Ammonia Compressor

An ammonia compressor is a mechanical device specially designed to compress gaseous ammonia.Its main function is to compress low-pressure gaseous ammonia into high-pressure gaseous ammonia for further processing or storage in industrial processes.Ammonia compressor is widely used in chemical, refrigeration and freezing industries, especially in refrigeration system, it is an important equipment to compress gaseous ammonia into liquid ammonia.

Lubrication method: pressure type, splash type.

Product structure: single-cylinder vertical, double-cylinder vertical, symmetrical balance type.

Discharge volume : 0.2m3/min-10m3/min

Discharge pressure: from 0.8Mpa-2.6Mpa

It can meet the needs of different working conditions such as loading and unloading, conveying, flushing and loading, and process pressurization of tertiary stations, secondary stations, fire tanks, terminals, refilling stations, industrial stations and refineries in different regions and seasons.

Key Working Steps

1. Suction Phase

Low-pressure gaseous ammonia enters the compressor's cylinder or compression chamber through the intake valve. During this phase, the piston or rotor of the compressor moves to increase the volume within the chamber, creating a vacuum that draws in the ammonia gas.

2. Compression Phase

The ammonia gas is compressed as the piston, screw, or impeller reduces the volume of the compression chamber. As the volume decreases, the pressure and temperature of the ammonia gas increase significantly.

3.Discharge Phase

Once the ammonia gas reaches the desired pressure, the discharge valve opens, and the high-pressure gaseous ammonia is expelled from the compression chamber into the condenser. At this point, the chamber volume is at its minimum, forcing the gas out.

4. Condensation Phase

The high-pressure gaseous ammonia enters a condenser, where it is cooled and converted into liquid ammonia. This process usually involves circulating cooling water or air to remove the heat from the gas.

5. Circulation and Storage

After condensation, the liquid ammonia is typically stored in a tank for use in refrigeration systems or other industrial applications. In refrigeration, the liquid ammonia evaporates to absorb heat, turning back into gaseous ammonia, which is then re-compressed by the compressor, continuing the cycle.

