PSA/VPSA Oxygen and Nitrogen Generation System Solutions

MINNUO——With over 30 years of expertise in gas separation technology,we provide comprehensive oxygen

and nitrogen generation solutions for industrial applications, covering a wide range of scenarios.

Validated by 2000+ successful cases worldwide.

and nitrogen generation solutions for industrial applications, covering a wide range of scenarios.

Validated by 2000+ successful cases worldwide.

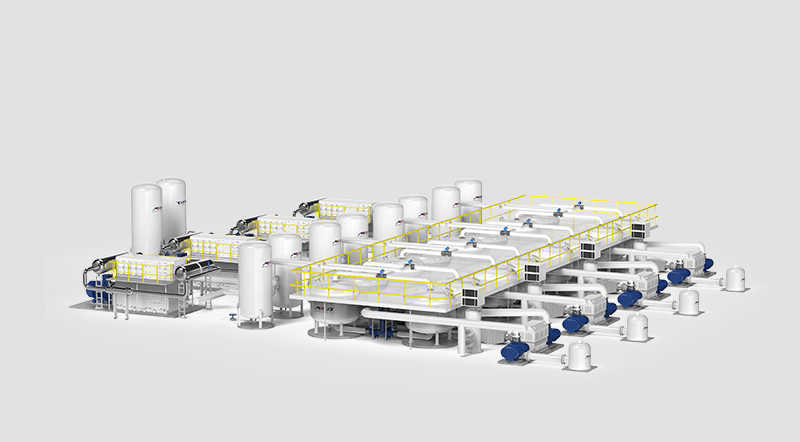

- PSA Oxygen Generation Equipment

- VPSA Oxygen Generation Equipment

- PSA Nitrogen Generation Equipment

Core Advantages

Why Choose MINNUO PSA/VPSA Systems?

- Ultra-Wide Capacity Range: Oxygen 1~80,000Nm³/h, Nitrogen 1~5,000Nm³/h

- Intelligent Purity Adjustment: Oxygen 30%-99.5%, Nitrogen 95%-99.9995%, one-click adjustment for different application needs

- Military-Grade Reliability: Molecular sieve warranty for 10 years, core valve warranty for 20 years, annual failure rate <1%

- Energy Efficiency Leader: VPSA oxygen comprehensive power consumption 0.28kWh/Nm³ (industry-leading), PSA nitrogen energy saving 50%-90%

- Full-Scenario Adaptability: Skid-mounted/containerized/explosion-proof/medical-grade customized solutions

Type Of PSA/VPSA Systems

Vacuum Pressure Swing Adsorption

- Oxygen Purity: 30%-93%

- Oxygen Capacity: 100-80000Nm³/h

- Start-up Time: <20mins

- Service life: ≥10 years

Product Matrix

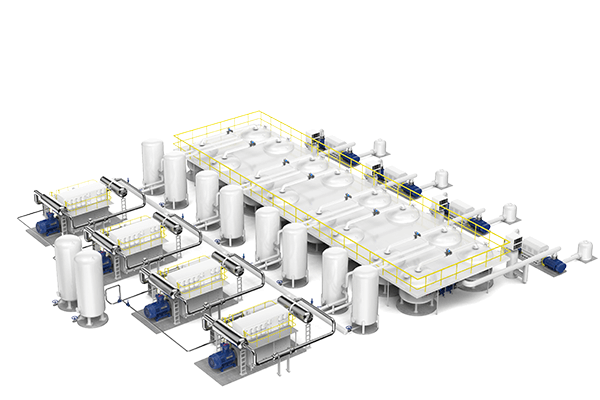

Full Range Coverage for Industrial and Medical Scenarios

Oxygen Solutions

| Model | Purity Range | Pressure Range | Key Applications |

|---|---|---|---|

| Medical-grade PSA |

93%±3% (ISO 7396-1) |

0.01-0.6Mpa | Hospital central oxygen supply emergency systems |

| Industrial-grade VPSA |

30%-93% | ≤20kpa | Metallurgy chemical/ wastewater treatment |

| Containerized O₂ | 90%-99.5% | Can be pressurized to 4.0Mpa |

Oil and gas fields offshore platforms mobile emergency oxygen supply |

Nitrogen Solutions

| Model | Purity Range | Dew Point | Industry Benchmark Cases |

|---|---|---|---|

| Food-grade PSA | 99.9995% | ≤-70℃ | Nitrogen packaging for milk powder wine preservation |

| Explosion-proof Nitrogen Generator |

95%-99.9% | ≤-40℃ | Chemical reaction protection coal mine explosion prevention |

| Skid-mounted Mobile Unit |

99%±0.5% | -40℃~-20℃ | Oilfield nitrogen injection tire vulcanization |

Core Technologies

Vacuum Pressure Swing Adsorption (VPSA)

