In the fields of environmental governance and specialty gas applications, nitrogen plays an indispensable role. SCR/SNCR denitrification systems require stable nitrogen to ensure atomized reductant injection; wastewater treatment relies on nitrogen for tank inerting and corrosion prevention; and high-pressure cylinder filling and tire inflation demand extremely high nitrogen purity and pressure stability. As the core equipment for nitrogen delivery and pressure regulation, the performance of nitrogen booster compressors directly determines environmental compliance, operational safety, and operational efficiency. Traditional single-purpose compressors often face problems such as poor adaptability, insufficient purity, and weak safety protection, making it difficult to meet the needs of multi-scenario collaboration. Jiangsu Minnuo Group, with 37 years of experience in compressor manufacturing, has developed nitrogen booster compressors that, with their core advantages such as dual-scenario adaptability, oil-free cleanliness, and comprehensive safety protection, have become an “all-around reliable partner” in the fields of environmental governance and specialty gas applications. This article will explain in detail why nitrogen booster compressors can become a “hardcore support” for dual-line operations from the perspectives of technical principles, core advantages, and application scenarios.

Technology Popularization: The Core Principle of “Dual-Scenario Adaptation” of Nitrogen Boosting Compressors

The demand for nitrogen in environmental protection and specialty gas applications exhibits significant differences: environmental protection scenarios (such as SCR/SNCR denitrification) require a low-pressure, high-flow, continuous, and stable nitrogen supply; while specialty scenarios (such as high-pressure cylinder filling) require a high-pressure, low-flow, and high-purity nitrogen output. The reason why nitrogen booster compressors can achieve precise adaptation to both scenarios lies in their integrated technology of three-stage boosting + oil-free sealing + intelligent control.

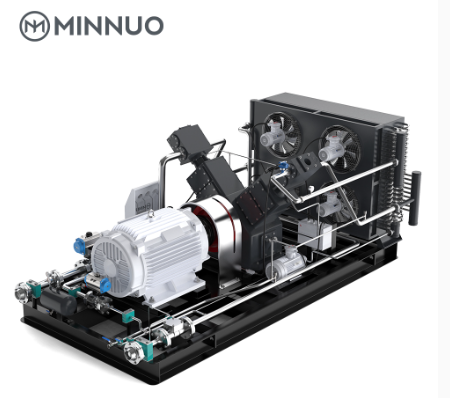

Traditional compressors are mostly designed for a single pressure level, which cannot simultaneously meet the needs of continuous low-pressure gas supply and high-pressure filling. Furthermore, some use oil-lubricated structures, which can easily lead to nitrogen contamination, reducing purity to below 95%, making them unsuitable for purity-sensitive applications such as tire inflation and precision industries. In contrast, Jiangsu Minnuo’s nitrogen booster compressor adopts a “three-stage high-pressure compression module” design. Through three-stage piston progressive compression, it can achieve a wide pressure adjustment range of 1.0–35.0 MPa: it can output low-pressure nitrogen of 1.0–2.5 MPa to meet the continuous gas supply needs of SCR/SNCR denitrification and wastewater treatment; it can also boost the pressure to 15.0–35.0 MPa to complete high-pressure cylinder filling, truly achieving “one machine for two uses.”

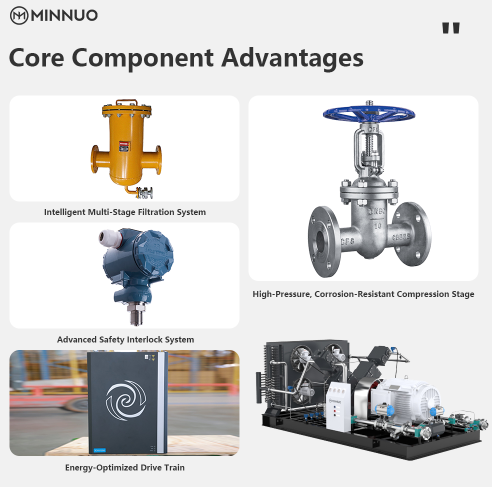

To ensure nitrogen purity of ≥99.9%, the equipment employs an innovative “oil-free piston + sealing system” design: a self-lubricating material seals the piston against the cylinder wall, eliminating the need for lubricating oil and preventing oil contamination at the source; coupled with a multi-stage filtration system, it effectively removes oil, particulate matter, and moisture, further purifying the nitrogen and ensuring clean, impurity-free output gas. This characteristic is particularly crucial in tire inflation scenarios—high-purity, dry nitrogen prevents internal tire oxidation and corrosion, extending tire life and improving driving safety.