Types Of Ammonia Compressor

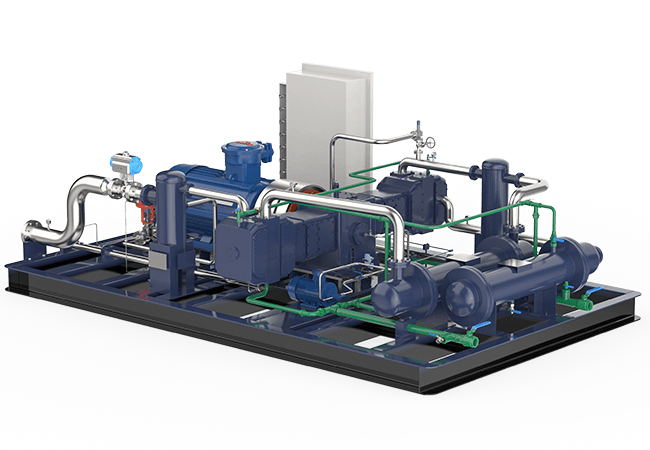

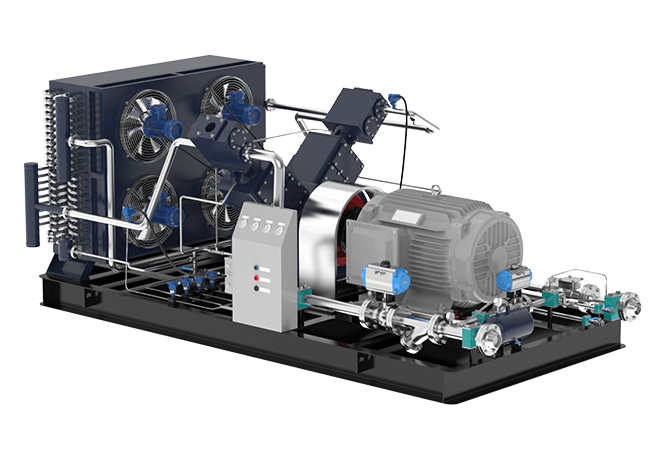

D Type

DW-6.4-0.4

Compressor model: MN-6.4/250

Compressed media: Ammonia

Structure type: Type DW

Compression stage: Two-stage compression

Nominal volume flow:6.4m3/min

Suction pressure: Atmospheric pressure

Exhaust pressure:2.5Mpa

Cooling method: Air cooling

Equipped power: 132KW

Dimensions (L×W×H) :5900*3100*2550mm

DW-10.7-0.4

Compressor model: MN-10.7/250

Compressed media: Ammonia

Structure type: Type DW

Compression stage: Two-stage compression

Nominal volume flow:10.7m3/min

Suction pressure:Atmospheric pressure

Exhaust pressure:2.5Mpa

Cooling method: Air cooling

Equipped power: 250KW

Dimensions (L×W×H) :4800*1600*1200mm

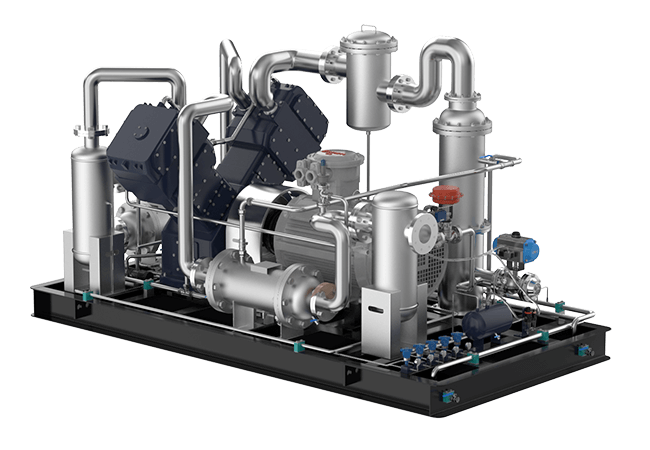

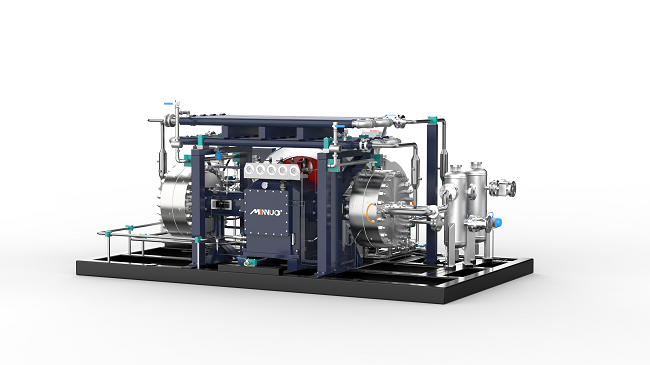

V Type

VW-6-3

Compressor model: MN-6/3

Compressed media: Ammonia

Structure type: Type VW

Compression stage: Two-stage compression

Nominal volume flow:6m3/min

Suction pressure:Atmospheric pressure

Exhaust pressure:0.3Mpa

Cooling method: Water cooling

Compressor speed: 740(r/min)

Equipped power: 30KW

Dimensions (L×W×H) :1850*1650*1600mm

Weight: 2500kg

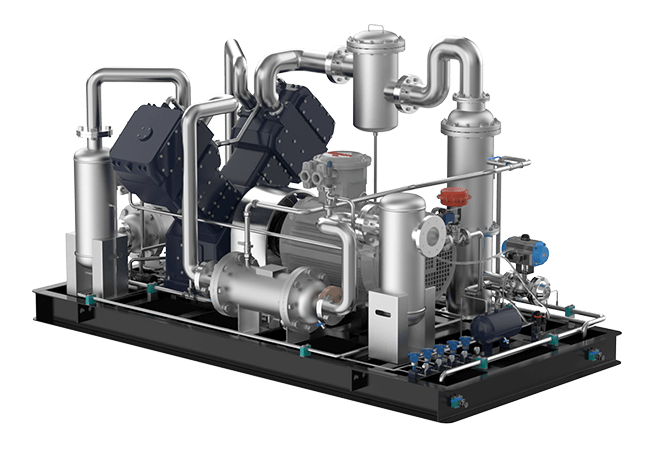

VW-9.8-4

Compressor model: MN-9.8/4

Compressed media: Ammonia

Structure type: Type DW

Compression stage: Two-stage compression

Nominal volume flow:9.8m3/min

Suction pressure:Atmospheric pressure

Exhaust pressure:0.4Mpa

Cooling method: Water cooling

Compressor speed: 980(r/min)

