As a global leader in compressor manufacturing, MINNUO is committed to providing customers with efficient and energy-saving compression system solutions. Accurately calculating compressor power and optimizing its operational efficiency are key elements in reducing energy consumption, extending equipment life, and achieving cost savings. This article systematically elaborates on the methods for calculating compressor power, influencing factors, and optimization strategies, combining practical cases and industry data to provide engineers and decision-makers with a comprehensive guide from theory to practice.

Compressor power calculation and optimization are key to enhancing energy efficiency, reducing costs, and extending equipment lifespan. Accurate calculations account for gas properties, compression types, and operational conditions, while optimization focuses on system matching, reducing losses, and integrating advanced technologies like AI and heat recovery.

I. Compressor Power Calculation Method: Precision Modeling and Engineering Practice

The power calculation of a compressor must consider the complexity of gas properties, the type of compression process, equipment efficiency, and actual operating conditions. The following is an in-depth analysis of key formulas and applicable conditions in different scenarios:

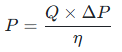

Extended Application of Basic Power Formulas

General Formula

Limitations: Does not account for thermodynamic characteristics of the gas compression process, requiring gas dynamics for refinement:

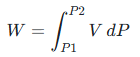

- Multi-state parameter correction: Gas density change with pressure must be calculated using an integral form of the compression work:

Case Study: In natural gas compression, where volume V changes non-linearly with pressure, multi-segment integration or empirical coefficients are required.

Standardization of unit conversion: Convert to SI units (e.g.,

1bar=105Pa,1cfm=0.0283m3/min) to avoid errors caused by mixing Imperial units.

MINNUO Technical Insight: For high-pressure hydrogen gas compression (>300 bar), the proprietary HydroCalc™ software integrates real gas equations of state (e.g., BWRS equation) and friction loss models, achieving accuracy within ±1.5%.

Power Calculation for Different Compression Processes and Engineering Selection

- Isothermal Compression: Theoretically the most efficient, requires forced cooling systems.Case Study: Water-injection screw compressors enhance efficiency by 12% with cooling, but the water pump consumes 3%–5% of total power.

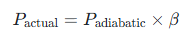

- Adiabatic Process Dynamic Correction: Introducing a “heat dissipation efficiency factor”

:

Note: High-speed centrifugal compressors (>10,000 rpm) require CFD simulation to determine the

β value.

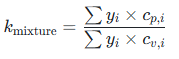

- Complex Gas Handling: For mixed gases (e.g., natural gas), the equivalent k value is calculated using a virtual critical parameter method:

Where y_i is the mole fraction of each component.

Power Correction in Actual Operations and Auxiliary System Considerations

Mechanical Losses Detailed Breakdown

| Loss Type | Typical Share | Optimization Measures |

| Bearing Friction | 2%–4% | Replace steel bearings with ceramic bearings |

| Gearbox Transmission | 3%–6% | Use magnetic couplers |

| Valve Throttling | 1%–3% | Optimize valve spring stiffness |

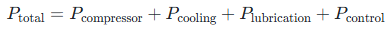

Auxiliary System Power Consumption: The total input power should add up the power of cooling, lubrication, and control systems:

Case Study: For a centrifugal compressor, the oil pump power accounts for 2.8%, while the inverter loss is 1.5%.

II. Key Factors Affecting Compressor Power: Multi-dimensional Analysis and Quantitative Evaluation

The Deep Impact of Gas Properties and Process Mediums

- Compressibility Factor Dynamic Mapping: For LPG and other phase-change media, real-time monitoring of z -value variations during compression. MINNUO’s supercritical CO₂ compressor embeds an online z -value sensor for dynamic control logic adjustments.

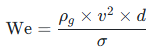

- Two-phase Flow Handling: For wet gas compression, the effect of droplet entrainment is evaluated using the Weber number:

When \text{We} > 10 , droplet breakage increases power consumption by 8%–15%.

Optimization Potential in Operating Conditions

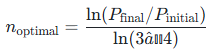

- Golden Ratio for Compression Ratio: Optimal number of compression stages formula:

Case Study: Compressing from 1 bar to 81 bar, a four-stage compression saves 9% compared to three stages.

- Inlet Pre-cooling Quantified Benefits: A certain chemical plant reduced the inlet temperature from 40°C to 25°C, reducing power consumption by 6.2%, saving 540,000 CNY in annual electricity costs .

Hidden Costs of Equipment Design and Maintenance

- Rotor Profile Optimization: MINNUO’s fifth-generation asymmetric rotor profile improves volumetric efficiency to 98.5%, saving 11% .

- Carbon Accumulation Impact: For screw compressors, a 0.1mm gap increase leads to a 3% efficiency drop, with online cleaning restoring 98% of initial efficiency.

III. Compressor Power Optimization Strategies: Full Lifecycle Energy Efficiency Management

Precise Model Selection and System Matching

- Dynamic Load Matching: The Digital Twin model predicts gas demand fluctuations and recommends combination schemes . Case Study: A car manufacturing plant adopted a “1 fixed-speed + 2 variable-speed” combination, saving 23% annually.

Pipeline Optimization Golden Rule

| Optimization Measure | Pressure Drop Reduction | Energy Saving Effect |

| Increase pipe diameter by 1 level | 35% | 2.8% |

| Reduce number of elbows | 20% | 1.5% |

| Install air receiver tank | 50% | 4.2% |

Intelligent Parameter Control

- AI Load Forecasting: The SmartOptima™ system uses LSTM algorithms to predict gas demand and reduce idle time by 60%.

