Air compressor is indispensable in a wide range of industrial applications, such as manufacturing, mining, construction, electronics, and chemical industries. The primary function of an air compressor is to intake air from the atmosphere and compress it to a higher pressure, providing a source of high-pressure air for various industrial processes. The power consumption, operating pressure, and volumetric flow rate are the three most important parameters determining the performance of the air compressor.

Power refers to the electrical or mechanical energy required to drive the compressor, while operating pressure dictates the pressure of the compressed air output, and volumetric flow rate represents the volume of air compressed and discharged per unit of time. These three parameters are intricately linked, and their relationship impacts the compressor’s energy efficiency and overall operational cost. Understanding and optimizing the interaction between these parameters can lead to significant improvements in the energy efficiency and operational performance of air compressors.This paper aims to investigate the relationships between compressor power, operating pressure, and volumetric flow rate, highlighting the interdependencies between these variables and discussing optimization strategies for improving energy efficiency and reducing operational costs.

Basic Principles and Key Parameters of Air Compressors

Working Principle of Air Compressors

The basic working principle of an air compressor is to take in atmospheric air and compress it to a higher pressure using a mechanical mechanism. Depending on the compression method, air compressors can be classified into several types, including piston, screw, and centrifugal compressors. Regardless of the type, the fundamental operation involves air intake, compression, and discharge.

During the compression process, the air’s volume decreases while its pressure increases, thereby altering its state. Due to energy losses (such as friction and heat loss) during compression, the compressor requires a power source to drive the compression process and provide the necessary high-pressure air.

Key Parameters

The performance of an air compressor is determined by several key parameters, including:

- Volumetric Flow Rate ( Q ): This represents the volume of air taken in or discharged by the compressor per unit of time, typically measured in cubic meters per minute ( m³/min ). The volumetric flow rate is a key measure of the compressor’s capacity to deliver compressed air and directly impacts the load on the compressor.

- Operating Pressure ( P ): This refers to the pressure of the compressed air at the outlet of the compressor, typically measured in bar or megapascals (MPa). The operating pressure determines the required energy input and the type of application the compressed air can be used for.

- Power ( P_power ): The power consumption of the air compressor, measured in kilowatts (kW), represents the energy required to drive the compressor. Power consumption is a critical factor in assessing the compressor’s efficiency and energy cost.

Relationship Between Power, Operating Pressure, and Volumetric Flow Rate

The power consumption of an air compressor, its operating pressure, and the volumetric flow rate are closely interconnected. To better understand these relationships, we can perform a theoretical analysis.

Relationship Between Power and Volumetric Flow Rate

The volumetric flow rate is a primary factor in determining the power consumption of an air compressor. For a given operating pressure, the power consumption of air compressors is directly proportional to the volumetric flow rate. Specifically, as the flow rate increases, the compressor requires more power to maintain the same level of compression.

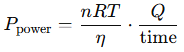

Assuming an ideal scenario where the compression process is isothermal (i.e., the temperature remains constant during compression), the relationship between power and volumetric flow rate can be expressed as:

where:

- P_power is the power (kW),

- n is the number of gas molecules,

- R is the gas constant,

- T is the gas temperature (K),

- η is the compressor efficiency,

- Q is the volumetric flow rate ( m³/min ).

This formula indicates that, at a constant operating pressure, an increase in volumetric flow rate will directly lead to an increase in power consumption. To meet higher air demand, the compressor must provide more compression power, which leads to higher energy consumption.

Relationship Between Power and Operating Pressure

Operating pressure is another critical factor that influences the power required by the compressor. As the operating pressure increases, the compressor must perform more work to compress the air to the desired pressure, resulting in higher power consumption.

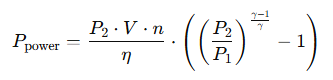

For an adiabatic compression process (where no heat is exchanged with the environment), the relationship between power and operating pressure can be expressed by the following formula:

where:

- P1 and P2 are the inlet and outlet pressures of the compressor,

- V is the volume of the gas,

- n is the number of moles of gas,

- γ is the specific heat ratio of the gas.

This equation shows that as the operating pressure P2 increases, the power required for compression grows exponentially. Specifically, as the compression ratio increases, the power requirement rises significantly. Therefore, choosing an appropriate operating pressure is critical to minimizing energy consumption.

Combined Effect of Volumetric Flow Rate and Operating Pressure

The combined effect of volumetric flow rate and operating pressure is common in real-world applications. Both the flow rate and the operating pressure impact the load on the compressor and, consequently, its power consumption.

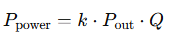

A general relationship that combines volumetric flow rate, operating pressure, and power consumption can be written as:

where:

- P_out is the outlet operating pressure,

- Q is the volumetric flow rate,

- k is a constant that accounts for gas properties and compressor efficiency.

This equation shows that both increasing the operating pressure and increasing the volumetric flow rate will lead to a significant rise in power consumption. Therefore, optimizing the balance between these two factors is key to reducing energy consumption and improving overall compressor performance.

Optimization Strategies in Practical Applications

Energy Efficiency Optimization

Energy efficiency is a critical factor in the operation of air compressors. As the power, operating pressure, and volumetric flow rate increase, the energy consumption rises significantly. Therefore, optimizing the relationships between these parameters is essential for reducing energy costs.

- Selecting the Right Operating Pressure: Although higher operating pressures can provide higher output air pressure, they also result in greater energy consumption. In practice, it is important to select an operating pressure that meets the actual demand without excessive margin, thus reducing unnecessary energy use.

- Controlling Volumetric Flow Rate: Excessively high volumetric flow rates can cause the compressor to operate under a heavy load, increasing power consumption. By adjusting the flow rate to match the actual needs of the process, energy consumption can be minimized.

Compressor Selection and Matching

When selecting an air compressor, it is important to consider the specific requirements of the application, including the desired operating pressure, flow rate, and energy efficiency. For applications with high flow demands, compressors capable of handling larger flow rates should be selected. Similarly, for applications requiring higher pressures, compressors designed for high-pressure outputs should be chosen. Properly matching these parameters ensures optimal performance and reduces the likelihood of energy waste.

Smart Control and Automatic Adjustment Systems

Modern air compressors feature advanced control systems that automatically adjust operating pressure and flow rate based on real-time demand. These systems monitor performance and make adjustments to optimize efficiency, ensuring peak performance and minimized energy consumption.

Conclusion

Power consumption, operating pressure, and volumetric flow rate are interrelated in air compressors, and understanding these relationships is key to optimizing performance and energy efficiency. Analyzing these parameters and applying optimization strategies can improve energy efficiency and reduce costs. As technology advances, the focus will shift towards smart control systems and energy-efficient designs to minimize consumption and enhance sustainability.

If you want to know more, please follow MINNUO, we will solve all your problems.

Email

Email sales:+86 15366749631

sales:+86 15366749631