Oil-free screw Air Compressor

- ISO 8573-1、 ISO 14001、CE、RoHS、ASME、CSA and ULCertification

- Environmentally friendly

- Silent and low decibel

Why you need Oil-free screw Air Compressor ?

In industries such as food, pharmaceuticals, and electronics, production processes demand absolutely clean compressed air. Traditional compressors use lubricating oil, which can result in trace oil particles mixing into the air and contaminating the product. MINNUO’s oil-free compressors completely eliminate the risk of oil contamination, meeting stringent air purity standards to ensure product quality and safety.

Because our oil-free compressors require no lubricating oil, maintenance costs and labor are significantly reduced. You won’t need to frequently replace lubricating oil, nor regularly clean and replace oil filters, thus minimizing downtime, increasing production efficiency, and lowering overall operational costs.

MINNUO’s oil-free compressors, which do not utilize oil, minimize the production of oily wastewater and emissions, reducing environmental impact. This eco-friendly feature not only helps meet local environmental regulations but also enhances your company’s green image among clients and the public.

With MINNUO’s oil-free compressors, you don’t need to worry about oil buildup in air systems and piping. This substantially lowers cleaning costs, allowing you to maintain a clean production environment.

Our oil-free compressors meet stringent air quality standards such as ISO 8573-1 Class 0, as well as ISO 14001, CE, RoHS, ASME, CSA, UL, and GMP standards, making them an ideal choice for projects that demand high-performance solutions.

Our main oil-free air compressors are divided into: oil-free screw air compressors and oil-free scroll air compressors. At present, all of them have realized the efficacy of mute and energy saving, and have obtained the oil-free guarantee ISO85730 standard certificate, you can rest assured that you can choose our products.

Oil-free screw Air Compressor for Sale

Oil Free Air Compressor of specificities

Oil-free screw compressor is divided into oil-free single-screw compressor and oil-free twin-screw compressor, the use of two-stage screw rotor compressed air, through the water-gas separator to get rid of water in the compressed air. At the same time, because there is no oil injection cooling, generally equipped with pre-cooler, intermediate cooler, after-cooler to cool down the compressed air to achieve the required exhaust temperature. In the rotor shaft through the excellent performance of the shaft seal to prevent lubricant leakage into the compressed air, in order to achieve the real oil-free.

Oil free screw compressor performance characteristics

- Large displacement (more than 10% higher than the same oil-filled twin-screw)

- High exhaust pressure (single-stage compression force up to 17Bar)

- High efficiency (first level energy efficiency)

- Close to isothermal compression

- Low noise

- Full food-grade stainless steel screw host (gas volume decreases 5% after 25,000 hours)

- Self-lubricating bearings

- Oil-free guarantee ISO85730 standard certificate

- High efficiency and low cost (no need for constant temperaturesaving more than 30% energy than the same oiled twin-screw)

- Lower maintenance costs (mainframe requires no maintenancefor 25,000 hours)

- Zero pollution to the environment, the compressed air is clean and safe

- Trouble-free 24-hour long-term continuous and stable operation

How does our Oil-free screw air compressor work?

The way an oil-free air compressor works relies on its special mechanical design in order to achieve a lubricant-free air compression process. Let us introduce you to the principles that make up a MINNUO oil-free air compressor!

1. Firstly, the intake process

The piston begins to move downward (or volume expansion), which causes the volume inside the cylinder to increase and the pressure to decrease, creating a partial vacuum. Since the atmospheric pressure is higher than the pressure inside the cylinder, outside air enters the cylinder through the intake valve.

2. followed by the compression process

The piston moves upwards (or the volume is reduced), compressing the volume of air. As the volume inside the cylinder is reduced, the pressure of the air rises until it reaches the set compression ratio. minnoo oil-free compressors use two-stage compression, where the air passes through a cooling system after the initial compression and enters the second-stage cylinder for further compression in order to obtain a higher output pressure.

3. Then comes the exhaust process

When the pressure in the cylinder exceeds atmospheric pressure, the exhaust valve opens automatically and the compressed air is discharged from the cylinder into a storage tank or delivered to the designated application area. After exhausting the air, the pressure in the cylinder drops back below atmospheric pressure, the exhaust valve closes and the air intake process then restarts.

