Centrifugal Compressor

30 years+ Centrifugal

Compressor Manufacturer, 132kw-14500kW,high flow rate, low pressure, low vibration and low noise.

- Medium: Air/Nitrogen

- Pressure: 0.6 to 25 MPa (MegaPascals)

- Power: 132 to 14,500 kW (kilowatts)

- Flow Rate: 25 to 3,000 m³/min (cubic meters per minute)

Centrifugal Compressor

Centrifugal compressor is a kind of compressor that utilizes a high-speed rotating impeller to do work on the gas, so that the pressure and kinetic energy of the gas in the centrifugal field are increased.

In the early days, the centrifugal compressor is mainly used to compress air, and is only suitable for low and medium pressure and very large volume occasions. With the demand of various production processes and the improvement of centrifugal compressor manufacturing technology and design technology, centrifugal compressors have been applied to high pressure areas.

Minnuo as a professional centrifugal compressor manufacturers and suppliers, has a wealth of experience in compressor manufacturing and sales, consult us to get the latest information and prices of centrifugal compressors!

Centrifugal compressor class structure

Centrifugal compressors have various structural types such as single-stage, double-stage and multi-stage. Single-stage compressor is mainly composed of suction chamber, impeller, diffuser, worm shell, etc. For multi-stage compressor, there are also components such as bends and reflows.

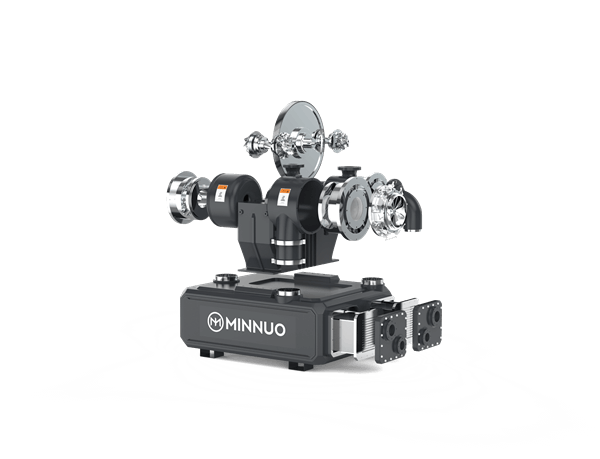

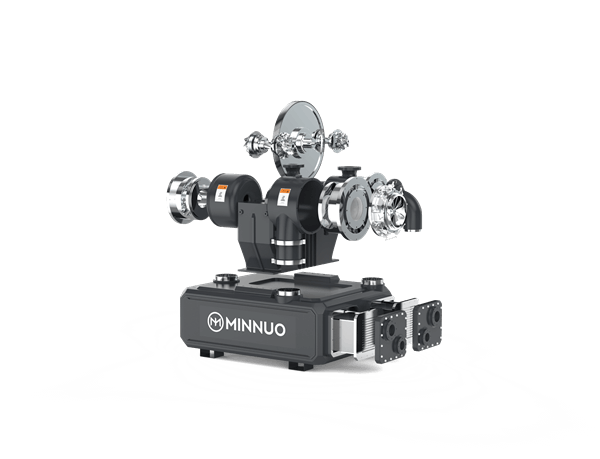

Components

The centrifugal compressor adopts modular design, including the host, cooling system, oil station system, motor, electric control system and other proprietary modules. It has the advantages of compact structure, reliable operation, energy saving and high efficiency, less assembly and easy installation. It can ensure to provide users with continuous, stable, oil-free compressed air of high quality.

Impeller

Rotor Dynamics Design

Integral Casting Gearbox-Modular Integrated Assembly

High Reliability Bearing

High Performance IGV

Feature

- Compact structure, good sealing effect, less leakage phenomenon, small size, thus the unit footprint and weight are much smaller than the same volume of piston compressor.

- Large flow rate, high power, conducive to energy saving. Turbomachinery flow through the impeller medium, has been continuous, the cylinder volume is larger, the impeller can rotate at high speed, so the turbomachinery exhaust flow and power can be greatly increased. So the centrifugal compressor exhaust gas uniformity, airflow without pulse.

- Smooth operation, reliable operation, so it has a high operating rate, a flat performance curve, a wider range of operations, maintenance costs and fewer personnel.

