In modern industrial system, gas compressor as “gas engine”, through the energy, chemical, medical, food, new materials and other key links, is to ensure the continuous operation of the process and product quality stability of the core equipment. Whether it is used for CNG refueling, oxygen supply, or in a clean room to press and send inert gas, the selection and configuration of the compressor are directly related to the efficiency of the entire system, safety and cost control.

However, in the actual procurement, many users often “only look at the power, do not assess the gas characteristics, do not match the mode of operation” and other errors in judgment, resulting in compression system in the long-term high energy consumption, high failure rate, the output of the gas is not up to standard, not only to affect the production, but also may be buried in the safety of hidden danger. Therefore, how to make the right decision at the selection stage has become a key part of the success or failure of the project.

In this article, we will start from five dimensions, combined with different working conditions and application requirements, in-depth analysis of the key selection parameters of the gas compressor, common misconceptions, configuration recommendations and MINNUO brand customized service system, to help you use professional logic to replace the experience of patting the head type of selection, to really do “on-demand choice, with peace of mind”. If you are facing the challenge of selecting gas equipment for your project, this article will provide you with practical reference.

1. Select the key parameters of the gas compressor

The correct choice of gas compressor not only determines the efficiency and stability of the system, but also has a direct impact on the later operating costs and maintenance difficulties. The following key parameters, is the procurement and technical selection must be in-depth understanding of the core elements of the comparison:

1.1 gas type

different gases have very different physical and chemical properties, such as:

oxygen, hydrogen, nitrogen and other common industrial gases, usually required to avoid the compression process of oil contamination, sparks and high temperatures.

Carbon dioxide (CO₂) tends to liquefy when compressed and requires drainage and corrosion protection.

Inert gases (e.g. helium, argon) have low density, high thermal conductivity and special requirements for sealing and energy efficiency.

Practical suggestions:

Before selecting the model, clarify the explosive, corrosive and humidity sensitivity of the gas, and confirm with the equipment manufacturer whether it supports oil-free/explosion-proof/corrosion-proof design.

1.2 Outlet Pressure and Flow

Common industrial requirements cover 0.8MPa to 25MPa, but continuity and stability requirements vary greatly from application to application.

High-pressure conditions (e.g. CNG refueling, deep-cooling separation) are usually equipped with multi-stage compression to reduce the compression ratio of a single stage, and to reduce temperature rise and energy consumption.

Common mistakes:

Selecting a compressor based on the rated pressure alone and ignoring the fluctuation of the maximum gas consumption may lead to long-term overloading of the equipment and a sudden drop in its service life.

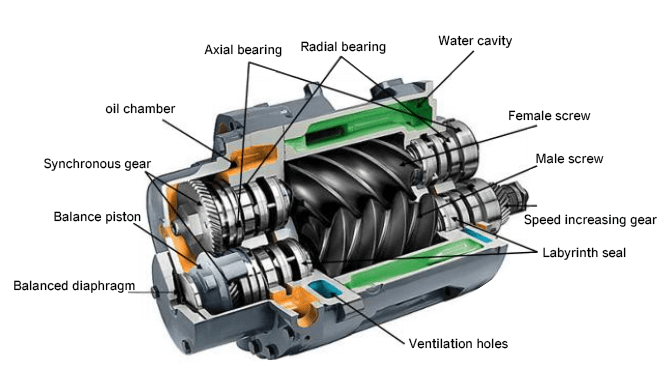

1.3 Number of Compression Stages

Single-stage compression: suitable for low-pressure, low-flow scenarios.

Two-stage compression: high efficiency, good heat dissipation, suitable for medium-pressure demand.

Multi-stage compression (more than 3 stages): suitable for ultra-high pressure, continuous operation, high purity requirements and other complex working conditions.

✅ Engineering Recommendation:

Prioritize multi-stage compression structure under high pressure conditions and combine with intercooler to reduce energy consumption and thermal stress.

