Diaphragm Compressor

- Structure type: Z Type,V Type,D Type, L Type

- Flow-Rate Range:3~3000Nm3/h

- Max.Discharge Pressure:14500psi(100MPa)

- Sound level: 58±2~65±2 dB(A)

- Max.Piston Force: 250kN

- Max. drive power: 600hp(450kw)

- Gas Type: H2、N2、O2、He、Ar、Xe、Ke、HCl、H2S、C2H4、HF、SiF4、SiH4、NF3,etc.

What is Diaphragm Compressor ?

Diaphragm compressors are classified from reciprocating compressors.

A diaphragm compressor is a specially constructed volumetric compressor that uses a rotating diaphragm to compress air or gas. The rotating diaphragm helps to deliver air or gas within the compression chamber and applies the required pressure to deliver air in the desired area.

The cylinders are highly sealed, no lubrication is required, and the compressed gas medium avoids contact with any lubricant, so diaphragm compressors can compress gases of very high purity, typically up to 99.999% purity. Diaphragm compressor is especially suitable for the compression, transport, bottling of precious and rare gases, in addition to extremely corrosive, toxic, flammable and explosive, radioactive gases, also suitable for the use of diaphragm compressor.

Why Choose Minnuo Diaphragm Compressor?

Established in 1987, Min Group has been developing and manufacturing industrial diaphragm gas compressors. They are the preferred equipment for high purity, hermetic gas lift compression for hydrogen fuel stations, chemicals, oil, and gas, etc. We have developed H, D, L, V, and Z models and more than 30 product series for intelligent diaphragm gas compression systems.

We can design and manufacture full instrumentation oil-free reciprocating diaphragm gas compression systems according to customer requirements.

Sizes range from 3 hp (2 kW) – 250 hp (186 kW). Output pressures range from 50 psi- 45,000 psi (3,100 bar).

1. High Compression Ratio

Large compression ratio, large compression chamber area, ***type compression ratio up to 10:1.

2. Quiet and low maintenance

Less than 85dBA @ 1m without sound enclosure

Easy to maintain and operate, with no oil distribution plate structure, and advanced oil pressure valve

3.High Discharge Pressure

Minnuo diaphragm gas compressor discharge pressures up to 43,511 psi (3,000 bar)

4.Triple Diaphragms Ensure Complete Isolation of Gas and Hydraulic Oil

Three layers of diaphragms completely isolate the gas and hydraulic oil, high purity of the compressed medium, the medium is sealed at rest, completely isolated, completely isolated from sealing particles into the airflow

5. Provide Test Report

Material testing of parts: mechanical property inspection and chemical composition analysis

Kerosene leak test for body

Water pressure test: water pressure test pressure is 1.5 times of the working pressure, and last for more than 30 minutes

Operation test: no-load mechanical operation test and full-load mechanical operation test

6. Quality Control

Conforms to the requirements of the EU Machinery Directive 2006/42/EC. Application standards. din en 1012 part 1, din en 12100 part 1, din en 60204 part 1, etc.

Explosion-proof according to EU Directive 2014/34/EU, if necessary

7. Extended service life

Wear parts life guarantee

Diaphragm: 4000 h Valve: 4000 h

Life of main parts

Piston rod: 100000h Cylinder head

cylinder block: 120000h Crankshaft: 120000

Connecting rod: 120,000h

Crankcase: 120,000h

Piston ring: 30,000h

Crosshead: 32000h Connecting rod bolt: 16000h

Unit sets test life:20 years

8. Safety Interlock

- High-pressure protection: when the gas pressure reaches the specified pressure, the diaphragm compressor automatically stops, to play a protective role.

- Low pressure starts: when the gas pressure is lower than the set pressure, the diaphragm compressor starts to pressurize.

- Oil pressure protection: equipment lubrication system oil pressure can not be lower than a certain value, when lower than the set value, the equipment alarm, and shutdown.

- low water pressure protection: when the water pressure is lower than the set value, the equipment alarm, and shutdown, etc.

