Nitrogen Booster Compressor

To safeguard the media from contamination and avoid loss of gas flow, and to reduce equipment maintenance costs,

we offer oil-free nitrogen compressor solutions up to 2500 bar.

- Type: air-cooled or water-cooled

- Power range: 5.5KW-1000KW

- Rotational speed range: 500-1440 r /min

- Flow range: 10-10000Nm3/h

- Suction pressure: ≤20Mpa

- Exhaust pressure:≤50Mpa

- Number of compression stages: 1-5

Type of Nitrogen Compressor

Reciprocating Piston Compressor

It uses a piston driven by a crankshaft to compress gas, providing high pressure and efficiency in various applications.

It’s typically robust and reliable, suitable for continuous or heavy-duty use.

Diaphragm Compressor

It utilizes a flexible diaphragm to compress the gas, offering a sealed environment that prevents contamination.

It’s ideal for handling corrosive or hazardous gases, ensuring purity and safety in applications like medical and laboratory settings.

*Our products go beyond the data presented here and can be customized according to your needs.

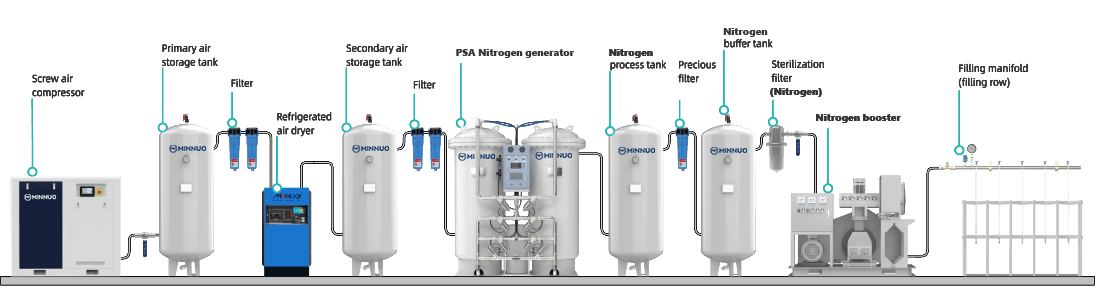

Nitrogen Recovery & Boosting System

1.System Process

Raw Gas Collection

Membrane Purification

Buffer Storage

Intelligent Booster

Closed-loop Control

Terminal Application

2.Core Equipment

- Intelligent Recovery Module: O₂ monitoring (0-1000ppm), purity upgrade

- Multi-stage Booster: Dual-unit for 0.5-50MPa (7,250psi) pressure range

- Energy-saving Dryer: -70°C dew point with 30% energy recovery

- IoT Control Platform: Real-time monitoring & self-diagnosis

3.Technical Advantages

- Pressure Flexibility: Single system handles 0.1-50MPa (7,250psi) scenarios

- Energy Cascade: 20% compression heat converted to self-power

- Smart Interlock: 0.8s backup gas switching ensures continuity

- Modular Design: 20% spare capacity for future expansion

Parameters

| Model | Volume Flow Rate | Intake air | Exhaust | Motor | External Dimensions | Interface |