In addition, the equipment is equipped with an industrial-grade PLC intelligent control system, which can monitor parameters such as pressure, flow rate, and temperature in real time. It automatically adjusts the compression power through variable frequency technology (VFD): increasing the speed to ensure air supply in low-pressure, high-flow scenarios, and reducing the speed to save energy in high-pressure, low-flow scenarios. It also supports seamless integration with the factory’s DCS system to achieve remote monitoring and automatic start-up and shutdown, fully adapting to the needs of 24-hour continuous operation.

Core Advantages: Precisely meets the stringent requirements of dual scenarios

Environmental protection and specialty gas applications place multi-dimensional demands on compressors: they must meet the corrosion resistance, continuous operation, and compliance requirements of environmental scenarios, while also adapting to the high-pressure stability, high purity, and safety protection needs of specialty scenarios. Jiangsu Minnuo’s nitrogen booster compressor precisely matches these dual requirements across key indicators, demonstrating multiple core advantages.

1. Dual-scenario adaptation: One device covers all needs, reducing overall costs.

The equipment’s pressure adjustment range covers 1.0–35.0 MPa, and the flow rate can be flexibly adjusted between 5–300 Nm³/h, perfectly matching two core scenarios: In environmental protection scenarios, the low-pressure output of 1.0–2.5 MPa and the high flow rate of 50–300 Nm³/h can meet the atomization requirements of reducing agent in SCR/SNCR denitrification systems and the inerting requirements of wastewater treatment tank areas; In special scenarios, the high-pressure output of 15.0–35.0 MPa and the flow rate of 10–100 Nm³/h can efficiently complete high-pressure cylinder filling, while the pressure of 1.0–1.6 MPa and the flow rate of 5–50 Nm³/h are suitable for inflating automotive and aviation tires. This “dual-purpose” design avoids companies from repeatedly purchasing equipment, significantly reducing initial investment and subsequent maintenance costs.

2. Clean and oil-free: 99.9% high purity, ensuring safety in the environment.

Nitrogen purity directly affects application performance and safety: In SCR/SNCR scenarios, impurities can clog the injection nozzles; in tire inflation scenarios, oil mist and moisture can cause tire aging; in cylinder filling scenarios, contaminated nitrogen can affect industrial or medical applications. Jiangsu Minnuo’s nitrogen booster compressor uses an oil-free piston and sealing system, combined with a multi-stage filtration module, to achieve 100% oil-free compression, ensuring nitrogen purity ≥99.9%. Simultaneously, the gas path contact components are made of 316L stainless steel, possessing extremely strong corrosion resistance, preventing component corrosion caused by humid, acidic, or alkaline environments in wastewater treatment scenarios, further ensuring gas cleanliness.

3. Safe and reliable: Multiple layers of protection, suitable for high-risk scenarios.

Both high-pressure filling and environmental remediation scenarios present safety risks: high-pressure nitrogen leaks may trigger physical explosions, and improper inerting in wastewater treatment tank areas can lead to gas accumulation. The equipment is equipped with a comprehensive safety protection system: dual overpressure protection via electronic pressure relief valves and mechanical safety valves, with a rupture disc as a final safety backup, automatically releasing pressure immediately if it exceeds the limit; temperature sensors and gas detectors monitor the operating status in real time, automatically shutting down and alarming in case of abnormalities; and a PLC-controlled pressure-gradient filling program prevents cylinder damage caused by sudden pressure changes during high-pressure filling. Furthermore, the equipment complies with international pressure equipment standards such as CE, PED, and ASME, boasting a high overall protection level and enabling safe operation in high-risk environments such as chemical plants and ports.

4. Corrosion resistant and durable: Suitable for harsh working conditions, extending service life.

Environmental protection and special-purpose environments often present complex and harsh conditions: wastewater treatment workshops are humid and prone to salt spray, chemical industrial parks contain corrosive gases, and port environments have high humidity. Jiangsu Minnuo’s nitrogen booster compressors utilize 316L stainless steel for their core components (gas lines, pistons, and seals), with anti-corrosion treatment to withstand corrosion from acids, alkalis, salt spray, and other corrosive media. A rigid base paired with shock absorbers reduces wear and tear on components due to operational vibrations. The equipment boasts a long design life, supports 24-hour continuous operation, and has extended maintenance intervals, significantly reducing downtime maintenance costs. It is particularly suitable for scenarios requiring uninterrupted operation, such as SCR/SNCR denitrification and gas cylinder filling stations.