PLC control of the equipment

9. Primary and secondary diaphragm rupture alarm

When the diaphragm on the oil or gas side is ruptured, the oil or gas passes through the guide groove of the middle diaphragm and transmits the pressure to the pressure switch, which generates an alarm because the pressure controlled by the pressure switch is much lower than the working oil or air pressure. Replace the ruptured diaphragm in time to avoid accidents.

Technology Features:

- The diaphragm compressor body adopts an integral body to reduce the sealing surface and improve processing and assembly accuracy.

- The charge pump adopts the built-in structure of the crankcase to provide stable hydraulic oil input to the cylinder while avoiding oil leakage.

- The piston rod and crosshead adopt a floating connection with an automatic centering function.

- The piston seal adopts German imported hydraulic seal to improve the stability of oil circuit system operation.

- High-pressure cylinder adopts the oil distribution structure without oil distribution plate sieve, which distributes hydraulic oil more evenly in the cylinder (non-ring groove oil distribution structure), and reduces the difficulty of assembly process and sealing surface.

- The diaphragm is designed without any openings, which improves the interchangeability and convenience of diaphragm installation and reduces the stress concentration caused by diaphragm openings.

- The diaphragm leakage alarm can alarm when the diaphragm ruptures or compressed media leaks, improving the reliability of the machine. Leak alarm is equipped with a venting valve for easy operation and maintenance.

- The regulator/following valve is equipped with an outlet flow sight glass, which makes it easy to observe the operation status of the compressor cylinder oil circuit system.

Select Your Model

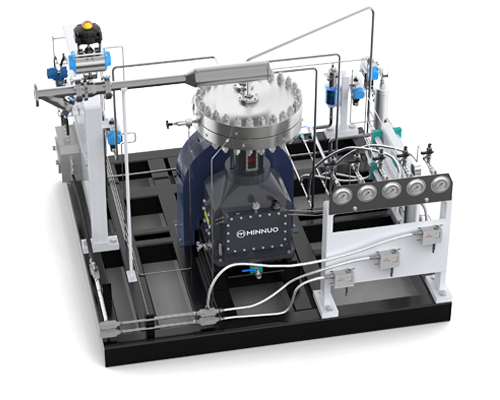

G1 Small diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 80kg

- Maintenance maximum space: the circle shall be not less than 1 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GZ1-0.01/15-150 | 0.01 | 1.5 | 15 | 100 | 225-450 | 1.1 | 1200*780*900 | 400 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100*600*950 | 400 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100*600*950 | 400 |

| GP1-50/90-95 | 50 | 9 | 9.5 | 400 | 500 | 3 | 1200*780*900 | 400 |

| GP1-6/10 | 6 | ATM | 1 | 600 | 600 | 4 | 1200*780*900 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1350×600×950 | 450 |

| GD1-150/90-95 | 150 | 9 | 9.5 | 400 | 600 | 3 | 1350×600×950 | 550 |

| GD1-8.6/0.5-40 | 8.6 | 0.05 | 4 | 300 | 600 | 4 | 1350×600×950 | 550 |

| GL1-15/10-220 | 15 | 1 | 22 | 500 | 500 | 3.5 | 1350*600*950 | 560 |

| Gl1-20/20-200 | 20 | 2 | 20 | 500 | 600 | 5.5 | 1350*600*950 | 560 |

G2 Medium-sized diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 100kg

- Maintenance maximum space: the circle shall be not less than 1 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm3/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GZ2-10/10-150 | 10 | 1 | 15 | 400 | 420 | 4 | 1400*850*1150 | 800 |

