Dry Oil Free Air Compressor

Dry oil free air compressors are air compressors that do not require lubricating oil for lubrication. This kind of air compressor is through its own special design, does not produce lubricating oil in the process of operation, so as to guarantee the purity of the output air. It is suitable for medical, pharmaceutical, semiconductor, national defense research, precision coating, electronics, food, and other industries.

- Working Power: 45~400kW

- Working Pressure: 0.7~1.0MPa

- Treatment Capacity :3.78~67.36m³/min

How it works ?

The dry oil free screw compressor draws in and compresses air through the relative motion of two screw rotors. The spiral grooves of the rotors rotate with the rotors, gradually compressing and pushing the air to the exhaust port, thus discharging the high-pressure gas. Since no lubricant is used in the compression process, the compressed air is dry and oil free.

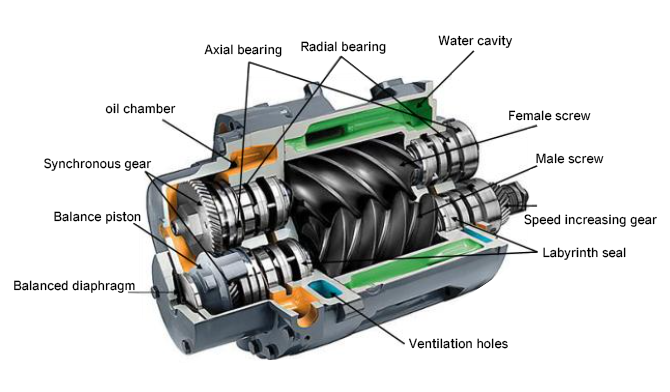

Details of Dry Oil Free Air Compressor

Newly designed dry screw air end

The screw compression air end adopts new energy-saving and high-efficiency design, and the mature processing technology and air end assembly precision ensure the efficiency and reliability of the air end. The running speed of the screw rotor is much lower than the critical speed, which ensures the running life of the air end.

SCR9000 Touch Screen Controller

7-inch touch screen PLC, easy to operate, support intelligent control, such as running schedule, power failure auto-start, etc. Remote monitoring can be realized.

Fully enclosed motor

IE3 high efficiency motor, IP55 protection class, F class insulation.

Low-voltage and high-voltage rotors

High-quality low-pressure and high-pressure rotors for efficient two-stage compression.

Energy-saving solenoid valve

The intercooler and aftercooler are forcibly drained using a timer and solenoid valves, and when unloaded, the system pressure is prevented from dropping by suppressing the unnecessary power loss caused by condensate drainage. A manual drain valve is also standard.

Dry Oil Free Air Compressor

Minnuo, as a professional air compressor manufacturer and supplier in China, we provide high quality oil free dry screw air compressor production and customized service, one-stop solution for your air compression problems.

Advantages of Dry Oil Free Air Compressor

- CLASS 0 Certification

Our oil-free screw compressors are CLASS 0 certified, ensuring an absolutely oil-free air output that meets the stringent standards of the food, pharmaceutical, and high-end manufacturing industries to safeguard product quality.

- Variable Frequency Drive (VSD)

Equipped with advanced variable frequency drive technology, it automatically adjusts the operating speed according to the actual demand to achieve the best energy efficiency and help you optimize the performance under different load conditions.

- Silent design

The special silent design minimizes the operation noise, providing a more comfortable experience for your working environment, suitable for use in noise-sensitive places.

- Energy saving up to 35%

Our oil-free screw compressor can save up to 35% energy, effectively reducing energy consumption, helping you to significantly reduce your electricity bill and improve overall economic efficiency.

- Significant cost savings

Through high energy efficiency and low maintenance requirements, our products can significantly reduce operating costs, making your return on investment more attractive.

- Low Maintenance Requirements

Designed to minimize the use of lubricants, our products not only reduce maintenance frequency, but also simplify the maintenance process, saving you valuable time and human resources.

Dry Oil Free VS. Oil Injected Rotary Screw Compressor

- Operation principle: oil-free screw air compressor with oil-free lubrication technology needs to meet Class 0 technical requirements, while oil-injected screw machines carry lubricant when compressing air.