1.4 Whether oil-free/pollution-free compression

Medical oxygen, food-grade carbon dioxide, semiconductor industry mandatory oil-free.

Some gases are extremely sensitive to oil vapor (e.g. hydrogen), and even a small amount of contamination can affect the subsequent reaction or safety.

Selection Points:

Evaluate whether an oil-free screw or diaphragm compressor is required and whether it supports clean zone certification (e.g. ISO 8573-1 Class 0).

1.5 Intake Air Conditions: Temperature, Humidity, Pretreatment Requirements

High temperature and high humidity environment: easy to cause intake air efficiency decline, condensate accumulation, need to cooperate with the front-end cold dryer or cooler.

Containing corrosive impurities: should increase the intake air filter or stainless steel/anti-corrosion lining structure.

Low temperature and high altitude: low air density, compression efficiency decreases, need to improve the power configuration or adaptive design.

Technical Supplement:

The compression efficiency is closely related to the air inlet conditions, it is recommended that customers provide on-site air inlet temperature and humidity data, to avoid parameter deviation during selection.

2.Selection Guidelines for Specific Industries

2.1 PSA Nitrogen & Oxygen Systems

Recommended type: oil-free piston compressor or scroll compressor

Requirements: low oil content, clean gas, 24h continuous operation

Recommended configuration: front-stage air compression + intermediate buffer tanks + back-stage oxygen/nitrogen booster

MINNUO Application Case: PSA Nitrogen Station for Egyptian Customer Booster system (flow and control system adaptable)

2.2 CNG (Compressed Natural Gas) Filling

Recommended type: 4-stage reciprocating high-pressure natural gas compressor

Characteristics: high pressure range (20-25 MPa), explosion-proof, exhaust gas temperature control

Recommended configuration: complete system with dryer, buffer tank, overpressure protection

Note for selection: for filling station, vehicle or industrial gas station For refueling station, vehicle or industrial gas

Customer feedback: Central Asia users are highly satisfied with high temperature resistant seals and service intervals

2.3 Food & Beverage Industry

Recommended type: oil-free scroll or water-lubricated oil-free screw compressor

Requirements: cleanliness class ISO8573-1 Class 0, avoiding odor contamination

Application scenarios: MAP (Modified Atmosphere Packaging), CO2 injection, fermentation gas supply

Recommended configuration: with food-grade filter + decontamination device

Case study: MINNUO’s CO₂ compression solution exported to Italy for wine bottling lines

2.4 Pharmaceutical and Medical Use

Recommended type: Oil-free silent compressor unit + storage system for medical use

Requirements: low noise, sterilized gas, cleanliness level according to pharmacopoeia Application: gas supply for medical use Requirements: low noise, sterilized gas, cleanliness level according to pharmacopoeia Application: gas supply for medical use Classes in accordance with pharmacopoeia

Applications: inhaled oxygen for hospitals, gas delivery stations, laboratory gas systems

Compliance certificates: CE, ISO13485

Recommended solution: modular dual backup system + intelligent alarm control

2.5 General Industrial Applications (e.g. Laser Cutting, Electronics, Metallurgy)

Types of compressor sets recommended: all oil-free silent compressor sets + medical storage systems Electronics, Metallurgy)

Diversified types: piston, screw, centrifugal (depending on gas volume and continuity requirements)

Requirements: high stability, high energy efficiency, good compatibility with system control

Laser Cutting Example: It is recommended to match with a 5-stage precision filtration + cold dryer system to ensure gas cleanliness

Electricity and Metallurgy Industry: It is recommended to add automatic drainage and self-protection logic.

3.The selection of compressors should be avoided when the common mistakes

In the compressor selection and system construction process, customers often fall into some “seemingly reasonable but actually very costly” misunderstanding. The following are the four most common mistakes in engineering practice and suggestions to deal with them:

❌ 3.1 Ignore the relationship between the purity of the gas source and the compression of residual oil

Compressor output gas often contains a small amount of residual oil and moisture, if the gas source is used for high-purity or downstream reaction-sensitive processes (eg, oxygen, food, electronics), it must be controlled to a very low range.

