Introduction: The Core Position of Piston Compressors in the Industrial Sector

Industrial piston compressors, as key power source equipment, are widely used in manufacturing, petrochemicals, mining, food processing, and engineering construction. Their performance parameters directly affect production efficiency and operating costs, with pressure range, displacement, and durability being the three most important indicators. This article will provide an in-depth analysis of these three core performance characteristics to help you make more informed equipment selection decisions.

I. Pressure range: Full coverage from low pressure to high pressure

1. Conventional pressure rating

Industrial piston compressors are typically classified by pressure range according to application requirements as follows:

• Low pressure range : 0.7-1.5 MPa (7-15 bar)

Suitable for pneumatic tools, packaging machinery, and textile equipment

Typical applications: auto repair shops, small manufacturing plants

• Medium pressure range : 1.6-10 MPa (16-100 bar)

Suitable for chemical processes, injection molding, and high-pressure cleaning.

Typical applications: chemical plants, plastic product manufacturing

• High pressure range : 10-40 MPa (100-400 bar) and above

Suitable for gas compression storage, high-pressure testing, and special industrial processes.

Typical applications: natural gas refueling stations, research laboratories

2. Key considerations for stress selection

• System requirement matching : Select a pressure capacity that is 10-15% higher than the actual requirement.

• Peak efficiency range : Each compressor is most efficient within a specific pressure range.

• Multi-stage compression technology : High-pressure applications typically employ multi-stage compression to reduce the load on individual stages and improve efficiency.

II. Displacement: A Comprehensive Solution from Micro to Large

1. Exhaust Displacement Standards and Calculations

• Displacement is typically expressed in cubic meters per minute (m³/min) or cubic feet per minute (CFM), and is affected by the following factors:

• Cylinder size and quantity

• Piston stroke length

• Rotational speed (RPM )

• Intake conditions (temperature, pressure, humidity)

2. Industrial-grade exhaust displacement classification

• Small units : 0.5-10 m³/min

Suitable for workshops and small factories

• Medium-sized units : 10-40 m³/min

Suitable for medium-sized manufacturing enterprises and district gas supply

• Large units : 40-100+ m³/min

Suitable for large factories and centralized gas supply systems

3. Practical suggestions for selecting engine displacement

• Demand assessment : Calculate the maximum air consumption of all pneumatic equipment operating simultaneously.

• Future Expansion : Reserve 20-30% capacity margin.

• Efficiency optimization : Multiple medium-sized units connected in parallel are often more energy-efficient and flexible than a single large unit.

III. Durability Analysis: The Key to Determining Total Cost of Ownership

1. Key factors affecting durability

• Structural design

Cast iron chassis vs. aluminum alloy chassis: Cast iron is more durable in heavy-duty applications.

Reinforcing rib design: Reduces vibration and extends service life

Crankshaft design: Forged crankshafts are superior to cast crankshafts

• Key component materials

Piston rings and cylinder liners: wear-resistant cast iron, PTFE coating

Valve system: stainless steel valve discs, precision-ground valve seats

Bearing types: Rolling bearings vs. sliding bearings

• Cooling system efficiency

Air-cooled system: Simple maintenance, suitable for small to medium power applications.

Water cooling system: provides more even heat dissipation and is suitable for continuous heavy-load operation.

2. Comparison of Mean Time Between Failures (MTBF)

• Economy units : 8,000-12,000 operating hours

• Industrial standard model : 15,000-25,000 operating hours

• Heavy-duty industrial type : 30,000-50,000+ operating hours

3. Maintenance Requirements and Life Extension Strategies

• Routine maintenance : Check air filter and oil level (every 8 hours).

• Regular maintenance : Lubricating oil change, valve inspection (every 500-2000 hours)

• Overhaul cycle : Piston ring replacement, bearing inspection (every 10,000-20,000 hours)

IV. Interrelationships and Optimization Balance of the Three Major Indicators

1. The trade-off between pressure and exhaust volume

• At a constant power output, an increase in pressure typically leads to a decrease in exhaust volume.

• Multistage compressors maintain high exhaust efficiency under high pressure.

• Variable frequency drive technology can optimize pressure-flow relationship under partial load.

2. Balance between durability and performance

• Reducing engine speed can significantly extend engine life, but it also reduces exhaust volume.