| GZ2-15/13 | 15 | ATM | 1.3 | 400 | 400 | 4 | 1400*850*1150 | 800 |

| GZ2-15/13-200 | 15 | 1.3 | 20 | 400 | 400 | 7.5 | 1400*850*1150 | 800 |

| GP2-50/4-10 | 50 | 0.4 | 1 | 400 | 430 | 5.5 | 1400*850*1150 | 800 |

| GZ2-12/160-1000 | 12 | 16 | 100 | 500 | 400 | 5.5 | 1400*850*1150 | 800 |

| GZ2-120/8-16 | 120 | 0.8 | 1.6 | 600 | 400 | 4 | 1100*600*950 | 450 |

| GZ2-100/15-80 | 100 | 1.5 | 8 | 900 | 430 | 11 | 1400*850*1150 | 900 |

| GL2-20/200 | 20 | ATM | 20 | 700 | 400 | 7.5 | 1700*850*1150 | 1100 |

| GL2-30/4-350 | 30 | 0.4 | 35 | 1000 | 420 | 11 | 1700*850*1150 | 900 |

| GD2-60/30-400 | 60 | 3 | 40 | 1000 | 400 | 11 | 1700*850*1150 | 850 |

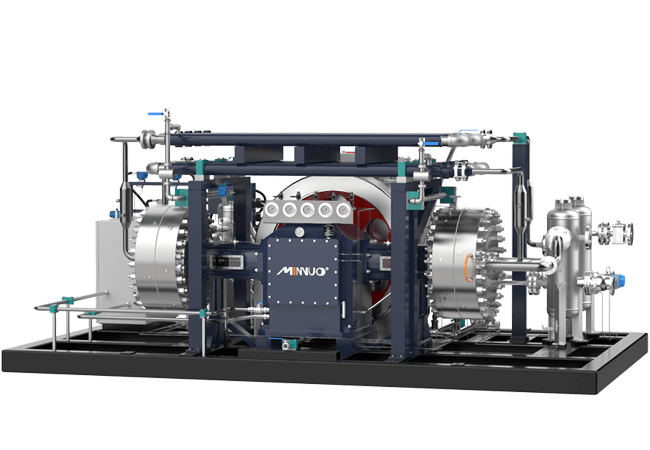

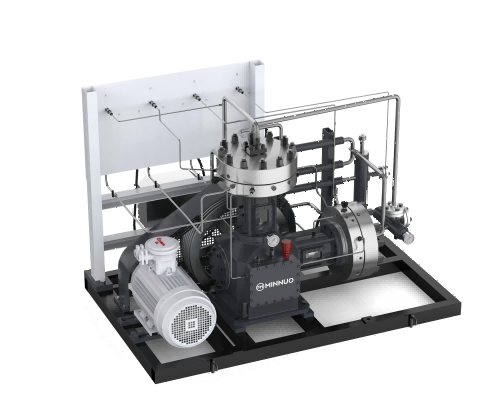

G3 Medium-sized diaphragm compressor

- Structure: Z, L,V, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 800kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GL3-60/200 | 600 | 8.3 | 8.5 | 600 | 300 | 7.5 | 2400*2400*2000 | 3400 |

