With the increasing awareness of environmental protection and the development of new energy technologies, hydrogen energy, as a clean and efficient form of energy, is gradually making its mark in the transportation sector. Hydrogen refueling stations, as energy supply points for hydrogen fuel cell vehicles, are of undeniable importance. This article will provide a detailed explanation of how hydrogen refueling stations work.

According to the source of hydrogen, refueling stations can be divided into two types: on-site hydrogen production and external hydrogen supply. On-site hydrogen production generates hydrogen through methods like water electrolysis or natural gas reforming, while external hydrogen supply is transported via long tube trailers or pipelines from external production plants. During the refueling process, hydrogen is purified, compressed, cooled, and then precisely dispensed into the vehicle using a hydrogen dispenser.

What is a Hydrogen Refueling Station?

A hydrogen refueling station is a dedicated facility for supplying hydrogen fuel to hydrogen fuel cell vehicles. Using specific equipment and processes, hydrogen is safely and efficiently dispensed into the vehicle’s hydrogen storage tank to provide the power source for the vehicle.

Types of Hydrogen Refueling Stations

Classified by Refueling Capacity

Hydrogen refueling stations can be classified into small, medium, and large capacity stations based on their refueling capacity.

Small Refueling Stations

These stations have relatively lower hydrogen refueling capacity and are suitable for areas or locations with small hydrogen refueling needs, such as small hydrogen demonstration zones.

Medium Refueling Stations

These stations meet the daily refueling needs of a certain number of vehicles and are commonly found in urban hydrogen refueling networks.

Large Refueling Stations

These stations have powerful refueling capabilities and are typically located near transportation hubs or hydrogen production bases. They can provide fast refueling services for a large number of hydrogen fuel cell vehicles, such as those around large logistics parks or long-distance passenger transport hubs.

Classified by Hydrogen Source

Hydrogen refueling stations can be divided into on-site hydrogen production stations and external hydrogen supply stations.

On-site Hydrogen Production Refueling Stations

Hydrogen is produced on-site through methods like water electrolysis or natural gas reforming, and then purified, compressed, and dispensed. This approach allows for self-sufficiency in hydrogen production but requires high technical and equipment standards.

- Water Electrolysis Hydrogen Production: Water electrolysis uses electricity to split water into hydrogen and oxygen. The hydrogen produced by this method has a purity of over 99.7% and is pollution-free, as the only byproducts are hydrogen and oxygen. However, the process consumes a large amount of electricity, resulting in higher costs, often relying on renewable energy sources such as solar or wind power to reduce expenses.

- Natural Gas Reforming Hydrogen Production: Natural gas reforming uses high temperatures (700-1000°C) and catalysts to react natural gas with steam to produce a mixture of hydrogen, carbon monoxide, and carbon dioxide, which is then purified into high-purity hydrogen. This method is well-established, cost-effective, and benefits from abundant natural gas resources. However, it generates carbon dioxide and other greenhouse gases during the reforming process, which has some environmental impact, and the equipment investment is relatively high with complex operations.

External Hydrogen Supply Refueling Stations

These stations receive hydrogen from external hydrogen production plants, which is then transported (via methods such as long tube trailers or pipelines) to the refueling station, where it undergoes pressure reduction, storage, and dispensing. The advantage of this method is simpler construction and relatively stable hydrogen supply.

- Long Tube Trailer Transport: Hydrogen is compressed at the production plant to high pressures and loaded into long tube trailers for transportation to the refueling station. Afterward, it is dispensed via pressure-reducing devices. This method is simple, with low initial investment, and is suitable for short-distance, small-scale transport. However, as transport distances increase, costs rise significantly, and hydrogen load capacity is limited, leading to lower transportation efficiency.

- Pipeline Transport: When the production plant is located close to the refueling station and the demand is large, pipeline transport is a more economical and efficient option. Hydrogen is transported through pipelines to the station, where it is regulated and measured before being dispensed. Pipeline transport offers high throughput, low costs, and high stability, making it suitable for large-scale networks, but it requires high upfront investment and handling of hydrogen purity and pressure requirements.

Hydrogen Refueling Process and Equipment

Hydrogen at the refueling station usually comes from industrial by-product hydrogen, water electrolysis hydrogen, etc. After purification, it is transported to the refueling station in either gas or liquid form. Inside the station, hydrogen first enters a buffer tank for pressure stabilization, then is pressurized to the appropriate level (usually 35-70 MPa) using a compressor. After being cooled and dried, it is dispensed into the vehicle’s hydrogen storage tank using a hydrogen dispenser.

The main equipment at a hydrogen refueling station includes:

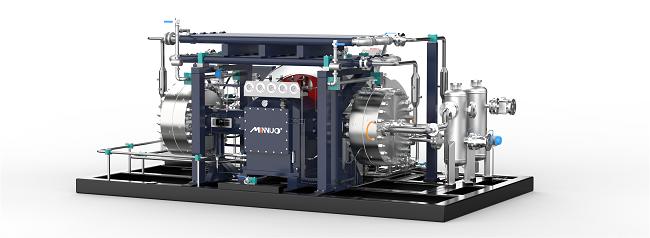

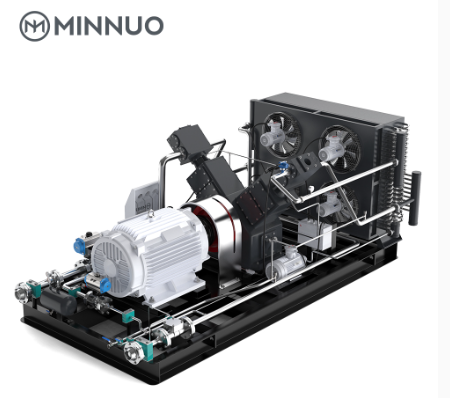

- Hydrogen Compressor: Compresses hydrogen to increase its pressure to meet dispensing requirements.

