In industrial applications, the selection of an air compressor significantly impacts the efficiency, stability, and long-term economic performance of the system. Proper compressor selection not only determines the performance and reliability of the equipment but also directly affects its adaptability and optimization in specific tasks. Below, we provide a detailed air compressor selection guide.

Selecting an air compressor requires a comprehensive consideration of pneumatic equipment needs, working pressure, flow rate (CFM), power (HP/kW), duty cycle, and future expansion to ensure efficient and stable operation. Matching the appropriate capacity and air quality requirements can optimize energy utilization and reduce long-term costs. Over- or under-sizing can negatively impact performance and economic efficiency.

1. Air Compressor Specification Selection Process

Determining the specifications of an air compressor should follow a systematic series of steps to ensure the selected equipment meets current and future application needs.

1.1 Determine Pneumatic Requirements for Tools and Equipment

The first step in selection is accurately identifying and evaluating the tools and equipment that will be used with the compressor. Each pneumatic tool has different requirements for the compressor, so it is essential to list the following parameters for each tool:

- Air Flow Requirement (CFM): The air flow rate (in cubic feet per minute) required for each tool or equipment during operation. This is one of the key factors in determining compressor selection.

- Working Pressure Requirement (PSI): The minimum pressure required by the pneumatic tool, measured in pounds per square inch (PSI). Pressure requirements vary depending on the type of tool and the nature of the task. Accurate calculation of the required pressure ensures efficient operation of the tool.

1.2 Evaluate Duty Cycle and Load Requirements

Evaluating the duty cycle of tools or equipment is crucial for selection. The frequency of use and continuous operation time of the tools determine the power and capacity required for the compressor:

- Continuous Operation Tools: Such as large industrial equipment and pneumatic tools, typically require the compressor to provide continuous air output over long periods, avoiding frequent shutdowns.

- Intermittent Operation Tools: Such as occasionally used pneumatic equipment, may allow for a smaller capacity compressor, but it must maintain stable performance during high-load operation.

1.3 Consider Future Load and Expansion Needs

In addition to current application needs, future potential demand growth should be anticipated. Selecting a compressor that can accommodate future loads can avoid frequent equipment replacements and improve return on investment. By reserving some margin, the compressor can effectively meet future needs when additional tools or tasks are introduced. MINNUO will also take this into account when providing solutions for you.

2. Air Compressor Selection Criteria

The following technical parameters are key considerations in air compressor selection:

2.1 Air Flow Rate (CFM)

Air flow rate refers to the amount of air the compressor can deliver per unit of time, usually expressed in cubic feet per minute (CFM). Insufficient air flow can cause the compressor to start and stop frequently, leading to system inefficiency and energy waste. Excessive flow, on the other hand, may result in over-investment and energy waste. Therefore, accurately matching the flow rate with application requirements is key to ensuring efficient compressor operation.

2.2 Working Pressure (PSI)

Working pressure is another important parameter affecting compressor performance. Different applications have different pressure requirements. For example, high-pressure applications (such as pneumatic tools and spray equipment) typically require higher pressure, while some low-pressure applications (such as cooling and pneumatic handling) have lower pressure requirements. During selection, it is essential to ensure the compressor can provide sufficient pressure to meet the needs of all tools or equipment.

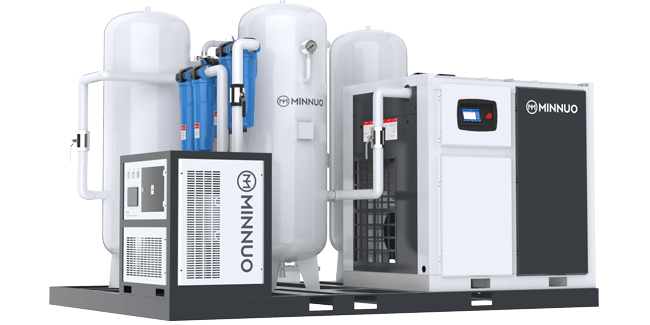

2.3 Application Environment and Air Quality Requirements

For certain specific applications, air quality may significantly impact equipment lifespan or production processes. In such applications, the compressor not only needs to provide stable air flow and pressure but should also be equipped with appropriate air purification systems, such as dryers, oil-water separators, and filters. These additional devices can effectively remove moisture, oil, and impurities from the air, ensuring stable operation of the compressor system.

2.4 Power (HP / kW)

The power of the compressor (usually expressed in horsepower (HP) or kilowatts (kW)) is also a consideration in selection, though it is generally not the primary decision criterion. Power is closely related to flow rate and pressure. Selecting the appropriate power ensures the compressor maintains stable output during load fluctuations or high-intensity operations. Insufficient power can cause the compressor to overload under high loads, while excessive power may lead to energy waste.

3. Air Compressor Capacity and Flow Rate

In the selection process, correctly understanding the difference between capacity and flow rate is crucial for proper compressor configuration:

3.1 Capacity

The capacity of an air compressor refers to the total amount of compressed air it can store, usually measured in gallons or liters. Capacity determines how much air the compressor can store in the short term, affecting its operating cycle and emergency capability. A large-capacity compressor can provide longer continuous output, suitable for applications requiring long-term stable operation.

3.2 Flow Rate

Air flow rate refers to the amount of compressed air the compressor can deliver per unit of time, usually expressed in CFM. Flow rate is a core parameter affecting the actual working efficiency of the compressor and should match the working load requirements of the actual tools. The flow rate directly determines the operating efficiency of the tools and the speed of task completion.

To more accurately assess flow rate requirements, it is recommended to use technical data sheets provided by equipment manufacturers or invite professional sales engineers to conduct a detailed “compressed air assessment” during the actual selection process. Of course, if you choose MINNUO, we will provide a free assessment for you.

4. Considerations in Actual Selection

When selecting a compressor, the following practical factors should also be considered:

4.1 Pressure (PSI)

Based on the nature of the tasks and tool requirements, select an appropriate pressure range. Insufficient pressure can lead to low work efficiency and failure to meet application needs, while excessive pressure may increase equipment wear and energy consumption.

4.2 Flow Rate (CFM)

Considering the actual scenarios of multiple tasks operating in parallel, choose a compressor that can support the maximum air flow demand. Insufficient flow rate can cause the compressor to start and stop frequently, interrupting operations and affecting overall work efficiency.

4.3 Undersized Compressor

An undersized compressor may fail to maintain the required pressure, affecting task completion. Prolonged pressure fluctuations or overload operation can damage the compressor system.

4.4 Oversized Compressor

An oversized compressor may lead to mechanical failures or maintenance issues. Oversizing not only causes energy waste but may also result in slow system response or unstable operation.

5. Conclusion

In conclusion, proper air compressor selection requires comprehensive consideration of specific application needs, operating environment, and future expansion requirements. Through a scientific selection process, the efficiency, reliability, and economic performance of the compressor system can be effectively improved.

As a professional air compressor manufacturer, MINNUO not only has an experienced technical team but also provides free customized gas solutions for you. Contact us today!

Email

Email sales:+86 15366749631

sales:+86 15366749631