• Using high-quality materials improves durability, but increases initial costs.

• Intelligent control systems extend lifespan by reducing the number of start-stop cycles.

3. Positive correlation between energy efficiency and durability

• High-efficiency compressors typically operate at lower temperatures, extending component life.

• Energy-saving designs (such as waste heat recovery) reduce thermal stress and improve reliability.

V. Selection Guide: Matching Your Specific Needs

Scenario 1: Intermittent production (e.g., machining workshop)

• Recommendation : Medium pressure range (8-12 bar), moderate displacement

• Durability focus : tolerance to frequent start-stop cycles, rapid response capability

• Typical configuration : Screw-reciprocating compound or variable frequency reciprocating compressor

Scenario 2: Continuous process industries (such as chemical plants )

• Recommendation : Medium to high pressure range (15-25 bar), stable exhaust volume

• Durability highlights : 24/7 continuous operation capability, efficient cooling system

• Typical configuration : Multi-stage water-cooled piston compressor, with redundant backup

Scenario 3: High-pressure special applications (such as gas filling)

• Recommended : High pressure range (30-40 bar), precise pressure control

• Durability highlights : high-pressure sealing system, safety protection devices

• Typical configuration : Four- or five-stage compression piston unit

Conclusion: Comprehensive evaluation, long-term perspective

When selecting an industrial reciprocating compressor, pressure range, displacement, and durability are not isolated parameters, but rather interrelated system characteristics. Modern industrial reciprocating compressor technology is quite mature, but significant differences still exist between different brands and models. Recommendations for purchasing:

1. Define actual needs : Based on the principle of specific applications rather than “the bigger the better”.

2. Calculate the total cost of ownership : including energy consumption, maintenance, and expected lifespan, rather than just focusing on the purchase price.

3. Considering technological trends : New technologies such as variable frequency control, IoT monitoring, and high-efficiency motors can significantly improve performance.

4. Verify manufacturer data : Require on-site testing or refer to successful case studies of similar operating conditions.

By scientifically analyzing pressure requirements, accurately calculating displacement, and comprehensively evaluating durability design, you will be able to select the most suitable industrial piston compressor to provide reliable, efficient, and economical power support for production operations.

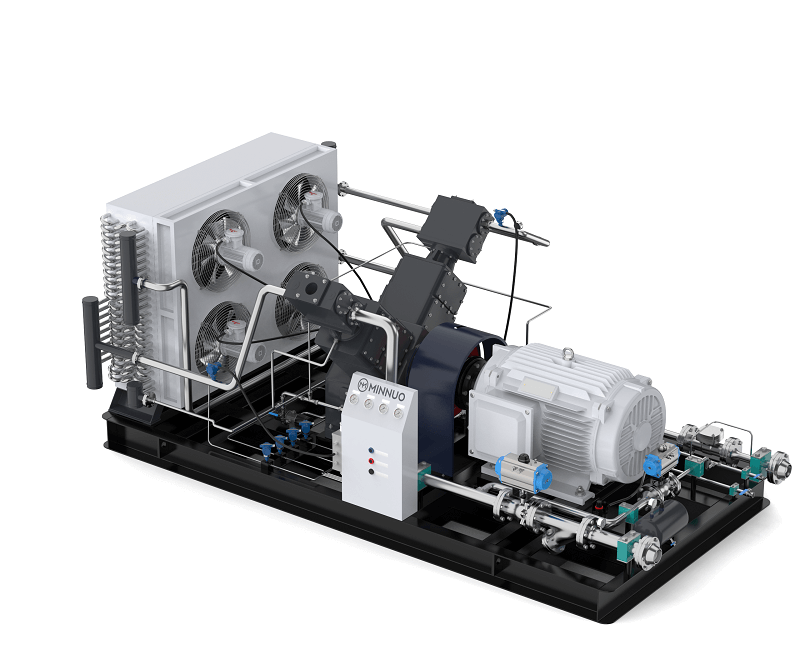

If you are looking for high-quality industrial piston compressors or need customized solutions based on your production conditions, please visit the MINNUO compressor website for more details. MINNUO – specializing in the R&D and manufacturing of industrial compressors, providing you with stable, efficient, and durable industrial power equipment .

Email

Email sales:+86 15366749631

sales:+86 15366749631