| GZ3-50/10-150 | 50 | 1 | 15 | 1000 | 400 | 11 | 2400*1400*2000 | 3500 |

| GZ3-40/30-400 | 40 | 3 | 40 | 1000 | 400 | 11 | 2400*2400*2000 | 3400 |

| GP3-50/3 | 50 | ATM | 0.3 | 1000 | 450 | 11 | 2400*2400*2000 | 3400 |

| GP3-340/4-10 | 340 | 0.4 | 1 | 1500 | 450 | 18.5 | 2800*1400*2000 | 3600 |

| GL3-50/5-160 | 50 | 0.5 | 16 | 2000 | 400 | 30 | 2800*1600*2000 | 4200 |

| GL3-80/7-320 | 80 | 0.7 | 32 | 2500 | 400 | 30 | 2800×1600×2000 | 4000 |

| GL3-80/4-350 | 80 | 0.4 | 35 | 2800 | 400 | 30 | 2800*1600*2000 | 4200 |

| GD3-100/9.5-200 | 100 | 0.95 | 20 | 2800 | 420 | 30 | 2800*1600*2000 | 4200 |

| GD3-200/9-120 | 200 | 0.9 | 12 | 4000 | 420 | 45 | 2800*1600*2000 | 5500 |

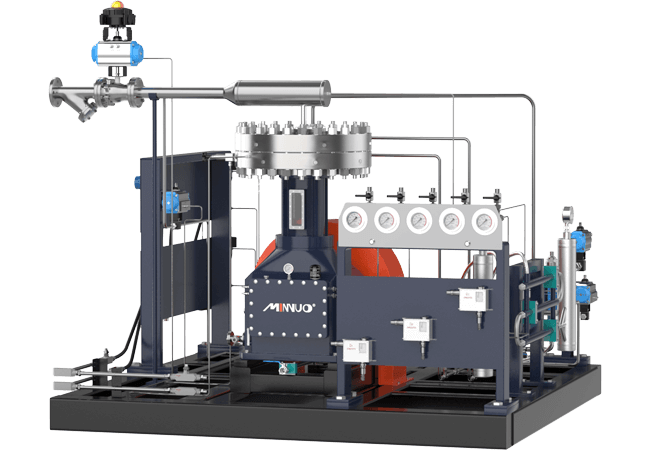

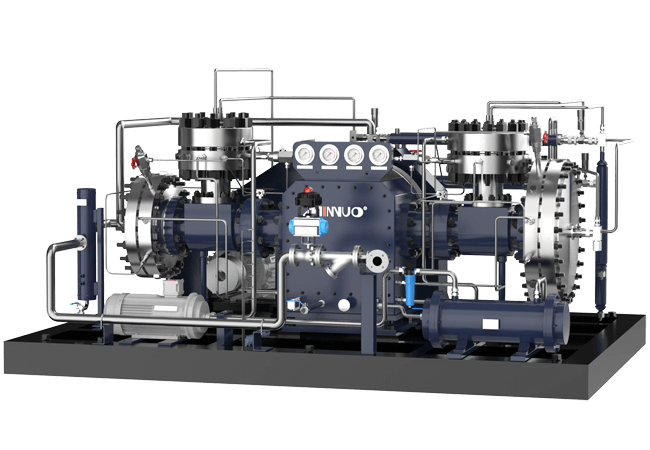

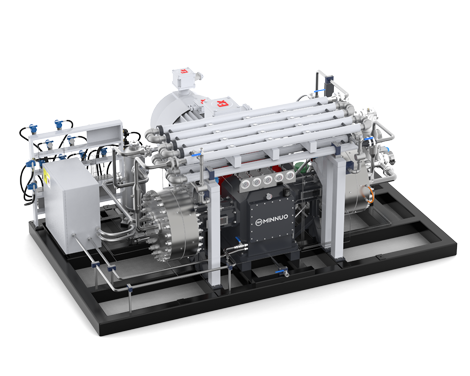

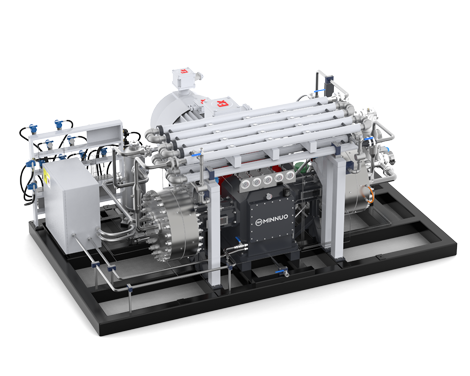

G4 Medium-sized diaphragm compressor (compact structure)

- Structure: D-type (two, three, four cylinelers)

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled

- Maintenance maximum weight per piece: 1000kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GP4-1175/48-62 | 1175 | 4.8 | 6.2 | 2500 | 420 | 30 | 3800*2600*1800 | 8000 |

