Introduction: The High Cost of “Just Turn It Up”

If your pneumatic tools are underperforming, your first instinct might be to crank up the compressor pressure. It seems logical—more pressure should mean more power, right?

This common misconception is costing factories thousands in wasted energy and unnecessary equipment wear. True compressed air efficiency isn’t about running at the highest possible PSI; it’s about delivering the right pressure, consistently, where and when it’s needed.

This guide will demystify compressor pressure, explain its critical relationship with airflow, and show you how to optimize your system for peak performance and minimal cost.

Pressure vs. Flow: The Two Pillars of Compressed Air

To master your system, you must understand its two most fundamental metrics:

1. Pressure (PSI – Pounds per Square Inch)

Think of PSI as the push or the force behind the air. It’s the potential energy stored in the compressed air that allows it to overcome resistance—whether that’s the mechanical resistance in a tool or the friction in your pipes.

2. Flow (CFM – Cubic Feet per Minute)

Think of CFM as the volume or the amount of air delivered. It’s the actual workhorse that does the job, like driving an impact wrench or supplying a spray gun.

The Garden Hose Analogy:

- PSI is the water pressure. It determines how far the water can spray.

- CFM is the diameter of the hose. It determines how much water comes out.

You can have high pressure (a strong spray) but if your flow is low (a tiny hose), you won’t have enough water to do meaningful work. In compressed air, both must be in balance.

The Hidden Costs of Incorrect Compressor Pressure

The Perils of Excessive Pressure:

- Skyrocketing Energy Bills: For every 2 PSI increase in system pressure, your compressor’s energy consumption rises by approximately 1%. Raising your system pressure by 15 PSI to satisfy one distant tool can easily waste over $1,000 annually on a single mid-sized compressor.

- Accelerated Wear & Tear: Higher pressure puts more stress on seals, hoses, and the compressor itself, leading to more frequent leaks and premature component failure.

The Problems of Insufficient Pressure:

- Underperforming Tools: Tools will lack power, slowing down production and compromising work quality.

- Tool Damage: Tools may stall or cycle excessively, causing the motors to overheat and burn out.

A Practical Guide to Optimizing Your System Pressure

Follow these steps to find your system’s sweet spot.

Step 1: Audit Your Demand

Create a simple table of your key equipment. The tool with the highest CFM and PSI demand sets your baseline.

| Tool / Equipment | Required PSI (Range) | Required CFM |

| Impact Wrench | 90 PSI | 4-5 CFM |

| Paint Spray Gun | 40-60 PSI | 10-15 CFM |

| Laser Cutter | 110-150 PSI | Varies by Model |

Step 2: Diagnose and Reduce Pressure Drop

Pressure drop is the loss of pressure between the compressor and the point of use, caused by friction in pipes, fittings, filters, and dryers.

- The Symptom: You set your compressor to 110 PSI, but your tool only gets 85 PSI. That’s a 25 PSI drop.

- The Solution: Instead of raising the compressor to 135 PSI, fix the root cause.

- Use Larger Main Pipes: Upsizing pipes is one of the most effective ways to reduce friction.

- Optimize Layout: Minimize tight bends and long runs.

- Fix Leaks: A single 1/8-inch leak can waste over $1,000/year.

Step 2.5: How to Calculate Pressure Drop in Compressed Air Lines

For engineers looking to precisely diagnose their system, pressure drop can be estimated. A fundamental formula for straight pipe sections is:

ΔP = f × (L/D) × (ρ × v²/2)

Where:

- ΔP = Pressure Drop

- f = Friction factor (dependent on pipe material and flow)

- L = Length of the pipe

- D = Diameter of the pipe

- ρ = Density of air

- v = Velocity of the air flow

The key takeaway: Notice that pressure drop is directly related to the pipe length (L) and inversely related to the fifth power of the pipe diameter (D⁵). This means that doubling your pipe diameter can reduce the pressure drop by a factor of 32! While online calculators can simplify this, the principle is clear: larger pipes are one of the most effective ways to combat pressure loss.

Step 3: Implement a Tiered Pressure Strategy

Not every application needs 100+ PSI. Use pressure regulators to step down the pressure for lower-demand applications like packaging machines or cleaning guns. This reduces overall system strain and energy consumption.

The Smart Solution: Moving Beyond Fixed-Speed Pressure

A traditional fixed-speed compressor cycles between “loaded” (producing air) and “unloaded” (idling but still using ~30% power) to maintain a pressure band (e.g., 110-125 PSI). This constant cycling is inefficient.