|---|---|---|---|---|---|---|

| m3/h | PressureMpa | PressureMpa | PowerKw | mm×mm×mm | Size | |

| ZWZT-(3~5)/5-30 | 3~5 | 5 | 30 | 2.2 | 860×830×950 | 1/2 |

| ZWZT-(6~9)/5-30 | 6~9 | 5 | 30 | 3 | 860×830×950 | 1/2 |

| VWZT-(10~20)/5-30 | 10~20 | 5 | 30 | 4 | 1150×850×950 | 1 |

| VWZT-(10~20)/5-30 | 10~20 | 5 | 30 | 5.5 | 1150×930×950 | 1 |

| VWZT-(31~40)/5-30 | 31~40 | 5 | 30 | 7.5 | 1150×930×950 | 1 |

| VWZT-(41~55)/5-30 | 41~55 | 5 | 30 | 11 | 1200×1000×950 | 1、1 |

| WWZT-(56~75)/5-30 | 56~75 | 5 | 30 | 11 | 1400×1020×950 | 11/2、1 |

| WWZ-(76~110)/5-30 | 76~110 | 5 | 30 | 15 | 1650×1150×1200 | DN40 、DN25 |

| WWZ-(111~130)/5-30 | 111~130 | 5 | 30 | 18.5 | 1650×1150×1200 | DN40 、DN25 |

| WWZ-(131~150)/5-30 | 131~150 | 5 | 30 | 22 | 1650×1150×1200 | DN40 、DN25 |

| SWZ-(161~200)/5-30 | 161~200 | 5 | 30 | 30 | 1850×1200×1200 | DN50 、DN40 |

| WWZ-(201~220)/5-30-II | 201~220 | 5 | 30 | 2X15 | 2300×1800×1400 | DN65 、DN40 |

| WWZ-(221~260)/5-30-II | 221~260 | 5 | 30 | 2X18.5 | 2300×1800×1400 | DN65 、DN40 |

| WWZ-(261~300)/5-30-II | 261~300 | 5 | 30 | 2X22 | 2300×1800×1400 | DN65 、DN40 |

| SWZ-(301~400)/5-30-II | 301~400 | 5 | 30 | 2X30 | 2500×2100×1400 | DN65 、DN40 |

Typical Applications

Battery Dry Rooms

O₂ <10ppm, humidity control ±3%RH

Central Nitrogen Supply

Multi-pressure distribution via pipelines

LNG Tank Protection

65% BOG reduction, 800t/year N₂ saved

Semiconductor Exhaust Recycling

90% etching gas reuse (99.99% purity)

Application

Nitrogen is compressed to high pressures (30-50MPa) for injection into low-permeability reservoirs, displacing residual crude oil and increasing recovery by 10-20%. This process improves oil displacement efficiency by making crude oil more fluid.

High-pressure nitrogen is injected into the annular space between tubing and casing, reducing liquid density and creating a pressure difference for smooth crude oil flow to the surface. Precise control of nitrogen injection ensures stable production in complex multiphase flow systems.

Nitrogen is pressurized to balance well pressure during workover, preventing blowouts and not contaminating the oil layer. The compressor allows for precise pressure control based on reservoir and wellbore pressures.

Compressed nitrogen mixed with well-washing fluids enhances the fluid’s carrying capacity, removing impurities and blockages more effectively than conventional methods while safeguarding long-term production capacity.

Nitrogen is supplied at the right pressures to reduce oxygen concentration below 12%, preventing fire and explosion risks in areas with explosive gas mixtures.

In case of fire, nitrogen compressors supply nitrogen to dilute oxygen in the combustion area, extinguishing the fire quickly with minimal environmental impact and aiding in rapid production restoration.

Nitrogen is pressurized for testing pipelines, pressure vessels, and other infrastructure, detecting leaks or structural defects based on pressure drops due to nitrogen leakage.

Advantages

- Explosion-Proof Design Designed to meet strict explosion-proof standards (ATEX, IECEx, GB 3836), MINNUO nitrogen compressors prevent sparks or high temperatures from causing explosions, with optimized sealing to prevent gas leakage.

- Stability Our nitrogen compressors provide stable pressurization over long periods, essential for consistent oil displacement. Advanced pressure control systems minimize fluctuations, improving oil recovery rates.

- Adaptability Built to withstand high temperatures, humidity, and harsh conditions, MINNUO nitrogen compressors feature corrosion-resistant materials, optimized lubrication, and cooling systems, ensuring reliable operation in challenging environments.

- High Efficiency Designed for large-scale oil field production, our nitrogen compressors offer high compression efficiency, reducing energy consumption, minimizing gas leakage, and lowering operation costs, benefiting oil field operators.

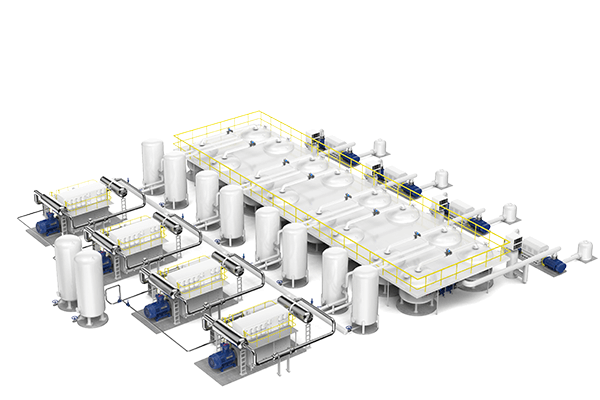

Case Project

MINNUO offers independent solutions according to flow/purity/pressure, usage environment, main application, and special customer requirements at a competitive prices. Our compressor booster is made of high-quality materials and has been tested thoroughly to ensure the best quality.

You May Like

Send Your Inquiry Now!

Get Nitrogen Booster Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631