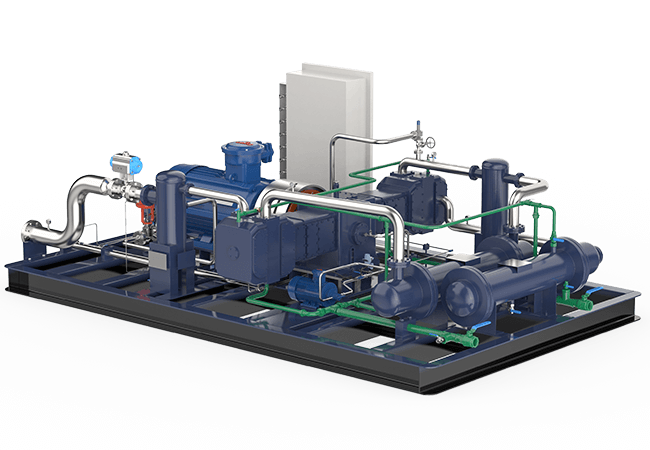

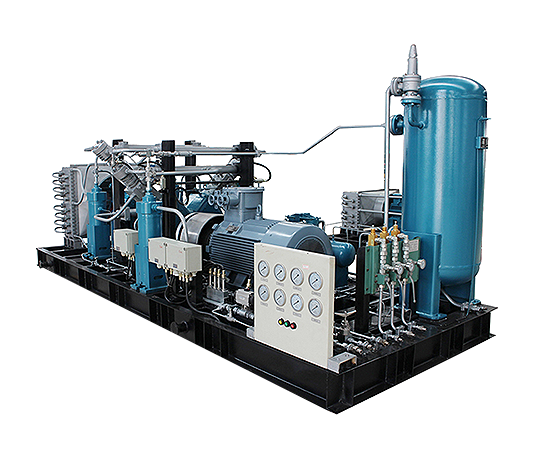

CNG Compressor

Minnuo natural gas compressors are designed for the compression of natural gas, sour gas, and biogas. We offer the most economical, efficient, and safe solution for customized CNG compressor systems.

Produced and designed for continuous operation under heavy load conditions, with excellent feedback from operation under the most demanding conditions in the site and offshore applications worldwide – the high-pressure CNG compressors are ideally suited to a wide range of bunkering stations and medium to large fleets.

- Flow-Rate Range:310~2680Nm3/h

- Sound level: ≤75(dB(A))

- Power: 75~355kW

- Exhaust pressure: 21~25MPa

- Working ambient temperature: -40~60(℃)

