In today’s era of rapid development of intelligent manufacturing, compressed air, an indispensable “fourth energy source” in the industrial sector, has become a crucial indicator of a company’s modernization level. With the deepening development of Industry 4.0, manufacturers are increasingly demanding higher standards for compressed air systems. These systems require not only a stable and reliable air supply but also intelligent management methods and energy-saving and environmentally friendly operation models. Unfortunately, however, many traditional manufacturers still rely on decentralized air compression systems. While these systems have played an important role over the past few decades, their inherent flaws and pain points have become increasingly prominent as production requirements increase, becoming a significant obstacle to enterprise transformation and upgrading.

I. The Constraints of Traditional Systems: The Hidden Costs of Decentralized Layouts

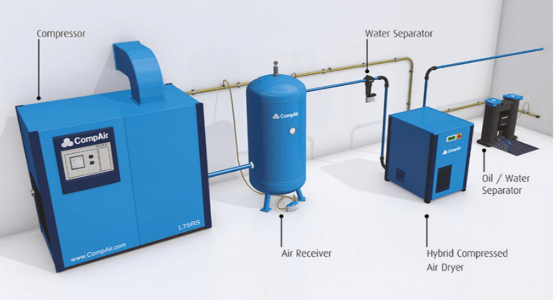

A deeper analysis of traditional decentralized air compression systems reveals that their problems are far more serious than they appear. First, from a space utilization perspective, traditional air compression systems typically require the installation of multiple separate devices, such as the compressor unit, air receiver, dryer, and filter. These devices not only occupy significant space individually, but the connecting piping between them also requires additional space. Industry statistics show that a standard traditional air compression system typically requires two to three times the floor space of an integrated system. In today’s context of increasingly scarce land resources and rising factory rents, this wasted space undoubtedly imposes a heavy financial burden on businesses.

In terms of energy consumption, the inefficiency of traditional systems is particularly prominent. Most traditional air compressors use a power frequency drive, which maintains the motor’s rated speed even when air usage is low, resulting in significant energy waste. Furthermore, the long connecting piping between devices leads to significant pressure loss. Research shows that every additional bar of pressure loss increases system energy consumption by approximately 7%. Furthermore, decentralized systems often lack effective heat recovery devices, and the significant amount of heat generated during the compression process is directly discharged into the atmosphere, creating secondary energy waste.

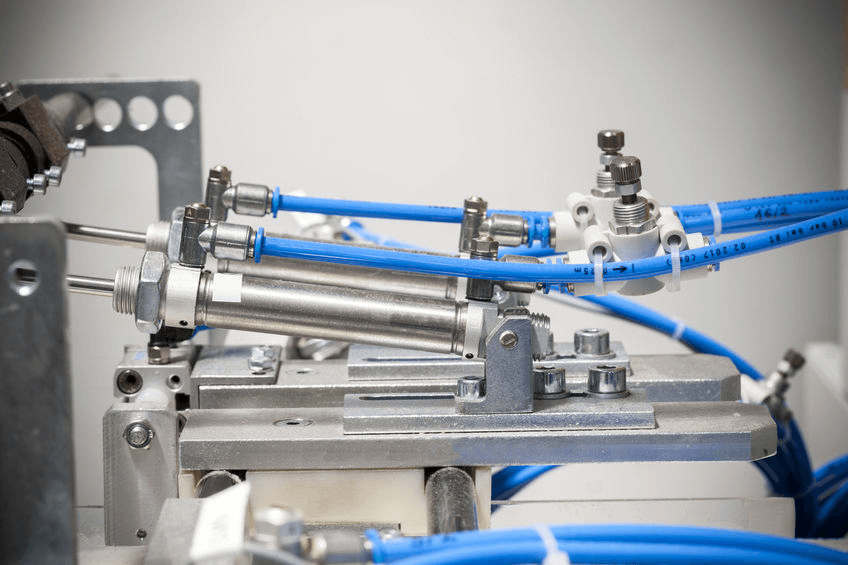

Air pressure stability is another significant drawback of traditional systems. Due to the dispersed layout of system components, pipe resistance varies significantly, leading to significant pressure fluctuations in end-use equipment. This pressure fluctuation directly impacts product quality and production efficiency in applications requiring high air source stability, such as precision machining equipment and automated production lines. For example, in welding robots used in the automotive industry, air pressure fluctuations can lead to unstable welding quality; in precision assembly in the electronics industry, pressure variations can reduce component installation accuracy.