- Compressed air quality: Since oil-free screw compressors do not spray oil, the quality of compressed air is higher, 100% compressed air. While oil-injected screw machines contain oil in the compression process, which will make the compressed air contain micro oil.

- Maintenance: Oil-free screw air compressors have a relatively low maintenance workload due to their oil-free design. However, the maintenance workload of oil-injected screw machines is relatively higher, as oil and filters need to be changed regularly.

- Scope of application: Oil-free screw compressors are suitable for applications that require high compressed air quality, such as the food and pharmaceutical industries. Oil-injected screw compressors are suitable for applications with lower compressed air quality requirements, such as the industrial sector.

- Energy consumption: Oil-free screw compressors are usually more energy efficient than oil-injected screw machines because they do not consume large amounts of oil to lubricate the machine.

- Noise: Oil-free screw compressors operate at a relatively low noise level because there is no sound of oil injection. In contrast, oil-injected screw machines are relatively noisy.

- Cost: The initial purchase cost of an oil-free screw compressor is usually higher than that of an oil-injected screw machine, but in the long run, the total cost of ownership of an oil-free screw compressor may be lower due to its low maintenance costs and high energy efficiency.

First Order 15% Discount Freight Fee

No spam, notifications only about new products, updates. new instant price.

Features of Oil Free Water Injected Rotary Screw Compressor

- Oil-free design, 0 risk of contamination: Since no lubricant is used, the dry oil-free screw compressor provides pure 100% compressed air for applications with very high air quality requirements, such as food processing, pharmaceutical manufacturing, etc. .

- High efficiency: The screw design improves energy efficiency and ensures an efficient and stable compressed air output.

- Low Maintenance: Reduced maintenance efforts and costs due to the absence of an oil lubrication system.

- Environmentally friendly: Oil-free design reduces the risk of environmental pollution.

MN-DOFP Power Frequency Series

| Model | Working Pressure | Air Capacity | Power | Voltage and IP Grade | Dimensions | Weight | Outlet Pipe Diameter | ||

