When Atlas Copco set up a 3-billion-yuan Wuxi base in the Yangtze River Delta, and when Honeywell acquired Shengdaine for 15.6 billion yuan to target the oil and gas sector, with the manufacturing section undergoing intelligent transformation and the service section extending value, China’s compressor industry is experiencing a triple transformation in technology, policy and capital. Under the strict background of the new national standard GB 19153-2025 raising the energy efficiency red line by 15%, this transformation interwoven with the strategic positioning of international giants and the domestic energy efficiency revolution has elevated compressors from power units to the “carbon efficiency heart” of the manufacturing industry.

This article addresses two core concerns of enterprises: How to leverage magnetic levitation/frequency conversion technology to bridge the energy efficiency gap of the new national standards? How to select truly reliable partners in the wave of intelligence? The answer lies in MINNUO’s full industrial chain technology closed loop and vertical industry solution library – from the precise control of -70℃ dew point in semiconductors to the 0.001ml/min leakage prevention standard for hydrogen energy compression, Chinese solutions are redefining the rules of the game in high-end manufacturing.

A certain German car factory suffered a 20% surge in the defect rate of spray painting due to a pressure fluctuation of 0.08MPa, resulting in a daily loss of 480,000 euros. TSMC lost orders worth tens of millions of dollars due to the scrapping of wafers caused by a ±3℃ fluctuation in the dew point of traditional compressors. The competition in high-end manufacturing has entered an era of war between micropascal (pressure) and microgram (oil content). The following text will describe how MINNUO has built this “energy efficiency lifeline” for global customers with a magnetic levitation accuracy of 0.001mm and a 2-hour ultra-fast response service network.

1. New trends in the development of the compressor industry

1.1 Technology Integration and in-depth exploration of scenarios

In May 2025, Atlas Copco officially launched a compressor technology park with an investment of 3 billion yuan in Wuxi. In response to China’s equipment renewal policy, it introduced a “variable frequency screw compressor + photovoltaic energy storage” linkage system. In the application of a certain automobile factory in the Yangtze River Delta, the proportion of grid electricity consumption decreased by 45%, and the annual electricity cost savings exceeded 2 million yuan. These major measures demonstrate its firm confidence in the Chinese market and the future of the compressor industry, and also reflect from the side that the compressor industry still holds huge potential for development.

Meanwhile, Honeywell acquired Sundyne, targeting the oil and gas and petrochemical industries. It integrated its high-speed centrifugal compressor technology and launched “zero leakage” compressor units suitable for the hydrogen energy sector. This product adopts magnetic drive technology. In the actual measurement at hydrogen refueling stations, energy consumption has been reduced by 18%. Moreover, through the blockchain traceability system, the full life cycle management of refrigerants has been achieved. This acquisition move further highlights the key position of compressors in the industrial field and their broad market prospects.

1.2 Intelligent Transformation of the manufacturing end

Hitachi Compressor (Suzhou) has achieved a 40% reduction in carbon emissions during its production process through 56+ digital twin technology. Its medical-grade oil-free compressor adopts liquid spray cooling technology, reducing vibration noise by 15%. Relying on the Changjiao supply chain, it achieves “R&D in China and global supply”, and the proportion of export orders has increased to 35%. Danfoss has adjusted its production lines in China, increasing the capacity of R290 scroll compressors by 50%. Its “intelligent oil return control technology” addresses the efficiency shortcomings of natural working fluids in scenarios with small temperature differences, adapting to the diverse demands of the domestic cold chain.

1.3 Value Extension of Service Model

Ingersoll Rand has collaborated with Huawei to develop the “56 + Edge Computing” compressed air management system, responding to the new national standard’s requirement for “real-time monitoring of system energy efficiency”. This system optimizes the operating parameters of equipment through AI algorithms. In the actual tests conducted in electronic factories in the Pearl River Delta, the comprehensive energy efficiency has increased by 22%, and the maintenance cost has decreased by 30%. Atlas Copco has launched an “Energy Efficiency Management Service”, where customers pay based on the amount of compressed air used, and suppliers are responsible for optimizing the entire life cycle. The average energy-saving benefit reaches 15%.

