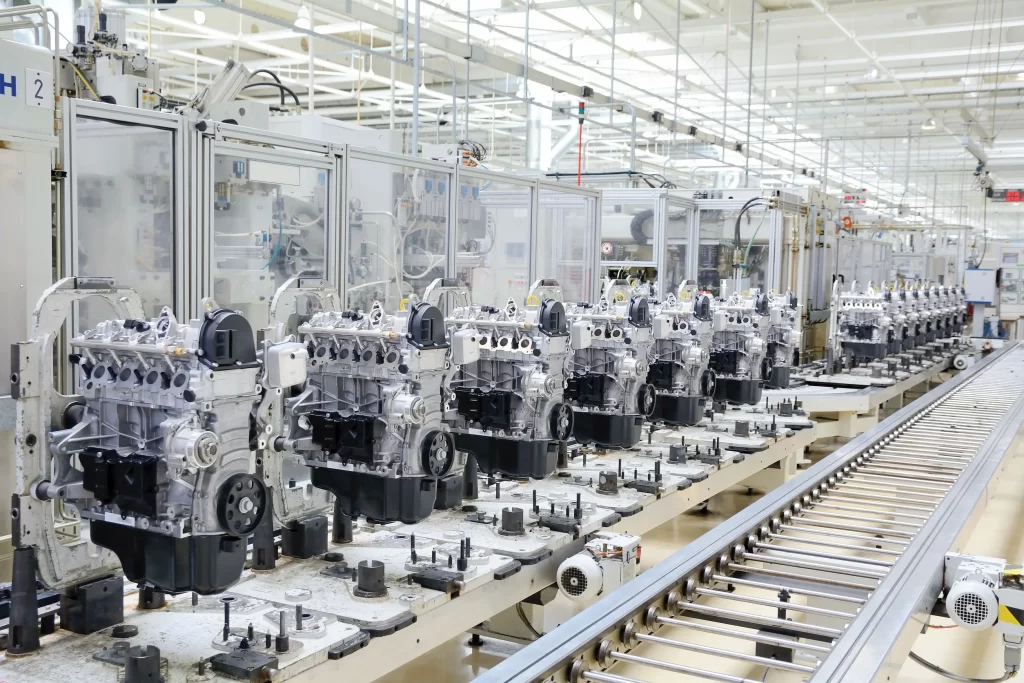

In the landscape of industrial air compression, three-phase air compressors—professionally abbreviated and widely known as “3 phase compressors”—stand as indispensable workhorses. They power core industrial systems, from manufacturing assembly lines and metal fabrication workshops to large-scale petrochemical plants. Unlike their single-phase counterparts, these industrial air compressors leverage three alternating electrical currents to deliver superior performance, efficiency, and reliability—making them the dominant choice for high-demand industrial applications. In contrast, single-phase compressors are now primarily suited for small-scale, low-power scenarios like home garages or tiny workshops, and see limited use in true industrial settings. This guide demystifies 3 phase compressors, covering their working principles, key advantages for industrial use, common types tailored to industrial air needs, selection criteria, and maintenance best practices to help industrial operators make informed decisions.

I. What Is a 3 Phase Compressor?

The term “3 phase compressor” is the standard industry shorthand for the complete technical term, “three-phase air compressor.” It specifically refers to air compression equipment powered by a three-phase electrical supply—meaning three alternating currents (each 120 degrees out of phase with the other two) work in tandem to drive the compressor’s motor. This configuration differs fundamentally from single-phase power (which relies on a single current) and delivers far more consistent energy flow—a must for industrial systems requiring uninterrupted operation.

At its core, the motor of a three-phase compressor converts electrical energy into mechanical energy. This energy drives a compression mechanism—such as pistons, screws, or scrolls—to reduce air volume and generate the high-pressure air needed for heavy-duty industrial tasks. The three-phase power supply minimizes torque fluctuations in the motor, resulting in smoother operation and higher power output. This is critical for applications demanding continuous, high-capacity air, like automated production lines or large-scale pneumatic machinery.