|---|---|---|---|---|---|---|---|---|---|

| MPa | m³/ min | kW | L( mm) | W( mm) | H( mm) | kg | |||

| MN-DOFP-45A | 0.7 | 7.70 | 45 | 380V IP54 | 2500 | 1600 | 2080 | 2090 | DN50 |

| 0.8 | 6.73 | ||||||||

| 1.0 | 5.10 | ||||||||

| MN-DOFP-55A | 0.7 | 9.60 | 55 | 380V IP54 | 2500 | 1600 | 2080 | 2600 | DN50 |

| 0.8 | 8.94 | ||||||||

| 1.0 | 7.78 | ||||||||

| MN-DOFP-75W | 0.7 | 12.12 | 75 | 380V IP54 | 2300 | 1600 | 1790 | 2850 | DN50 |

| 0.8 | 12.10 | ||||||||

| 1.0 | 11.10 | ||||||||

| MN-DOFP-90W | 0.7 | 13.13 | 90 | 380V IP54 | 2300 | 1600 | 1790 | 2850 | DN50 |

| 0.8 | 13.11 | ||||||||

| 1.0 | 13.00 | ||||||||

| MN-DOFP-110W | 0.7 | 19.50 | 110 | 380V IP54 | 2800 | 1800 | 1860 | 3300 | DN65 |

| 0.8 | 18.31 | ||||||||

| 1.0 | 16.00 | ||||||||

| MN-DOFP-132W | 0.7 | 23.00 | 132 | 380V IP54 | 2800 | 1800 | 1860 | 3450 | DN65 |

| 0.8 | 21.66 | ||||||||

| 1.0 | 19.44 | ||||||||

| MN-DOFP-160W | 0.7 | 26.30 | 160 | 380V IP54 | 2800 | 1800 | 1860 | 3550 | DN65 |

| 0.8 | 26.23 | ||||||||

| 1.0 | 23.00 | ||||||||

| MN-DOFP-185W | 0.7 | 29.17 | 185 | 380V IP54 | 2800 | 1800 | 1860 | 3950 | DN65 |

| 0.8 | 29.13 | ||||||||

| 1.0 | 26.23 | ||||||||

| MN-DOFP-200W | 0.7 | 35.00 | 200 | 380VIP54 | 3400 | 1900 | 2200 | 4500 | DN100 |

| 0.8 | 32.60 | ||||||||

| 1.0 | 29.05 | ||||||||

| MN-DOFP-220W | 0.7 | 37.63 | 220 | 380V IP54 | 3400 | 1900 | 2200 | 5000 | DN100 |

| 0.8 | 35.10 | ||||||||

| 1.0 | 32.39 | ||||||||

| MN-DOFP-250W | 0.7 | 45.20 | 250 | 380V IP54 | 3400 | 1900 | 2200 | 5200 | DN100 |

| 0.8 | 41.64 | ||||||||

| 1.0 | 37.32 | ||||||||

| MN-DOFP-280W | 0.7 | 45.50 | 280 | 380VIP54 | 3400 | 2200 | 2200 | 6400 | DN100 |

| 0.8 | 45.44 | ||||||||

| 1.0 | 41.56 | ||||||||

| MN-DOFP-315W | 0.7 | 50.09 | 315 | 380V IP54 | 3400 | 2200 | 2200 | 6700 | DN100 |

| 0.8 | 50.06 | ||||||||

| 1.0 | 45.37 | ||||||||

| MN-DOFP-355W | 0.70 | 56.96 | 355 | 380V IP54 | 5000 | 2200 | 2500 | 9800 | DN100 |

| 0.80 | 56.86 | ||||||||

| 1.0 | 49.98 | ||||||||

| MN-DOFP-400W | 0.70 | 67.36 | 400 | 380V IP54 | 5000 | 2200 | 2500 | 9800 | DN100 |

| 0.80 | 67.27 | ||||||||

| 1.0 | 56.65 | ||||||||

MN-DOFV Variable Frequency Series

| Model | Working Pressure | Air Capacity | Power | Voltage and IP Grade | Dimensions | Weight | Outlet PiPe Diameter | |||