| GD4-170/0.3-8 | 170 | 0.03 | 0.8 | 3000 | 420 | 37 | 4000*2850*2000 | 10800 |

| GD4-90/200 | 90 | ATM | 20 | 3200 | 430 | 45 | 4000*2850*2000 | 10800 |

| GD4-105/0.1-29 | 105 | 0.01 | 2.9 | 4000 | 420 | 45 | 3800*2600*2100 | 10000 |

| GD4-200/0.1-6 | 200 | 0.01 | 0.6 | 4000 | 420 | 45 | 4200*2600*2100 | 14000 |

| GD4-150/1.5-150 | 150 | 0.15 | 15 | 4000 | 430 | 55 | 3800*2600*1800 | 9000 |

| GD4-200/15-350 | 200 | 1.5 | 35 | 4600 | 360 | 55 | 3800*2600*1800 | 9000 |

| GD4-225/9-200 | 225 | 0.9 | 20 | 5000 | 420 | 55 | 3800*2600*1800 | 9500 |

| GD4-800/12-40 | 800 | 1.2 | 4 | 5400 | 400 | 75 | 3800*2600*1800 | 9200 |

| GD4-570/28-220 | 570 | 2.8 | 22 | 7500 | 360 | 90 | 4200*2600*2100 | 14000 |

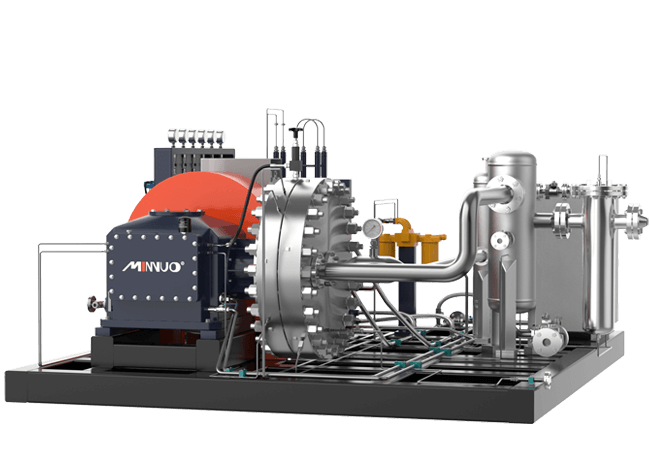

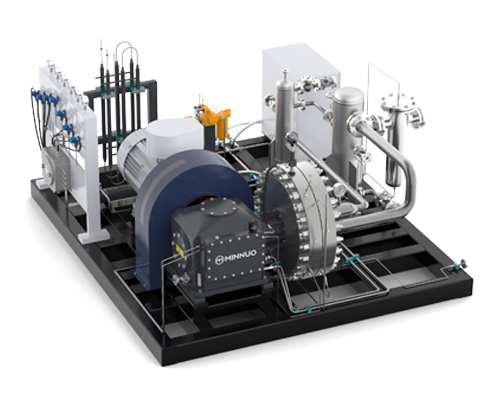

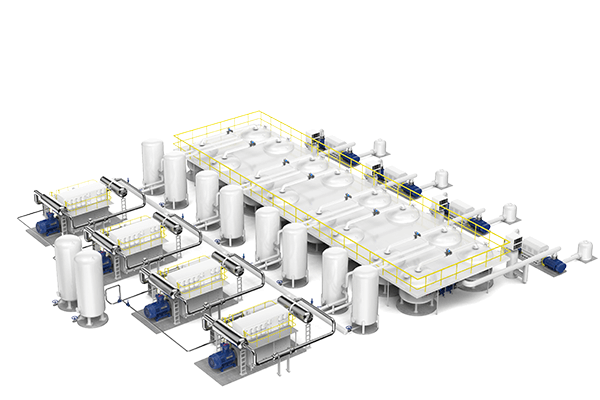

G5 Super-large diaphragm compressor

- Structure: D-type (two, three, four cylinelers)

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled

- Maintenance maximum weight per piece: 1500kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GD5-500/6-210 | 500 | 0.6 | 21 | 10000 | 420 | 110 | 4300*3200*2200 | 14000 |

| GD5-750/6-210 | 750 | 0.6 | 21 | 12000 | 420 | 160 | 4300*3200*2200 | 16000 |

| GD5-750/15-210 | 750 | 1.5 | 21 | 10000 | 420 | 110 | 4300*3200*2200 | 14000 |

| GD5-1000/15-210 | 1000 | 1.5 | 21 | 12000 | 4200 | 160 | 4300*3200*2200 | 16000 |

| GD5-1250/15-210 | 1250 | 1.5 | 21 | 15000 | 450 | 160 | 4300*3200*2200 | 15000 |

| GD5-1000/20-210 | 1000 | 2 | 21 | 12000 | 420 | 160 | 4300*3200*2200 | 16000 |

| GD5-750/20-210 | 750 | 2 | 21 | 11000 | 420 | 132 | 4300*3200*2200 | 15000 |

| GD5-1250/20-210 | 1250 | 2 | 21 | 15000 | 420 | 160 | 4300*3200*2200 | 16000 |

G1 Small diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication:splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece:80kg