With the continuous advancement of global industrialization, the demand for compressors in traditional industries such as oil and gas and petrochemicals not only remains stable but is also constantly upgrading towards high efficiency, energy conservation and intelligence. This series of industry trends clearly indicates that the compressor industry is at a critical period of rapid development and transformation.

2. Recommendations and Guidance under the New National Standards

The new version of China’s “Minimum Energy Efficiency Limits and Energy Efficiency Grades for Positive Displacement Air Compressors” (GB 19153-2025) was officially implemented in April 2025. This policy has had a profound impact on the compressor industry. This standard has raised the overall energy efficiency limit value by 10% to 15%, clearly guiding the industry to transform towards high-efficiency directions such as magnetic levitation and frequency conversion technology. As the original manufacturer of the product, MINNUO has the responsibility and ability to provide relevant recommendations and guidance to customers.

2.1 Magnetic Levitation Compressor Recommendation

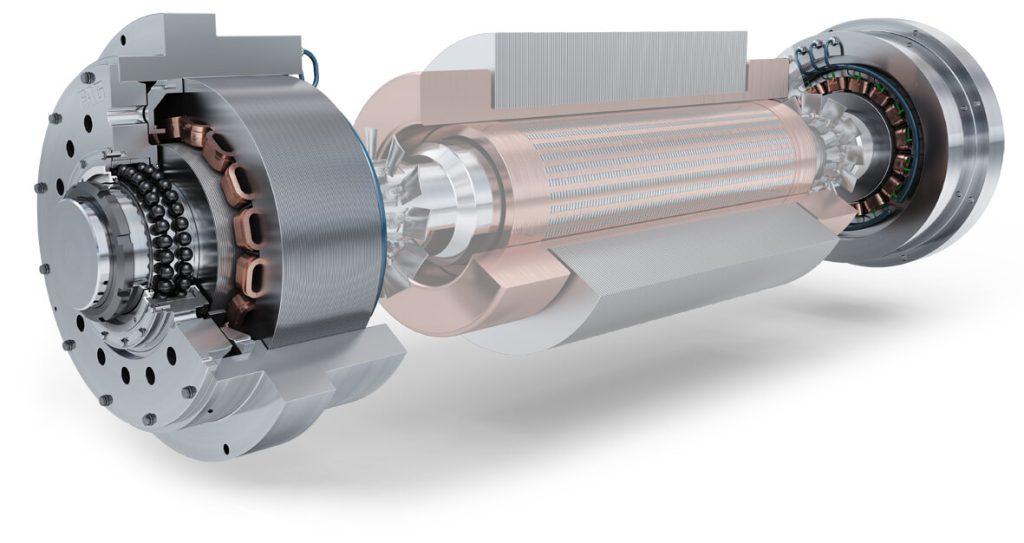

The magnetic levitation compressor adopts advanced magnetic levitation bearing technology, enabling the rotor to rotate at high speed without contact, significantly reducing mechanical friction losses and thus greatly enhancing the efficiency of the compressor. Compared with traditional compressors, the energy efficiency of magnetic levitation compressors can be increased by 20% to 30%, featuring significant energy-saving effects, high operational stability and low noise. For customers with high requirements for energy consumption and strict demands for operational stability, such as large data centers and semiconductor manufacturing enterprises, magnetic levitation compressors are the ideal choice. The magnetic levitation compressor independently developed by MINNUO is at the leading level in the industry in terms of technical performance. It adopts advanced permanent magnet synchronous motor technology and intelligent control system, which can precisely control the operating status of the compressor and ensure that the equipment is always in an efficient operating state.

