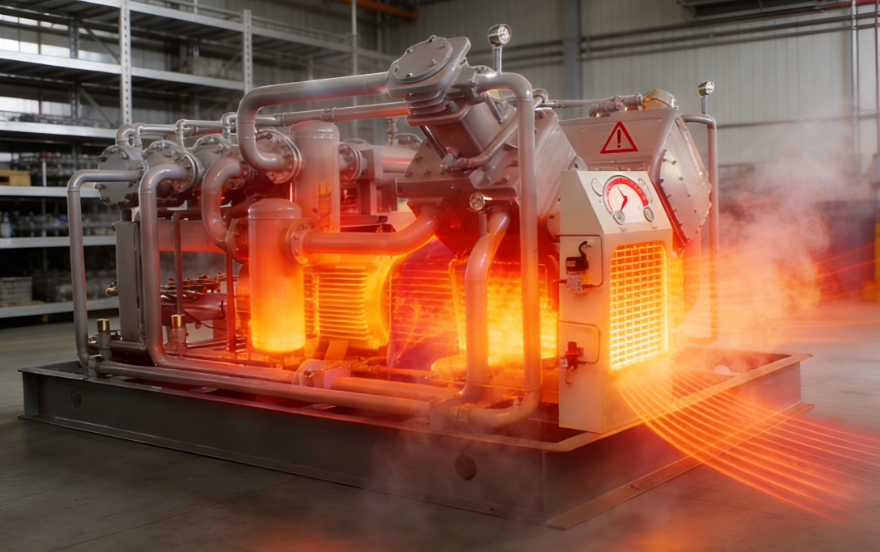

An overheating air compressor is a critical alarm. Essentially, operating above safe temperatures accelerates component wear, degrades lubricants, and triggers catastrophic failures—like seized bearings or rotor damage. As a result, you could face thousands in unplanned repairs and costly downtime.

Therefore, catching the early signs is key. This guide will first detail the seven critical warning signals and then provide actionable steps to diagnose and fix the root cause, helping you restore safe and efficient operation.

7 Critical Warning Signs of an Overheating Compressor

To proactively manage your equipment, watch for these red flags well before an automatic shutdown occurs:

- High Discharge Temperature Reading: This is the most direct sign. Specifically, temperatures consistently exceeding 95°C (203°F) for screw compressors or 120°C (248°F) for pistons signal trouble.

- Frequent Thermal Shutdowns: The unit cuts out repeatedly, especially during warm days or extended operation cycles.

- Burning Oil Smell: A sharp, acrid odor indicates the oil is breaking down due to excessive heat—a process known as oil coking (or carbonization). Consequently, it loses its lubricating and cooling properties.

- Increased Motor Amperage: An overheating compressor works harder. So, monitor amp readings; a sustained rise of 10-15% above normal is a key indicator.

- Reduced Air Output & Pressure: Heat increases internal leakage and reduces volumetric efficiency (the ratio of actual to theoretical air delivery). This leads to longer tank fill times and pressure drops.

- Excessive Condensate in Lines: Hot, saturated air holds more moisture. Then, as it cools in your pipes, it creates more liquid water downstream, which risks tool and product damage.

- Visible Heat Radiation: The compressor cabinet feels dangerously hot, or paint on discharge piping shows discoloration or blistering.

Diagnose and Fix: The 7 Root Causes & Step-by-Step Solutions

1. Clogged Air/Oil Coolers (Radiators)

The Problem: Dirt and dust on the fins act as insulation, which cripples heat exchange.

The Fix:

- First, power down and isolate the compressor.

- Then, use low-pressure compressed air to blow out debris from the opposite direction of normal airflow.

- For heavy grease, apply a non-corrosive fin cleaner, rinse gently, and ensure components are dry.

- For prevention, install intake filters and maintain a quarterly cleaning schedule in dusty environments.

2. Inadequate Lubricant Level or Degraded Oil

The Problem: Oil cools as much as it lubricates. Thus, low levels or oxidized oil fail at both tasks.

The Fix:

- Check the sight glass with the unit off. Then, top up with the manufacturer-recommended oil type.

- If the oil is dark or sludgy, perform a complete oil and filter change immediately.

