Product:

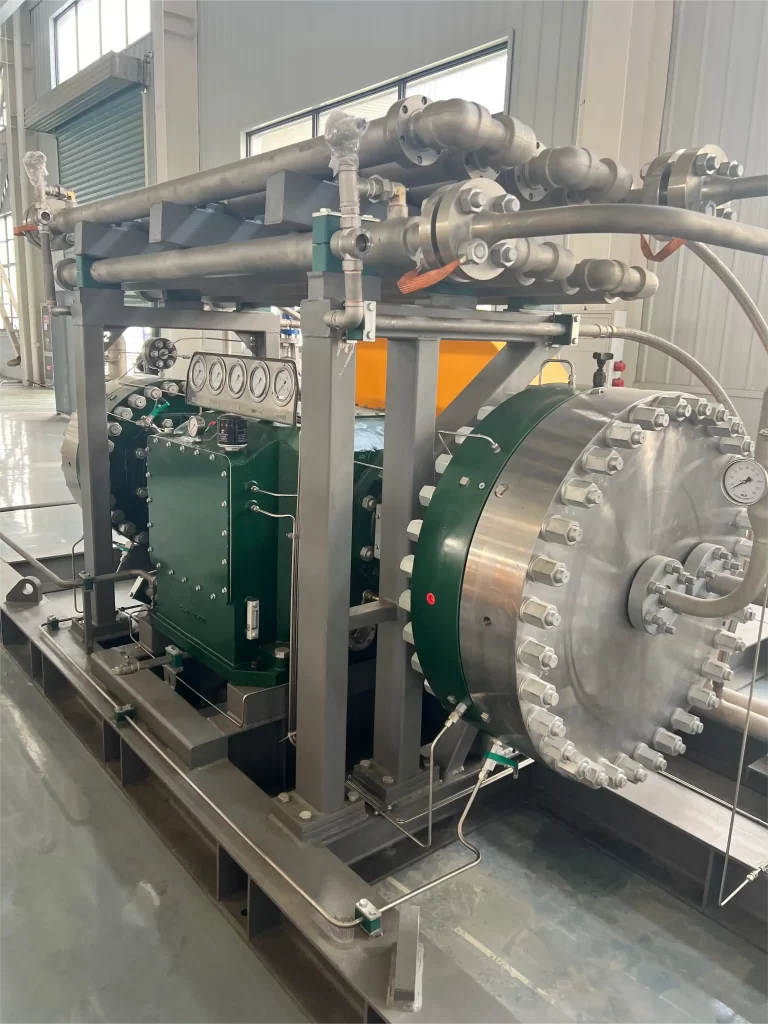

Diaphragm Hydrogen Compressors

Customer:

Sasha – an employee of Gazprom Neft. The company is engaged in the oil and gas business, engineering services, new energy development, and other businesses.

Customer demand:

Sasha filled out a form on Minnuo’s website to say that her company needed a hydrogen compressor for an oil refinery. The compressor can compress hydrogen to 500 MPa with a capacity of at least 1000 Nm3/h. She provided WhatsApp and email contact information and requested a quote.

Demand analysis: After an exchange on WhatsApp, we analyzed that Sasha wanted a hydrogen compressor that could run continuously and stably. And the following recommendations were made for his needs:

- The most stable compressor of type D compared to other models, which meets the requirements of the refinery.

- Hydrogen is a flammable and explosive gas, and diaphragm compressors are safer.

- A Diaphragm compressor working cylinder with good heat dissipation can use a higher compression ratio.

- Diaphragm compressor cylinders do not need lubrication and do not produce contamination.

- Diaphragm compressors have good sealing performance and do not leak during compression.

- As the compressor is used in the refinery, it needs to have good overall performance and a compact structure. The use of the whole skid-mounted is more secure and reliable.

After the communication, Minnuo custom-made the GD134-1759/38-41 hydrogen diaphragm compressor mainframe for the customer.

- Type: D type, double-cylinder, water-cooled, single-acting, two-stage compression

- Compression medium: hydrogen

- Inlet pressure: 3.8MPa(G)

- Exhaust pressure: 4.1MPa (G)

- Inlet gas temperature: 35℃

- Exhaust gas temperature: ≤40℃ (after cooling)

- Rated flow rate: 1759Nm 3/h

- Crankshaft speed: 420 r/min

Excellent service:

- Efficient demand feedback, 24h online response

- Send detailed technical documents in Russian when quoting

- Professional custom compressor, from design to product tailor-made

- Suggests skid-mounted all-in-one units to reduce customer equipping procedures

- Sends video and photos during production to ensure that the customer keeps track of the production progress

- Provide test run video before delivery to ensure product quality

- Arrange the most efficient freight company to ensure timely delivery

- Provides complete training and support services

After-sales technical service:

The following commitments are made to give customers high-quality products and excellent after-sales service.

- Minnuo handles on-site equipment delivery, unpacking and inspection of goods, equipment quality issues, guidance on installation and commissioning

- Minnuo provides technical training, and the training content is consistent with the progress of the project

- Customers can contact us at any time if technical problems arise during the use of the equipment. Minnuo will provide free technical training within 16 hours.

- If there is any quality problem during the quality guarantee period, Minnuo will repair and replace the required parts in time.

Email

Email sales:+86 15366749631

sales:+86 15366749631