- Flexible Pressure Band Control: Allowing pressure fluctuation within ±0.3 bar reduces power consumption by an average of 4.1% .

Heat Recovery and System Integration

Stepwise Waste Heat Utilization

| Temperature Range (°C) | Utilization Method | Energy Efficiency Improvement |

| >120 | Drive absorption chiller | 18% |

| 80–120 | Process heating | 15% |

| <80 | Building heating | 10% |

- ORC low-temperature power generation technology: Utilizing 90–150°C waste heat to generate power, recovering 5%–8% of total input energy.

IV. Industry Application Cases and Data In-depth Analysis

Case Study 1: Steel Plant Air Compressor Station Global Optimization

A steel plant integrated 12 air compressors (total power 18MW) into the Energy Hub platform, saving 15.2 million CNY annually:

- Pressure reduced from 7.5 bar to 6.8 bar (saving 7.5%);

- Retiring old equipment (specific power reduced from 7.1 to 5.9);

- Waste heat power generation system recovered 9% of energy.

Case Study 2: LNG Reception Station Cold Energy Utilization

- Using -162°C LNG cold energy for inlet pre-cooling, compressor power consumption was reduced by 38%;

- Cold-electric cogeneration system achieved overall energy efficiency of 72%.

Case Study 3: Data Center Green Gas Supply System

- Utilizing magnetic levitation centrifugal machines + plate heat exchangers + AI control;

- Specific power reduced from 5.8 to 4.3 kW/(m³/min), PUE optimized by 0.12.

V. Future Trends and Disruptive Technologies

Digital Twin and Real-time Energy Efficiency Management

- Embedded sensor networks collect 10,000+ data points in real time;

- Digital dashboards based on Digital Twin technology for instant feedback and adjustment.

New Materials and Turbine Technology

- Superconducting materials are being used to reduce electrical losses and are entering the mass production stage.

- Turbomachinery-based compression technology is under development, with expected efficiency improvements of 12%.

Intelligent Value-added Services

- Remote diagnostics + cloud monitoring technology will become widespread, with market penetration expected to reach 48% by 2027.

FAQ

Q1: How to choose the number of compression stages for different pressure ranges?

A1: The number of compression stages is mainly determined by the total compression ratio and gas properties. For low-pressure scenarios (compression ratio ≤4), a single stage is sufficient; for medium-pressure (4<compression ratio ≤16), two stages are recommended; for high-pressure (16<compression ratio ≤64), 3-4 stages are optimal. You can also use the optimal stage number formula mentioned in the article for quantitative calculation. For example, when compressing from 1 bar to 81 bar, four-stage compression can save 9% of power compared to three stages. Additionally, for gases with high adiabatic index (such as hydrogen), increasing the number of stages appropriately can further reduce energy consumption.

Q2: What is the payback period for compressor heat recovery system transformation?

A2: The payback period is usually 1-3 years, which varies depending on the system scale, heat utilization rate and regional energy prices. Taking a medium-sized air compressor station (total power 5MW) as an example, transforming the heat recovery system to supply process heating or building heating can recover about 15%-20% of the total input energy. According to the electricity price of 0.15 USD/kWh, the annual energy saving benefit is about 1.08 million USD, and the payback period is about 1.8 years. For high-temperature waste heat (>120℃) utilized for absorption chillers, the payback period can be shortened to 1-1.5 years due to higher energy efficiency improvement.

Q3: How to solve the power loss caused by carbon accumulation in screw compressors?

A3: First, adopt proactive prevention measures: use high-quality lubricating oil that is resistant to carbon deposition, and regularly replace air filters to reduce impurity intake. Second, implement regular online cleaning: use professional cleaning agents to remove carbon deposits without disassembling the equipment, which can restore 98% of the initial efficiency. For severe carbon accumulation (gap increase ≥0.1mm), it is necessary to disassemble and grind the rotor profile. MINNUO’s fifth-generation asymmetric rotor profile has strong anti-carbon deposition performance, which can reduce the frequency of cleaning by 50% compared with traditional profiles.

Q4: What are the key parameters for selecting a high-pressure hydrogen compressor?

A4: The key parameters include four aspects: ① Compressibility factor (z-value) adaptability: select equipment with real-time z-value monitoring function (such as MINNUO’s supercritical CO₂ compressor with embedded online z-value sensor) to adapt to the significant changes of hydrogen z-value under high pressure; ② Material compatibility: use corrosion-resistant materials (such as 316L stainless steel) to avoid hydrogen embrittlement; ③ Sealing performance: adopt dry gas seal technology to ensure zero leakage; ④ Efficiency under high pressure: prioritize equipment integrated with real gas equations of state (such as BWRS equation) for power calculation, ensuring calculation accuracy within ±1.5% and optimizing energy efficiency.

Conclusion

Compressor power optimization is a system engineering integrating thermodynamics, materials science, and digital technology. MINNUO, with over 200 successful global cases, offers a complete solution from precise calculation to intelligent optimization. We invite industry partners to explore energy efficiency limits and support achieving the “dual carbon” goals.

Email

Email sales:+86 15366749631

sales:+86 15366749631