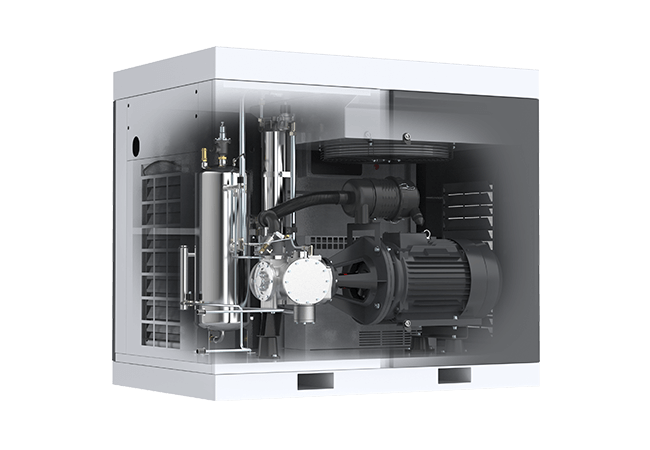

the “powerhouse” in industrial production, widely utilized across sectors such as manufacturing, food processing, chemicals, electronics, and pharmaceuticals. As critical energy supply equipment, they play a pivotal role in generating and distributing compressed air. With the global trend of industrial equipment becoming smarter and more automated, their application scenarios and technical requirements continue to expand. Scientifically selecting a screw air compressor can not only effectively enhance production efficiency and reduce energy consumption but also ensure the reliability and stability of the system.

MINNUO, drawing on its experience in global projects, will comprehensively interpret the principles and key considerations for selecting screw air compressors. This aims to help international users avoid common pitfalls in the selection process, optimize compressor performance configurations, and ensure maximum efficiency in energy-saving and stable operation.

1. Core Parameters

One of the most fundamental and critical factors in choosing a screw air compressor is its ability to precisely match actual air demand. Different industrial applications have varying requirements for air pressure, flow rate, quality, and other factors. Therefore, the selection must be comprehensively evaluated based on these demands.

1.1 Exhaust Pressure and Grade Selection

The pressure setting of a screw air compressor directly impacts the efficiency and service life of the entire system. When determining exhaust pressure, both the required pressure and pipeline loss must be considered. Inadequate pressure can disrupt equipment operation, while excessive pressure leads to energy waste.

- Basic Pressure Requirements: Most general-purpose equipment operates at 0.7MPa (7 bar), a standard working pressure. However, specific applications may require lower or higher pressures. For example, some food processing processes may need only 0.4MPa, while certain heavy industrial applications may require pressures above 8 bar.

- Pressure Loss Compensation: For equipment connected to long pipelines, every 100 meters of pipeline causes approximately 0.05MPa pressure loss. In such cases, pressure compensation is essential to ensure stable air source system operation.

- High-Pressure Special Requirements: Industries like textiles and fermentation, which use low pressure (typically 0.2–0.5MPa), should opt for low-pressure models. High-pressure models (e.g., 0.8MPa) will cause unnecessary energy waste and increase operating costs.

1.2 Exhaust Volume Calculation and Redundancy Design

Calculating exhaust volume and designing system redundancy are key to ensuring the stable operation and reliability of screw air compressors. When multiple devices operate in parallel, reasonable exhaust volume and redundancy design can enhance overall system efficiency and stability.

- Total Air Volume Formula: ∑(All device flow) × 1.2 (simultaneous use factor) + 10%–20% margin. This formula calculates the total air volume demand for the compressor, ensuring the system can supply sufficient compressed air when multiple devices run concurrently.

- Load Strategy: In scenarios with significant air demand fluctuations (e.g., large differences between production peaks and troughs), parallel operation of multiple screw air compressors is recommended. For example, two 60% capacity machines in parallel allow for on-demand startup/shutdown, reducing energy consumption while providing system backup to ensure production continuity.