Air quality is also a critical issue. Post-processing equipment in traditional systems is often selected based on minimum configuration requirements, and the compatibility between individual devices may not be ideal. This results in ineffective removal of oil, moisture, and impurities from the compressed air during operation. Long-term use of such compressed air not only accelerates wear of pneumatic components and shortens equipment life, but can also contaminate the final product. This risk is particularly concerning in industries with extremely high air quality requirements, such as food and pharmaceuticals.

II. Integrated Innovation: A Breakthrough in Integrated Design

The emergence of four-in-one screw compressors can be considered a revolutionary breakthrough in compressed air supply. This innovative equipment, through meticulous system design and advanced technological integration, organically integrates traditionally dispersed components within a compact chassis, achieving highly integrated systems. This integration goes beyond simple physical integration; it encompasses deep synergy and optimized coordination between the various subsystems.

From a space utilization perspective, the four-in-one screw compressor minimizes its footprint through optimized internal structure and layout. Compared to traditional decentralized systems, its footprint can be reduced by over 50%. This compact design is particularly well-suited for modern production workshops with limited space, facilitating rapid deployment and flexible adjustment of equipment. This space advantage is particularly valuable in urban industrial parks, where land resources are limited. Furthermore, the equipment’s unified exterior design creates a cleaner and more aesthetically pleasing layout, meeting the requirements of modern factory environments.

To enhance energy efficiency, the four-in-one screw compressor utilizes a number of innovative technologies, the most crucial of which is the seamless combination of a permanent magnet variable frequency motor and an intelligent variable frequency drive system. This system monitors the production line’s actual gas demand in real time and automatically adjusts the motor’s operating speed accordingly, achieving intelligent “on-demand” gas supply control. Compared to traditional mains-frequency air compressors, this variable frequency control method avoids unnecessary no-load operation and significantly reduces energy consumption during partial-load conditions. Actual operating data shows that under typical variable-load conditions, four-in-one screw compressors achieve 30%-40% energy savings compared to traditional equipment. In applications with large load fluctuations, the energy savings are even more significant.

The system’s stability and reliability have also been comprehensively improved. Thanks to the integrated optimization of each component design, internal system resistance losses are significantly reduced, greatly improving pressure stability. The built-in intelligent control system precisely regulates parameters such as pressure and flow, ensuring output pressure fluctuations within ±0.02 MPa. This highly stable air supply provides reliable support for precision manufacturing and effectively prevents product quality issues caused by pressure fluctuations.

To ensure air quality, the four-in-one screw compressor utilizes a fully optimized purification system. The dryer and filter are perfectly matched to the compressor unit, ensuring optimal operation of the entire system. The multi-stage filtration system design enables compressed air to achieve ISO 8573-1 Class 0 oil-free quality, fully meeting the stringent compressed air quality requirements of high-end manufacturing. This integrated purification solution not only ensures air quality, but also simplifies equipment maintenance and reduces operating costs.

III. Technical Analysis: The Core Advantages of Intelligent Integration

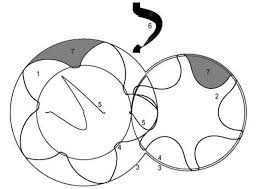

The technical advantages of the four-in-one screw compressor are reflected in multiple aspects, which together contribute to its superior system performance. First, the core compression unit utilizes advanced screw compressor technology, coupled with a specially optimized rotor profile design, ensuring a highly efficient gas compression process. The rotor system undergoes precision machining and dynamic balancing, ensuring smooth and reliable operation and significantly extending its service life. Notably, the compressor main unit adopts a fully enclosed design, effectively preventing external contaminants from entering the system and reducing operating noise.

Another highlight of the four-in-one screw compressor is its intelligent control system. The system’s high-performance PLC controller collects and processes a large amount of operating data in real time, including pressure, temperature, flow, current, and other parameters. Through intelligent analysis of this data, the system automatically optimizes operating strategies to maximize energy efficiency. For example, the system can predict load changes based on gas usage patterns and proactively adjust operating conditions to avoid frequent starts and stops. Furthermore, the intelligent control system features a fault warning function that analyzes trends in operating parameters to identify potential problems and alert users to preventive maintenance.

In terms of thermal management, the four-in-one screw compressor features a fully optimized cooling system. The air duct design, optimized using computational fluid dynamics (CFD) technology, ensures uniform distribution of cooling air and efficient heat exchange. The use of large radiators enhances the system’s heat dissipation capacity, maintaining stable operating temperatures even in high-temperature environments. Of particular note, some high-end models are equipped with heat recovery devices, which can utilize the heat generated during the compression process for workshop heating or process heating, achieving cascade energy utilization and further improving system energy efficiency.