II. Key Advantages of 3 Phase Compressors for Industrial Use

3 phase compressors dominate industrial settings because they align perfectly with industrial air demands—especially when compared to single-phase models, which have little place in industrial use. Below are their most critical advantages for industrial applications:

1. Higher Power Output & Capacity

Three-phase motors deliver significantly more power than single-phase motors of the same size—a non-negotiable for industrial systems. Overlapping electrical currents create steady rotational force (torque), eliminating the “dead spots” common in single-phase motors. As a result, 3 phase compressors handle the large air flow (typically 0.5 m³/min to 50+ m³/min) and high pressure (up to 30 MPa) that define industrial needs, making them ideal for heavy-duty uses like metal fabrication, automotive manufacturing, and large-scale industrial HVAC.

2. Improved Energy Efficiency

Energy efficiency is a top priority for industrial operations, and 3 phase compressors excel here—directly cutting operational costs. Their motors operate at a high power factor (0.85–0.95, versus 0.6–0.7 for single-phase models), meaning more electrical energy becomes useful mechanical energy for air production. This reduces waste, which is especially impactful for compressors running 24/7 to support continuous air supply. Many modern three-phase models also feature variable speed drives (VSD), adjusting motor speed to match real-time demand and slashing energy use by 20–30%.

3. Smoother, More Reliable Operation

Continuous energy from the three-phase supply ensures smoother motor operation with minimal vibration—vital for consistent air quality and supply in industrial settings. This reduces wear on internal components (bearings, valves, compression chambers), extending the compressor’s lifespan. Unlike single-phase motors (which often struggle to start under load), three-phase motors have steady starting torque, lowering the risk of burnout and unplanned downtime—where even an hour of disruption can mean significant losses for operations relying on steady air flow.

4. Compact Design for High Power

Three-phase motors offer higher power density than single-phase alternatives—delivering more air production capacity relative to their size and weight. This makes 3 phase compressors compact, saving valuable floor space in factories and workshops. Since industrial facilities often allocate space to core production rather than air supply equipment, this is a decisive advantage for sites with limited room but high air demands.

5. Compatibility with Industrial Infrastructure

Virtually all industrial facilities have three-phase power systems to support heavy machinery—making 3 phase compressors a seamless fit. They integrate directly with existing electrical infrastructure, eliminating the costly upgrades needed to run high-power single-phase equipment for air production. This simplifies installation, cuts upfront costs, and speeds up the deployment of reliable air supply systems.

III. Common Types of 3 Phase Compressors for Industrial Applications

3 phase compressors come in multiple configurations, each engineered for specific industrial air requirements. The right choice depends on your air flow needs, pressure ratings, noise constraints, and maintenance budget. Below are the most widely used models in industrial settings:

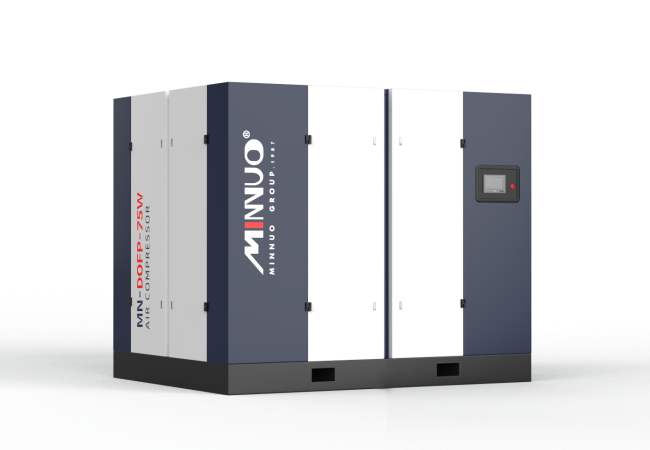

1. Screw Compressors: Workhorse for Continuous Industrial Air

Working Principle: These compressors use two interlocking helical screws (rotors) to trap and compress air. As the rotors turn, air is drawn into the gap between them, squeezed into a smaller volume, and discharged at high pressure.