- Hydrogen Storage Tanks: Store high-pressure hydrogen in either gaseous or liquid form. Gaseous storage tanks can be further classified by pressure level.

- Hydrogen Dispenser: Similar to a fuel dispenser at a gas station, it is the key equipment for dispensing hydrogen into vehicles. It precisely controls the amount and speed of hydrogen dispensing.

- Coolers and Dryers: Used to cool and dry the compressed hydrogen, ensuring the quality and safe dispensing of hydrogen.

How Do These Types of Equipment Work?

Hydrogen Compressor

Uses mechanical devices to compress hydrogen, raising its pressure from low to high. Common types of compressors include reciprocating compressors, diaphragm compressors, and ionic liquid compressors. Reciprocating compressors use piston movements to compress gas, while diaphragm compressors compress hydrogen through diaphragm deformation, offering good sealing and high gas purity. Ionic liquid compressors use ionic liquids as the compressing medium, offering high efficiency and low energy consumption.

Hydrogen Storage Tanks

Gaseous hydrogen storage tanks are made of high-strength materials to withstand high-pressure hydrogen storage. The working principle is to store hydrogen in a sealed container, maintaining specific pressure and temperature conditions. Liquid hydrogen storage tanks require hydrogen to be cooled to extremely low temperatures (around -253°C), liquefying it for storage. Low temperature and high-pressure environments ensure the stable storage of liquid hydrogen.

Hydrogen Dispenser

The dispenser includes flow control systems, pressure regulation systems, and safety protection devices. When a vehicle is connected to the dispenser, the system first communicates with the vehicle’s hydrogen storage tank to obtain information such as pressure, temperature, and remaining capacity. Based on this data, it automatically adjusts the dispensing pressure and flow rate, safely and quickly filling the vehicle while monitoring the process to ensure compliance with safety standards and vehicle requirements.

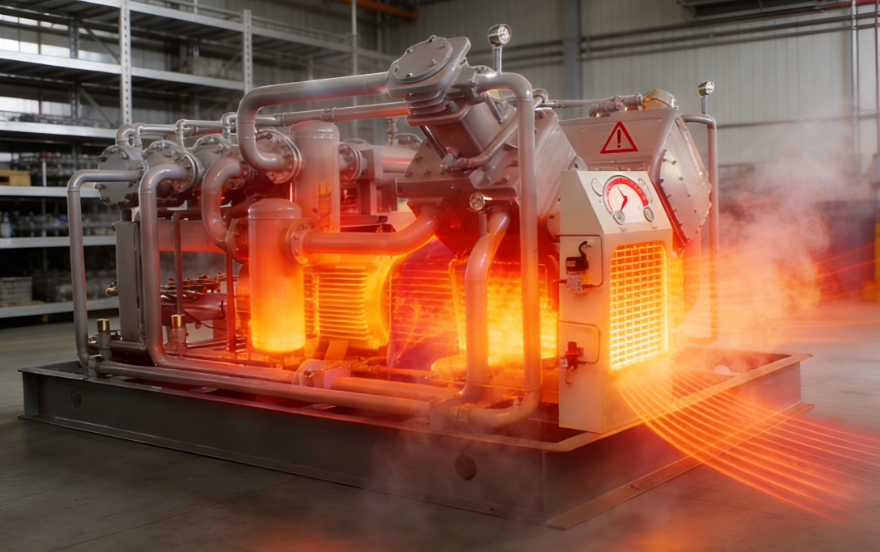

How to Ensure the Safe Operation of a Hydrogen Refueling Station?

- Smoking and open flames are strictly prohibited inside the refueling station, with clear fire hazard signs posted. The station is equipped with fire alarms and extinguishing devices.

- The station area should be strictly managed into zones, including unloading, compression, storage, and refueling areas, with sufficient safety distances between them and appropriate isolation facilities.

- All personnel and vehicles entering the station must adhere to safety regulations. Vehicles should drive at controlled speeds within the station, and must be turned off with all electrical equipment switched off during refueling, with reliable braking measures in place.

- The equipment at the refueling station, such as hydrogen compressors, storage tanks, and dispensers, should be regularly maintained and tested to ensure reliable performance and safe operation.

- Operators must undergo professional training to become familiar with the station’s process flows, equipment operations, and emergency procedures, obtaining relevant operational qualifications before starting work.

Conclusion

Hydrogen refueling stations are crucial for hydrogen fuel cell vehicles. Both on-site hydrogen production and external hydrogen supply refueling stations have their advantages. With technological advancements and policy support, refueling stations will improve efficiency and promote the application of hydrogen energy in the transportation sector, contributing to green travel and low-carbon development.

As a manufacturer with over 30 years of experience, MINNUO can provide a complete set of hydrogen refueling system air solutions. For more information, feel free to contact us!

Email

Email sales:+86 15366749631

sales:+86 15366749631