We are experts in oil-free high-pressure piston compressor solutions.

30 years+ air compressor Manufacturer,We provide professional air compressor solutions.

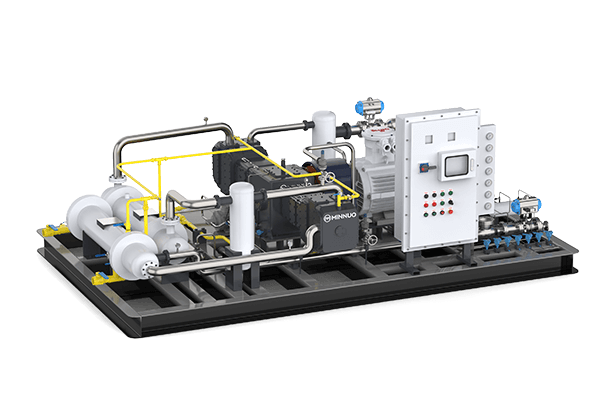

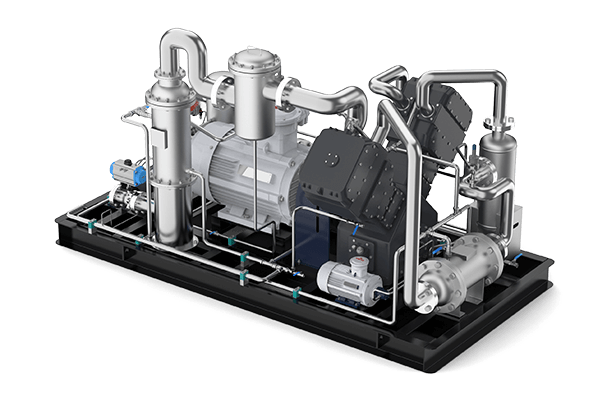

- Skid-mounted complete units

- Stable compressed air supply 24 hours a day

- ISO 8573-1 Class 0 oil-free certification

- Safe and reliable

Application of oil-free piston compressors

Discover the Key Differences in Application Areas

Traditional compressors often involve oil in the compression process, which can contaminate the gas, making it difficult to achieve 100% oil-free purity. MINNUO’s high-pressure oil-free piston compressors are designed to ensure clean gas and have achieved the ISO 8573-1 Class 0 oil-free certification, guaranteeing the highest level of air purity.

MINNUO high-pressure piston air compressors, on the other hand, are specifically designed to meet high-pressure demands. These compressors can compress gas to tens or even hundreds of atmospheres, making them ideal for industries that require high-pressure gas. For example:

- In medical equipment, devices like ventilators, anesthesia machines, and oxygen supply systems require clean, oil-free high-pressure air.

- In chemical and gas separation industries, high-pressure nitrogen, oxygen, and other gases are produced and transported.

- In laboratories and research environments, high-purity, high-pressure gas is required for experiments and analysis.

- For diving equipment and pressure chambers, they are used to fill and supply high-pressure gas.

- In the automotive spray painting and coating industries, high-pressure oil-free air is needed for precision spraying.

Providing professional high pressure oil-free piston air compressor solutions

Types of air compressors

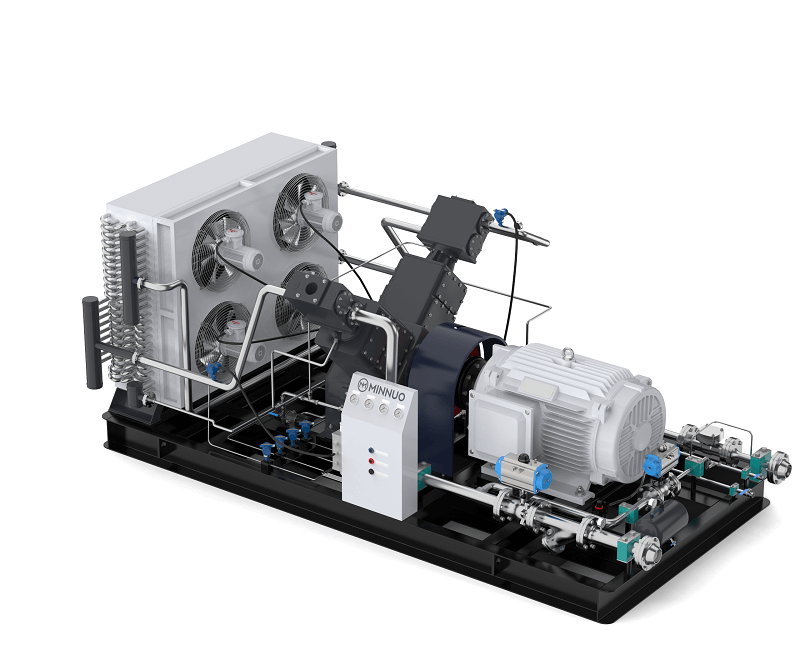

D SERIES

Compression medium: hydrogen, nitrogen, LPG,light hydrocarbon gas, ethylene, propylene, rich gas,analysis gas and other special gases.

