- Home >

- Gas Compressor >

- PSA Oxygen Generator

PSA Oxygen Generator

- Oxygen Production: 1~1000 m³/h

- Oxygen Purity: 93%±3% (can be customized to 99.5%)

- Dew Point: -40℃~-20℃

- Oxygen Pressure: 0.01~0.6 MPa (can be equipped with a booster to increase pressure)

- Types: Containerized, Skid-mounted

Product Types

PSA Oxygen Generator

Purity Range: 90%-99.5% adjustable, meets both medical (EN ISO 7396-1) and industrial standards.

Modular Design: Supports later expansion, maximum production capacity up to 1000 m³/h.

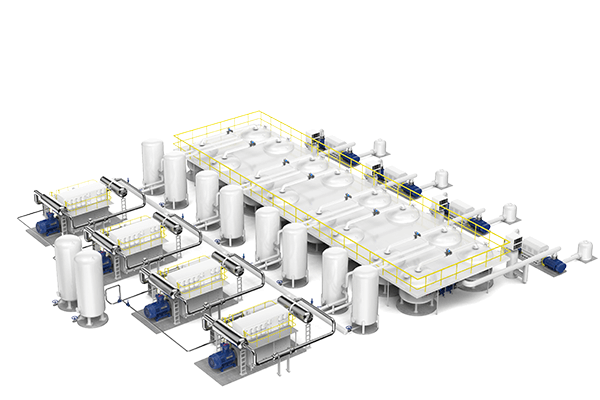

Skid-mounted Oxygen Generation System

Plug-and-Play: Pre-installed compressor, dryer, and oxygen generation host, produces oxygen immediately after on-site power connection.

Space-saving: Suitable for workshops and mining areas with limited space, reducing installation costs by 50%.

Containerized Oxygen Generation Solution

Mobile Deployment: Standard 20/40 ft container encapsulation, equipped with lifting interfaces, can be quickly relocated within 72 hours.

All-weather Adaptation: Built-in temperature control system and dust-proof structure, stable operation in desert and coastal areas.

Product Description

Since its establishment in 1987, MINNUO Group has been dedicated to the research and manufacturing of VPSA oxygen generation technology, becoming a global leader in pressure swing adsorption (PSA) oxygen systems. Our VPSA oxygen generators efficiently separate oxygen through low-pressure adsorption and vacuum desorption technology. They are widely used in industries such as steel metallurgy, healthcare, wastewater treatment, aquaculture, chemical environmental protection, and electronics manufacturing. With integrated design, ultra-low energy consumption, and intelligent control as core advantages, we provide customers with cost-effective on-site oxygen generation solutions.

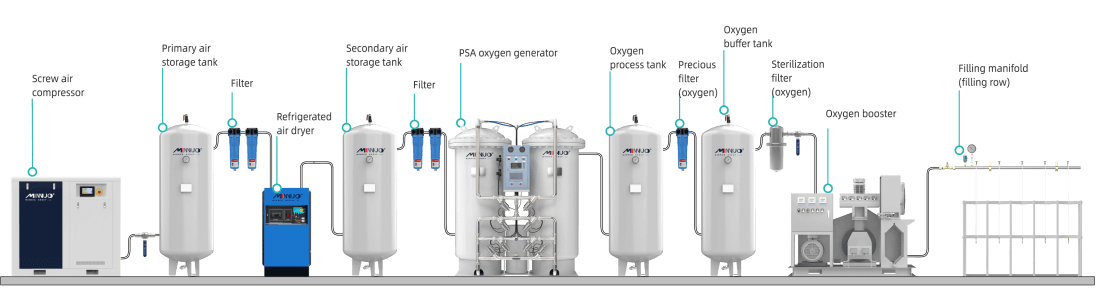

PSA Oxygen Generation Working Principle

The PSA oxygen generator achieves oxygen-nitrogen separation through the preferential adsorption characteristics of zeolite molecular sieves for nitrogen:

- Compression and Purification: Air is dried, filtered, and pressurized to 0.5~0.7 MPa.

- Adsorption and Oxygen Production: Compressed air enters the adsorption tower, where the molecular sieve rapidly adsorbs nitrogen, and oxygen is enriched to a product purity of 93%±3%.

- Desorption and Regeneration: After adsorption saturation, the pressure is reduced to release nitrogen, and reverse purging regenerates the molecular sieve.

- Dual Tower Alternation: Two towers are controlled by PLC to switch pneumatic valves. While one tower produces oxygen, the other regenerates, ensuring continuous oxygen supply.