5. Energy-efficient and high-performance: Intelligent control reduces operating costs.

In environmental protection and special scenarios, nitrogen usage often involves long-term continuous operation, making energy consumption a key concern for enterprises. The equipment is equipped with a high-efficiency motor and optional VFD inverter technology, which automatically adjusts the operating power according to actual gas demand: reducing speed during low-load scenarios (such as tire inflation intervals) and increasing speed during high-load scenarios (such as continuous SCR/SNCR operation), resulting in energy savings of over 20% compared to traditional fixed-speed compressors. Simultaneously, the optimized compression duct design reduces airflow resistance, resulting in high isentropic efficiency and significantly reduced energy consumption per unit gas (kWh/Nm³), leading to substantial savings in electricity costs over the long term.

Application scenarios: covering core areas of environmental protection and special projects

With its core advantages of being adaptable to dual scenarios, clean and safe, energy-saving and durable, nitrogen booster compressors have been widely used in many key scenarios of environmental protection and special gas applications, providing customized solutions for different needs.

1. SCR/SNCR denitrification system: stable gas supply, ensuring environmental compliance.

SCR/SNCR denitrification systems in thermal power and chemical plants require a continuous and stable supply of nitrogen to atomize reducing agents such as ammonia and inject them into the furnace. Interruptions in nitrogen supply or pressure fluctuations can lead to decreased denitrification efficiency, resulting in emissions exceeding standards and fines. Jiangsu Minnuo’s nitrogen booster compressor can output nitrogen at a low pressure of 1.0–2.5 MPa and a high flow rate of 50–300 Nm³/h, with pressure stability ≤ ±0.05 MPa, ensuring uniform atomization of the reducing agent and improving denitrification efficiency by more than 10%. Its 24-hour continuous operation design and intelligent alarm system prevent gas supply interruptions due to equipment failure, ensuring environmental compliance for enterprises. After adopting this equipment, a US power company experienced significantly improved operational stability of its denitrification system, with emissions consistently exceeding national standards and no fines incurred for exceeding limits.

2. Wastewater treatment: Corrosion prevention and inerting to ensure operational safety.

Anaerobic reactors and sludge storage tanks in wastewater treatment plants require nitrogen inerting to prevent the accumulation of flammable and explosive gases such as methane, and to avoid equipment corrosion caused by humid environments. The equipment outputs 99.9% high-purity nitrogen, which quickly replaces the air inside the tank, creating an inert environment and reducing the risk of explosion. Made of 316L stainless steel, it is moisture-resistant and corrosion-resistant, allowing for long-term stable operation in the harsh environment of wastewater treatment workshops. Its low-pressure, high-flow output is suitable for the inerting requirements of large storage tanks, and its operating noise is ≤75dB, meeting the environmental protection requirements of the workshop. After adopting this equipment, a wastewater treatment plant in a German chemical industrial park reduced the tank area’s safety accident rate to zero and lowered equipment corrosion maintenance costs by 40%.

3. High-pressure gas cylinder filling: Highly efficient and safe, meeting industrial needs.

Filling high-pressure nitrogen cylinders for industrial and medical applications requires compressing nitrogen to 15.0–35.0 MPa, placing extremely high demands on the pressure stability and safety of the equipment. Jiangsu Minnuo’s nitrogen booster compressor features a three-stage pressurization design that quickly reaches the target pressure, increasing filling efficiency by 30% compared to traditional equipment. Multiple overpressure protection measures and a pressure-gradient filling procedure prevent cylinder damage caused by sudden pressure changes during filling. 99.9% high-purity nitrogen ensures the quality of the filled gas, meeting the needs of industrial cutting, medical auxiliary, and other applications. A gas service company in Mexico increased its daily cylinder filling capacity from 50 to 75 cylinders after adopting this equipment, without any safety incidents, resulting in significantly improved customer satisfaction.