- Working Power:30~90 KW

- Working Pressure:0.05/0.65~5.0/5.5 Mpa

- Treatment Capacity :3.0~91.8 NM3/H

| MODEL | INLET PRESSURE MPA(G) |

OUTLET PRESSURE MPA(G) |

NOMINAL VOLUME FLOW RATE NM3/H |

LUBRICATION METHOD |

POWER KW |

ROTATIONAL SPEED R/MIN |

|---|---|---|---|---|---|---|

| DW-3/0.5-6.5 | 0.05 | 0.65 | 3.0 | Oil-free | 45 | 420 |

| DW-57/27-30 | 2.7 | 3.0 | 57 | Oil-free | 37 | 420 |

| DW-10/10-25 | 1.0 | 2.5 | 10 | Oil-free | 45 | 420 |

| DW-10/2-8 | 0.2 | 0.8 | 10 | Oil-free | 45 | 420 |

| DW-4/0.5-7 | 0.05 | 0.7 | 4.0 | Oil-free | 45 | 420 |

| DW-6/6-16 | 0.6 | 1.6 | 6.0 | Oil-free | 45 | 420 |

| DW-32/8-16 | 0.8 | 1.6 | 32 | Oil-free | 90 | 420 |

| D3.5W-7/9-26 | 0.9 | 2.6 | 7.0 | Oil-free | 37 | 420 |

| DW-27.5/6.5-8 | 0.65 | 0.8 | 27.5 | Oil-free | 30 | 420 |

| DW-91.8/50-55 | 5.0 | 5.5 | 91.8 | Oil-free | 55 | 420 |

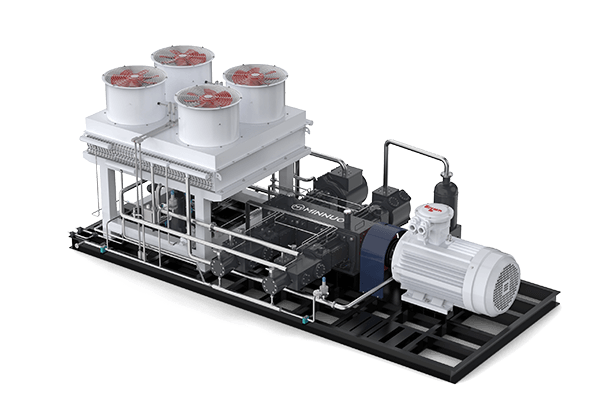

V SERIES

air-cooled and water-cooled

The transmission part adopts forward or reverse lubrication technology, and the piston and crosshead adopt semi-hydraulic or threaded connection technology.

- Working Power:185~4500 KW

- Working Pressure:1~3 Mpa

- Treatment Capacity :6~35 NM3/H

| MODEL | OUTLET PRESSURE MPA(G) |

NOMINAL VOLUME FLOW RATE NM3/H |

DIMENSION(L*M*H) | TOTAL WEIGHT KG |

|---|---|---|---|---|

| V-1.1/350 | 1.1 | 35 | 2800*1780*1600 | 2600 |

| V-3/250 | 3 | 25 | 2890*2300*1736 | 3000 |

| V-3/350 | 3 | 35 | 2890*2300*1736 | 3000 |

| VF-1/150 | 1 | 15 | 2500*1500*1500 | 2000 |

| VF-1/250 | 1 | 25 | 2500*1500*1500 | 2000 |

| VF-1/350 | 1 | 35 | 2500*1500*1500 | 2000 |

| VF-1/60 | 1 | 6 | 2500*1500*1500 | 2000 |

| VF-1.5/250 | 1.5 | 25 | 2500*1500*1500 | 2100 |

| VF-1.5/350 | 1.5 | 35 | 2500*1500*1500 | 2100 |

| VF-1.5/60 | 1.5 | 6 | 2500*1500*1500 | 2000 |

| VF-1.5/150 | 1.5 | 15 | 2500*1500*1500 | 2100 |

| VF-2/150 | 2 | 15 | 3000*1600*1600 | 2700 |

| VF-2/60 | 2 | 6 | 3000*1600*1600 | 2700 |

| VF-2/250 | 2 | 25 | 3000*1600*1600 | 2800 |

| VF-2/350 | 2 | 35 | 3000*1600*1600 | 2800 |

| VF-3/150 | 3 | 15 | 3000*1600*1600 | 2800 |

| VF-3/250 | 3 | 25 | 3000*1600*1600 | 2800 |

| VF-3/60 | 3 | 6 | 3000*1600*1600 | 2800 |

M SERIES

Compression medium: hydrogen, nitrogen, LPG,light hydrocarbon gas, ethylene, propylene, rich gas,analysis gas and other special gases.