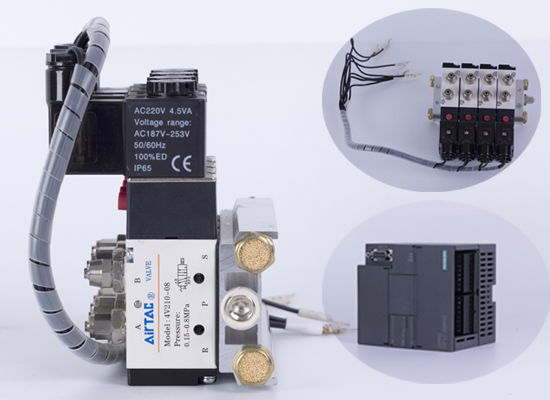

- Control System: Siemens SIMATIC S7-200 SMART PLC + P950 Online Analyzer

- Molecular Sieve: JALOX/UOP Medical-grade Zeolite Molecular Sieve | CMS Carbon Molecular Sieve

- Valve System: German Burkert Pneumatic Valves | SMC Solenoid Valves (2 million maintenance-free cycles)

- Safety Certifications: ASME/PED/CE Medical Certification/ATEX Explosion-proof Certification

Five Intelligent Systems

- Adaptive Adsorption Cycle Adjustment Technology

- Automatic Alarm and Interlock for Purity <90%

- 3D Airflow Simulation and Optimization Design

- Submarine-grade Acoustic Noise Reduction Solution (Noise ≤85dB)

- Cloud-based Remote Monitoring + Predictive Maintenance

Industry Pain Point Solutions

Your Concerns → MINNUO Answers

Frequent Asked Question

- PSA Oxygen: 0.35-0.4kWh/Nm³ (93% purity).

- VPSA Oxygen: 0.28-0.32kWh/Nm³ (90% purity).

- PSA Nitrogen: 0.1-0.15kWh/Nm³ (99.9% purity).

- Energy-saving tip: Larger VPSA scale results in lower unit energy consumption.

- Routine Maintenance: Only requires filter replacement every 6-12 months.

- Core Components: Molecular sieve warranty for 10 years, valve warranty for 20 years.

- Intelligent Monitoring: PLC system provides real-time monitoring and automatic fault alarms.

- Remote Support: Cloud-based remote diagnostics and predictive maintenance.

- Air filters: Regularly check and replace the filter elements to ensure clean air intake.

- Cooling system: Whether air-cooled or water-cooled, regularly check the cooling efficiency to prevent overheating.

- Moving parts: Periodically inspect the wear on piston rings and seals to ensure smooth operation.

- Pressure and temperature checks: Ensure the equipment operates within the recommended pressure and temperature ranges to avoid damage from excessive pressure or heat. These simple maintenance steps can effectively extend the equipment’s lifespan and maintain efficient, stable operation.

- Warranty Period: 1 year for the whole machine, 10-20 years for core components

- Technical Support: 7×24h online response

- Training Services: Free operation and maintenance training

- Spare Parts Supply: Global warehouse network for fast delivery

| Comparison Item | Liquid Oxygen/Nitrogen | MINNUO PSA/VPSA |

|---|---|---|

| Operational Cost | High (transportation + storage) | Saves 50%-90% |

| Gas Supply Stability | Affected by supply chain | 24h uninterrupted supply |

| Safety | High pressure/low temperature risks | Ambient temperature and low pressure, safer |

| Flexibility | Fixed supply points | On-site gas generation, on-demand production |

Simply provide the following information for an accurate quote:

- Gas type (oxygen/nitrogen)

- Flow rate requirement (Nm³/h)

- Purity requirement (%)

- Pressure requirement (Mpa)

- Installation environment (altitude/temperature)

You May Like

Send Your Inquiry Now!

Get VPSA/PSA System Solutions

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631