2.2 Recommendations for Variable Frequency Compressors

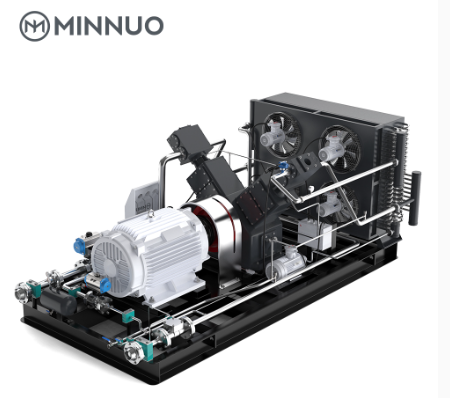

Variable frequency compressors control the exhaust volume of the compressor by adjusting the motor speed, and can automatically adjust the operating power of the compressor according to the actual gas demand, avoiding energy waste during loading and unloading in traditional compressors. The energy efficiency of variable-frequency compressors can be increased by 10% to 20% compared with that of ordinary fixed-frequency compressors, and the energy effect is particularly significant during partial load operation. For customers with large fluctuations in gas demand, such as pharmaceutical enterprises and food and beverage enterprises, variable frequency compressors can better meet their production needs and reduce production costs. MINNUO’s variable frequency compressors, equipped with high-performance frequency converters and advanced control algorithms, can quickly and accurately respond to changes in customers’ gas demands, achieving efficient and stable operation of the compressors.

2.3 Provide customers with energy efficiency upgrade solutions

In addition to recommending highly efficient and energy-saving compressor products, MINNUO can also provide customers with comprehensive energy efficiency upgrade solutions. Organize a professional technical team to conduct a comprehensive assessment of the customer’s existing compressor system, including aspects such as equipment operation status, energy consumption level, and gas demand. Based on the assessment results, personalized energy efficiency upgrade plans will be formulated for customers. The plans may include measures such as equipment replacement, system optimization, and intelligent control transformation. For some old compressor equipment, it is recommended that customers directly replace it with high-efficiency and energy-saving products that meet the requirements of the new national standards. For some equipment that still has practical value, intelligent control transformation can be carried out on it, such as installing an intelligent control system, to achieve real-time monitoring and optimized regulation of the equipment’s operating status, and improve the energy utilization efficiency of the equipment. During the implementation of the plan, MINNUO will provide the customer with full technical support and services to ensure the smooth implementation of the energy efficiency upgrade plan, help the customer achieve the goal of energy conservation and emission reduction, and enhance the economic and social benefits of the enterprise.

3. Key considerations for choosing an intelligent compressor factory

With the wave of intelligent upgrading in compressor production sweeping in, customers need to carefully consider from multiple key dimensions when choosing a cooperative factory.

3.1 Technological innovation capacity

Factories with strong technological innovation capabilities can closely follow the development trends of cutting-edge technologies in the industry and continuously launch innovative products. For instance, in the field of intelligent control technology, more advanced intelligent control systems can be developed to achieve precise monitoring and regulation of the operating status of compressors. Through sensors, key data such as the pressure, temperature and rotational speed of the compressor are collected in real time, and advanced algorithms are used for in-depth analysis, thereby automatically optimizing the operating parameters of the compressor to keep it in the best working condition at all times. This not only significantly enhances the energy utilization efficiency of the compressor and reduces energy consumption, but also effectively extends the service life of the equipment and reduces the probability of equipment failure.

3.2 Product quality reliability

Product quality is the lifeline of an enterprise, and this is especially true for compressors. Particular attention should be paid to whether the factory has established a complete and strict quality control system. From the procurement stage of raw materials, strict screening and testing are carried out on each batch of raw materials to ensure that their quality meets high standards. During the production and processing, advanced manufacturing techniques and precision processing equipment are adopted to conduct meticulous processing on each component of the product, strictly controlling the dimensional accuracy and surface quality of the product. In the processing of the core component of the compressor – the compressor rotor, high-end equipment such as five-axis linkage machining centers are used to ensure that the dynamic balance accuracy of the rotor reaches the industry-leading level, thereby effectively reducing the vibration and noise during the operation of the compressor and improving the stability and reliability of the product.