Equipped power: 30KW

Dimensions (L×W×H) :1850*1780*1600mm

Weight: 2500kg

VW-40-2.5

Compressor model: MN-40/2.5

Compressed media: Ammonia

Structure type: Type VW

Compression stage: Two-stage compression

Nominal volume flow:40m3/min

Suction pressure:Atmospheric pressure

Exhaust pressure:0.25Mpa

Cooling method: Water cooling

Compressor speed: 980(r/min)

Equipped power: 30KW

Dimensions (L×W×H) :3000*1850*1780mm

Weight: 3500kg

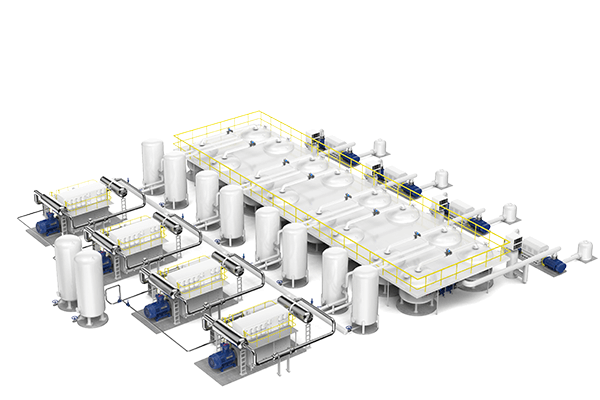

Solution of Ammonia Compressor

The core pressurisation equipment of the ammonia filling station is the diaphragm compressor. The diaphragm of the diaphragm compressor completely separates the cylinder from the oil cylinder, and the diaphragm chamber is well sealed to ensure the purity of ammonia.

Its working principle is that the diaphragm reciprocating movement when the oil pressure drops, so as to achieve the purpose of ammonia pressurisation.

Features

- Diaphragms, wear parts for long life.

- Single unit capacity up to 1000Kg/d

- Low procurement costs, small footprint, and low energy consumption;

- High operational safety, no gas leakage due to the short life of wearing parts.

Get Your Compression Soution

"Ready to take your compressor project to the next level? Fill out our form now and receive a FREE high-quality compressor solution that will boost your efficiency and productivity. Don't miss out on this opportunity to improve your operations - fill out the form today!"

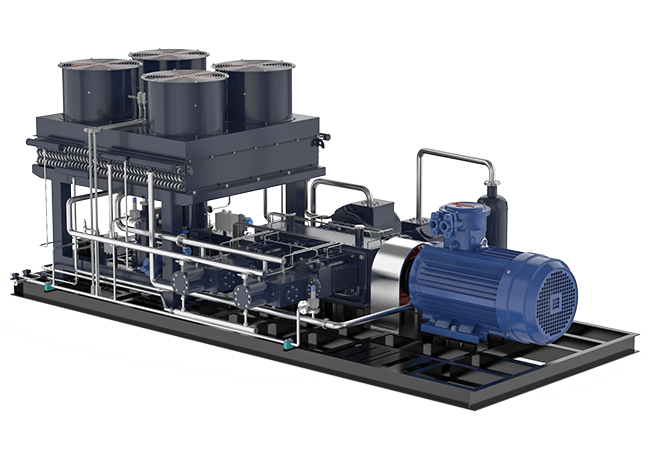

The difference between Air-Cooled compressor and Water-Cooled Compressors

Air-Cooled Ammonia Compressors

Pros:

– Easy installation: No need for water sources or piping.

– Low maintenance costs: Fewer components to maintain.

– Ideal for water-scarce areas: No water required.

– Environmentally friendly: No water consumption or discharge.

Cons:

– Lower cooling efficiency: Less effective in high temperatures.

– Noisier: Fans can generate significant noise.

– Affected by ambient temperature: Performance drops in hot environments.

Water-Cooled Ammonia Compressors

Pros:

– Higher cooling efficiency: Better for continuous, stable operation.

– Quieter: Less noise compared to air-cooled systems.

– Stable performance: Less affected by external temperatures.

Cons:

– Higher installation and maintenance costs: Requires additional equipment like pumps and cooling towers.

– Water consumption: Not suitable for areas with limited water resources.

