- Home >

- Gas Compressor >

- PSA Nitrogen Generation Plant

PSA Nitrogen Generation Plant

- Nitrogen Production: Up to 5000 cubic meters per hour

- Nitrogen Purity: 95% - 99.9995% (automatically adjustable) Dew Point: ≤ -70℃

- Nitrogen Pressure: 0.5 - 0.8 MPa (can be equipped with a booster for higher pressure)

- Plant Types: Containerized, Skid-mounted, Explosion-proof, Mobile

- Gas Production Time: 10 - 15 minutes

- Warranty: Molecular sieve warranty for 10 years, core valve warranty for 20 years

Product Description

Since 1987, MINNUO Group has been deeply involved in gas separation technology, focusing on the research and production of PSA nitrogen generation Plant for over 30 years. We have served more than 2000 systems globally. We provide nitrogen solutions with purity up to 99.9995%, with molecular sieves and core valves enjoying 10-year and 20-year warranties respectively, ensuring long-term stable operation of the Plant.

Advantages of PSA Nitrogen Generation Technology

(1) Energy Efficient, Cost Reduction by 90%

- Compared to liquid nitrogen or cylinder supply, operating costs are reduced by 50%-90%, producing gas on demand and automatically idling when not needed.

- Pressure, purity, and flow rate can be precisely adjusted to match diverse industrial scenarios.

(2) Dual Safety Assurance

- Operates at room temperature, eliminating the risk of high-pressure cylinder explosions; intelligent interlock devices automatically discharge unqualified nitrogen.

- Complies with ASME standard pressure vessels and ISO 9001 certification, ensuring system safety and reliability.

(3) Fully Automated Operation

PLC intelligent control, one-click start/stop, self-diagnosis of faults; optional oxygen content analyzer (P950, core imported from Germany) for real-time purity monitoring.

(4) Flexible Adaptation, Fast Delivery

Provides customized designs such as containerized and skid-mounted systems, producing nitrogen in 10 minutes, ready for immediate use; standard models have a delivery cycle of only 4-6 weeks.

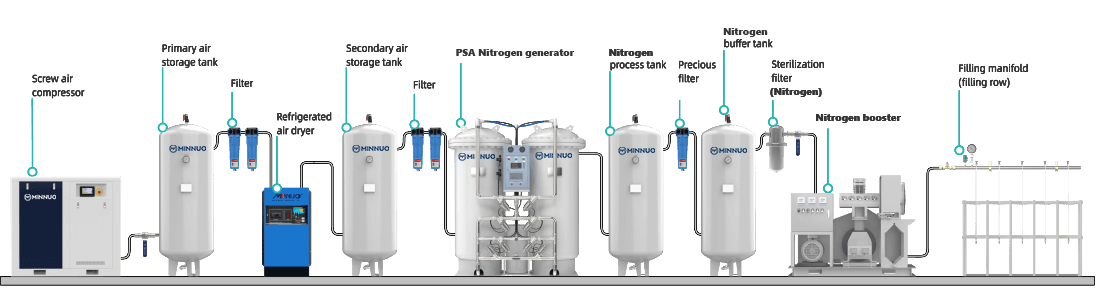

Working Principle

PSA (Pressure Swing Adsorption) technology uses compressed air as the raw material, leveraging the high adsorption characteristics of carbon molecular sieves for oxygen to achieve nitrogen-oxygen separation through a dual-tower cycle:

- Adsorption Phase: Clean air enters Tower A, where oxygen is adsorbed by the molecular sieve, and nitrogen is enriched and output.

- Desorption Phase: Tower B is depressurized to release the adsorbed oxygen, regenerating the molecular sieve.

- Cycle Alternation: The dual towers are automatically switched by PLC control to ensure continuous nitrogen production with purity up to 99.9995%.

Product Description

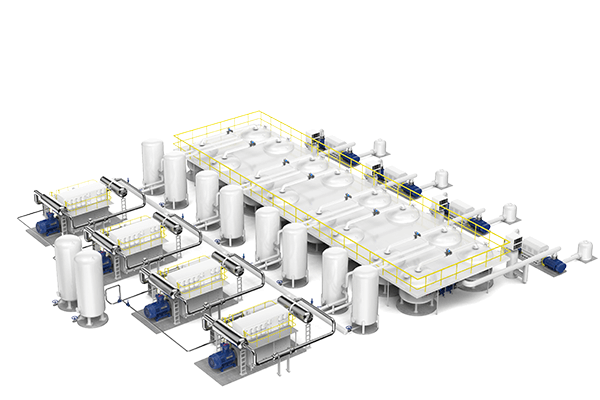

| Type | Applicable Scenarios | Characteristics |

|---|---|---|

| Skid-mounted | Small to medium flow demand (≤1000 Nm³/h) | Plug-and-play, small footprint, suitable for factory workshops, mines, etc. |

