Oil-Free Oxygen Compressor

- Completely oil-free

- Silent operating ,noise less than 75dB, can work silently in the medical station area

- Low speed, long service life

- Cooling method: air cooling or water cooling

- Eu CE certification

Features of Postion Oil-free Compressor

This oil-free oxygen compressor is designed for applications where clean and reliable oxygen compression is required. Since no lubricating oil is involved in the compression process, the compressed oxygen remains clean and free from oil-related contamination, helping users maintain stable product quality and system safety.

Compared with traditional oil-lubricated compressors, this type of compressor offers simpler operation and easier maintenance. Users do not need to deal with oil replacement, oil separation, or downstream oil treatment systems, which reduces daily maintenance work and lowers overall operating costs. For many oxygen applications, this also means a simpler system layout and fewer auxiliary components.

Thanks to its clean compression principle and stable performance, this series is commonly used in air separation systems, oxygen circulation processes, centralized medical oxygen supply, and industrial oxygen cutting and combustion, where oxygen purity and system reliability are critical.

The Advantages of an Oil-Free Oxygen Compressor

- The entire compression system is oil-free, avoiding the possibility of oil coming into contact with high-pressure, high-purity oxygen, ensuring equipment safety.

- The whole system does not require lubricating oil or an oil distribution system, resulting in a simpler machine structure that is easy to control and operate.

- The system is completely oil-free, so the oxygen being compressed is free of contamination, maintaining consistent purity at both the intake and exhaust ports of the compressor.

- Equipped with multi-stage compression, each stage includes high-pressure protection, high exhaust temperature protection, a safety valve, and a temperature display device. If the temperature becomes too high or there is an overpressure condition, the system will issue an alarm and stop operation to ensure safe operation. The bottom of the compressor is fitted with forklift slots for easy transportation.

- Our standard high-pressure oxygen compressors are CE-certified by the European Union, meeting the requirements of the EU market.

The Feature of an Oil-Free Oxygen Compressor

- No oil, stainless steel cylinder.

- Suitable for pressurization of VPSA PSA oxygen source.

- No pollution, keep the purity of gas unchanged.

- Safe and reliable quality, good stability, comparable to and replace similar foreign brands.

- Low procurement cost, low maintenance cost, simple operation.

- The service life of the piston ring under low pressure conditions is 4000 hours, and the service life of the piston ring under high pressure conditions is 1500-200O hours.

- Brand motor, you can specify the brand, such as Siemens or ABB brand.

- Supply to the Japanese market to meet the strict quality requirements of Japan.

- According to the specific working conditions of customers, the compressor is designed for single-stage compression, two-stage compression, three-stage compression and four-stage compression.

- Low speed, long life, average speed 260-400RPM.

- Low noise, the average noise is less than 75dB, can work quietly in the medical field.

- Continuous continuous heavy operation, can run stably for 24 hours without stopping (depending on the specific model).

Medium and low pressure oxygen compressor with full oil-free lubrication series

| Model | Volume flow | Inlet pressure | Exhaust pressure | Power | Length × Width × Height | Weight | Interface size |

|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | Mpa(G) | KW | mm | kg | RC | |

| MN-5/4-10 | 5 | 0.4~20Mpa | 1.0~20Mpa | 1.5 | 860×830×1000 | 90 | 1/2 |

| MN-10/4-10 | 10 | 0.4~20Mpa | 1.0~20Mpa | 2.2 | 860×830×1000 | 100 | 1 |

| MN-15/4-10 | 15 | 0.4~20Mpa | 1.0~20Mpa | 2.2 | 860×830×1000 | 110 | 1 |

| MN-20/4-10 | 20 | 0.4~20Mpa | 1.0~20Mpa | 3.0 | 860×830×1000 | 120 | 1 |

| MN-25/4-10 | 25 | 0.4~20Mpa | 1.0~20Mpa | 3.0 | 860×830×1000 | 120 | 1 |

| MN-30/4-10 | 30 | 0.4~20Mpa | 1.0~20Mpa | 3.0 | 860×830×1000 | 120 | 1 |

| MN-40/4-10 | 40 | 0.4~20Mpa | 1.0~20Mpa | 4.0 | 1100×830×850 | 245 | 1 |

| MN-50/4-10 | 50 | 0.4~20Mpa | 1.0~20Mpa | 4.0 | 1100×830×850 | 245 | 1 |

| MN-60/4-10 | 60 | 0.4~20Mpa | 1.0~20Mpa | 5.5 | 1200×650×800 | 255 | 11/2 |

| MN-70/4-10 | 70 | 0.4~20Mpa | 1.0~20Mpa | 5.5 | 1200×650×800 | 302 | 11/2 |

| MN-90/4-10 | 90 | 0.4~20Mpa | 1.0~20Mpa | 7.5 | 1400×1100×1100 | 302 | 11/2,1 |