Key Features: Deliver air continuously with low noise (60–75 dB(A)) and minimal vibration. Available in oil-injected (for lubrication and cooling) and oil-free variants—the latter critical for food & beverage, pharmaceutical, and electronics industries.

Best For: Industrial applications needing constant high-volume air, such as manufacturing, construction, and power generation. Flow rates typically range from 1 m³/min to 50 m³/min, matching mid-to-large industrial air demands perfectly.

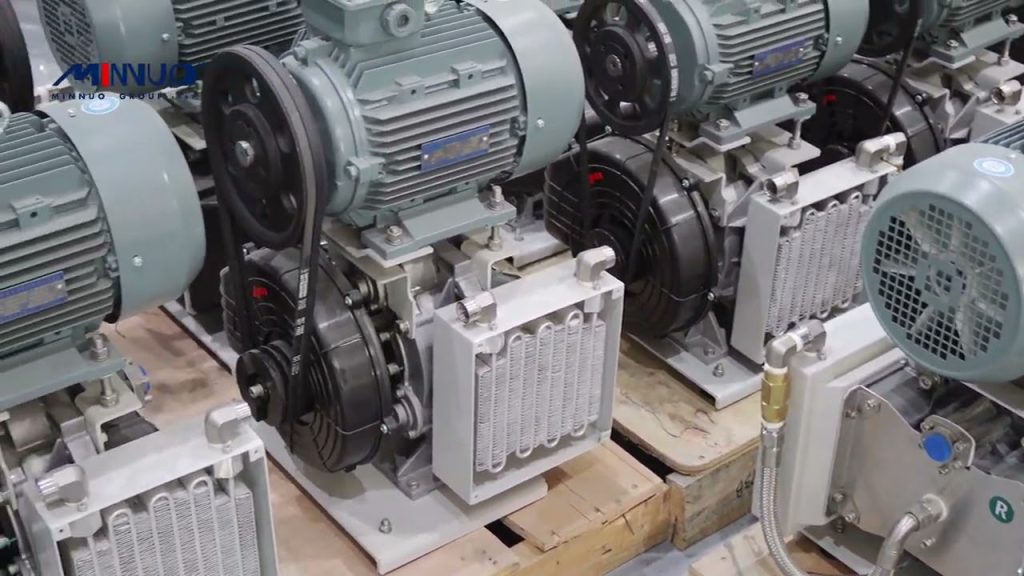

2. Reciprocating Compressors: High-Pressure Industrial Solution

Working Principle: A piston moves up and down inside a cylinder—drawing in air on the downstroke and compressing it on the upstroke. Valves control air intake and discharge to ensure efficient compression.

Key Features: Boast high pressure ratings (up to 30 MPa), are cost-effective for medium-duty use, and easy to maintain. Available in single-stage (for low pressure) and two-stage (for high pressure) designs.

Best For: Industrial applications requiring high pressure but moderate air volume, such as automotive component manufacturing, pneumatic tool operation in workshops, and small-scale industrial processes. Flow rates range from 0.5 m³/min to 10 m³/min, suiting targeted needs.

3. Scroll Compressors: Low-Noise Industrial Air Option

Working Principle: Two spiral-shaped scrolls (one fixed, one orbiting) trap air between their grooves. As the orbiting scroll moves, the air is gradually compressed and forced toward the center of the scrolls, where it is discharged.

Key Features: Ultra-quiet operation (45–60 dB(A)), oil-free options, and high energy efficiency. They have fewer moving parts than piston or screw compressors, reducing maintenance needs.