| Containerized | Medium to high flow demand (≤5000 Nm³/h) | Integrated in 20/40-foot standard containers, easy to transport, suitable for remote areas. |

| Explosion-proof | Chemical, oil and gas hazardous environments | Complies with ATEX explosion-proof certification, ensuring safety in flammable environments. |

| Mobile | Temporary operations or emergency nitrogen supply | Vehicle-mounted design, rapid deployment, suitable for oil field exploration, emergency repairs. |

Core Components

- Molecular Sieve: Uses high-efficiency carbon molecular sieves from international brands like JALOX and UOP, with strong adsorption performance and a lifespan of up to 10 years.

- Pneumatic Valve: Burkert high-speed valves from Germany, with fast response and zero leakage, capable of withstanding millions of cycles.

- Control System: Siemens PLC (SIMATIC S7-200 SMART) for fully automatic operation, supporting remote monitoring.

- Purification System: Precision filters remove water, oil, and particles to protect the molecular sieve from contamination.

Application Fields

Petrochemical

Pipeline purging, reactor protection, tank nitrogen sealing.

Food and Pharmaceutical

Nitrogen filling packaging, sterile filling, extending shelf life.

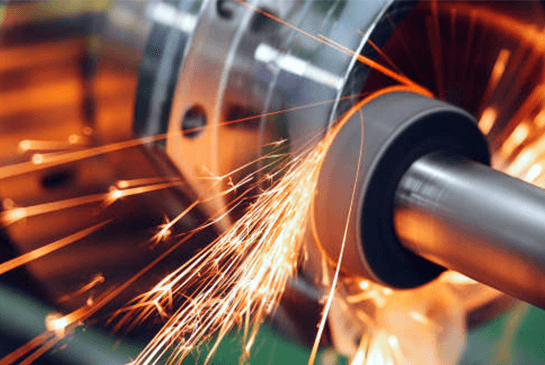

Metal Treatment

Bright annealing, brazing protection, preventing oxidation and discoloration.

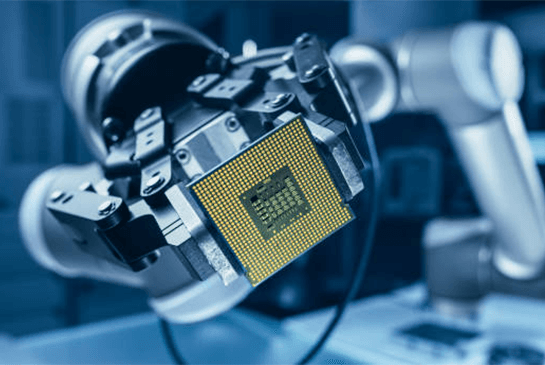

Electronics Manufacturing

Semiconductor production, SMT welding, ensuring an oxygen-free environment.

Coal and Power

Mine explosion prevention, coal dust silo inerting, enhancing safety.

How to Choose PSA Nitrogen Generation Plant?

Helping you choose products

- Clarify Purity Requirements: Each 0.1% increase in purity significantly increases Plant costs; it is recommended to choose based on the actual process lower limit.

- Calculate Flow Demand: Summarize all gas usage points and convert the total consumption to standard cubic meters per hour (Nm³/h, 1 bar, 20℃).

- Environmental Adaptation: Enhanced heat dissipation is required for high-temperature environments; choose models with corresponding certifications for explosion-proof areas.

- Reserve 10% Margin: To cope with peak gas usage and system losses, ensuring stable supply.

Frequent Asked Question

PSA is suitable for small to medium flow (≤5000 Nm³/h) and 95%-99.9995% purity scenarios, with low energy consumption and fast start-up; cryogenic method is suitable for ultra-high purity (≥99.9999%) and large-scale liquid nitrogen production, with higher investment and maintenance costs.

Molecular sieves are replaced every 5-8 years, filter cartridges are replaced every 6-12 months, and the PLC system is maintenance-free. Lifetime technical support is provided.

Supports customization for 0.5-10 MPa pressure, with purity up to 99.9995%, requiring the configuration of boosters and multi-stage purification modules.

Standard models take 4-6 weeks, customized solutions take 8-12 weeks, and expedited orders can be shortened to 3 weeks.

Email

Email sales:+86 15366749631

sales:+86 15366749631