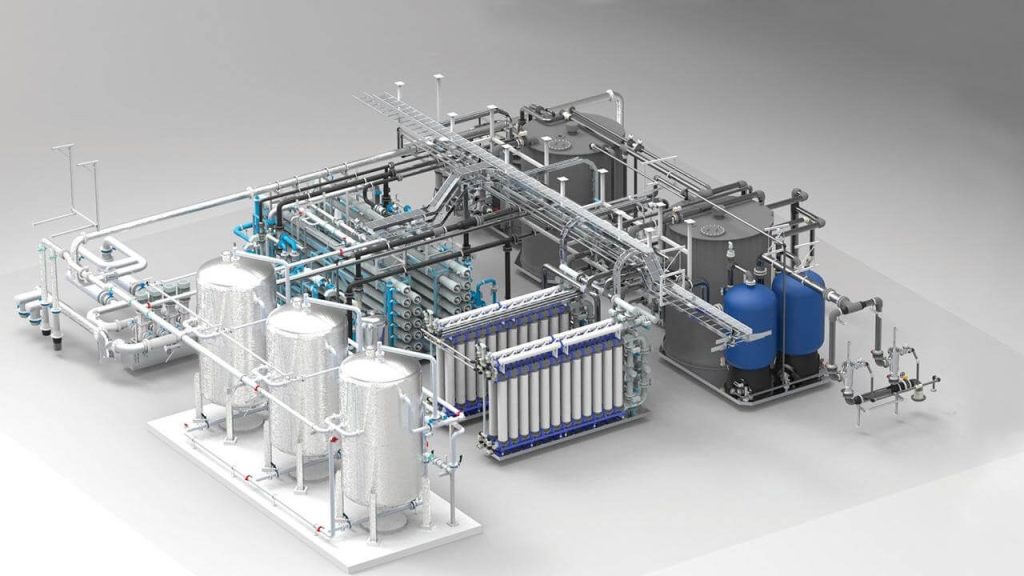

Against the backdrop of the global upgrading of water resource protection and the demand for healthy drinking water, water treatment filling production lines have become a key area of infrastructure construction in many countries. From municipal water supply to bottled water and beverage production, the efficient operation of this production line is directly related to the quality and cost of the end products – among which, an easily overlooked but crucial link is the bottle blowing compressor.

The key to the compatibility of bottle blowing compressors with water treatment filling production lines lies in precisely matching production capacity demands, material properties and environmental protection standards: it is necessary to ensure that the pressure, cleanliness and flow rate of compressed air form a dynamic balance with the scale of the production line and the bottle type process, while also meeting the compliance requirements of different regions and the cost reduction and efficiency improvement goals of enterprises.

As the “power core” of the bottle blowing machine, the quality and stability of the compressed air provided by the bottle blowing compressor directly determine the accuracy of bottle forming, production efficiency and the qualification rate of the final product. So, as a professional compressor supplier, how does MINNUO recommend suitable bottle blowing compressors for water treatment filling production lines in different scenarios? This article will conduct an analysis from three dimensions: technical features, scene requirements, and selection logic.

1. Bottle blowing compressor:The “Invisible Cornerstone” of bottle blowing machines

In the water treatment filling production line, the production of “bottles” is the core front-end link. Whether it is PET bottles, HDPE bottles or containers made of other materials, they all need to be blow-molded into shape through a bottle blowing machine. The normal operation of the bottle blowing machine relies on the high-pressure, clean and stable compressed air provided by the bottle blowing compressor. It can be said that the bottle blowing compressor is like the “heart” of the entire bottle forming process, and its performance directly affects the smoothness of the subsequent series of production processes.

Specifically, the bottle blowing process has three core requirements for compressed air, each of which affects the quality of the final product and production efficiency:

1.1 Pressure stability:

During bottle blowing, a high pressure of 15-40bar must be achieved instantaneously (adjusted according to the bottle specifications). This is similar to inflating a balloon; unstable pressure can easily lead to an irregular shape of the balloon. During the bottle blowing process, if the pressure fluctuation exceeds ±0.5bar, it may cause uneven wall thickness of the bottle body. In mild cases, it will affect the appearance and feel of the bottle; in severe cases, it may cause the bottle to break during subsequent filling and transportation, resulting in unnecessary losses. For instance, a small bottled water manufacturer once had about 5% of the bottles scrapped each batch due to wall thickness issues because of the use of compressors with unstable pressure. This not only increased production costs but also delayed the delivery cycle.