|---|---|---|---|---|---|---|---|---|---|---|

| MPa | Min.(m³/ min) | Max.( max) | kW | L( mm) | W( mm) | H( mm) | kg | |||

| MN-DOFP-45A | 0.7 | 4.75 | 7.70 | 45 | 380V IP54 | 2500 | 1600 | 2080 | 2140 | DN50 |

| 0.8 | 4.14 | 6.73 | ||||||||

| 1.0 | 3.78 | 5.10 | ||||||||

| MN-DOFP-55A | 0.7 | 4.93 | 9.60 | 55 | 380VIP54 | 2500 | 1600 | 2080 | 2650 | DN50 |

| 0.8 | 4.58 | 8.94 | ||||||||

| 1.0 | 4.00 | 7.78 | ||||||||

| MN-DOFP-75A | 0.7 | 6.56 | 12.12 | 75 | 380V IP54 | 2500 | 1600 | 2080 | 2850 | DN50 |

| 0.8 | 6.71 | 12.10 | ||||||||

| 1.0 | 5.80 | 11.10 | ||||||||

| MN-DOFP-90A | 0.7 | 7.13 | 13.13 | 90 | 380V IP54 | 2500 | 1600 | 2080 | 3100 | DN50 |

| 0.8 | 7.11 | 13.11 | ||||||||

| 1.0 | 6.93 | 13.00 | ||||||||

| MN-DOFP-110A | 0.7 | 11.44 | 19.50 | 110 | 380V IP54 | 2800 | 1800 | 1860 | 3450 | DN65 |

| 0.8 | 10.71 | 18.31 | ||||||||

| 1.0 | 9.82 | 16.00 | ||||||||

| MN-DOFP-132A | 0.7 | 11.16 | 23.00 | 132 | 380V IP54 | 2800 | 1800 | 1860 | 3650 | DN65 |

| 0.8 | 10.48 | 21.66 | ||||||||

| 1.0 | 10.69 | 19.44 | ||||||||

| MN-DOFP-160A | 0.7 | 11.18 | 26.30 | 160 | 380V IP54 | 2800 | 1800 | 1860 | 3750 | DN65 |

| 0.8 | 11.14 | 26.23 | ||||||||

| 1.0 | 10.32 | 23.00 | ||||||||

| MN-DOFP-185A | 0.7 | 11.54 | 29.17 | 185 | 380V IP54 | 2800 | 1800 | 1860 | 4150 | DN65 |

| 0.8 | 11.49 | 29.13 | ||||||||

| 1.0 | 11.05 | 26.23 | ||||||||

| MN-DOFP-200W | 0.7 | 24.91 | 35.00 | 200 | 380V IP54 | 3400 | 1900 | 2200 | 4700 | DN100 |

| 0.8 | 23.18 | 32.60 | ||||||||

| 1.0 | 20.40 | 29.05 | ||||||||

| MN-DOFP-220W | 0.7 | 26.95 | 37.63 | 220 | 380V IP54 | 3400 | 1900 | 2200 | 5200 | DN100 |

| 0.8 | 25.10 | 35.10 | ||||||||

| 1.0 | 22.99 | 32.39 | ||||||||

| MN-DOFP-250W | 0.7 | 32.78 | 45.20 | 250 | 380V IP54 | 3400 | 1900 | 2200 | 5500 | DN100 |

| 0.8 | 30.18 | 41.64 | ||||||||

| 1.0 | 26.80 | 37.32 | ||||||||

| MN-DOFP-280W | 0.7 | 33.20 | 45.50 | 280 | 380V IP54 | 3400 | 2200 | 2200 | 6700 | DN100 |

| 0.8 | 33.16 | 45.44 | ||||||||

| 1.0 | 30.10 | 41.56 | ||||||||

| MN-DOFP-315W | 0.7 | 36.79 | 50.09 | 315 | 380V IP54 | 3400 | 2200 | 2200 | 7000 | DN100 |

| 0.8 | 36.75 | 50.06 | ||||||||

| 1.0 | 33.06 | 45.37 | ||||||||

| MN-DOFP-355W | 0.70 | 45.92 | 56.96 | 355 | 380V IP54 | 5000 | 2200 | 2500 | 9800 | DN100 |

| 0.80 | 45.80 | 56.86 | ||||||||

| 1.0 | 46.57 | 49.98 | ||||||||

| MN-DOFP-400W | 0.70 | 54.67 | 67.36 | 400 | 380V IP54 | 5000 | 2200 | 2500 | 10000 | DN100 |

| 0.80 | 54.57 | 67.27 | ||||||||

| 1.0 | 45.60 | 56.65 | ||||||||

Frequent Asked Question

Consider the following factors:

- Required Airflow and Pressure: Select a model based on your equipment’s needs.

- Application Environment: Choose a compressor suitable for your environmental conditions (temperature, humidity).

- Energy Efficiency: Look for models with a high energy efficiency ratio (refer to product specifications).

When you don’t know how to choose a model, you can contact us for professional guidance and customized service solutions.

While the initial investment might be higher, these compressors typically offer high energy efficiency, saving on electricity costs over time. Opting for energy-efficient models is recommended.

Regular Filter Checks: Keep the intake filter clean to ensure proper airflow.

- Monitor Temperature and Pressure: Check operating temperature and pressure regularly to ensure they are within normal ranges.

- Lubricate and Replace Parts: Regularly inspect and replace wear parts to extend the compressor’s life.

- Not Running or Low Efficiency: Check power supply, control systems, and air filters.

- Excessive Noise: Ensure proper installation and check for any obstructions.

- Unusual Vibration: Inspect screw connections for any looseness.

We offer a two-year warranty on the air end and a one-year warranty on other components, along with long-term after-sales support. Before making a purchase, please be sure to inquire about the specific warranty policies and services available.

Email

Email sales:+86 15366749631

sales:+86 15366749631