Best For: Industrial settings where low noise and air purity are critical, such as precision electronics manufacturing, pharmaceutical production, and cleanroom operations—alongside commercial HVAC that supports industrial facilities. Flow rates range from 0.3 m³/min to 15 m³/min, fitting specialized air requirements.

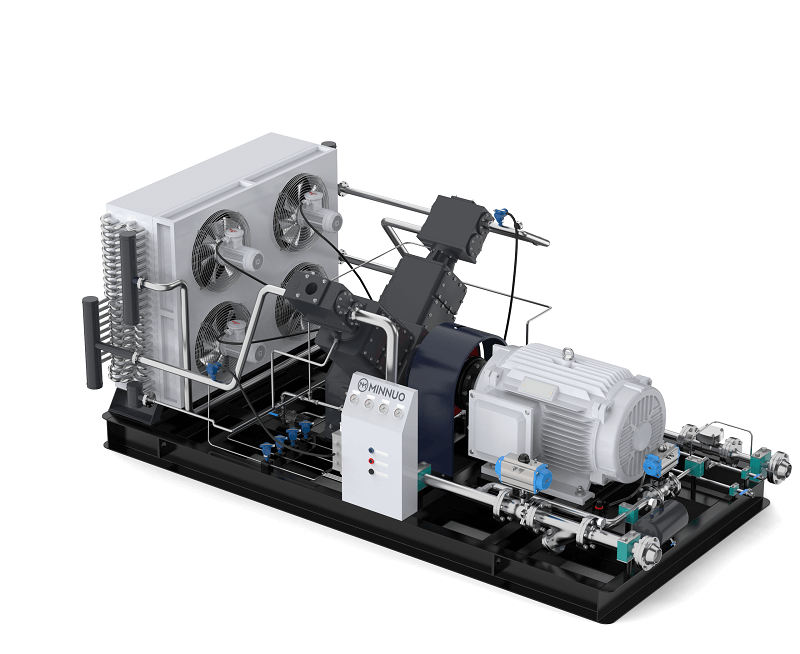

4. Centrifugal Compressors (Massive Industrial Air Supply)

Working Principle: A high-speed impeller spins to accelerate air, which is then slowed down in a diffuser, converting kinetic energy into pressure. These compressors rely on centrifugal force for compression.

Key Features: Extremely high flow rates (50+ m³/min) and oil-free operation. They are designed for large-scale industrial use and require minimal maintenance for their size.

Best For: Heavy-industry applications demanding massive air volumes, such as petrochemical plants, steel mills, and large power plants. Their ultra-high flow rates ensure uninterrupted air supply for large-scale processes.

IV. How to Select the Right 3 Phase Compressor for Industrial Air Systems

Choosing the right 3 phase compressor means aligning it with your industrial air demands and operational constraints. Follow these steps to select a model that boosts performance and delivers long-term value:

1. Define Industrial Air Demand: Flow Rate & Pressure

Start by calculating your required industrial air flow (m³/min or CFM) and pressure (MPa or psi). For flow rate, add up the air consumption of all tools and machinery that run simultaneously, then add a 20–30% buffer to cover peak demand and potential system leaks. For pressure, check your equipment specifications: most industrial tools need 0.7–1.0 MPa, while specialized processes like high-pressure metal forming may require 10+ MPa.

2. Match Industrial Air Purity Requirements

If your industrial process demands clean, oil-free air—such as in food processing, pharmaceutical manufacturing, or electronics assembly—opt for oil-free 3 phase compressors (scroll, centrifugal, or oil-free screw models). For general industrial use like construction or automotive repair, oil-injected three-phase compressors strike a cost-effective balance while meeting basic air quality needs.

3. Evaluate Energy Efficiency for Industrial Air Operations

Prioritize 3 phase compressors with high energy efficiency ratings—look for IE3 or IE4 motors, which meet international industrial standards. Variable speed drive (VSD) technology is a game-changer for systems with fluctuating industrial air demand, as it adjusts motor speed to avoid wasting energy during low-usage periods. When evaluating costs, focus on total cost of ownership (TCO)—including purchase price, energy expenses, and maintenance—rather than just the upfront cost.