4. Automotive/Aircraft Tire Inflation: High-purity and dry, improving driving safety.

Nitrogen inflation reduces tire pressure fluctuations, extends tire life, and improves fuel efficiency, making it particularly suitable for the automotive and aerospace industries. The equipment outputs ≥99.9% high-purity dry nitrogen, free of oil mist and moisture, preventing internal rubber aging and steel wire corrosion. A pressure adjustment range of 1.0–1.6 MPa accommodates the inflation needs of different tire sizes, and stable flow ensures accurate tire pressure. At a port in Singapore, after adopting this equipment for inflating tires on dockside vehicles, tire replacement cycles were extended by 6 months, vehicle fuel consumption decreased by 5%, and operating costs were significantly reduced.

Selection Guide: How can businesses choose the right nitrogen booster compressor?

The performance of a nitrogen booster compressor directly determines the application effect, safety, and cost. When selecting a model, enterprises need to consider both scenario requirements and focus on the following four key dimensions:

1. Matching pressure and traffic requirements

Different scenarios have significantly different requirements for pressure and flow rate: SCR/SNCR denitrification requires low pressure (1.0–2.5MPa) and high flow rate (50–300Nm³/h), gas cylinder filling requires high pressure (15.0–35.0MPa) and low flow rate (10–100Nm³/h), and tire inflation requires medium pressure (1.0–1.6MPa) and medium flow rate (5–50Nm³/h). When selecting equipment, it is necessary to confirm whether the pressure and flow rate adjustment range of the equipment covers the core requirements to avoid application limitations due to parameter mismatch.

2. Verify purity and material compatibility

The purity requirements of the application scenario must be considered when selecting equipment: for tire inflation and medical cylinder filling, the purity must be ≥99.9%, and it is necessary to confirm whether the equipment has oil-free compression technology and a multi-stage filtration system; for sewage treatment and chemical applications, attention should be paid to the corrosion resistance of the material, and equipment with 316L stainless steel gas circuits should be given priority to avoid the impact of component corrosion on service life and gas purity.

3. Emphasize security and compliance certification

For both high-pressure and environmental protection scenarios, equipment must have comprehensive safety design and compliance qualifications: products that have passed international certifications such as CE, PED, and ASME should be selected; it should be confirmed whether the equipment is equipped with safety functions such as dual overpressure protection, temperature monitoring, and automatic shutdown. In particular, for high-pressure filling scenarios, special safety designs such as rupture discs and pressure gradient filling should be checked.

4. Focus on energy efficiency and after-sales service

For long-term continuous operation scenarios, energy-saving equipment should be prioritized: models that support VFD frequency conversion and have low unit energy consumption can significantly reduce electricity costs; pay attention to the equipment maintenance cycle and convenience, and choose products with long maintenance intervals and modular designs to reduce downtime losses. At the same time, examine the brand’s after-sales service capabilities to ensure global 72-hour spare parts delivery, remote diagnostics, and on-site technical support to avoid downtime due to equipment failure.

Conclusion: Nitrogen-Boosted Compressor – A “Versatile Power Engine” for Dual-Scenario Collaboration

Against the backdrop of increasingly stringent environmental regulations and the expanding applications of specialty gases, nitrogen booster compressors, as core equipment across various scenarios, are becoming crucial for enterprises to reduce costs, increase efficiency, and achieve compliant and safe operations due to their “dual-purpose” adaptability, high purity, and comprehensive safety. Jiangsu Minnuo Group, leveraging 37 years of experience in compressor manufacturing, has developed nitrogen booster compressors that perfectly meet the dual needs of environmental protection and specialty scenarios. These compressors achieve industry-leading levels in core indicators such as pressure regulation, purity control, and safety protection, and have passed multiple international certifications, making them a trusted choice for numerous companies worldwide.

In the future, with the upgrading of environmental standards and the diversification of special gas applications, nitrogen booster compressors will continue to develop towards being “more intelligent, more energy-efficient, and more adaptable.” Jiangsu Minnuo will continue to focus on technological innovation and optimize product design to provide more reliable solutions for scenarios such as SCR/SNCR denitrification, wastewater treatment, gas cylinder filling, and tire inflation, helping enterprises achieve the dual goals of environmental compliance and efficient and safe special operations, becoming an “all-around partner” for the coordinated development of both scenarios.

Email

Email sales:+86 15366749631

sales:+86 15366749631