- Working Power:355~3500 KW

- Working Pressure:0.006/0.3~0.6/8.0

- Treatment Capacity :40~1667 NM3/H

| MODEL | INLET RESSURE MPA(G) |

OUTLET PRESSURE MPA(G) |

NOMINAL VOLUME FLOW RATE NM3/H |

LUBRICATION METHOD |

POWER KW |

ROTATIONAL SPEED R/MIN |

|---|---|---|---|---|---|---|

| 4M40-420/0.06-3 | 0.006 | 0.3 | 420 | OIL-FREE | 1800 | 330 |

| 4M32-117/0.2-40 | 0.02 | 4.0 | 117 | OIL-FREE | 1400 | 330 |

| 4M32W-270/16 | 0.1 | 1.6 | 270 | OIL LUBRICATION | 2400 | 330 |

| 4M32W-100/80 | 0.1 | 8.0 | 100 | OIL LUBRICATION | 1600 | 330 |

| 4M32W-343/6-57 | 0.6 | 5.7 | 343 | OIL LUBRICATION | 2300 | 330 |

| 4M32W-185/0.2-25 | 0.02 | 2.5 | 185 | OIL LUBRICATION | 1900 | 330 |

| 4M32W-1667/4.2-5.7 | 0.42 | 0.57 | 1667 | OIL LUBRICATION | 1600 | 330 |

| 4M25-156/26 | 0.1 | 2.6 | 156 | OIL-FREE | 1600 | 370 |

| 4M25W-115/0.86-20 | 0.086 | 2.0 | 115 | OIL LUBRICATION | 1000 | 370 |

| 4M25-180/16 | 0.1 | 1.6 | 180 | OIL-FREE | 1600 | 370 |

| 4M16-80/25 | 0.1 | 2.5 | 80 | OIL-FREE | 900 | 370 |

| 4M16-79/0.1-33 | 0.01 | 3.3 | 79 | OIL-FREE | 900 | 370 |

| 4M16W-84/0.4-8.8 | 0.04 | 0.88 | 84 | OIL LUBRICATION | 560 | 370 |

| 4M10W-40/38 | 0.1 | 3.8 | 40 | OIL LUBRICATION | 500 | 420 |

| 4M10W-57/0.1-16 | 0.01 | 1.6 | 57 | OIL LUBRICATION | 500 | 420 |

Advantages of our products

A high-pressure oil-free piston compressor refers to a compressor that operates without using lubricating oil inside the cylinder, relying on the coordination of its piston, crankshaft, and cylinder. MINNUO offers a completely oil-free dry-structure crankcase, ensuring no lubricating oil comes into contact with the compressed air source. As a result, the discharged air is 99% free of oil particles.

- Simple construction and easy maintenance

Firstly, MINNUO high-pressure piston compressors are ideally suited to heavy-duty applications and are easy to maintain thanks to their simple and robust design. Their easy maintenance process helps to reduce downtime and associated maintenance costs.

- Suitable for high pressures

In industries that require compressed air as a critical resource, such as medical, food, electronics, automotive, energy, etc., the MINNUO High Pressure Piston Air Compressor therefore has the capacity to fulfil your high pressure air needs.

- OEM available, customised sizes

In addition, piston air compressors can be easily integrated into other machines as OEM components. However, it is worth noting that piston compressors typically have run-time limitations and may require cooling periods to avoid overheating.

- Reduced energy consumption saves costs

MINNUO high pressure piston compressors do not need to consume large amounts of air or power to meet the compression requirements of your project. They can operate at airflows of less than 4 litres per second and less than 1.5 kW.

- Economical

MINNUO high pressure piston air compressors are generally more affordable than other types of compressors, with lower initial investment costs. This makes it an ideal choice for projects with limited budgets.

Low energy consumption

Specialized shaft tile technology, gas valve technology makes the transmission efficiency greatly improved, the unit power consumption significantly reduced.

Programmatic Design

Complete corporate standardization and a rich library of base parts allow for quicker product customization.

High precision

The core components are processed by high precision CNC machine tools, which fully guarantee the reliable operation of the unit.

WHY CHOOSE US ?

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

Real Feedback From Whatsapp

Frequently Asked Questions

Fill Form Get Our Compelete price list

Choosing a MINNUO oil-free high-pressure piston compressor not only ensures high-quality compressed air but also provides the added benefit of our professional sales team helping you significantly reduce purchasing costs. If you’re looking to maintain production efficiency while minimizing your investment and operational expenses, contact us today. We will provide a customized solution tailored to meet your specific needs.

Your email address will not be published. Required fields are marked *

Email

Email sales:+86 15366749631

sales:+86 15366749631