- Maintenance maximum space:the circle shall be not less than 1 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GZ1-0.01/15-150 | 0.01 | 1.5 | 15 | 100 | 225-450 | 1.1 | 1200*780*900 | 400 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100*600*950 | 400 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100*600*950 | 400 |

| GP1-50/90-95 | 50 | 9 | 9.5 | 400 | 500 | 3 | 1200*780*900 | 400 |

| GP1-6/10 | 6 | ATM | 1 | 600 | 600 | 4 | 1200*780*900 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1350×600×950 | 450 |

| GD1-150/90-95 | 150 | 9 | 9.5 | 400 | 600 | 3 | 1350×600×950 | 550 |

| GD1-8.6/0.5-40 | 8.6 | 0.05 | 4 | 300 | 600 | 4 | 1350×600×950 | 550 |

| GL1-15/10-220 | 15 | 1 | 22 | 500 | 500 | 3.5 | 1350*600*950 | 560 |

| Gl1-20/20-200 | 20 | 2 | 20 | 500 | 600 | 5.5 | 1350*600*950 | 560 |

G2 Medium-sized diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication:Forced lubrication

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece:100kg

- Maintenance maximum space:No less than 1 meter around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm3/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GZ2-10/10-150 | 10 | 1 | 15 | 400 | 420 | 4 | 1400*850*1150 | 800 |

| GZ2-15/13 | 15 | ATM | 1.3 | 400 | 400 | 4 | 1400*850*1150 | 800 |

| GZ2-15/13-200 | 15 | 1.3 | 20 | 400 | 400 | 7.5 | 1400*850*1150 | 800 |

| GP2-50/4-10 | 50 | 0.4 | 1 | 400 | 430 | 5.5 | 1400*850*1150 | 800 |

| GZ2-12/160-1000 | 12 | 16 | 100 | 500 | 400 | 5.5 | 1400*850*1150 | 800 |

| GZ2-120/8-16 | 120 | 0.8 | 1.6 | 600 | 400 | 4 | 1100*600*950 | 450 |

| GZ2-100/15-80 | 100 | 1.5 | 8 | 900 | 430 | 11 | 1400*850*1150 | 900 |

| GL2-20/200 | 20 | ATM | 20 | 700 | 400 | 7.5 | 1700*850*1150 | 1100 |

| GL2-30/4-350 | 30 | 0.4 | 35 | 1000 | 420 | 11 | 1700*850*1150 | 900 |

| GD2-60/30-400 | 60 | 3 | 40 | 1000 | 400 | 11 | 1700*850*1150 | 850 |

G3 Medium-sized diaphragm compressor

- Structure: Z、L、V、P、D Type

- Lubrication:Forced lubrication

- Oil type:Oil replenishment

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 60-70 KG

- Maintenance maximum space:No less than 1 meter around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GL3-60/200 | 600 | 8.3 | 8.5 | 600 | 300 | 7.5 | 2400*2400*2000 | 3400 |

| GZ3-50/10-150 | 50 | 1 | 15 | 1000 | 400 | 11 | 2400*1400*2000 | 3500 |

| GZ3-40/30-400 | 40 | 3 | 40 | 1000 | 400 | 11 | 2400*2400*2000 | 3400 |

| GP3-50/3 | 50 | ATM | 0.3 | 1000 | 450 | 11 | 2400*2400*2000 | 3400 |

| GP3-340/4-10 | 340 | 0.4 | 1 | 1500 | 450 | 18.5 | 2800*1400*2000 | 3600 |

| GL3-50/5-160 | 50 | 0.5 | 16 | 2000 | 400 | 30 | 2800*1600*2000 | 4200 |

| GL3-80/7-320 | 80 | 0.7 | 32 | 2500 | 400 | 30 | 2800×1600×2000 | 4000 |

| GL3-80/4-350 | 80 | 0.4 | 35 | 2800 | 400 | 30 | 2800*1600*2000 | 4200 |

| GD3-100/9.5-200 | 100 | 0.95 | 20 | 2800 | 420 | 30 | 2800*1600*2000 | 4200 |

| GD3-200/9-120 | 200 | 0.9 | 12 | 4000 | 420 | 45 | 2800*1600*2000 | 5500 |

G4 Medium-sized diaphragm compressor (compact structure)

