In an era of rising energy costs and focus on efficiency, choosing the right air compressor technology is a critical business decision. Minnuo Group, with over 35 years of core engineering and a presence in 150+ countries, provides this definitive guide to cut through the noise, helping you select the technology that maximizes your productivity and profitability.

Core Differences: How Your Compressor’s Engine Thinks

Understanding the fundamental operating principles is key to making the right choice.

Standard Air Compressor (Constant Speed): The Steady, Reliable Powerhouse

How It Works: Imagine a car that only has one speed. A Standard (Constant Speed) compressor’s motor runs at a fixed RPM. It regulates output by repeatedly loading and unloading—consuming significant power even when no air is being used. This “on-off” cycling causes pressure bands and wastes energy under variable demand.

The Minnuo Advantage: Our Standard series is the epitome of robust engineering. Built with high-efficiency, low-friction air ends and premium motors, they are designed for maximum durability and straightforward maintenance in stable, high-duty cycle environments.

Permanent Magnet VSD Air Compressor: The Intelligent, Adaptive Manager

How It Works: Now, imagine a car with advanced, predictive cruise control. A PM VSD compressor doesn’t cycle. Instead, its integrated inverter adjusts the motor speed in real-time to precisely match your air consumption. It seamlessly ramps up and down, delivering “exactly what you need, when you need it” and completely eliminating off-load energy waste.

The Minnuo Advantage: Our PM VSD series leverages rare-earth permanent magnet motors that deliver higher torque and efficiency. This ensures soft starts, exceptional pressure stability (±0.01 bar), and unparalleled energy savings.

The True Cost of Ownership: A Deeper Financial Look

While the initial purchase price is important, the real cost of an air compressor is measured over years. Let’s break down the financials beyond the sticker price.

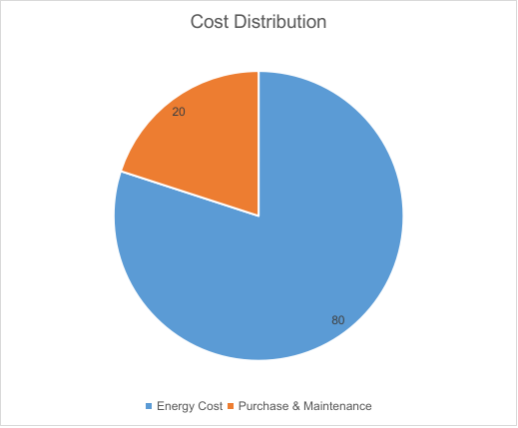

The 80/20 Rule of Compressed Air: It’s an industry axiom that up to 80% of a compressor’s lifetime cost is electricity. The remaining 20% encompasses the initial purchase and maintenance. A higher upfront investment in efficiency can yield exponential returns.

The PM VSD Financial Case: The core of VSD savings lies in eliminating off-load running power and inrush current peaks. In a typical shift with fluctuating demand, a Minnuo PM VSD compressor can reduce energy consumption by 30% to 50%, allowing it to pay back its premium often within 12-24 months.

When Standard Technology Shines: The financial argument for a Minnuo Standard compressor is strongest under one condition: consistently high load. If your operation runs with a steady demand above 80% of capacity, it operates near peak efficiency, making it the most prudent capital investment.

Your Industry-Specific Decision Guide

The “best” choice is the one that fits your specific operational profile. Here’s a breakdown tailored to different industrial scenarios.

Choose a Minnuo PM VSD Compressor If Your Industry Is…

Automotive & Metal Fabrication: With frequent use of intermittent tools like pulse drills and laser cutters.

Plastics & Injection Molding: Cycle times create natural peaks and valleys in air consumption.

Woodworking & Furniture: Sanders, spray guns, and CNC machines create a “peaky” load profile.

Packaging & Material Handling: Air usage spikes with actuators and fillers on production lines.

Choose a Minnuo Standard Air Compressor If Your Application Is…

Continuous Process Manufacturing: Plants running at a constant rate.

Bulk Material Transport: Pneumatic conveying systems with steady operation.

OEM Integration: As a built-in, cost-effective air source for constant-output machinery.

Dedicated Backup Unit: A reliable and economical machine to ensure business continuity.

Beyond the Basics: Minnuo’s Comprehensive Solutions

Your needs might be more specific. Minnuo’s extensive portfolio ensures we have the perfect solution.

100% Oil-Free Air: Our Water-Lubricated Oil-Free Screw and Scroll Compressors are TUV certified to ISO 8573-1 Class 0, essential for food & beverage, pharmaceuticals, and electronics.

Power on the Move: Our Diesel Mobile Compressors are built to deliver reliable air in the toughest environments, from construction sites to remote mining operations.

Specialty Gas Compression: We provide dedicated compressors for Natural Gas (CNG), Nitrogen, and Hydrogen, supporting a wide range of industrial and energy applications.

Case Studies: How Minnuo Compressors Drive Efficiency Worldwide

Don’t just take our word for it. Explore how businesses across the globe have leveraged the right Minnuo technology to solve their challenges and achieve significant returns on investment.

Case Study 1: A Leading Automotive Parts Supplier in Southeast Asia

Challenge: Significant energy waste due to large fluctuations in air demand between production cycles.

Solution: Implementation of a Minnuo Permanent Magnet VSD system.

Result: Achieved a 35% reduction in energy consumption for their compressed air system, with the investment paying for itself in under 22 months.

Case Study 2: A Large Textile Mill Operating 24/7

Challenge: Needed a reliable and cost-effective air source for a capacity expansion with a consistently high demand.

Solution: Installation of a Minnuo Standard Screw Air Compressor as the primary workhorse.

Result: Gained a highly reliable and robust air source that met their production goals while staying within budget.

Case Study 3: A European Craft Beverage Producer

Challenge: Required 100% oil-free air to eliminate any risk of product contamination during packaging.

Solution: Deployment of a TUV-certified Minnuo Water-Lubricated Oil-Free Screw Compressor.

Result: Now operates with complete confidence, ensuring the highest food safety and product quality standards.

Your Questions, Answered by Minnuo Experts

Q: I have multiple small air tools that run intermittently. Which type is better?

A: This is a classic scenario for a PM VSD compressor. Its ability to ramp down to very low speeds when demand is minimal will lead to substantial energy savings compared to a standard unit constantly cycling on and off.

Q: Are PM VSD compressors more expensive to maintain?

A: Not necessarily. While the inverter is an additional component, the soft start feature significantly reduces stress on the motor and mechanical parts, potentially extending their service life. Maintenance requirements are comparable when using genuine Minnuo parts.

Q: My workshop has a very stable air demand. Is there any reason to consider a PM VSD?

A: For truly stable, near-capacity demand, a high-efficiency Standard compressor is an excellent and cost-effective choice. The financial argument for VSD diminishes in this specific scenario. Our consultants can help you analyze your load profile to be certain.

Conclusion: Partner with Experts Who Speak Your Language

Choosing between Standard and PM VSD isn’t about finding the “best” technology, but the right technology for you. With Minnuo, you gain a partner with decades of experience, not just a supplier.

Let our engineers help you analyze your specific needs. Contact Minnuo today for a free, no-obligation compressed air consultation and discover the most efficient path forward for your business.

Email

Email sales:+86 15366749631

sales:+86 15366749631