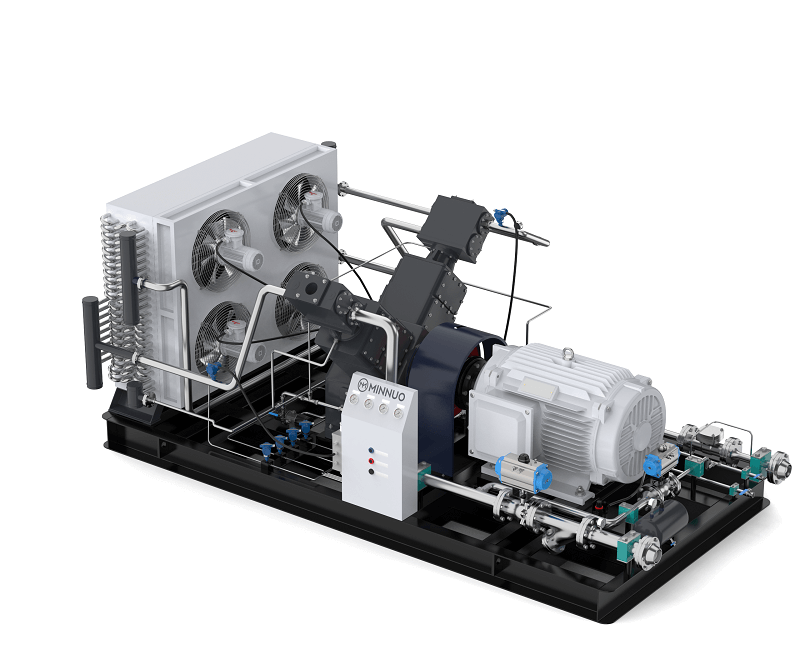

A Variable Speed Drive (VSD) Compressor is the modern solution. It works like a cruise control for your air demand:

- It adjusts its motor speed in real-time to produce exactly the amount of air needed.

- It maintains a rock-steady pressure, typically within ±1-2 PSI.

- By eliminating unloaded running, it can reduce energy costs by 20-40% or more.

VSD vs Fixed-Speed Compressor: An Energy Comparison

The energy savings of a VSD unit aren’t just theoretical. Consider a compressor that runs with a 70% average load:

- A fixed-speed compressor would spend significant time in the unloaded state, still consuming ~30% of its full-load power while producing no air. This cycling creates massive inefficiency.

- A VSD compressor seamlessly adjusts its motor speed to match the 70% demand, drawing almost exactly 70% of the power needed. It avoids the unloaded losses entirely.

The result? It’s not uncommon for a well-sized VSD compressor to achieve energy savings of 20% to 40% compared to a fixed-speed counterpart in a typical industrial application. This direct VSD vs fixed-speed compressor energy comparison makes a compelling financial case for upgrading, where the ROI is often measured in just a few years.

Frequently Asked Questions (FAQ)

Q1: My tool needs 90 PSI. What should I set my compressor to?

A1: It depends on your system’s pressure drop. Start at 95-100 PSI and measure the pressure at the tool while it’s running. If it’s below 90 PSI, focus on reducing pressure drop in your piping rather than turning up the compressor.

Q2: What’s more important, pressure (PSI) or horsepower (HP)?

A2: Neither is more important in isolation. Horsepower is the engine’s potential, while PSI and CFM are the delivered performance. A high-HP compressor with inadequate CFM at your required PSI is like a powerful truck with a tiny trailer hitch—it can’t do the job efficiently.

Q3: Why does my compressor struggle to reach its set pressure?

A3: This is a classic sign of one of two issues:

1) Excessive demand: You are using more air (CFM) than the compressor can produce.

2) A failing component: Worn valves, a clogged air filter, or internal leaks can prevent the compressor from building full pressure.

Conclusion: Pressure for Performance, Not Just Power

Managing your compressor pressure is not a “set it and forget it” task. It’s a continuous pursuit of efficiency that pays dividends in lower operating costs, improved tool life, and unwavering production reliability.

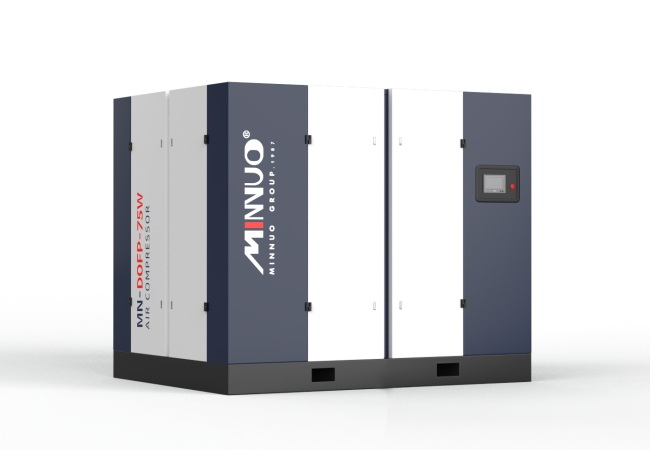

At MINNUO, we engineer compressed air solutions that deliver precise, consistent pressure without the energy waste. Our range of VSD compressors is designed to be the intelligent heart of your system, automatically adapting to your needs.

Ready to stop wasting air and money? Contact our team for a free consultation!

Email

Email sales:+86 15366749631

sales:+86 15366749631