Risk example:

The gas source contains untreated oil, which leads to poisoning and failure of PSA molecular sieve;

Used in fermentation or pharmaceutical system, which leads to microbial contamination or product out of specification.

✅ Suggested solutions:

Use oil-free compressors (Class 0) or install high-efficiency oil-removal filters and cold dryers;

Define standards for end-gas use (e.g., ISO 8573) and feed back to suppliers for selection.

❌ 3.2 Selection only according to power, without considering the number of hours of operation and load ratio

Many users only look at the power and rated pressure selection, ignoring the actual operating conditions of the system, such as:

Annual operating hours: whether 24 hours, seasonal gas

Load fluctuations: the existence of frequent start-stop, peak impact

Consequences of the performance:

big marat car: high energy consumption, waste of investment;

long-term full load: serious heat, shorten the life of the easy to overload shutdown. Practical advice: communicate with the supplier about the actual operation.

Practical suggestions:

Communicate with the supplier about the actual running hours and load profile, and prioritize the selection of frequency conversion or automatic start/stop control type compressors.

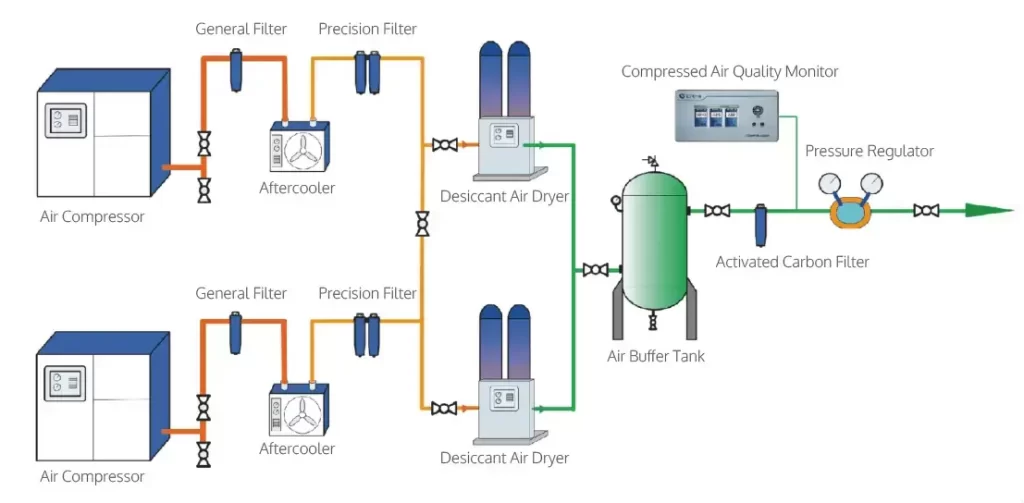

❌ 3.3 Failure to evaluate the after-treatment system and the whole machine linkage (drying/buffering/cooling)

Compressors do not work in isolation, but usually form a complete system with a dryer, a storage tank, an after-cooler, and so on. Neglecting these ancillary equipment can result in degradation of the compressed gas quality and even cause equipment alarms or damage.

Examples of problems:

No storage tank: large fluctuations in outlet pressure, affecting downstream equipment;

No drying equipment: high water content, leading to rust or icing of piping;

No aftercooler: high temperature of the outlet gas, affecting the operation of subsequent precision instruments.

Suggested Configuration Reference:

“Compressor + Storage Tank + Aftercooler + Precision Filtration + Cooler” is the industrial standard configuration, especially in the south of the high temperature and high humidity environment is more critical.

❌ 3.4 Wrong choice of non-explosion-proof model for combustible gas

When the compressed gas is hydrogen, methane, acetylene and other combustible gases, it is necessary to choose explosion-proof motors, explosion-proof control cabinets, anti-static seals and other configurations.

