In industrial manufacturing, painting, mechanical automation, and other fields, air compressors are essential core equipment for generating gas. However, facing a wide range of brands and models on the market, how to choose an air compressor that is energy-saving, efficient, and meets your needs? This article outlines the key points for purchasing, including core parameters, type comparison, brand recommendations, and practical maintenance tips to help you reduce long-term operating costs.

I. Analysis of Air Compressor Types and Applications

1. Piston Air Compressor:

Features: Simple structure and low cost, suitable for low power requirements (≤30 kW).

Applications: Small workshops, pneumatic tool driving, etc.

2. Rotary Screw Air Compressor:

Features: Stable operation, strong continuous output, and energy efficiency 30%-50% higher than piston machines.

Applications: Medium to large factories, automated production lines.

3. Oil-Free Air Compressor:

Features: Output gas is without oil contamination, meeting food, medical, and other industry standards.

Applications: High cleanliness work environments (such as laboratories, pharmaceuticals).

II. Core Parameters and Considerations for Purchasing

1. Power and Discharge Volume Matching:

Select an appropriate power based on the total air consumption of equipment and pneumatic tools (m³/min) to avoid overpowering or insufficient power.

2. Energy Efficiency Rating:

Prioritize national first-level energy efficiency products to save over 30% on electricity costs over the long term.

3. Brand Technical Strength:

Choose a brand with independent research and development capabilities, focusing on the stability of key components such as the compressor (main engine, motor, control system).

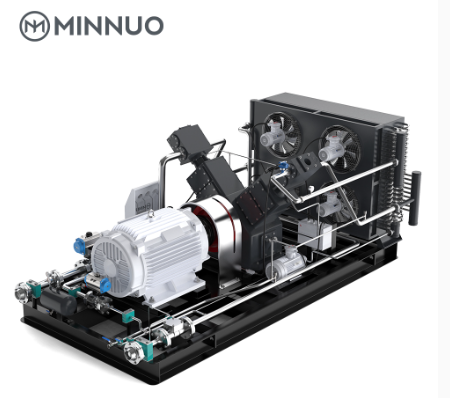

III. Brand Recommendation: Cost-Effective Choice

Core Advantages:

Intelligent Frequency Conversion Technology: Dynamically adjusts the rotation speed based on real-time air demand, saving 20%-30% on energy compared to traditional fixed-frequency machines.

German Engineering Standards: The main engine adopts a dual-rotor screw design with low noise at 65 dB and a service life of over 15 years.

All models equipped with a smart monitoring system allow for real-time viewing of operating data through a mobile app with fault warnings.

Applications: Suitable for small and medium-sized factories, painting workshops, etc., especially recommending the Minnuo MT30 series with an energy efficiency rating of IE4 that can quickly recover initial investment costs.

IV. Practical Tips to Extend the Life of Air Compressors

1. Regular Maintenance: Monthly checks of air filters and oil filters with lubricant oil replacement after 2000 hours of use.

2. Environmental Optimization: Avoid direct sunlight or high-temperature environments with good ventilation to reduce the impact of heat island effects.

3. Rational Use of Gas Peaks: Use equipment starting at different times or configure gas tanks to avoid frequent start-ups and stoppages that can damage the motor.

V. Conclusion: Make Wise Decisions to Reduce Total Cost of Ownership

When choosing an air compressor, it’s not only about the equipment price but also about energy consumption, maintenance costs, brand service, and other multi-dimensional assessments. With its efficient energy-saving technology, intelligent management functions, and long lifespan design, Minnuo has become a preferred choice for many companies upgrading their equipment.

Email

Email sales:+86 15366749631

sales:+86 15366749631