- Technical Note: High-quality synthetic compressor oils are formulated with superior thermal-oxidative stability. They resist breakdown at extreme temperatures far longer than standard mineral oils, providing a critical safety margin and extending oil change intervals in demanding applications.

3. Faulty Thermostatic Valve

The Problem: This valve directs oil to the cooler. If it sticks closed, hot oil bypasses cooling entirely.

The Fix:

- After the unit reaches operating temperature, feel the inlet and outlet pipes of the oil cooler. If they feel similarly hot, the valve is likely stuck.

- Please note: This issue requires a technician. You should schedule a service call for inspection and replacement.

4. Restricted Airflow Around the Compressor

The Problem: Installations in tight spaces cause the system to recirculate hot air.

The Fix:

- Ensure you maintain 3-5 feet (1-1.5 meters) of clearance on all sides, especially near coolers and vents.

- Remove any obstructions.

- For confined spaces, consider installing ducted exhaust vents to actively expel hot air.

5. Malfunctioning Cooling Fan

The Problem: A faulty fan cannot provide sufficient airflow.

The Fix:

- Carefully visually inspect the fan for damage while running. Ensure it spins at full speed.

- Listen for grinding noises that indicate bearing failure.

- Check electrical connections. Importantly, replace a failed fan immediately.

6. High Ambient Temperature

The Problem: The compressor simply ingests air that is already too hot.

The Fix:

- Improve room ventilation with exhaust fans.

- Provide shade for outdoor units.

- Use a ducted fresh air intake from a cooler location.

- For critical cases, consult an expert about upgrading to a model with a higher cooling capacity.

7. Internal Component Wear (Advanced Issue)

The Problem: Worn bearings or failing valves generate abnormal friction and heat.

The Fix:

- You should suspect this if high temperatures accompany unusual noises (grinding, knocking) or a severe efficiency loss.

- In this scenario, seek professional diagnosis immediately. Continued operation risks total failure. Request a vibration analysis and performance evaluation.

When to Call a Professional: Critical Red Flags

However, there are limits to DIY fixes. You should stop troubleshooting and immediately seek expert help if you encounter any of the following:

- Persistent high temperatures after performing basic maintenance.

- Any metallic grinding or knocking sounds from the compressor block.

- Oil contamination with metal particles (check the drain plug magnet).

- A confirmed faulty thermostatic valve or cooling fan that needs replacement.

- Rapid, cyclical overheating that suggests a complex control or internal issue.

At MINNUO, our service team specializes in remote diagnostics and thermal performance audits. We can pinpoint elusive overheating causes and provide lasting solutions.

FAQ: Quick Answers on Overheating

Q1: What’s a “normal” operating temperature for my screw air compressor?

A1: A healthy screw compressor typically runs between 75°C and 85°C (167°F – 185°F). However, consistently operating above 90°C (194°F) demands investigation.

Q2: Can I use high-temp synthetic oil to ignore overheating?

A2: No. Overheating damages seals, warps components, and degrades air quality. Remember, it’s a system problem you must fix, not mask with different oil.

Q3: How often should I clean my air compressor cooler?

A3: Generally, clean it every 3-6 months in a standard workshop. In contrast, in dusty environments like sawmills, you may need to do it monthly.

Q4: My compressor only overheats in summer. Is that normal?

A4: Higher ambient temperatures will raise operating temps, but they should not cause shutdowns. Often, summer simply exposes an already marginal cooling system.

Conclusion: Proactive Cooling is Cheaper Than a Repair

In summary, an overheating compressor demands immediate attention. By recognizing the seven warning signs and applying these targeted fixes, you can effectively protect a critical asset.

It’s crucial to remember that routine preventive maintenance costs far less than an emergency repair. Moreover, if symptoms point to a complex internal fault, engaging a specialist not only resolves the issue but also proves to be the most economical long-term decision.

Need help diagnosing a persistent overheating issue? Contact MINNUO support. Our engineers will review your symptoms and operating data to provide a precise, actionable solution, ensuring your compressor runs cool, efficient, and reliable for years to come.

Email

Email sales:+86 15366749631

sales:+86 15366749631