- Fewer wearing parts, long operating cycle, fewer and simpler moving parts, and low manufacturing precision, so its manufacturing costs are relatively low and high reliability. Easy to automate and large-scale.

- Centrifugal compressor compression process can be done without oil, the machine does not need lubrication, which is very important for the production of many industries.

General centrifugal compressors

Type | Pressure | Flow range | Power | Dimensions L×W×H | ||

DAC-50 | 0.6~8 | 25~48 | 132~ 263 | 2650 | 1650 | 1850 |

DAC-80 | 0.6~10 | 40~85 | 225~ 450 | 3350 | 1860 | 2150 |

DAC-120 | 0.6~13 | 75~132 | 400~630 | 3850 | 2100 | 2250 |

DAC-200 | 0.6~13 | 115~208 | 618~1120 | 4250 | 2150 | 2250 |

DAC-250 | 0.6~20 | 175~260 | 925~1375 | 4500 | 2250 | 2380 |

DAC-300 | 0.6~25 | 228~310 | 1225~1600 | 4650 | 2250 | 2450 |

DAC-350 | 0.6~25 | 283~360 | 1500~1850 | 4850 | 2250 | 2500 |

DAC-450 | 0.6~25 | 350~460 | 1800~ 2350 | 5250 | 2300 | 2950 |

Large centrifugal compressors (air/nitrogen)

Type | Pressure | Flow range | Power | Dimensions L×W×H | ||

DAC-550 | 0.6~25 | 430~586 | 2250~3150 | 6250 | 3250 | 3550 |

DAC-1000 | 0.6~25 | 550~1015 | 2850~5750 | 8350 | 3850 | 3850 |

DAC-1500 | 0.6~25 | 920~1650 | 6000~10500 | 12500 | 4550 | 4550 |

DAC-3000 | 0.6~25 | 1680~3000 | 10800~20000 | 14500 | 5350 | 5350 |

Pressurized units (air/nitrogen)

Type | Pressure | Flow range | Power | Dimensions L×W×H | ||

DAC-550-HB | 0.3~1.0 | 436~586 | 1214~1758 | 5250 | 3250 | 2850 |

DAC-1000-HB | 0.3~1.0 | 550~1020 | 1925~3570 | 5850 | 3550 | 3150 |

DAC-1500-HB | 0.3~1.0 | 920~1650 | 3220~5775 | 6500 | 4350 | 3550 |

DAC-3000-HB | 0.3~1.0 | 1680~3000 | 5880~10500 | 7500 | 5350 | 4250 |

Our compressors are applied in the following industries

Chemical industry

A Compressed air acts as an oxidizing reaction gas

B Compressed air for power

C Refining, production of hydrogen peroxide

Automotive/Manufacturing Industry

A Pneumatic, instrumentation, stamping, plating, painting, heat treatment and other production lines

B Pneumatic wrenches, pneumatic sanders, dust blowers, and other end-of-line tools

C Protective air, cooling, dust removal, and cleaning

Aerospace Industry

A Engine Simulation Wind Tunnel

B High Altitude Stage Test Systems

C Pneumatic Component Test Systems

Metal smelting industry

A Nitrogen, oxygen and hydrogen production by air separation

B iron and steelmaking, sintering, rolling and other process instrumentation gas

C Metallurgy of alumina, electrolytic aluminum, lead and zinc smelting and other instruments with gas

Textile and chemical fiber industry

A Air-jet textile weft leading

B Roll pressurization

C Breading and instrumentation gas

Pharmaceutical Industry

A Bio-fermentation

B Chemical raw materials and preparations

WHY CHOOSE US

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

How to buy centrifugal compressor

Partners You can Rely On

Read the above about centrifugal compressors, you still can not confirm the purchase of the right centrifugal compressor, I help you summarize a few aspects.

- Clear your purpose: you buy centrifugal compressor mainly for what? Is it for industrial manufacturing, chemical processes, air conditioning systems or other applications?

- Parameters of the compressor: Flow rate (m³/h): what is the flow rate you need? This determines the specifications of the compressor. Pressure (bar or MPa): What is the working pressure you need? Efficiency: An efficient compressor saves energy and costs.

- Type of gas to be compressed

- Budget

- Installation and maintenance: The indoor or outdoor environment will affect the service life of the compressor.

Fill Form Get Our Compelete price list

Your email address will not be published. Required fields are marked *

Email

Email sales:+86 15366749631

sales:+86 15366749631