In the world of painting, whether you’re embarking on a home renovation or handling a large-scale commercial project, the quality of your tools can significantly impact the outcome. Air compressors are vital in this equation, providing the pressurized air needed for spray guns to achieve a flawless, even finish.

An air compressor in painting provides the pressurized air required to operate spray guns efficiently. It ensures a consistent and even application of paint, which is crucial for a flawless finish. By delivering the right amount of pressure and airflow, it helps achieve a professional-quality look, speeds up the painting process, and allows for versatility in various paint applications.

To appreciate the role of an air compressor in painting, it’s essential to first understand what an air compressor is and how it functions. This knowledge will help you grasp why it’s a crucial tool for achieving a professional finish.

What is an Air Compressor?

An air compressor is a mechanical device that converts power into potential energy stored in pressurized air. This pressurized air can then be used to power various tools and equipment. In painting, an air compressor supplies the necessary air pressure to spray guns, enabling a smooth and even application of paint.

How Air Compressors Work

The operation of an air compressor involves drawing in air and compressing it to increase its pressure. This process involves several key components: the compressor pump, storage tank, pressure gauge, and regulator. Understanding this mechanism helps you appreciate how air compressors provide the consistent and reliable airflow needed for effective painting.

Why Air Compressors are Essential for Painting

Having a solid grasp of how air compressors work sets the stage for understanding why they are indispensable for painting tasks. Let’s delve into their specific role and the benefits they bring to the painting process.

Role in Painting

Air compressors are fundamental in painting because they supply the pressurized air necessary to operate spray guns. This consistent air pressure is critical for applying paint evenly and achieving a smooth, professional finish. Without a reliable air compressor, achieving the desired paint application would be challenging, leading to uneven coverage and less satisfactory results.

Advantages of Using Air Compressors for Painting

Utilizing an air compressor in your painting projects offers several advantages. It enhances efficiency by speeding up the painting process, ensures a high-quality finish with even coverage, and provides versatility in handling various paint types and applications. These benefits highlight the importance of investing in a good air compressor to elevate your painting results.

Types of Air Compressors Suitable for Painting

Now that we’ve established the importance of air compressors in painting, let’s explore the different types available. Each type has unique features that can cater to specific painting needs, so understanding these will help you choose the best option for your projects.

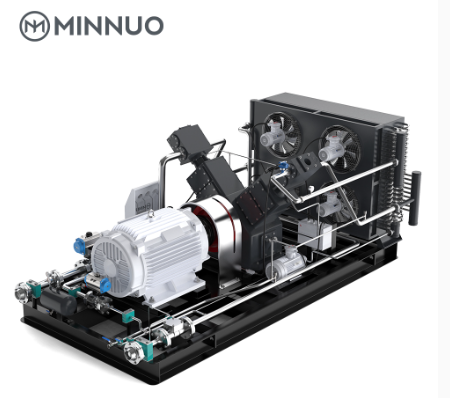

Piston Compressors

Piston compressors, also known as reciprocating compressors, are widely used for painting due to their ability to deliver high pressure. They operate by using pistons to compress air, making them suitable for tasks that require substantial air pressure. While effective, they can be noisy and require regular maintenance to ensure optimal performance.

Rotary Screw Compressors

For those needing a more continuous and efficient air supply, rotary screw compressors are an excellent choice. They use rotating screws to compress air and are known for their efficiency and quieter operation compared to piston compressors. Though generally more expensive, they are ideal for high-demand and prolonged painting tasks.

Scroll Compressors

Scroll compressors offer a quieter alternative with their unique design involving interleaved spirals to compress air. They are valued for their efficiency and are suitable for both residential and commercial painting needs. However, their higher cost might be a consideration for some users.

Other Types

While less common in painting, other types of compressors, such as centrifugal compressors, may be used in specific industrial applications. These compressors are known for their high efficiency and are typically employed in large-scale operations.

Key Features to Consider When Choosing an Air Compressor for Painting

With an understanding of the different compressor types, it’s crucial to evaluate the key features that will influence your choice. These features directly impact the performance and suitability of the compressor for your specific painting needs.

