- Home >

- Gas Compressor >

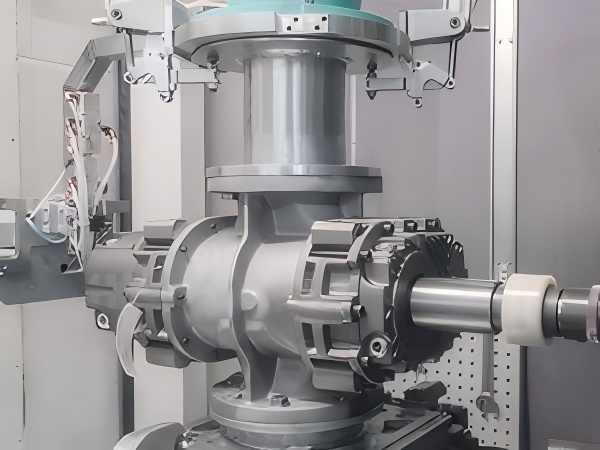

- XHWR Series Three-Lobe Roots Blower

XHWR Series Three-Lobe Roots Blower

- Cooling Water Flow Rate: 5~25 L/MIN

- Drive Side Oil Tank: 0.35~34 L (Air-cooled/Water-cooled).

- Main Oil Tank: 0.52~60 L (Air-cooled/Water-cooled).

- Grease Amount: 10~60

- Cooling Water Inlet Pressure: 196~294 kPa

- Cooling Water Inlet Temperature: ≤25℃.

Products Description

The XHWR series three-lobe Roots blower adopts an efficient three-lobe rotor design, with low vibration, low noise, and high reliability as its core advantages. It is widely used in sewage treatment, pneumatic conveying, aquaculture, chemical metallurgy, and other fields. With precision manufacturing processes and intelligent control systems, it ensures long-term stable operation, meeting the stringent demands of industrial scenarios.

Working Principle

The motor drives the blower through a narrow V-belt, causing the gas inhaled from the intake port to be pressurized by a pair of three-lobe impellers and then discharged from the exhaust port.

Parameters

| Model | Cooling Water Flow Rate (L/min) |

Cooling Water Requirements | Drive-Side Oil Tank (L) | Main Oil Tank (L) |

Grease Quantity |

|---|---|---|---|---|---|

| XHWR65 | 5-8 | Inlet Pressure: 196-294 kPa (2-3 kgf/cm²); Inlet Temp: ≤25℃ |

0.35 | 0.52 | 10 |

| XHWR100 | 0.5 | 0.78 | 15 | ||

| XHWR125 | 8-10 | 1.1 |

1.6 |

23 |

|

| XHWR125C | |||||

| XHWR150 | 10-13 | 1.6 |

2.1 |

35 |

|

| XHWR175A | |||||

| XHWR200 | 12-15 | 2.1 |

3 |

45 |

|

| XHWR250B | |||||

| XHWR250 | 15-18 |

4.5 (Air) / 7 (Water) | 10 (Air) / 26 (Water) | 60 |

|

| XHWR300 | |||||

| XHWRR250 | 10 (Air) / 7 (Water) |

40 (Air) / 26 (Water) |

/ | ||

| XHWRR290 | |||||

| XHWRR300 | |||||

| XHWRR350 | |||||

| XHWRG350 | 20-25 |

34 (Air) | / | ||

| XHWRG400 | 26 (Water) | 60 | |||

| XHWRG450 | / | / | |||

| XHWRG500 | / | / | / |

Structural Advantages

- Three-Lobe Rotor Design: Non-contact meshing of dual impellers, zero leakage, reduces airflow pulsation by 30% (compared to traditional two-lobe blowers).

- High-Precision Gearbox: Imported SKF bearings + carburized hardened gears, lifespan up to 50,000 hours.

- Modular Structure: Main and auxiliary oil tanks, silencers, and safety valves can be quickly disassembled, reducing maintenance time by 50%.

Performance Advantages

- High Efficiency and Energy Saving: Optimized impeller profile design increases volumetric efficiency by 15% and reduces energy consumption by 10%.

- Low Noise Operation: Three-lobe synchronous gear transmission, noise ≤75dB(A), compliant with environmental standards.

- Durable: High-precision cast body, IP55 protection rating, suitable for high temperature, humidity, and other complex environments.

- Intelligent Maintenance: Equipped with pressure relief valves, temperature sensors, and supports remote monitoring, reducing maintenance costs.

Application Fields

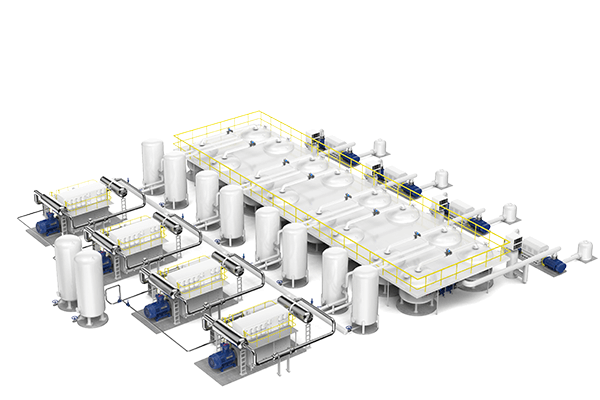

Environmental Engineering

Sewage aeration, desulfurization, and denitrification.

Industrial Manufacturing

Pneumatic conveying,

vacuum packaging.

Energy Industry

Biogas pressurization,

gas recovery.

Aquaculture

Oxygenation aeration, circulating water treatment.

Models

| Blower Model | Weight (kg) | Shaft Diameter (mm) |

|---|---|---|

| XHWR-40 | 1-1.5 | 3.5 |

| XHWR-50 | 1-2 | 4 |

| XHWR-65 | 1-1.7 | 4.5 |

| XHWR-80 | 1.5-2.5 | 4.5 |

| XHWR-100 | 2-3 | 5.5 |

| XHWR-125A | 1.5-3 | 6.5 |

| XHWR-150A | 3.5-5 | 7 |

| XHWR-175 | 3.5-5 | 7 |

| XHWR-200 | 4-5.5 | 8 |

| XHWR-250 | 4-5.5 | 8 |

| XHWR-300 | 4-5.5 | 8 |

| XHWR-350 | 4-5.5 | 8 |

Our After-Sales Service

Warranty Period

1-year free warranty for the whole machine (excluding consumables).

Quick Response

24-hour technical consultation, 48-hour on-site service.

Lifetime Support

Provide original spare parts, remote diagnosis, and upgrade services.

Frequent Asked Question

| Cycle time | Contents of operation | Tools/supplies |

|---|---|---|

| Daily | Check oil level, belt tension, abnormal vibration | Oil dipstick, tension gauge |

| Monthly | Clean intake filter element, replenish grease (ZL-3H) | Compressed air gun, grease injection gun |

| Semi-annually | Change gear oil (N220 medium load gear oil) | Used oil recycling drum, new oil |

| Every year | Align coupling, check bearing wear | Laser alignment gauge, micrometer |

Possible Causes: Loose belt, insufficient bearing lubrication, foreign object in impeller.

Solution: Adjust belt tension to 4-5mm deflection; replenish grease; stop and clean impeller.

Possible Causes: Ambient temperature >40℃, insufficient cooling water flow.

Solution: Install exhaust fan; check water pressure ≥196kPa, flow rate ≥8L/min.

Possible Causes: Filter clogging, pipeline leakage, safety valve failure.

Solution: Clean/replace filter; detect leaks with soapy water; recalibrate safety valve.

You May Like

Get Product Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631