1.2 Air Cleanliness:

Moisture, oil, and particulate impurities in compressed air can contaminate preforms, thereby affecting water quality or the safety of beverages. Imagine that if the compressed air contains moisture, water droplets may form inside the bottle during the bottle blowing process. Once these water droplets come into contact with water or beverages, they may breed bacteria. The oil content and particulate impurities will directly affect the taste and quality of the product. Therefore, the compressed air needs to meet ISO 8573-1 Class 1 (oil ≤0.01mg/m³, water ≤0.1mg/m³, particles ≤0.1μm). Data shows that compressed air that does not meet cleanliness standards can increase the rate of bacteria exceeding the standard in products by more than 30%.

1.3 Flow Adaptability:

Production lines with different production capacities (such as 10,000 bottles per hour and 100,000 bottles per hour) have extremely different requirements for air flow. Insufficient flow can lead to production interruption, just as insufficient water supply can affect residents’ lives. The stagnation of production lines can cause huge economic losses. Excessive traffic, however, will lead to energy waste and increase the operating costs of enterprises. After calculation, if the data flow exceeds by 10%, it will consume tens of thousands of dollars more in electricity bills each year.

Therefore, the selection of a bottle blowing compressor is by no means a simple “power matching”, but requires customized design in combination with the full chain requirements of the production line. Only in this way can the efficient and stable operation of the entire bottle blowing process be ensured.

2.MINNUO’s recommendation logic: Start from the scenario and return to the essence of production

As a supplier deeply engaged in the compressor field for 15 years, MINNUO has always adhered to the principle of “scenario-based selection”, that is, based on the core parameters such as the customer’s production line scale, bottle shape characteristics, and environmental protection requirements, it recommends the most suitable solution. We are well aware that each water treatment filling production line has its uniqueness, and only tailor-made solutions can bring the greatest value to customers. It can be specifically divided into the following three major dimensions:

2.1 According to the scale of the production line: Match the balance point of “capacity – energy consumption”

The scale of the production line is one of the key factors in determining the selection of bottle blowing compressors. Production lines of different scales vary greatly in terms of production capacity, operation mode, etc., and the corresponding compressor demands are also different.

Small-scale production line (capacity ≤1000 bottles per hour) :

Such scenarios are mostly local water plants and small beverage factories, characterized by batch production and intermittent operation. These enterprises usually have limited funds, are sensitive to costs, and also hope that the equipment can meet the basic production needs. It is recommended to use the MINNUO medium and high-pressure air compressor. With a power of 15kW, it can stably output a flow rate of 1m³/min and support pressure adjustment from 35 to 70bar. It can fully meet the pressure and flow requirements of small-scale production lines for bottle blowing. Moreover, this series of compressors is equipped with a “no-load sleep” function – when the production line is suspended, the compressor automatically reduces its energy consumption to less than 30% of the rated power. Based on intermittent operation for 4 hours per day, compared with traditional compressors, it can save up to 12,000 kilowatt-hours of electricity annually. This is a considerable savings for small enterprises. In addition, this series of compressors are compact in size, occupying only 1.5 square meters of space, making them highly suitable for the layout of small production workshops. After a small beverage factory in a certain place adopted this series of compressors, not only was the production efficiency guaranteed, but the monthly electricity bill was also reduced by nearly $150 compared to before.

Medium-sized production line (1,000-10,000 bottles per hour) :

It is applicable to regional-level bottled water enterprises that require continuous production and frequent bottle type switching (such as 500ml, 1.5L, 5L, etc.). Such enterprises have high requirements for the continuity and flexibility of production, and also pay attention to the stability of product quality. We recommend the MINNUO integrated compressed air system: The 18.5kW main unit provides a flow rate of 1.6m³/min, which can meet the continuous production flow requirements of medium-sized production lines. The three-stage precision dryer and filter used in combination ensure that the dew point of the air is ≤-40℃, effectively removing moisture and impurities from the compressed air and ensuring the cleanliness of the bottle body. Meanwhile, this system supports one-click switching between multiple pressure segments (30-35bar/28-32bar/35-40bar), meeting the blow molding requirements of different bottle types. It eliminates the cumbersome parameter adjustment process and improves production efficiency. After a regional-level bottled water enterprise adopted this system, the bottle type switching time was reduced from the original 30 minutes to 5 minutes, significantly enhancing the flexibility of the production line and increasing the monthly output by about 10%.