2. Key Type Selection

Selecting a screw air compressor involves not only performance but also application scenarios. Different working environments and industry requirements determine the type, configuration, and technical approach of the compressor. Choosing the right screw air compressor maximizes equipment performance and minimizes unnecessary costs.

2.1 Oil-Injected vs. Oil-Free

- Necessity of Oil-Free Technology: Oil-free screw air compressors are widely used in industries with extremely high air quality requirements, such as food, pharmaceuticals, and semiconductor manufacturing. Their key advantage is avoiding oil contamination, ensuring product cleanliness and system safety. For these industries, selecting an ISO 8573-1 Class 0 certified oil-free screw air compressor is critical. MINNUO’s oil-free series uses three-stage filtration + catalytic oxidation technology, ensuring residual oil content <0.01ppm to meet the strictest air quality standards.

- Oil-Injected Screw Air Compressors: Suitable for general industrial applications with relatively lenient air quality requirements. They offer cost advantages but require regular replacement of oil separators and filters, resulting in higher maintenance costs.

2.2 Single-Stage vs. Two-Stage

- Single-Stage Screw Air Compressors: Ideal for low-to-medium pressure applications (typically in stable air flow and lower pressure environments). They feature simple structures, cost-effectiveness, and suit general industrial processing, construction, and similar applications.

- Two-Stage Screw Air Compressors: Suitable for high-pressure demands (>8 bar) or environments requiring low temperature differences. Two-stage compression lowers exhaust temperature and improves efficiency, making them suitable for high-pressure, heavy-load sectors like petrochemicals and heavy industry.

2.3 Air-Cooled vs. Water-Cooled

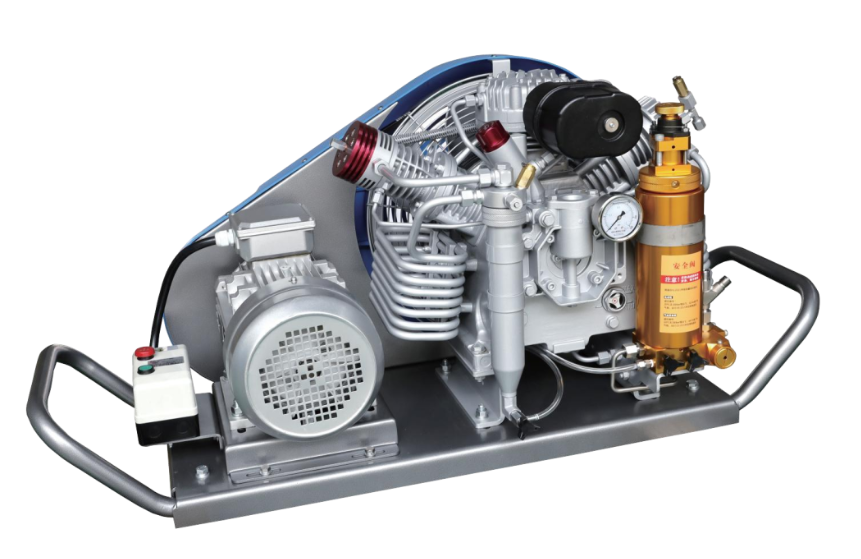

- Air-Cooled Screw Air Compressors: Suitable for areas with unstable water sources. They are typically used in ambient temperatures ≤40°C, are easy to maintain, and suit small-to-medium industrial applications.

- Water-Cooled Screw Air Compressors: Ideal for high-temperature environments, using water cooling to reduce equipment temperature and improve compression efficiency. They can recover waste heat, enhancing energy savings by 15%–30%, making them suitable for large industrial projects and high-temperature settings.

3. Energy Efficiency and Cost

With rising global energy costs, choosing an energy-efficient and eco-friendly screw air compressor has become a priority for many companies. A well-selected compressor can significantly reduce long-term operating costs.