Accident Hazards:

motor start spark ignition gas;

pipe static discharge caused by ignition;

control system does not have Ex certification, can not pass the safety supervision review.

Practical advice:

clear combustible gas use area of the explosion-proof zoning level (such as Zone 1, Zone 2), and to the compressor manufacturer to put forward the explosion-proof customization needs, to avoid the misuse of general-purpose models.

4. How MINNUO can help you customize the right solution

Every compression system has different application scenarios: some pursue high pressure output, some focus on cleanliness control, and some face extreme conditions such as high temperature, dust, altitude, or power outage, etc. What MINNUO provides is not just equipment, but a complete set of professional solutions for actual working conditions.

4.1 Research on working conditions and operation simulation to ensure that the program is adapted to the ground

We do not rely on customers to“self-estimate”parameters, but:

Field collection of data on working conditions (such as temperature and humidity, air source composition, installation space, etc.)

Simulation of the operating model (through the pressure-flow curve, load changes, operating frequency, etc.)

Predicting the equipment energy consumption and operating costs, to help customers avoid the“selection of equipment”

Example: A customer originally planned to use 90kW compressor, but after simulation found that its maximum load is only 75kW, and finally chose a more energy-efficient 75kW inverter model, which saves up to 18% of the annual electricity bill.

4.2 Multi-dimensional customized recommendations to accurately match project needs

We not only select according to the pressure + flow rate, but also recommend the following key variables:

gas purity and component changes (such as 99% oxygen, hydrogen containing micro-water need to be dehumidified, etc.)

frequency of use (intermittent use of the gas and 24-hour continuous operation of the selection of the great difference)

safety (such as combustible gases in the place of explosion-proof grade Exd II BT4)

project output include Project output includes: configuration drawings, P&I flow charts, installation interface standards, recommended exhaust pipe diameter, etc.

4.3 Flexible Configuration Options to Meet Multi-Industry Technical Detail Requirements

We offer a wide range of modular configurations that can be freely combined according to budget and process requirements:

| Configuration Module | Options |

| Cooling Methods | Air-cooled / Water-cooled / Forced circulation cooling / High altitude cooling system |

| Control Methods | Touch screen + PLC / Modbus protocol / Remote monitoring system / SCADA interface support |

| Cleanliness Levels | Normal industrial grade / Medical clean grade (Class 0) / Food grade stainless steel piping configuration |

| Silent Construction | Additional muffler / Silent base / Noise reduction in compression chamber |

4.4 Transnational service guarantee, solving the “last kilometer” problem of overseas customers

For export projects, we provide one-stop support:

Remote diagnosis: with the customer’s factory mobile phone/tablet device to achieve video link to guide the installation of

Rapid spare parts delivery: the global cooperative logistics network, parts can be reached in 3-5 days

Online document support: provide PDF version of the wiring diagrams, equipment instructions, maintenance reports and other technical compliance information in PDF. Online Documentation Support: Provide PDF wiring diagrams, equipment instructions, maintenance intervals and other multi-language versions

Additional Services: According to customer needs, we can provide a full set of technical compliance information, such as CE, ISO13485, pressure vessel license, material traceability report, etc.

4.5 Selected Customer Cases: Cross-scenario Verification of Minnor’s Strength

Middle East CNG Project Station Cluster (Dubai, Saudi Arabia)

Adopting two-stage high-pressure compression solution + explosion-proof electric control, adapting to sand and dust and high temperature, with an average daily refueling capacity of 28,000 Nm³ per station.

South America Beverage Gas Plant (Peru)

provides clean CO₂ compression solution with five-stage filtration and food-grade grease removal system, which saves more than 20% of annual nitrogen cost.

Southeast Asia Hospital Medical Oxygen Supply Project (Vietnam)

Medical grade oil-free compressor + medical gas storage tank + PLC automatic switching control, realizing 365 days uninterrupted gas supply.