4. Assess Industrial Installation & Space Constraints

Measure the available space in your industrial facility to ensure the 3 phase compressor fits. Also, note key installation requirements: these compressors need a dedicated industrial electrical connection (verify voltage and phase compatibility with your facility’s supply), proper ventilation to prevent overheating during operation, and easy access for maintenance. For outdoor industrial use, choose weather-resistant models.

5. Prioritize Reliability for Uninterrupted Industrial Air

Select reputable brands with a proven track record in industrial air compressors—such as Minnuo, Atlas Copco, or Ingersoll Rand. Check the warranty period (2–5 years is ideal) and ensure the manufacturer offers local after-sales support, including easy access to replacement parts and certified technicians. Unplanned downtime for your industrial air system is costly, so reliable equipment and support are non-negotiable.

V. Maintenance Best Practices for 3 Phase Industrial Air Compressors

Proper maintenance is key to maximizing the lifespan, efficiency, and reliability of your 3 phase compressor—ensuring a steady supply of industrial air for your operations. Follow these best practices to avoid costly repairs and unplanned downtime:

1. Inspect & Replace Filters for Clean Industrial Air

Air intake filters prevent dust and debris from contaminating your industrial air and damaging compressor components. Clean or replace pre-filters every 1–3 months (more frequently in dusty industrial environments) and precision filters every 6–12 months. For oil-injected 3 phase compressors, replace oil filters every 3–6 months to maintain lubrication quality and air purity.

2. Monitor Oil for Oil-Injected Industrial Air Compressors

For oil-injected 3 phase compressors, check oil levels daily and top up as needed. Replace the oil every 1,000–2,000 operating hours (per the manufacturer’s guidelines) and change the oil separator every 1–2 years. Use only the manufacturer-recommended oil—improper oil can damage the motor and compromise the quality of your industrial air.

3. Drain Moisture to Protect Industrial Air Systems

Moisture buildup in air tanks and lines causes rust, corrosion, and contaminated industrial air. Drain tanks daily (or install automatic drain valves) and inspect lines regularly for leaks or condensation. In humid industrial environments, pair your 3 phase compressor with a dryer (refrigerated or desiccant) to remove moisture from the compressed air.

4. Inspect Electrical Components of Industrial Air Compressors

Schedule quarterly inspections of your 3 phase compressor’s electrical system, including wires, terminals, and motors. Look for signs of wear, overheating (such as discoloration), or loose connections—common risks in industrial electrical environments. Ensure the compressor is properly grounded and keep electrical panels free of dust. Have a certified industrial electrician perform annual testing.

5. Keep Industrial Air Compressors Clean & Ventilated

Regularly clean the exterior and cooling fins of your 3 phase compressor to remove industrial dust and debris, which can block airflow and cause overheating. Maintain at least 1 meter of clearance around the unit and ensure ventilation fans (if equipped) are working properly—critical for equipment operating under heavy industrial loads.

6. Follow Industrial-Grade Preventive Maintenance Schedules

Keep a detailed maintenance log for your 3 phase compressor, tracking inspections, filter changes, oil replacements, and repairs. Stick to the manufacturer’s maintenance schedule, which is tied to operating hours. For 24/7 industrial operations, consider partnering with specialized service providers for professional maintenance support.

VI. Common Myths About 3 Phase Industrial Air Compressors

Misconceptions about 3 phase compressors often lead to poor purchasing decisions in industrial settings. Here are the most common myths, debunked for industrial operators:

Myth 1: 3 Phase Industrial Air Compressors Are Too Expensive

Fact: While 3 phase compressors have higher upfront costs than single-phase models, their lower energy expenses and longer lifespans result in a lower total cost of ownership (TCO) for industrial operations. For high industrial air demand, the energy savings alone often offset the initial investment within 1–2 years—critical for industrial cost control.