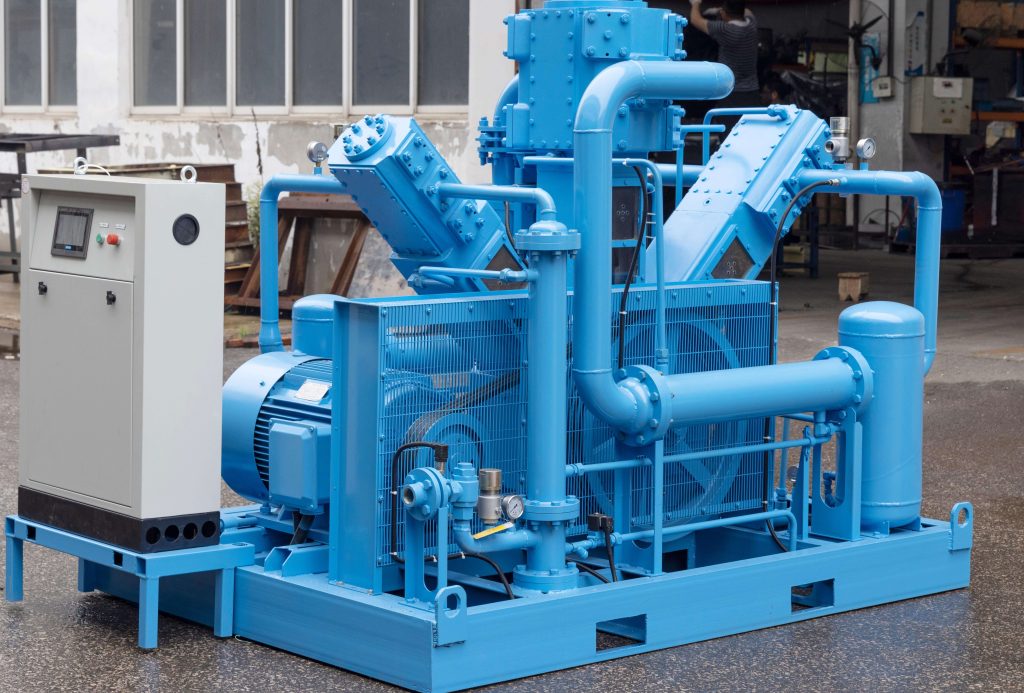

Large-scale production line (capacity ≥ 10,000 bottles per hour) :

It is commonly seen in multinational beverage groups or national-level drinking water projects, with extremely high requirements for stability and continuity (losses can reach tens of thousands of dollars for a one-hour downtime). Once the production lines of these enterprises break down, the losses caused will be incalculable. Therefore, there are extremely high requirements for the reliability and stability of compressors. We recommend the MINNUO compressor cluster solution. The parallel connection of two machines can provide a flow rate of 3.2m³/min and support medium to high pressure output of 40-50bar, which can meet the high-intensity bottle blowing requirements of large-scale production lines. Moreover, this solution is equipped with an intelligent monitoring system – which can monitor 16 parameters such as exhaust pressure, temperature and oil level in real time, and issue a 48-hour early warning of potential faults, enabling enterprises to make maintenance preparations in advance and avoid sudden shutdowns. With a global 2-hour response after-sales service, we ensure zero downtime of the production line. After a large production line of a certain multinational beverage group adopted this solution, the annual downtime was controlled within one hour, reducing the downtime loss by nearly 20 hours compared to before, and indirectly creating economic benefits of several million dollars.

2.2 By bottle type characteristics: Focus on the compatibility of “material – process”

Due to the differences in physical properties and production processes, bottles of different materials have significant variations in their requirements for compressed air. Only by choosing the appropriate compressor based on the characteristics of the bottle shape can the forming quality of the bottle body be guaranteed.

PET bottles (mainstream containers for bottled water and beverages) :

During blow molding, rapid temperature rise (80-120℃) is required. At this temperature, if the compressed air contains oil, it will produce an unpleasant odor, affecting the taste and quality of the water or beverage inside the bottle. MINNUO recommends oil-free screw compressors, which adopt water lubrication technology to completely eliminate the risk of oil contamination and ensure the cleanliness of the bottle body. Meanwhile, the exhaust temperature of this series of compressors is controlled below 45℃ to prevent the preforms from deforming due to high temperatures. After testing, the PET bottles produced by this series of compressors have a qualification rate of over 99.5%, which is 3% higher than that produced by traditional oil-containing compressors. After a large bottled water enterprise adopted this series of compressors, the complaint rate of customers regarding the taste of the products dropped by 50%.