Product Description

Molecular Sieve Adsorption Tower

Uses imported zeolite molecular sieves from JALOX and UOP, achieving efficient adsorption through dynamic compaction technology, extending service life.

Intelligent Control System

Equipped with Siemens SIMATIC S7-200 SMART PLC, fully automated operation, real-time monitoring of oxygen purity and pressure.

Precision Pneumatic Valve Group

German Burkert pneumatic valves ensure precise and reliable switching of adsorption towers, reducing maintenance frequency.

Safety Protection Design

Automatic alarm when purity is below 90%, optional stainless steel pipelines to reduce pressure loss and improve energy efficiency.

Advantages of PSA Oxygen Generator

- Rapid Commissioning, High Efficiency and Energy Saving: Can produce 93% purity oxygen within 15-30 minutes after startup. PLC automatically adjusts adsorption cycles, reducing energy consumption by up to 20%.

- Fully Automated, Unattended Operation: Integrated intelligent alarm system and remote monitoring function, stable operation 24/7, reducing manual intervention.

- Long-lasting Molecular Sieve: Patented filling technology avoids particle wear, extending molecular sieve life to 8-10 years, reducing maintenance costs by 30%.

- Flexible Adaptation to Multiple Scenarios: Oxygen pressure, flow rate, and purity can be adjusted online, supports medical-grade purification module expansion, complies with ISO 7396-1 and CE medical certification.

- Sturdy Structure, Safe and Reliable: Containerized/skid-mounted design with IP55 protection certification, suitable for harsh environments from -20℃ to 50℃, failure rate <0.5%.

How to Choose a PSA Oxygen Generator?

Calculate Oxygen Demand

- Medical Oxygen Supply: Number of beds × (2-3 L/min) × 60 minutes × 1.2 (redundancy factor).

- Oxygen Cylinder Filling: Single cylinder capacity × daily filling volume ÷ 24 hours ÷ 0.8 (efficiency factor).

Confirm Environmental Parameters

- Altitude >1000 meters requires increasing compressor power by 15%-20%.

- Voltage Matching: 380V/50Hz (Asia, Africa), 220V/60Hz (parts of America).

Choose Configuration Extensions

- Medical use requires adding sterilization modules and online purity monitoring.

- High-pressure demand (>0.6 MPa) requires multi-stage booster units.

Frequent Asked Question

PSA (Pressure Swing Adsorption) technology utilizes the high selectivity of zeolite molecular sieves for nitrogen adsorption. During the pressurization stage, nitrogen in the compressed air is adsorbed by the molecular sieve, and oxygen is enriched and output. During the depressurization stage, the molecular sieve releases nitrogen to complete regeneration. The system typically has two adsorption towers working alternately (one tower adsorbs and produces oxygen, while the other desorbs and regenerates), controlled by PLC to switch pneumatic valves, ensuring continuous oxygen supply.

The oxygen purity produced by PSA oxygen generation process is usually 93±3%. The remaining components are mainly argon. In industrial oxygen production, the argon content is 95%. The World Health Organization’s medical standard for PSA oxygen generators is an oxygen purity of 93%±3%. If 99% or higher purity oxygen is required, additional purification devices are needed.

- Temperature: The optimal operating temperature range is 4℃~27℃. High temperatures reduce adsorption efficiency, and low temperatures may affect the dew point of compressed air.

- Humidity: The inlet air dew point must be ≤4℃, otherwise a dryer needs to be installed. Refrigerated dryers can meet most scenarios, but desiccant types offer better performance with higher energy consumption.

- Altitude: At altitudes >1000 meters, compressor power needs to be increased by 15%~20% to compensate for the decrease in air density.

- Medical Standards: Must comply with ISO 7396-1 and CE medical certification, purity ≥93%±3% (argon content allowed). Some countries still follow old regulations requiring 99% purity, but the international trend is shifting towards accepting the 93% standard.

- Industrial Standards: Purity of 90%~93% is sufficient for metallurgy, chemical industry, etc., and costs are lower.

- Air Compressor Shutdown: Check if the temperature is too high, ambient temperature should be ≤40℃, voltage fluctuation should be controlled within ±10%.

- Low Oxygen Purity: Check if the solenoid/pneumatic valve is damaged, if the adsorption towers are working alternately, or if the oxygen analyzer is faulty.

- Molecular Sieve Failure: Immediately stop and replace, check if the pre-oil filter is faulty.

Email

Email sales:+86 15366749631

sales:+86 15366749631