Myth 2: Three-Phase Power Is Unavailable for Industrial Air Equipment

Fact: All industrial facilities, warehouses, and manufacturing plants are equipped with three-phase power to support heavy machinery—making it readily available for 3 phase compressors. For small industrial workshops without three-phase power, phase converters can be installed, adding minimal cost relative to the performance benefits of a 3 phase compressor.

Myth 3: All 3 Phase Industrial Air Compressors Are Identical

Fact: There are significant differences between 3 phase compressor types—screw, piston, scroll, and centrifugal—each designed for specific industrial air needs. Air flow, pressure, efficiency, and purity vary widely, so selecting a model tailored to your specific industrial process is essential.

Myth 4: Three-Phase Industrial Air Compressors Need Complex Maintenance

Fact: Maintenance for 3 phase compressors is no more complex than for single-phase models—it involves regular filter changes, oil checks, and electrical inspections. Many modern 3 phase compressors even include smart monitoring systems that alert operators to maintenance needs, simplifying industrial upkeep.

FAQ About 3 Phase Compressors for Industrial Use

Below are answers to the most frequently asked questions about 3 phase compressors, addressing common concerns for industrial operators:

Q1: Can a 3 phase compressor work with a single-phase power supply in small industrial workshops?

A1: Yes, but you’ll need a phase converter or VFD to convert single-phase power. This works only for small/medium models (below 10 HP); larger industrial compressors are better paired with dedicated three-phase power to avoid performance loss or higher energy use.

Q2: How do I determine if my industrial facility needs an oil-injected or oil-free 3 phase compressor?

A2: It depends on air purity needs. Oil-injected models suit general use (construction, auto repair) where minor oil residues are acceptable; oil-free ones (scroll/centrifugal) are mandatory for food, pharma, and electronics to avoid contamination.

Q3: What’s the typical lifespan of an industrial 3 phase compressor, and how to extend it?

A3: Typical lifespan is 10–15 years (20+ for screw/centrifugal models with good maintenance). Extend it by following filter/oil replacement schedules, draining moisture, keeping it clean/ventilated, and avoiding overloading.

Q4: Is a VSD-equipped 3 phase compressor worth the extra cost for industrial use?

A4: Yes, if air demand fluctuates (e.g., batch production). VSD cuts energy use by 20–30%, recouping extra costs in 1–2 years for 24/7 operations. Fixed-speed models are better for constant high demand.

Q5: How to troubleshoot common issues with 3 phase compressors, like failure to start?

A5: First, check three-phase power (stable voltage, all phases functional). Inspect wiring, motor starter, and overload protector for issues. If it hums but won’t start, it may be motor phase loss or seized parts—call a pro. Always disconnect power first.

Conclusion: 3 Phase Compressors—The Backbone of Industrial Air Systems

For industrial operations with high air compression demands, 3 phase compressors deliver unmatched performance, efficiency, and reliability. Their ability to provide consistent high-volume industrial air, reduce energy costs, and minimize downtime makes them the backbone of modern industrial air systems—from manufacturing floors to petrochemical processing plants. By aligning your 3 phase compressor with your specific air needs, selecting the right type, and following preventive maintenance, you’ll maximize your investment and keep your industrial operations running smoothly.

Whether your business is in manufacturing, construction, or healthcare, a 3 phase industrial air compressor is a long-term solution that scales with your growth. At MINNUO, we’ve integrated advancements like VSD and smart monitoring into our 3 phase compressors, making them more efficient and user-friendly than ever—solidifying their role as essential industrial equipment. For any industrial air requirement, upgrading to a reliable 3 phase compressor like ours is a strategic decision that drives productivity and cost savings.

Email

Email sales:+86 15366749631

sales:+86 15366749631