Noise control technology is also a key feature of the four-in-one screw compressor. Through a variety of measures, including the use of low-noise rotor profiles, optimized chassis sound insulation, and vibration damping devices, operating noise is effectively controlled. Test data shows that under standard operating conditions, the operating noise level typically does not exceed 68 decibels, significantly improving the working environment and meeting the occupational health and safety requirements of modern factories.

Maintenance access was another key design consideration. The four-in-one screw compressor adopts a modular design concept, with key maintenance components easily accessible. The intelligent maintenance reminder function can indicate maintenance time based on actual operating conditions, avoiding over-maintenance or under-maintenance. Centrally located maintenance points make daily maintenance more convenient and significantly reduce the time and labor costs required for maintenance.

IV. Industry Application Scenarios: Comprehensively Empowering Smart Manufacturing

Four-in-one screw compressors, with their superior performance, have been widely used in numerous industrial sectors. In the automotive manufacturing industry, this equipment demonstrates unique value. Automotive welding production lines place extremely high demands on the stability and cleanliness of compressed air. Any pressure fluctuations or oil contamination can affect welding quality. Four-in-one screw compressors ensure reliable operation of welding robots through stable pressure output and Class 0 oil-free air. After introducing this equipment, a well-known automobile manufacturer reduced the failure rate of its welding production line by 35% and increased its first-pass yield by 2.3 percentage points.

The electronics manufacturing industry is another key application area. In this industry, where air quality is extremely demanding, even the slightest trace of oil or moisture can render a product scrapped. The oil-free compressed air provided by four-in-one screw compressors fully meets the requirements of manufacturing precision electronic components such as semiconductors and integrated circuits. In particular, the equipment’s built-in precision filtration system effectively removes particles larger than 0.01 microns, ensuring that compressed air cleanliness meets the stringent standards of the electronics industry. A semiconductor manufacturer reported that after using a four-in-one screw compressor, the product defect rate due to air source contamination dropped from 0.15% to below 0.02%.

In the food and beverage industry, compressed air quality is directly related to product safety. The oil-free, sterile compressed air provided by the four-in-one screw compressor fully meets food industry hygiene standards. The equipment utilizes food-grade materials and stainless steel piping, ensuring hygienic and safe compressed air throughout the entire delivery process. A large beverage manufacturer has not only improved product quality and safety by using this equipment, but has also achieved significant energy savings by utilizing a heat recovery system to recycle heat into production processes.

Medical device manufacturing is another important application area. In this industry, where production environments are extremely demanding, the stability and cleanliness of compressed air are crucial. The four-in-one screw compressor utilizes multiple safeguards to ensure the purity and stability of its output air. A medical device manufacturer has significantly improved the cleanliness level of its production environment, increased its product qualification rate by 1.8%, and reduced equipment maintenance costs by 25%.

Furthermore, four-in-one screw compressors have demonstrated excellent adaptability in a variety of industries, including textiles, chemicals, and power generation. In the textile industry, a stable air supply ensures the stable operation of spinning and weaving equipment; in the chemical industry, a special explosion-proof design meets the requirements for use in hazardous environments; and in the power generation industry, reliable performance ensures the stable operation of power generation equipment. These successful application cases fully demonstrate the wide applicability and excellent performance of four-in-one screw compressors in various industrial fields.

V. Economic Analysis: Value Creation Throughout the Lifecycle

A thorough analysis of the economic benefits of a four-in-one screw compressor from the perspective of return on investment reveals that its value far exceeds the initial investment cost. First, while the price of a single four-in-one screw compressor may be higher than that of a traditional air compressor unit, the overall investment cost is actually more advantageous when considering its integrated air receiver, dryer, filter, and other equipment. More importantly, due to the significant simplification of installation procedures, installation costs can typically be reduced by 40%-60%.

In terms of operating costs, four-in-one screw compressors offer the most significant energy savings. Based on statistics from multiple real-world application cases, four-in-one screw compressors can achieve an average energy saving of over 30% compared to traditional mains frequency air compressors. For example, for an air compression system with an annual electricity consumption of 1 million kWh, using a four-in-one screw compressor could save up to 300,000 kWh. Based on an industrial electricity price of 0.8 yuan per kWh, this translates to an annual electricity savings of 240,000 yuan. This energy saving is particularly valuable given the continued rise in energy prices.