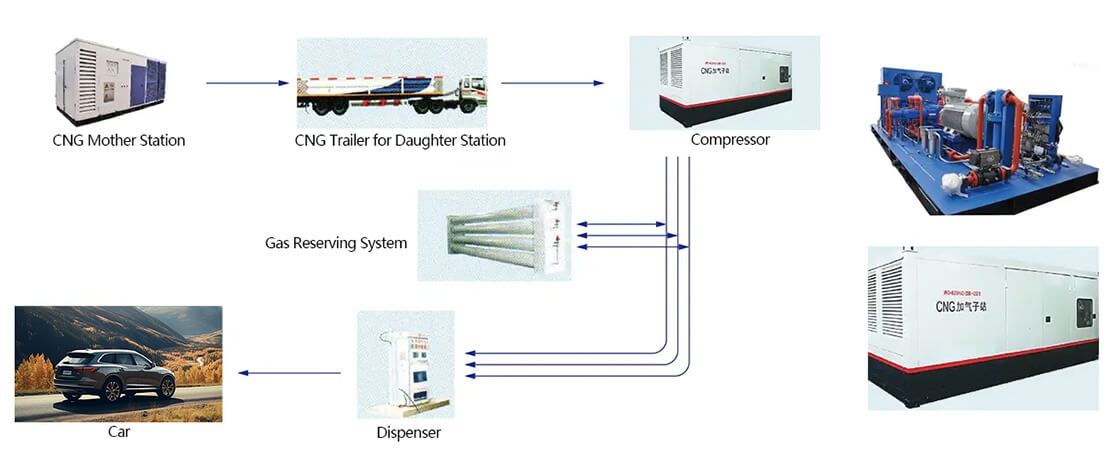

Types of CNG filling stations

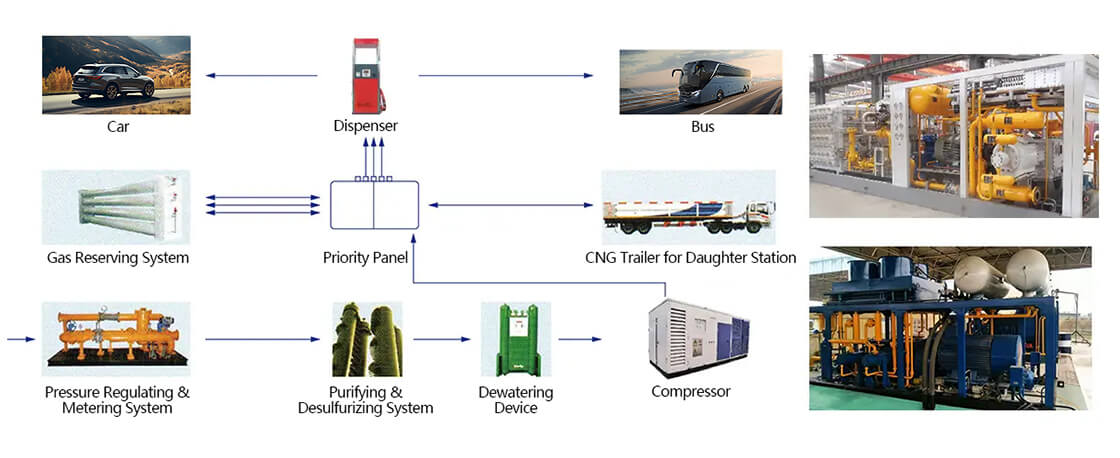

CNG Parent Station

CNG parent stations are typically located near urban gate stations, directly sourcing gas from the natural gas pipeline network. The inlet pressure is 0.2-8 MPa. After processes such as desulfurization, pressure regulation, metering, filtration, and dehydration, the natural gas enters the compressor unit. After compression, cooling, and purification, the gas is pressurized to 25 MPa, then transported to sub stations via CNG tankers for vehicle fueling. Finally, the dispensing machine fills the vehicle with gas. The company provides complete turnkey project solutions.

- ● Fueling capacity range: 2500-6000 Nm³/h

- ● Land area: Approximately 2000-4000㎡

- ● Optimal transportation radius: 150 km

- ● Applicable scale: ≥40,000 Nm³/d

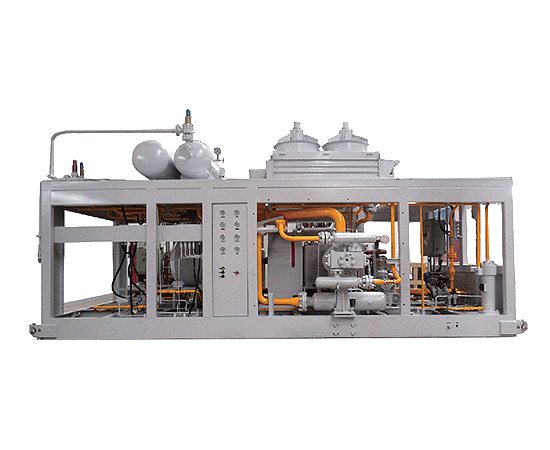

CNG Standard Station

CNG Standard stations are typically built in areas covered by the natural gas pipeline network, directly sourcing gas from the pipeline. The inlet pressure is 0.05-4.0 MPa. The natural gas undergoes desulfurization and dehydration processes before entering the compressor, where it is compressed to 25 MPa, and then dispensed into vehicles through fueling machines.