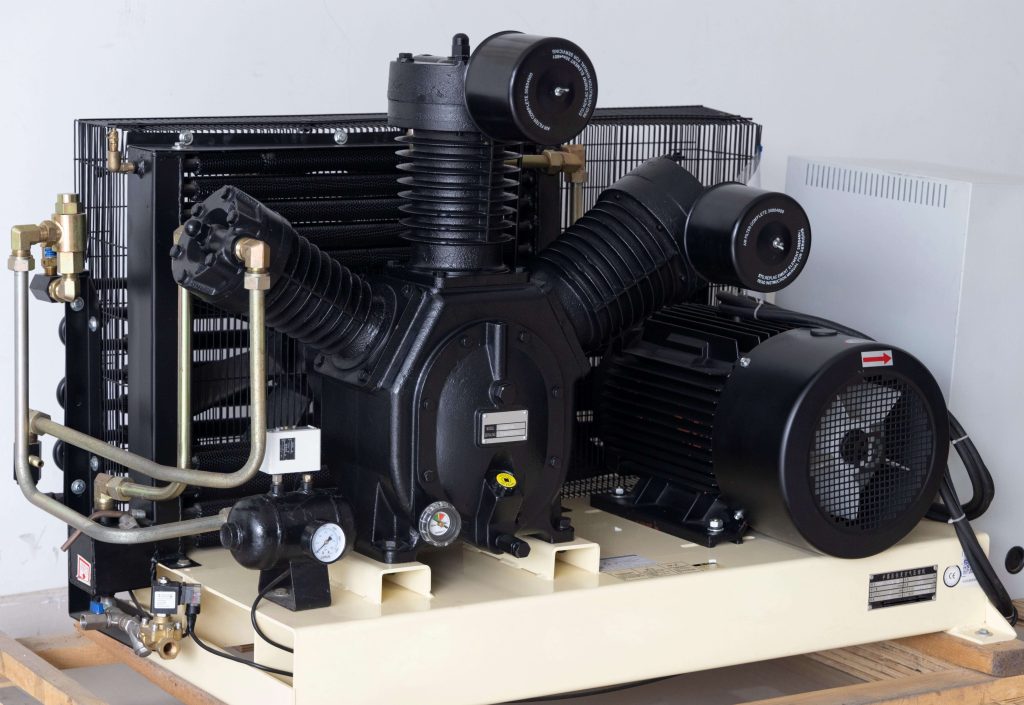

HDPE bottles (mostly used for large-capacity bottled water) :

The wall thickness is relatively thick (0.8-1.2mm), and a lower instantaneous pressure (6-12bar) is required to make the bottle body fully formed. If the pressure is too high, it will lead to problems such as uneven wall thickness of the bottle body and rupture of the preform, affecting the quality and service life of the product. It is recommended to use the MINNUO (08VW, 10WW) medium and high-pressure compressor, with the exhaust pressure maintained at around 9 bar to ensure the bottle body is fully formed. This series of compressors also features a stable pressure output function, with pressure fluctuations controlled within ±0.3bar, further ensuring the quality stability of the bottle body. After a certain enterprise that produces large-capacity bottled water adopted this series of compressors, the scrapping rate of the bottle bodies dropped from the original 4% to less than 1%.

Special bottle shapes (such as irregular-shaped bottles and wide-mouth bottles) :

The blow molding molds are complex, and the bottle body shapes are irregular, with extremely high requirements for the uniformity of air flow. If the airflow is uneven, it will cause problems such as wrinkles and deformations on the bottle body, affecting the appearance and quality of the product. MINNUO offers customized air valve design. By optimizing the intake Angle and flow distribution, it enables compressed air to form a “laminar flow” within the mold, reducing the bottle body wrinkle rate to below 0.1%. Our engineers will conduct specialized airflow simulation and analysis based on the bottle mold drawings provided by the customer, and design the most suitable gas valve structure. After a certain enterprise that produces irregular-shaped beverage bottles adopted our customized solution, the appearance qualification rate of its products increased by 8%, and the market competitiveness of its products was significantly enhanced.

2.3 In accordance with environmental protection and compliance requirements: Conform to regional standards

Different countries and regions have different regulations on environmental protection and energy consumption standards for industrial equipment. To ensure that the production activities of enterprises comply with local laws and regulations and also to respond to the global environmental protection trend, the environmental protection and compliance requirements of the region must be considered when choosing compressors.

Eu market:

CE certification and ERP directive (energy efficiency grade ≥IE3) are required. The MINNUO compressor adopts a variable-frequency motor and magnetic levitation bearings, with a coefficient of performance (COP) reaching 4.2, which is 15% higher than the EU standard, significantly reducing energy consumption. Moreover, the noise of this series of compressors is as low as 72dB (A), meeting the environmental protection requirements of factories in residential areas and reducing the impact on the surrounding environment. After a water treatment filling plant in a certain EU country adopted this series of compressors, its annual carbon emissions were reduced by more than 10 tons, and it received environmental protection subsidies from the local government.