Pressure and Flow Rate

Selecting an air compressor involves matching the PSI (pounds per square inch) and CFM (cubic feet per minute) of the compressor to the requirements of your paint spray gun. Ensuring that the compressor meets these specifications is essential for consistent performance and uninterrupted painting.

Tank Size

The tank size of an air compressor affects its performance and efficiency. Larger tanks allow for extended painting sessions without frequent interruptions, making them ideal for larger projects. Conversely, smaller tanks may suffice for smaller or less demanding tasks.

Portability

Consider whether you need a stationary or portable model based on your project’s nature. Portable compressors offer flexibility and are well-suited for DIY projects, while stationary models provide stability and are better for commercial use.

Noise Level

Noise level is an important consideration, especially for residential or noise-sensitive environments. Compressors designed to operate quietly can enhance the working experience and reduce disruption.

Power Source

Air compressors can be powered by electricity or gas. Electric compressors are ideal for indoor use, providing consistent power, while gas-powered models offer greater mobility for outdoor or remote locations.

Comparing Air Compressors for Different Painting Needs

With key features in mind, it’s important to match the right compressor to your specific painting needs. This involves considering factors such as the scale of the project and the frequency of use.

Residential vs. Commercial Use

For residential projects, smaller and more cost-effective compressors may be sufficient. In contrast, commercial use often requires high-capacity models that can handle continuous operation and demanding tasks.

DIY Projects vs. Professional Use

DIY enthusiasts may benefit from more affordable, less powerful models, whereas professionals might invest in robust and efficient compressors to meet the demands of regular use.

Small vs. Large Scale Projects

The size and capacity of the compressor should align with the scale of your project. Small projects may require a compact compressor, while large-scale jobs necessitate models with greater capacity and tank size.

Maintenance and Care of Air Compressors

Proper maintenance ensures the longevity and efficiency of your air compressor. Regular care and attention can prevent issues and keep your equipment running smoothly.

Routine Maintenance Tasks

Routine maintenance includes checking and changing the oil, cleaning filters, and inspecting hoses. These tasks are essential for maintaining optimal performance and extending the lifespan of your compressor.

Troubleshooting Common Issues

Common issues such as low pressure or excessive noise can often be resolved with simple troubleshooting steps. Addressing these problems promptly can prevent further damage and ensure the compressor functions effectively.

Safety Precautions

Adhering to safety guidelines, such as wearing protective gear and ensuring proper ventilation, is crucial when operating an air compressor. Avoid overloading the equipment and ensure it is well-maintained to prevent accidents.

Cost Considerations and Budgeting

Understanding the costs involved helps in making a well-informed purchase decision. Consider both initial and long-term expenses to determine the best value for your investment.

Initial Costs

Air compressor prices vary based on type, capacity, and features. It’s important to balance your budget with the required specifications to ensure you get a quality product.

Long-Term Costs

In addition to the initial purchase price, consider ongoing costs such as maintenance, operating expenses, and potential repairs. Investing in a high-quality compressor can reduce these long-term costs.

Value for Money

Assess the overall value of the compressor by weighing its features, performance, and durability against the cost. A higher upfront investment might offer better long-term benefits and efficiency.

Conclusion

Choosing the right air compressor for painting involves understanding your specific needs, evaluating various models, and considering key features. A well-chosen compressor not only enhances the quality of your work but also ensures efficiency and reliability for all your painting projects.

FAQs

The size depends on the type of paint sprayer you use. Typically, a compressor with a PSI of 30-90 and a CFM of 2-10 is suitable for most painting tasks.

Yes, portable compressors are suitable for professional use, especially for smaller or mobile projects. Ensure it meets the pressure and flow rate requirements of your spray gun.

Yes, scroll and certain rotary screw compressors are designed to operate more quietly, making them ideal for residential applications.

Electric compressors are ideal for indoor use and offer consistent power, while gas-powered compressors provide mobility and are suitable for outdoor or remote locations.

Email

Email sales:+86 15366749631

sales:+86 15366749631