– Water quality issues: Poor water quality can cause corrosion or blockages.

| NO | model | Exhaust volume m3/h | Inlet pressur Mpa | Outlet pressure Mpa | Motor power kw | Dimension mm |

|---|---|---|---|---|---|---|

| 1 | VW-1.67/6 | 100 | Atmospheric pressure | 0.6 | 11 | 1680*800*1300 |

| 2 | VW-0.83/250 | 50 | Atmospheric pressure | 25 | 30 | 1680*800*1300 |

| 3 | VW-6/3 | 6 | Atmospheric pressure | 0.3 | 30 | 1850x1650x1600 |

| 4 | DW-6.5/0.035-8 | 6.5 | 0.0035 | 0.8 | 45 | 1850x1780x1600 |

| 5 | VW-9.8/4 | 9.8 | Atmospheric pressure | 0.4 | 45 | 1850x1780x1600 |

| 6 | VW-40/2.5 | 40 | Atmospheric pressure | 0.25 | 132 | 3000x1850x1780 |

| 8 | VW-0.67/1-250 | 80 | 0.1 | 25 | 30 | 1680*800*1300 |

| 9 | ZW-1.5/0.1-250 | 100 | 0.01 | 25 | 30 | 2100*1170*1960 |

| 10 | ZW-1.67/30 | 100 | Atmospheric pressure | 3 | 30 | 2100*1170*1960 |

| 11 | ZW-3.33/20 | 200 | Atmospheric pressure | 2 | 55 | 2180*1250*2360 |

| 12 | ZW-4/80 | 240 | Atmospheric pressure | 8 | 75 | 2100*1170*1960 |

| 13 | ZW-3.2/ 0.3-50 | 250 | 0.03 | 5 | 55 | 2100*1170*1960 |

| 14 | ZW-2.3/04-250 | 200 | 0.04 | 25 | 75 | 2180*1250*2360 |

| 15 | ZW-6/50 | 360 | Atmospheric pressure | 5 | 90 | 3150*1350*2360 |

| 16 | ZW-5/150 | 300 | Atmospheric pressure | 15 | 110 | 3150*1350*2360 |

| 17 | ZW-5/0.2-250 | 360 | 0.02 | 25 | 110 | 3150*1350*2360 |

| 18 | ZW-3.34 /1-250 | 400 | 0.1 | 25 | 132 | 3500*2100*2300 |

| 23 | DW-6.4/0.4-250 | 800 | 0.04 | 25 | 132 | 5900*3100*2550 |

| 24 | DW-10.7/0.4-250 | 900 | 0.04 | 30 | 250 | 4800*1600*1200 |

| 25 | DW-18/250 | 1080 | Atmospheric pressure | 25 | 320 | 6000*1600*1200 |

Working Principle

The working principle of ammonia compressor is to use mechanical energy to turn the gaseous ammonia into a high -pressure liquid ammonia gas. The ammonia compressor includes a motor, reducer, condenser, and compressor. Gas ammonia enters the compressor from the power thermal exchange device, and a reducer is installed in the compressor to convert the high -speed rotation energy of the motor into a low -pressure liquid ammonia gas. The liquid ammonia is cooled by the condenser and stored in the storage tank.

Benifits

- High Efficiency: Ammonia compressors are designed to be highly efficient and reliable. They are capable of delivering high-pressure air or gas with minimal energy consumption.

- Low Maintenance: Ammonia compressors are designed to be low maintenance and require minimal servicing.

- Low Noise: Ammonia compressors are designed to be quiet, reducing noise pollution in the workplace.

- Durability: Ammonia compressors are designed to be durable and can withstand long-term use.

We Serivice for many customer

Minnuo offers independent solutions according to flow/purity/pressure, usage environment, main application, and special customer requirements at a competitive prices. Our compressor booster is made of high-quality materials and has been tested thoroughly to ensure the best quality.

Get Your Free Solution

Ammonia compressors are an important part of the ammonia production process. They help to reduce the volume of ammonia, making it easier to store and transport. At Minnuo, we offer a wide range of ammonia compressors to meet your needs. Our compressors are designed to be reliable, efficient and economical. To find the ammonia compressor that best suits your needs, simply fill out our web form and one of our experts will contact you to discuss your requirements.

You May Like

Get Ammonia Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631