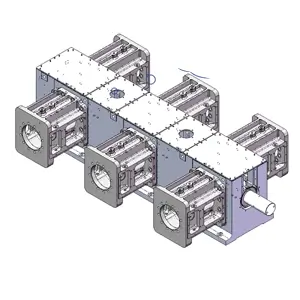

Reciprocating Compressor

Reciprocating compressors are most commonly known as piston compressors and we offer complete solutions for different applications and cost requirements. Guaranteed low maintenance, high precision, high air output, and reasonable prices.

- Discharge volume: 0.2-80m³/min

- Discharge pressure: 0.2-35Mpa

- Power: 5.5-250kw

- Compression media: hydrogen, natural gas, alkanes, olefins, carbon monoxide, carbon dioxide, nitrogen and hydrogen, desorption gas, raw material gas and other single or mixed media.

Product Overview

The reciprocating compressor has long served the petroleum, chemical and natural gas industries with reliable performance. The design and manufacture follow the latest international and domestic standards such as API618 and absorb the advanced technology from Germany. We have introduced the design and manufacturing technology of large reciprocating process compressors from Japan’s Kobe Steel, forming a large, medium, and small series from 6.5T to 125T piston force.

Modular design to guarantee speed of design

Forged parts are 20% stronger than machined, stress resistant, corrosive and have a long service life

Modular design to guarantee speed of design

The extensive use of synthetic materials and the highly balanced power performance of the units provide for a reduction in the noise level of the units.

Less vulnerable parts and long service life

The use of high-performance materials and the structural design of the parts improve the use of vulnerable parts and make them more adaptable to the working conditions.

Low energy consumption

The structural features of the compressor, the special shaft tile technology, the valve technology and the use of special material technology have greatly improved the transmission efficiency and friction losses and airflow resistance losses, resulting in a significant reduction in the power consumption of the unit.

High technical accuracy and low maintenance

From design, manufacture to installation, strict technical standards, norms and quality assurance systems are in place, and the core components of the main engine are machined by high-precision CNC machine tools, fully guaranteeing the reliability of the unit.

Advanced connection method

The crankshaft end of the compressor and the flywheel adopt the keyless expansion sleeve type connection, which completely removes the weakening of the crankshaft strength caused by the healthy groove and the crankshaft fatigue damage caused by the stress concentration caused by the healthy groove, and further improves the safety factor.

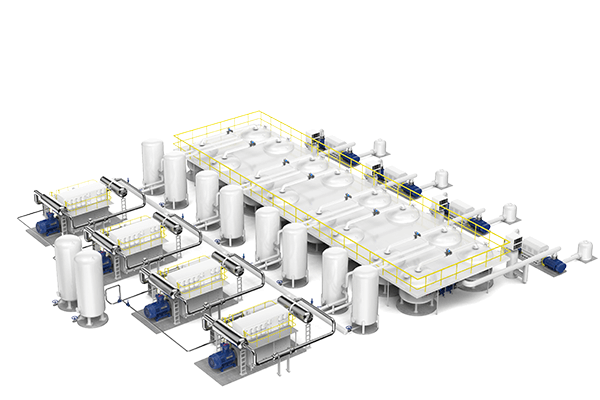

Multi stage postion compressor

The range of pressures that can be increased by a single-stage compressor is very limited for applications requiring higher working pressures of gas, such as oil, oilfield pressurization, and large and medium-sized blowing machines to supply gas.

- Manufactured using air-cooled and water-cooled pressure technology for high reliability and long service life.

- The compressor unit is highly automated and its operation is controlled by a programmable PLC with various protections.

- Flow rate: ≤50 Nm³/min

Pressure: ≤ 40 MPa

Medium: air, nitrogen, carbon dioxide, natural gas - Control: PLC automatic control

- Drive: motor, diesel engine

- Cooling mode: air-cooled, water-cooled, mixed cooling

- Installation mode: trailer mobile, container skid mounted, fixed

Case Project

The Kennedy Space Center in the United States has deployed a 100MPa reciprocating nitrogen compressor for leak testing of rocket fuel systems prior to launch.

In Japan, the Tokyo Electronics Industrial Cluster has installed an 1800 cubic meter per hour reciprocating argon compressor to supply gas for semiconductor chip manufacturing.

In Germany, a chemical company in the Ruhr area has completed a 2500 cubic meter per hour postion compressor project for chemical raw material conversion and storage.

In Dubai, UAE, a 30MPa diaphragm carbon dioxide compressor has been deployed at a clean energy park to support carbon capture and storage for solar power generation projects.

Get Reciprocating Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631