| MN-120/4-10 | 120 | 0.4~20Mpa | 1.0~20Mpa | 11 | 1400×1100×1100 | 352 | 11/2,1 |

| MN-12/0-6 | 12 | 0.5~20Mpa | 0.6~20Mpa | 2.2 | 1100×830×750 | 200 | 1,1 |

| MN-30/0-6 | 30 | 0.5~20Mpa | 0.6~20Mpa | 5.5 | 1200×950×750 | 270 | 11/2,1 |

| MN-60/0-6 | 60 | 0.5~20Mpa | 0.6~20Mpa | 11 | 1650×850×950 | 380 | 11/2,1 |

| MN-90/0-6 | 90 | 0.5~20Mpa | 0.6~20Mpa | 15 | 1650×850×950 | 420 | 2,11/2 |

| MN-120/0-6 | 120 | 0.5~20Mpa | 0.6~20Mpa | 18.5 | 1870×1000×1000 | 540 | 2,11/2 |

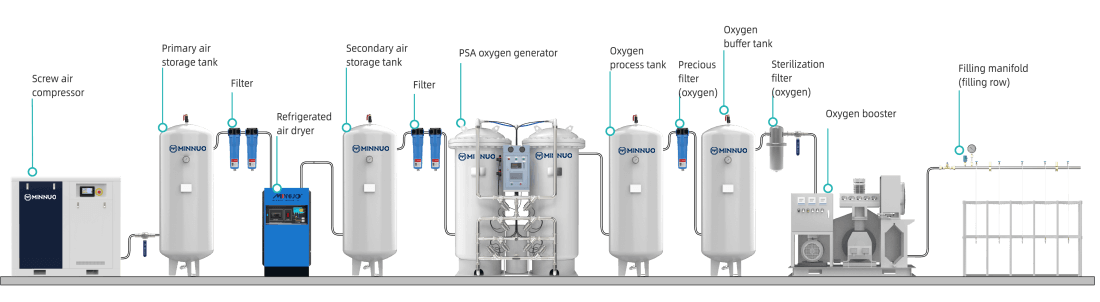

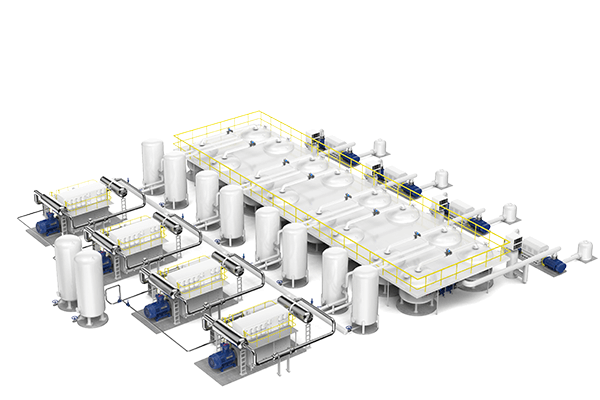

Complete Oxygen Generation Solutions

At MINNUO, we provide more than just oxygen compressors—we deliver fully customized oxygen generation solutions tailored to your needs. Our PSA oxygen systems ensure a seamless and efficient gas supply for your operations. Whether you require a standalone compressor or a complete oxygen production system, we have the right solution for you.

1. Working Principle

The PSA system utilizes zeolite molecular sieves to separate oxygen from compressed air. Under pressure, nitrogen is adsorbed while oxygen is collected as the product gas. The entire process is fully automated, with two adsorption towers operating alternately in production and regeneration cycles.

2. Key Features

- Oxygen Purity:93% ± 3% (upgradeable to 99.5% upon request)

- Capacity:1–1000 Nm³/h

- Dew Point:-40°C to -20°C

- Pressure:01–0.6 MPa (higher pressure available with a booster)

- Fully Automated Operation:PLC-controlled for unattended operation

- Fast Startup:Produces qualified oxygen within 15–30 minutes

- Energy-Efficient Design:Low power consumption with stable performance

3. Applications

Ideal for medical oxygen supply, metal processing, chemical production, aquaculture, and glass manufacturing.