5. Frequently Asked Questions – Compressor Selection and After-sales Support

Around gas compressor selection and after-sales support, we have compiled the top 5 most common questions users ask, and based on MINNUO’s practical experience, we provide real and actionable suggestions for answers.

❓ How to determine whether an oil-free compressor is needed?

✅ Answer:

The judgment criteria depends on the gas application and industry standards. If the application involves sensitive scenarios such as medical, food, electronic semiconductor, fermentation reaction, etc., an oil-free compressor should be selected to ensure that the gas source is free from oil contamination.

Practical advice:

Check to see if you need to meet the ISO 8573-1: Class 0 standard;

Confirm if there is a high cleanliness requirement downstream (e.g., respiratory-related, human contact products);

If you are not sure, you can choose oil lubrication + multi-stage de-oiling system as an economical transition solution.

❓ Can I use the same compressor for different gases?

✅ Answer:

Direct switching of gas types is not recommended, especially when it comes to flammable, corrosive and highly oxidizing gases. Differences in the physical/chemical properties of the different gases may lead to:

failure of the lubricant reaction;

corrosion or swelling of the seals;

increased risk of leakage/explosion.

MINNUO Solution:

Systems with gas line switching modules can be designed for customer multi-gas usage scenarios, subject to complete corrosion/explosion protection/material compatibility verification.

❓ Does MINNUO support customization if the local voltage and power frequency are different?

✅ Answer:

supports worldwide power supply customization, including but not limited to:

single-phase 220V / three-phase 380V / three-phase 440V / three-phase 480V;

50Hz and 60Hz;

special frequencies such as 400Hz military power supply or solar energy off-grid system interface.

Remarks:

The export equipment will be configured with motor, electronic control system, inverter and plug standard according to the customer’s specified standard, and passed the full-voltage simulation test before delivery to ensure that it is ready for use on the spot.

❓ Does the export equipment include complete CE certification and operation information?

✅ Answer:

All export equipments include by default:

CE Certification Declaration of Conformity

Product nameplate and safety marking (Chinese/English)

Complete operation manual / wiring diagrams / installation instructions

Factory performance test report

Additional information optional: UL, ASME, PED, GMP validation documents, etc., according to the project requirements application.

❓ What maintenance kits or remote technical support services are available?

✅ Answer:

MINNUO provides a variety of after-sales packages to solve the problem of “no one to maintain after delivery”:

Basic toolkit (included with the equipment)

Toolkit (seals, wrenches, screwdrivers)

Frequently used spare parts (primary cartridges, O-rings, lubricants)

Upgrade service packages

1 year, 2 years, 3 years maintenance parts program

Quick Replacement Video Tutorials + Chinese Voice Explanation

Remote Video Diagnosis, Parameter Debugging, Start-up Accompanying Service

Customer Case:

A Southeast Asian user encountered a PLC failure during on-site installation, and the engineer completed the troubleshooting within 30 minutes through remote screen sharing, avoiding the risk of round-trip flights and production stoppages.

Conclusion

Choosing the right compressor is never a price game or a blind brand selection, but an accurate matching of “gas characteristics + working condition demand + long-term cost”.

This guide takes you through the key perspectives of gas type, pressure and flow rate, number of compressor stages, oil-free requirements, environmental suitability, etc., to clarify the selection logic step by step, avoid common misunderstandings, and ensure stable, efficient, and compliant operation of the system.

MINNUO team always insists that equipment matching is more important than equipment price. Through in-depth understanding of your application environment, combined with global project experience, we provide customized selection simulation and recommendation services for each customer, truly “selecting the compressor for the working conditions”.

Whether you are in the food, medical, energy, chemical, or new energy industries, we can quickly generate a customized solution by providing your gas parameters, and provide you with global remote technical support, certification materials, and long-term spare parts service.

Email

Email sales:+86 15366749631

sales:+86 15366749631