3.3 Customized Service level

The demands for compressors vary greatly among different industries and customers. Therefore, the customized service level of the factory is of vital importance. A professional pre-sales technical team should be capable of promptly engaging in in-depth communication with customers, comprehensively and meticulously understanding their usage scenarios, process requirements, budget constraints and other detailed information. Then, based on the specific needs of the customers, we will tailor personalized compressor solutions for them. During the implementation of the plan, the after-sales team should follow up throughout the process and provide one-stop services including installation and commissioning, operation training, maintenance and upkeep. For the special process flow of a certain chemical enterprise, a compressor with explosion-proof function and strong corrosion resistance was customized for it, and professional technicians were arranged to guide the installation and commissioning on site to ensure that the equipment could be put into use smoothly. At the same time, provide systematic and detailed operation training and maintenance knowledge training for enterprise operators to help enterprises improve equipment management levels and reduce the risk of equipment failure.

3.4 Degree of Digitalization and Intelligence

In today’s digital age, the degree of digitalization and intelligence of compressor factories directly affects their production efficiency and product quality. A factory with a high degree of digitalization and intelligence can achieve automated and information-based management of the production process. By deploying a large number of sensors and intelligent devices on the production line to collect production data in real time and using big data analysis technology to process and analyze the data, precise control and optimization of the production process can be achieved. In the compressor assembly process, technologies such as RFID (Radio Frequency Identification) and machine vision are utilized to achieve automatic identification and precise assembly of components, thereby enhancing assembly efficiency and quality. Meanwhile, by establishing an intelligent production management system, intelligent scheduling and management of production plans, material distribution, equipment maintenance, etc. can be carried out, significantly enhancing production efficiency and reducing production costs.

4.MINNUO’s market advantages and professional capabilities

As a leading enterprise in the compressor field, MINNUO has accumulated profound technical expertise and service experience over its long-term development. These advantages not only serve as the foundation for the company to stand firm in the market but also bring tangible and visible value to customers.

4.1 Full industrial chain technology closed-loop capability

MINNUO has established a full industrial chain technology system covering core technology research and development to the launch of terminal products, achieving independent control in key links such as efficient compression, intelligent control, and precision manufacturing. For instance, the independently developed magnetic levitation bearing technology has broken the foreign monopoly. Its rotor levitation accuracy can reach 0.001mm, which is 50% higher than the industry average. This means that the mechanical loss of the compressor during operation is reduced by more than 30%, directly reducing the energy cost for customers by 15% to 20%. In the field of variable frequency control, MINNUO’s independently developed vector variable frequency algorithm has a response time of 0.1 seconds, which can precisely match the fluctuations in customers’ gas load and avoid the energy waste of traditional equipment such as “a big horse pulling a small cart”. After a certain auto parts manufacturer applied it, the monthly energy consumption of the air compressor on a single production line was reduced by 8,000 kilowatt-hours.

This technical closed-loop capability not only brings performance advantages to the product, but also provides customers with a “technical safety net” guarantee. When customers encounter special working conditions, MINNUO can quickly mobilize resources throughout the entire chain, including R&D, production, and testing. For instance, the ultra-clean compressor customized for semiconductor industry customers, through its independently developed oil-free lubrication system and multi-stage filtration technology, achieves a compressed gas dew point of ≤-40℃ and a particle size of ≤0.1μm. It fully meets the Class 5 cleanroom standards for chip manufacturing and shortens the delivery cycle by 40% compared to competing products that rely on external technology integration.

4.2 Full life cycle service ecosystem

MINNUO has established a service network covering the entire life cycle of equipment, from “selection – installation – operation and maintenance – upgrade”. It has set up 28 regional service centers across the country and is equipped with over 500 certified engineers, capable of fulfilling the service commitment of responding within 2 hours and arriving within 24 hours. This service density brings about a significant reduction in downtime costs for customers A customer in a certain chemical industrial park in Southeast Asia once encountered a sudden compressor failure. MINNUO engineers arrived at the scene within 1.5 hours. Through the intelligent diagnostic terminal they carried, they quickly located the bearing wear problem and completed the replacement and debugging within 4 hours. Compared with the industry average of 12 hours for emergency repair, they saved the customer nearly 100,000 yuan in downtime losses.