- ● Fueling capacity range: 600-5000 Nm³/h

- ● Land area: Approximately 1500-3000㎡

- ● Optimal transportation radius: 10-30 km

- ● Applicable scale: ≥10,000 Nm³/d

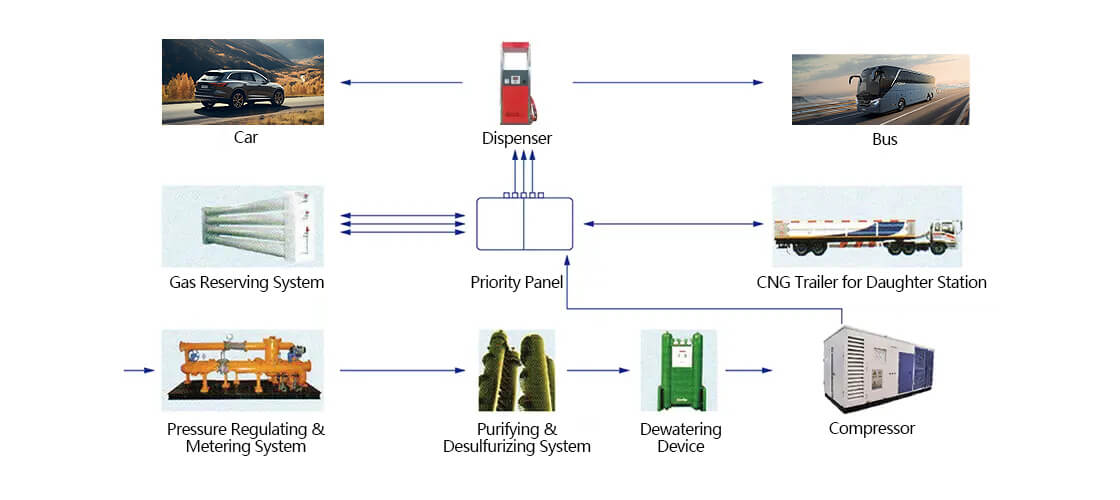

CNG Sub Station

CNG sub stations are typically built in areas without natural gas pipeline coverage, such as industrial zones around urban outskirts or rural areas, to provide CNG refueling services for local vehicles or natural gas energy for industrial users. The parent station compresses and stores the natural gas, which is then transported via dedicated trucks to the sub station. The gas is offloaded through an unloading tower and then dispensed into CNG vehicles via fueling machines.

- ● Fueling capacity range: 1800-4000 Nm³/h

- ● Land area: Approximately 1000-1500㎡

- ● Optimal transportation radius: 50-100 km

- ● Applicable scale: ≥20,000 Nm³/d

CNG Compressor Working Principle:

Compressed natural gas compressors are reciprocating piston types.

When the compressor is working, the compression device of the compressor can realize the rotation of the crankshaft, and then through the transmission of the connecting rod, the piston of the natural gas compressor can do reciprocating cycle movement, so that the working volume of the cylinder in the natural gas compressor can change periodically. When the piston of the natural gas compressor starts to move from the cylinder head, the working volume in the cylinder of the natural gas compressor can increase and then when the inlet door of the natural gas compressor is pushed open, the natural gas can enter the cylinder.

When the piston of the natural gas compressor moves in the opposite direction, accordingly the volume of the cylinder in the natural gas compressor becomes smaller, the space becomes smaller, the gas does not change and so the air pressure increases. When the air pressure in the natural gas compressor reaches a certain height, the exhaust valve opens and the gas exits the cylinder. This cycle continues with the piston of the natural gas compressor reciprocating once, completing four cycles of suction, compression, exhaust, and expansion in a circle.

CNG Compressor Features

- Soft start, allowing frequent compressor starts and stops.

- Wide range of air inlet, adaptable to a wide range of applications.

- Integral skid-mounted structure, low noise, easy to install in urban areas, saving investment.

- Optional air-cooled and water-cooled, two types of cooling.

- The natural gas compressor is not only suitable for CNG filling stations, but also for boosting, pressure stabilization, power, and blowing in industrial processes and can also provide a stable power source for power plants, the food industry, pharmaceuticals and experimental research units.

- The service life of valves, piston rings and other consumable parts is more than 8,000 hours.

- Siemens PLC control system, high degree of automation.

You May Like

Get CNG Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631