4. Cooling and heat dissipation process

Compressed air generates heat. In order to maintain the normal temperature and life of the equipment, the compressor is equipped with a cooling system (e.g. water or air cooling). This cooling system dissipates the heat from the compression process and ensures that the compressor operates stably at the right temperature.

5. Automatic control and cycling processes

Compressors are usually equipped with an automatic pressure control system that automatically stops the compressor when the pressure in the storage tank reaches a set value. When the pressure in the storage tank drops to the set lower limit value, the compressor will automatically restart and enter the next compression cycle to maintain a stable air supply.

6. Finally, the sealing and self-lubrication process

6. Finally, the sealing and self-lubrication process

Oil-free compressors use self-lubricating materials between key components such as piston rings and cylinders. These materials reduce friction in the absence of lubricating oil, reducing wear and tear on the equipment. In addition, the sealing system uses stainless steel or labyrinth seals to ensure that no oil contamination enters the cylinder, keeping the air clean.

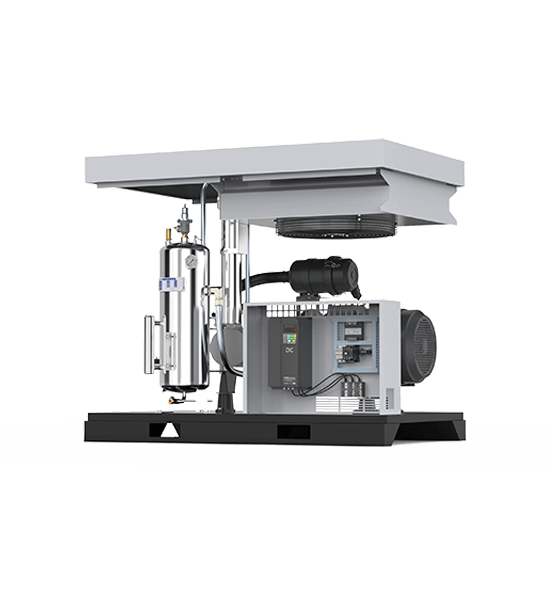

Main components of oil-free air compressor

High efficiency and high performance motor

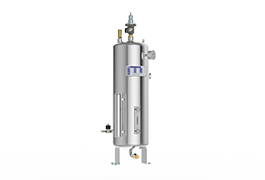

Stainless steel gas storage tank

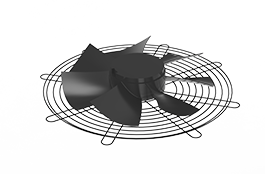

Centrifugal fan is adoptedwith low noise

Atlas Copco Filters

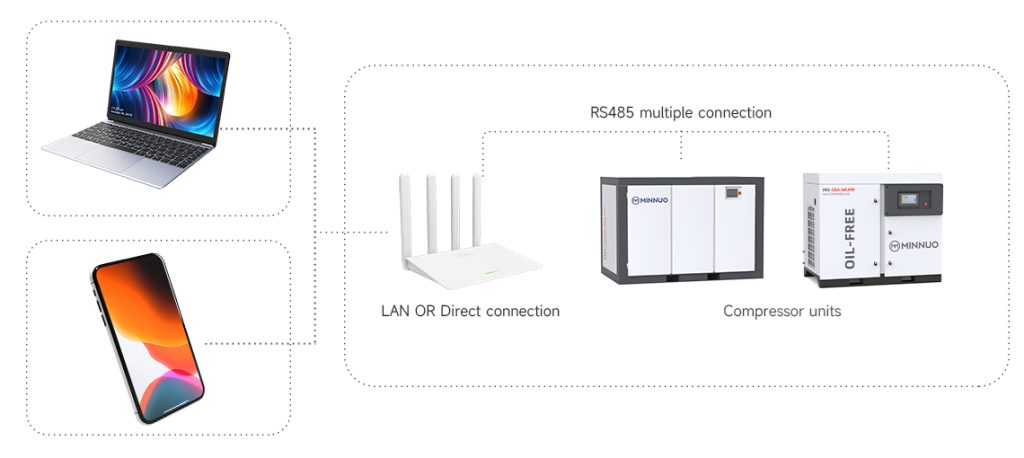

With remote control system

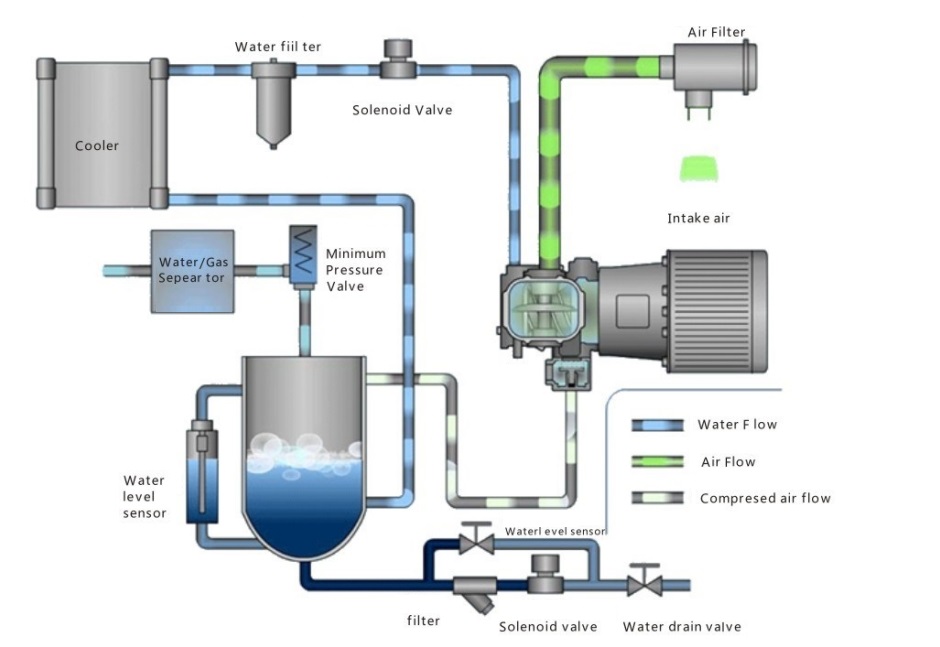

Compressor system flow chat

Main application areas of oil-free screw compressors

Minnuo produces oil free silent air compressors that can be widely used in environments where the air is free of oil contaminants to ensure the purity of products and processes, such as medical, video, and electronic manufacturing.

Food And Beverage Industry

Electronics Manufacturing

Medical Industry

WHY CHOOSE US