Maintenance costs are another important consideration. The intelligent maintenance system used in four-in-one screw compressors accurately indicates maintenance timelines, avoiding unnecessary maintenance and unexpected failures. Statistics show that maintenance costs can be reduced by 25%-35% compared to traditional systems. This is primarily due to several factors: first, extended maintenance intervals. Thanks to high-quality filter elements and intelligent monitoring, filter replacement intervals can be extended by 30%-50%; second, reduced maintenance time, thanks to a modular design that makes maintenance more convenient; and finally, reduced failure rates, thanks to an intelligent early warning system that effectively prevents unexpected failures.

Extending equipment life is also a key factor in economic analysis. The heavy-duty design and high-quality components of four-in-one screw compressors ensure long-term reliability. Actual operating data shows that overhaul intervals are over 40% longer than those of traditional equipment, with a service life of over 15 years. This long-term reliability provides companies with stable equipment support, avoiding the additional investment required for equipment upgrades.

The indirect benefits of increased production efficiency should also be considered. Because four-in-one screw compressors provide a stable, clean air source, the failure rate of production equipment is significantly reduced, and the product quality rate is significantly improved. Statistics from a manufacturing company show that after using a four-in-one screw compressor, equipment downtime caused by air source problems was reduced by 70%, and the product rework rate was reduced by 1.2%. These indirect benefits are often more significant than direct energy-saving benefits.

VI. Future Outlook: Trends in Integration and Intelligence

With the deepening advancement of Industry 4.0, compressed air systems are moving towards greater intelligence and networking. Four-in-one screw compressors, as a typical example of this trend, hold great promise for their future development. From a technological perspective, the new generation of four-in-one screw compressors will place greater emphasis on deep integration with the Industrial Internet. Equipped with more advanced sensors and communication modules, these devices will enable higher levels of data collection and remote monitoring, providing stronger support for predictive maintenance and intelligent management.

In terms of energy efficiency, future four-in-one screw compressors will utilize more advanced variable frequency technology and permanent magnet materials to further enhance efficiency under partial load conditions. Furthermore, heat recovery technology will receive greater attention and optimization, enabling more efficient utilization of the heat generated during the compression process. Some leading manufacturers have already begun developing fully variable frequency controlled four-in-one screw compressors, which are expected to improve energy efficiency by an additional 5%-8%.

Intelligent management will be another key development direction. Future four-in-one screw compressors will be equipped with more powerful artificial intelligence algorithms, capable of automatically optimizing operating strategies through deep learning from historical operating data. For example, the system can learn a company’s production patterns, predict changes in gas demand, and proactively adjust operating conditions to achieve more accurate load matching. Furthermore, blockchain-based equipment maintenance record systems are expected to be implemented, making equipment maintenance management more transparent and reliable.

In terms of system integration, four-in-one screw compressors will develop towards greater modularity and standardization. Equipment of varying capacity levels will adopt unified interface standards to facilitate system expansion and upgrades. Furthermore, the integration of equipment with other factory systems will continue to improve, enabling seamless integration with production and energy management systems, providing companies with holistic solutions.

Environmental protection and sustainable development requirements will drive innovation in material selection and manufacturing processes for four-in-one screw compressors. The use of recyclable materials will continue to increase, and the production process will prioritize environmental friendliness. Furthermore, the use of low-global warming potential (GWP) refrigerants and stricter noise control standards will become key considerations in future product development.

VII. Conclusion: Ushering in a New Era for Compressed Air Systems

The advent and development of the four-in-one screw compressor heralds a new era for compressed air supply systems. This innovative device, through its highly integrated design and advanced intelligent control technology, successfully addresses many of the pain points of traditional decentralized systems, providing businesses with a more efficient, reliable, and economical compressed air solution.

From a technical perspective, the four-in-one screw compressor not only enables miniaturization and intelligentization, but more importantly, significantly improves energy efficiency through system optimization. From an economic perspective, its comprehensive cost advantages throughout its lifecycle provide businesses with substantial returns. In terms of application, its stable and reliable performance provides strong support for smart manufacturing upgrades across various industries.

With the accelerating pace of manufacturing transformation and upgrading, and the increasing demand for energy conservation and environmental protection, the four-in-one screw compressor is poised to play a vital role in a wider range of fields. It not only represents the direction of development in compressed air technology, but also serves as a crucial equipment support for the sustainable development of the manufacturing industry. For manufacturing companies striving for operational excellence, choosing a four-in-one screw compressor is not only a wise choice for technological upgrading, but also a strategic decision to enhance corporate competitiveness. In the future, with the continuous advancement of technology and the continuous expansion of application scenarios, the four-in-one screw compressor will continue to evolve and improve, injecting new impetus into the innovative development of the global manufacturing industry and making greater contributions to promoting the progress of industrial civilization.

Email

Email sales:+86 15366749631

sales:+86 15366749631