Choosing Minnuo’s Oil-Free Oxygen Compressor means selecting exceptional quality, enhanced productivity, and reliable after-sales support. Let’s work together to take your business to the next level!

WHY CHOOSE US ?

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

Frequent Asked Question

As a professional manufacturer of oil-free oxygen compressors, the equipment we offer is significantly different from traditional oil-lubricated compressors. Traditional oil-lubricated compressors rely on lubricating oil to reduce internal friction, which can lead to oil contamination in the exhaust gas, compromising the purity of the oxygen. Additionally, they increase maintenance complexity and costs. In contrast, our oil-free compressors feature a completely oil-free design, ensuring no oil or oil vapors in the exhaust, preventing any oil contamination, and guaranteeing oxygen purity. This makes them particularly suitable for medical and high-precision industrial applications. Moreover, without an oil system, maintenance is simplified, significantly reducing operational costs.

Our oil-free oxygen compressors are designed to eliminate the use of oil, reducing the maintenance burden typical of traditional oil-lubricated systems. However, regular maintenance is still essential, including:

- Air filters: Regularly check and replace the filter elements to ensure clean air intake.

- Cooling system: Whether air-cooled or water-cooled, regularly check the cooling efficiency to prevent overheating.

- Moving parts: Periodically inspect the wear on piston rings and seals to ensure smooth operation.

- Pressure and temperature checks: Ensure the equipment operates within the recommended pressure and temperature ranges to avoid damage from excessive pressure or heat. These simple maintenance steps can effectively extend the equipment’s lifespan and maintain efficient, stable operation.

Our oil-free oxygen compressors are highly adaptable and perform excellently in the following environments:

- Moist environments: The oil-free design prevents performance degradation caused by oil emulsification in traditional compressors.

- Dusty environments: The sealed structure of the equipment reduces the impact of external dust, ensuring stable operation.

- High-purity gas requirements: Ideal for industries with strict oxygen purity standards, such as medical oxygen supply systems and electronics manufacturing, preventing oil contamination and ensuring gas quality. We offer tailored solutions based on specific customer needs to ensure the equipment performs optimally in different work environments.

- Oxygen demand (flow rate): Please provide the required oxygen flow rate (unit: Nm³/h or L/min). This helps us determine the compressor specifications needed to meet your requirements.

- Operating pressure: Based on your application, specify the required working pressure (unit: bar), e.g., 5-10 bar for medical applications, 150 bar or higher for industrial use. This information allows us to recommend the most suitable compressor model.

- Working environment: Provide details on environmental temperature (unit: °C), humidity (unit: % RH), and air quality. For harsh environments (e.g., high humidity or dust), we can customize additional features like dust proof or corrosion-resistant options.

- Power requirements: Please provide local voltage (unit: V), current (unit: A), and frequency (unit: Hz). We will match the appropriate motor and drive system based on your power standards.

- Special requirements: If you have specific needs such as low noise (unit: dB), explosion-proof features, or industry certifications (e.g., ISO, CE), please inform us for customized design.

Under proper working conditions and regular maintenance, our oil-free oxygen compressors have a long service life:

- At low-pressure conditions, piston rings can last up to 4000 hours.

- At high-pressure conditions, piston rings typically last 1500-2000 hours, depending on load and operating environment. To extend the lifespan, we recommend regularly checking the cooling system, lubricating system (if using water or air cooling), and seals, and replacing worn parts in a timely manner. Our products are designed for long-term durability, helping minimize downtime and maintenance costs.

Safety is a top priority in the design of our oil-free oxygen compressors. The equipment is equipped with multiple safety features to ensure safe operation in high-pressure, high-temperature environments:

- High-pressure protection: Each stage is equipped with high-pressure protection devices to prevent system over pressure.

- Temperature protection: Temperature sensors monitor the operational state; if the temperature exceeds safe limits, protective measures will be triggered to avoid damage.

- Safety valve: The safety valve automatically vents the system when pressure becomes too high, preventing over pressure damage.

- Automatic alarm system: If an anomaly occurs, the system will automatically issue an alarm and shut down, ensuring the safety of both the equipment and operators.

You May Like

Send Your Inquiry Now!

Get Oxygen Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631