Partners You can Rely On

System and compressed air super clean

The whole system is made of stainless steel alloy material to ensure durability and non-corrosive, with a long service life, to ensure that the compressed air “0” pollution is more energy-saving, stable, green and environmentally friendly.

Why More Than 300+ Clients Trust Us?

Strict manufacturing process

Each component is strictly tested, striving for excellence, from raw materials to finished parts of each procedure is strictly controlled to ensure that each component reaches the superior quality, each component is optimized design to ensure more durable.

Ultra-quiet design of the whole machine

The whole machine chassis adopts ultra-quiet design, low speed and large air volume cooling fan adopts oversized cooler to reduce the air convection friction, and at the same time has excellent cooling effect.

Humanized structure design

Humanized structural design, simplify the installation, while the follow-up maintenance is more convenient, very low maintenance costs, no need for professional staff, users can also be professional guidance for their own maintenance, and easy to popularize and promote.

Frequently Asked Questions

Technical Services

- Regardless of pre-sale, sale, after-sale, as long as the user needs technical help and advice, the company will be within 24 hours to provide relevant technical support free of charge.

- After the successful on-site start-up and commissioning, our after-sales service engineers are responsible for the user’s operators to carry out routine operation training.

- In the warranty period, the user equipment failure notification, after-sales service engineers within 24 hours to the scene (except in remote areas), the integrity of the enterprise’s service is well received by the user!

It is a good experience to choose Minnuo as your air compressor partner, welcome to contact us!

Fill Form Get Our Compelete price list

Your email address will not be published. Required fields are marked *

Email

Email sales:+86 15366749631

sales:+86 15366749631