3.1 Identifying Real Energy Efficiency

- Check Specific Power: When selecting an energy-efficient compressor, pay close attention to specific power (kW/m³/min), a key indicator. Request third-party certification reports (e.g., TÜV or UL) to verify compliance with standards. Beware of overstated exhaust volumes, as inflated values often reduce efficiency and increase energy consumption.

- MINNUO Full Range of Models: All MINNUO screw air compressors are EUROVENT-certified, ensuring transparent energy efficiency data. Users can evaluate performance through verified real-world measurement data.

3.2 Life Cycle Cost Model

- ROI for Efficient Models: High-efficiency screw air compressors (e.g., MINNUO’s variable frequency series) may have a 20% higher initial cost but can recoup the difference within 1–2 years via smart load adjustment and energy recovery systems, saving 30%–50% on energy costs long-term.

- Total Life Cycle Cost (LCC): Choosing an energy-efficient and low-maintenance compressor reduces LCC. By calculating the total operating cost over the lifecycle, companies can make cost-effective decisions.

4. Engineering Adaptation

Selecting a screw air compressor must also consider environmental factors and safety requirements. Environmental adaptability, installation specifications, and safety designs directly impact operational efficiency and stability.

4.1 Space and Installation Specifications

- Compressor Room Space: The room must allow adequate ventilation and heat dissipation. Reserve 1.5 times the equipment volume for maintenance space. Ventilation volume should exceed 1.349 times the equipment’s air flow to prevent overheating during long-term operation.

- Centralized Installation: In large projects, centralized installation is more cost-effective than decentralized setups. It reduces pipeline costs, simplifies maintenance, and improves system management efficiency.

4.2 Safety and Redundancy Design

- Double Safety Mechanism: To prevent overpressure accidents from equipment failure, compressors must have dual safety features (e.g., pressure regulators and safety valves). MINNUO compressors are equipped with a triple safety shutdown system (temperature, pressure, current) to ensure operational safety.

5. Brand and Service

5.1 Verification of Technical Strength

- Rotor Profile Patents: When choosing a supplier, check for rotor profile patents (e.g., Sigma profile). This technology enhances compressor efficiency, durability, and energy savings.

- Smart Control Systems: Devices with smart control systems (e.g., IoT remote monitoring) enable real-time data analysis, fault warning, and remote monitoring, helping detect issues early and reduce downtime.

5.2 International Service Network

- Global Service: MINNUO has established spare parts centers in 12 countries, committing to a 4-hour response time and 48-hour on-site service (in major industrial zones). This global network ensures quick support during equipment failures, minimizing downtime.

6. FAQ

Q1: Does an oil-free screw air compressor require no maintenance?

A1: No. While oil-free compressors eliminate oil separator replacement costs, they still require regular air filter changes (recommended every 8,000 hours) and seal maintenance. Their maintenance costs are 40% lower than oil-injected models.

Q2: Are variable frequency (VSD) screw air compressors suitable for all scenarios?

A2: VSD models are recommended only for applications with load fluctuations >30%. For constant loads, fixed-speed machines are more efficient and 20% cheaper.

Q3: How to select compressors for high-temperature environments (>45°C)?

A3: In high-temperature settings, choose water-cooled models or high-temperature-specific air-cooled models (e.g., MINNUO HT series). Standard air-cooled models lose 20% exhaust volume at 45°C.

Q4: How to verify a supplier’s technical parameter authenticity?

A4: Request on-site air volume testing (per ISO 1217 standards) to measure the deviation between actual and nominal exhaust volumes. Reputable manufacturers allow a tolerance of ±5%.

7. Conclusion

Choosing a screw air compressor is a systematic decision involving technical parameters, brand capabilities, and more. As a global manufacturer with ISO 9001, CE, and ASME certifications, MINNUO provides localized selection simulation software and energy efficiency guarantee plans to help users achieve optimal total life cycle costs.

Email

Email sales:+86 15366749631

sales:+86 15366749631