- Home >

- Gas Compressor >

- VPSA Oxygen Generator

VPSA Oxygen Generator

- Oxygen Purity: 30% - 93% (customizable)

- Oxygen Output: 100 - 80,000 m³/h

- Start-up Time: <20 minutes

- Power Consumption: 0.28 - 0.37 kWh/m³ (at 90% purity)

- Noise Level: ≤85 dB (measured at 1 meter from the equipment)

Product Description

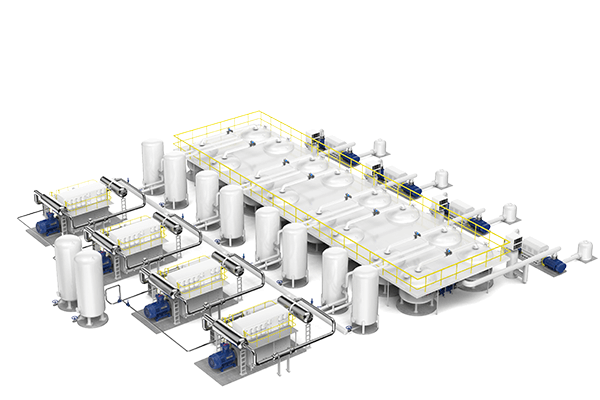

Since its establishment in 1987, MINNUO Group has been dedicated to the research and manufacturing of VPSA oxygen generation technology, becoming a global leader in pressure swing adsorption (PSA) oxygen systems. Our VPSA oxygen generators efficiently separate oxygen through low-pressure adsorption and vacuum desorption technology. They are widely used in industries such as steel metallurgy, healthcare, wastewater treatment, aquaculture, chemical environmental protection, and electronics manufacturing. With integrated design, ultra-low energy consumption, and intelligent control as core advantages, we provide customers with cost-effective on-site oxygen generation solutions.

Working Principle: Four-Step Cycle for Efficient Oxygen Production

Air Purification and Pressurization

Raw air is filtered twice (dust removal precision ≤0.1mm) and then pressurized to 0.06-0.08 MPa by a Roots blower.

It is cooled to 30-40°C, and the noise is reduced to ≤75 dB with a silencer design.

Molecular Sieve Dual Purification

13X Molecular Sieve Layer: Adsorbs moisture, carbon dioxide, and other impurities.

CaX Molecular Sieve Layer: Specifically adsorbs nitrogen, allowing oxygen to accumulate (90-95% purity) and be output from the top of the tower to the buffer tank.

Vacuum Desorption Regeneration

After adsorption saturation, a wet Roots vacuum pump reduces the pressure to -0.05 MPa to desorb nitrogen. The waste gas is discharged through a silencer separator, and oxygen backflushing technology improves regeneration efficiency, reducing energy consumption by 40% compared to PSA.

Dual-Tower Intelligent Alternation

Two towers automatically switch via a pneumatic valve group (5-10 minutes per cycle): one tower adsorbs and produces oxygen while the other undergoes vacuum regeneration, ensuring continuous and stable oxygen supply.

Core Technical Components

Roots Blower and Vacuum Pump

Equipped with imported stainless steel silencers, reducing noise by 30%. Paired with high-efficiency wet Roots vacuum pumps, energy consumption is 15% lower than traditional equipment.

Noise Reduction Design

Submarine-grade soundproofing technology with multi-layer fireproof sound-absorbing materials, ensuring overall equipment noise ≤85 dB, compliant with GB3096 industrial zone standards.

Molecular Sieve System

Utilizes high-efficiency CaX/13X double-layer molecular sieves, increasing adsorption capacity by 20% and extending service life to ≥10 years without frequent replacement.

Unique axial/radial tower design, combined with CFD fluid simulation, optimizes airflow distribution to maximize adsorption efficiency.

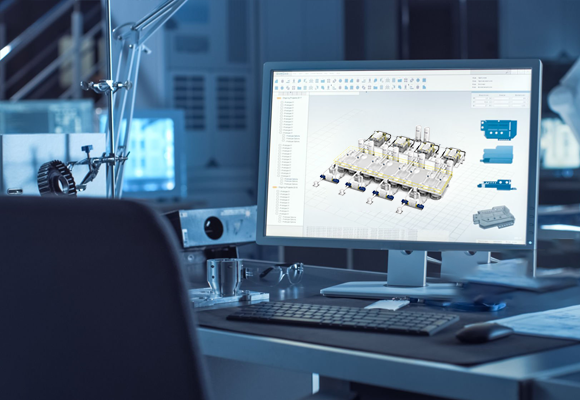

Intelligent Control System

Fully automated PLC + touchscreen operation, with one-click start/stop, remote monitoring, and data download and analysis capabilities. Annual operational rate ≥95%.

German-imported pneumatic switching valves, maintenance-free for 2 million cycles, with a response time ≤0.1 seconds, ensuring continuous and stable operation.

Core Advantages of VPSA Oxygen Generators

Industry-Leading Ultra-Low Energy Consumption

Utilizes lithium-based molecular sieves and high-efficiency blowers, with pure oxygen power consumption as low as 0.28 kWh/m³ (380V PSA models), 10% lower than international peers.

Fully Automated, Maintenance-Free Operation

One motor + 11 valves complete the entire process control, supporting unmanned operation. Maintenance only requires periodic filter replacement.

Modular Expansion and Flexible Customization

Oxygen purity (30%-93%) and pressure (≤20 kPa) can be adjusted as needed. Single-unit capacity covers 100-80,000 m³/h, supporting multi-unit parallel operation.

Fast Delivery and Low-Cost Infrastructure

Occupies only 50% of the space required by cryogenic methods, reduces water usage by 67%, and provides 3D construction drawings for rapid deployment in 60-120 days.

Military-Grade Safety and Reliability

Low-pressure operation (no high-pressure oxygen storage risk), certified by ASME/CE/CRN. Key valves use PTFE seals with anti-leakage design.

Frequent Asked Question

VPSA does not require cryogenic liquefaction of air, directly separating oxygen at room temperature, reducing energy consumption by 40%. It is more suitable for small to medium-scale continuous oxygen supply needs.

With patented molecular sieve filling technology, the service life under normal conditions is ≥10 years, with lifetime free performance monitoring services provided.

Dual-tower alternation adsorption + oxygen buffer tank design ensures pressure fluctuations ≤±2% and purity deviation <0.5%.

We provide PSA-to-VPSA upgrade solutions, utilizing existing infrastructure, reducing the retrofit cycle by 50%, with an investment payback period <2 years.

Email

Email sales:+86 15366749631

sales:+86 15366749631