- Structure: D Type (Two cylinders, Three cylinders,Four cylinders)

- Lubrication:Forced lubrication

- Oil type:Forced Oil Replenishment

- Cooling way:Water cooling

- Maintenance maximum weight per piece:1000 KG

- Maintenance maximum space:No less than 1.5 meters around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GP4-1175/48-62 | 1175 | 4.8 | 6.2 | 2500 | 420 | 30 | 3800*2600*1800 | 8000 |

| GD4-170/0.3-8 | 170 | 0.03 | 0.8 | 3000 | 420 | 37 | 4000*2850*2000 | 10800 |

| GD4-90/200 | 90 | ATM | 20 | 3200 | 430 | 45 | 4000*2850*2000 | 10800 |

| GD4-105/0.1-29 | 105 | 0.01 | 2.9 | 4000 | 420 | 45 | 3800*2600*2100 | 10000 |

| GD4-200/0.1-6 | 200 | 0.01 | 0.6 | 4000 | 420 | 45 | 4200*2600*2100 | 14000 |

| GD4-150/1.5-150 | 150 | 0.15 | 15 | 4000 | 430 | 55 | 3800*2600*1800 | 9000 |

| GD4-200/15-350 | 200 | 1.5 | 35 | 4600 | 360 | 55 | 3800*2600*1800 | 9000 |

| GD4-225/9-200 | 225 | 0.9 | 20 | 5000 | 420 | 55 | 3800*2600*1800 | 9500 |

| GD4-800/12-40 | 800 | 1.2 | 4 | 5400 | 400 | 75 | 3800*2600*1800 | 9200 |

| GD4-570/28-220 | 570 | 2.8 | 22 | 7500 | 360 | 90 | 4200*2600*2100 | 14000 |

G5 Super-large diaphragm compressor

- Structure: D Type (Two cylinders, Three cylinders, Four Cylinders or Six Cylinders )

- Lubrication:Forced Lubrication

- Oil type:Forced oil replenishment

- Cooling way:Water cooling

- Maintenance maximum weight per piece:5000 KG

- Maintenance maximum space:No less than 2.5 meters around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GD5-500/6-210 | 500 | 0.6 | 21 | 10000 | 420 | 110 | 4300*3200*2200 | 14000 |

| GD5-750/6-210 | 750 | 0.6 | 21 | 12000 | 420 | 160 | 4300*3200*2200 | 16000 |

| GD5-750/15-210 | 750 | 1.5 | 21 | 10000 | 420 | 110 | 4300*3200*2200 | 14000 |

| GD5-1000/15-210 | 1000 | 1.5 | 21 | 12000 | 4200 | 160 | 4300*3200*2200 | 16000 |

| GD5-1250/15-210 | 1250 | 1.5 | 21 | 15000 | 450 | 160 | 4300*3200*2200 | 15000 |

| GD5-1000/20-210 | 1000 | 2 | 21 | 12000 | 420 | 160 | 4300*3200*2200 | 16000 |

| GD5-750/20-210 | 750 | 2 | 21 | 11000 | 420 | 132 | 4300*3200*2200 | 15000 |

| GD5-1250/20-210 | 1250 | 2 | 21 | 15000 | 420 | 160 | 4300*3200*2200 | 16000 |

Case Project

The Kennedy Space Center in the United States has deployed a 100MPa reciprocating nitrogen compressor for leak testing of rocket fuel systems prior to launch.

In Japan, the Tokyo Electronics Industrial Cluster has installed an 1800 cubic meter per hour reciprocating argon compressor to supply gas for semiconductor chip manufacturing.

In Germany, a chemical company in the Ruhr area has completed a 2500 cubic meter per hour diaphragm ethylene compressor project for chemical raw material conversion and storage.

In Dubai, UAE, a 30MPa diaphragm carbon dioxide compressor has been deployed at a clean energy park to support carbon capture and storage for solar power generation projects.

You May Like

Get Diaphragm Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631