In the Southeast Asian market:

The high-temperature and high-humidity environment (with an average annual temperature of 30-35℃ and a humidity of over 80%) is prone to causing internal rust in compressors, which affects the service life and performance stability of the equipment. We recommend the MINNUO anti-corrosion version. Its core components are made of 316 stainless steel, which has extremely strong corrosion resistance and can operate stably for a long time in high-temperature and high-humidity environments. Meanwhile, the cooling system has been upgraded to a dual-circulation heat dissipation system to ensure the heat dissipation effect of the equipment in extreme environments, extending the equipment’s lifespan to over 10 years. After a bottled water enterprise in a certain Southeast Asian country adopted this series of compressors, the frequency of equipment maintenance was reduced from five times a year to one, significantly lowering maintenance costs.

North American market:

ASME certification is required, and the quality requirements for compressed air are more stringent (Class 0 oil-free). MINNUO’s oil-free scroll air compressors adopt fully oil-free scroll technology. They have been tested by third-party laboratories and are 100% oil-free, far exceeding the North American food-grade packaging standards. This series of compressors also features a complete safety protection system, meeting the safety standards of the North American market. After a certain North American beverage enterprise adopted this series of compressors, it smoothly passed the local food production certification, and its products successfully entered the local mainstream market.

3. Why choose MINNUO? Full-cycle support from equipment to ecosystem

In the highly competitive compressor market, MINNUO has stood out and gained the trust of many customers. This is not only due to the technical advantages of its products themselves, but more importantly, it is because we provide full-cycle support from equipment to ecosystem, creating continuous value for our customers.

Early stage:

We offer a free production line audits. This is not just a simple equipment inspection. Our professional technical team will have an in-depth understanding of the customer ‘s production process, capacity planning, bottle shape characteristics and other information. Through advanced 3D simulation software, we will precisely calculate the best compressed air parameters, including pressure, flow rate, cleanliness, etc. Thus, we can recommend the most suitable compressor model and configuration to customers, avoiding situations such as “a big horse pulling a small cart” or insufficient production capacity. For instance, there was an enterprise that was preparing to build a new production line. Initially, it planned to purchase a high-power compressor. After our audits, it was found that its actual demand did not require such a large power. We recommended a more suitable medium-power compressor for it, helping the customer save nearly 30% of the initial equipment investment.

Mid-term:

Supports modular installation, a feature that is highly suitable for enterprises with capacity expansion plans. Customers can install some compressor units first based on their current production needs. When production capacity increases, they can gradually add more compressor units without having to replace the entire system, which significantly reduces the initial investment cost. Moreover, the modular installation method also has the advantages of short installation period and high flexibility, which can quickly meet the production needs of customers. In the early stage of production, a certain enterprise had a relatively low production capacity and only installed two of our compressor modules. With the growth of market demand, another module was added half a year later. The entire process only took three days and hardly affected normal production.

Later stage:

Remote operation and maintenance are achieved through the IoT platform. Each of our compressors is equipped with intelligent sensors that can collect real-time operation data of the equipment, such as exhaust pressure, temperature, energy consumption, etc., and transmit these data to the IoT platform. Our professional operation and maintenance team can monitor the operation status of the equipment in real time through the platform, promptly identify potential fault hazards, and provide remote diagnosis and maintenance suggestions for customers. Meanwhile, the platform will also automatically optimize the operation parameters based on the operation data of the equipment, ensuring that the equipment is always in the best operating condition and reducing the operation and maintenance costs by an average of 10-15%. After a certain enterprise adopted our remote operation and maintenance service, the failure rate of its equipment decreased by 40%, and the annual operation and maintenance cost was reduced by nearly $3,000.

As of 2024, MINNUO’s bottle blowing compressors have served over 500 water treatment and filling enterprises worldwide, including regional factories of international brands such as Coca-Cola and Nestle Water. It has maintained the top market share in emerging markets such as Southeast Asia, the Middle East, and South America for three consecutive years. This is not only an endorsement of the quality of our products, but also an affirmation of our full-cycle service.

Conclusion

In today’s increasingly competitive water treatment filling industry, reducing unit energy consumption and improving the pass rate have become the core approaches for enterprises to cut costs and increase efficiency. As a key front-end equipment, the rationality of the selection of the bottle blowing compressor directly affects the “health” of the entire production line.

MINNUO always believes that the best recommendation is not “the most expensive product”, but “the solution that understands you best”. If you are planning or upgrading your water treatment filling production line, please feel free to contact our technical team to obtain a customized selection plan for bottle blowing compressors – ensuring that every bit of compressed air is transformed into tangible production value.

Email

Email sales:+86 15366749631

sales:+86 15366749631