During the operation and maintenance stage, MINNUO’s Internet of Things monitoring platform can collect real-time operation data of equipment and predict potential faults through AI algorithms. Data shows that for customers who have connected to this platform, the number of unplanned equipment outages has decreased by 60%, and the average failure interval has been extended to over 18 months. For old equipment, MINNUO also offers an “Energy Efficiency upgrade package” service. Through renovations such as replacing the frequency conversion module and optimizing the flow channel design, the energy efficiency of the equipment can be increased by 10% to 15%, helping customers meet the new national standards without replacing the entire machine. A certain food processing plant has undergone such renovations The first-level energy efficiency standard was achieved by investing only 30% of the cost of a new machine.

4.3 Customized Solution Library for Vertical Industries

Based on a deep understanding of over 30 niche industries, MINNUO has accumulated more than 100 mature customized solution templates. For the hydrogen compression scenario in the new energy battery industry, an explosion-proof diaphragm compressor has been developed, with a leakage rate of ≤0.001ml/min, far lower than the industry standard of 0.01ml/min, ensuring production safety. The silent air compressor customized for the medical industry, through acoustic wrapping and shock absorption design, has an operating noise as low as 55 decibels, equivalent to the volume of a normal conversation, solving the noise problem in hospital consultation rooms.

This industry-deep cultivation capability enables customers to avoid having to “pay” for general-purpose products. A certain biopharmaceutical customer, by adopting MINNUO’s “compressed air + purified water” integrated solution, reduced system integration costs by 25% compared to the model of purchasing a single device and then combining them, saved 30% of the floor space, and avoided compatibility issues with equipment of different brands.

4.4 Cost control and value balance capabilities

Relying on the advantages of large-scale production and supply chain management, MINNUO has achieved cost optimization while ensuring high quality. By building its own precision casting factory, the procurement cost of core components has been reduced by 18% compared with external purchases. By adopting an intelligent production scheduling system, production efficiency has been increased by 25%. These cost advantages eventually translates into purchasing value for customers. For the same configuration of magnetic levitation compressors, MINNUO is 30% cheaper than imported brands, but its mean time between failures (MTBF) reaches 40,000 hours, which is on par with imported products.

In a distributed energy project of a certain logistics park, through comparative tests, it was found that although the initial purchase price of MINNUO’s variable frequency screw compressor was 10% higher than that of a certain domestic brand, due to its high operating efficiency and low maintenance cost, the total cost throughout its life cycle (10 years) was actually 18% lower, fully demonstrating the value balance ability behind “cost performance”.

Compared with the over a hundred years of brand accumulation of some international giants, MINNUO still has room for improvement in brand recognition in the global market, especially in the high-end markets of Europe and America, where channel penetration is still in progress. However, this has also prompted MINNUO to serve overseas customers with a more flexible cooperation model. For instance, it offers a “equipment + energy consumption guarantee” cooperation for European customers, promising that if the actual energy consumption exceeds the value stipulated in the contract, the difference will be borne by MINNUO. This pragmatic cooperation attitude has helped the company establish its first batch of benchmark customers in markets such as Germany, Southeast Asia, and the Middle East.

Conclusion

The billion-yuan layout of Atlas and Honeywell has confirmed the strategic value of the Chinese compressor market. The implementation of the new national standard GB 19153-2025 further announces that the ultimate battlefield of the energy efficiency competition is in China. While international giants build walls with capital and technology, MINNUO breaks the deadlock with “technology as a safety net + service penetration” – from the domestic substitution of magnetic levitation bearings (reducing costs by 30%) to the establishment of a 2-hour rescue circle with 28 service centers, the full life cycle service ecosystem of Chinese enterprises is becoming the new infrastructure of global manufacturing.

Email

Email sales:+86 15366749631

sales:+86 15366749631