Air-cooled Chiller / Water-cooled Chiller Manufacturer

Minnuo is a professional chiller manufacturer with 36 years of experience in chiller manufacturing and sales. Come to us for a quotation!

- Superior technology

- First-class products

- Professional service

- Reasonable price

Overview Chiller

Chiller, is a kind of cooling water equipment that can provide constant temperature, constant flow, constant pressure, its working principle is that the refrigerant is compressed into a high temperature and high pressure gas through the compressor, and then through the condenser exothermic cooling and condensation, into a high-pressure liquid, and then throttled and expanded through the expansion valve, so that the refrigerant absorbs the heat and evaporates inside the evaporator, to achieve the purpose of refrigeration. Water chiller mainly through the circulation flow refrigerant to reduce the temperature. Water chillers are divided into two types: air-cooled chillers and water chillers.

Hot Chiller for Sale

Professional non-standard customized chiller, 36 years quality assurance.

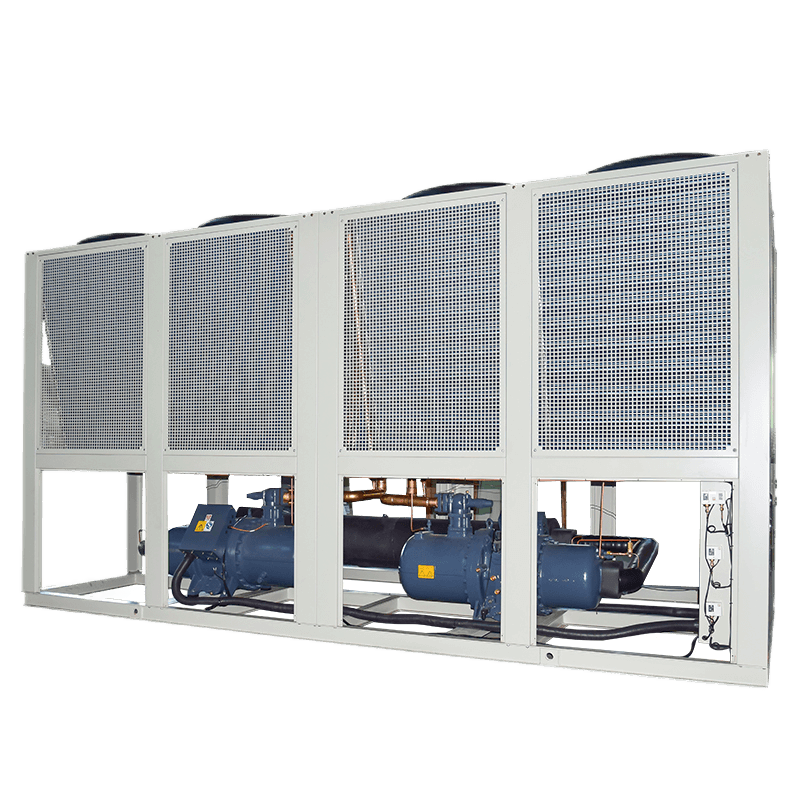

Air-cooled chiller

- No installation cooling tower, easy to install, easy to move, suitable for the lack of water sources no installation water tower occasions.

- Low noise fan motor, excellent cooling condensation effect, stable throttling mechanism, excellent anti-rust treatment.

- Adopt high performance compressor imported from Europe and America, high EER value, low noise, stable operation.

| Model | KC -0.6 | KC -001 | KC -002 | KC -003 | KC -005 | KC -006 | KC -008 | KC -010 | KC -012 | KC -015 | KC -020 | KC -025 | KC -030 | KC -035 | KC -040 | KC -045 | KC -050 | KC -060 | ||

| cooling capacity | kW | 1.6 | 2.95 | 5.19 | 9.0 | 15.2 | 18.0 | 21.2 | 27.5 | 34.8 | 42.6 | 56.5 | 65.2 | 84.2 | 97.5 | 113.1 | 125.2 | 139.3 | 167.1 | |

| 50HZ/60HZ | 1.92 | 3.54 | 6.2 | 10.8 | 18.24 | 21.6 | 25.44 | 33 | 41.76 | 51.1 | 67.8 | 78.2 | 101 | 117 | 135.7 | 150.2 | 167.2 | 200.5 | ||

| kcal/h | 1612 | 2462 | 4453 | 7,820 | 13,070 | 15,310 | 18,230 | 23,650 | 29,930 | 36,630 | 48,590 | 56,070 | 72,410 | 83,850 | 97,260 | 107,660 | 119,790 | 143,700 | ||

| 50HZ/60HZ | 1934 | 2954 | 5344 | 9384 | 15684 | 18372 | 21876 | 28380 | 35916 | 43956 | 58308 | 67284 | 86892 | 100620 | 116712 | 129192 | 143748 | 172440 | ||

| Input power | kW | 0.93 | 1.38 | 2.15 | 2.65 | 4.47 | 6.30 | 6.55 | 8.65 | 11.05 | 13.5 | 17.6 | 21.7 | 26.8 | 30.5 | 35.2 | 40.9 | 43.3 | 52.9 | |

| Chilled fluid flow | m3/h | 0.26 | 0.5 | 0.91 | 1.6 | 2.6 | 3.1 | 4.3 | 5.5 | 6.9 | 8.2 | 10.8 | 13.6 | 16 | 18.8 | 21.2 | 24.1 | 26.5 | 31.8 | |

| 0.312 | 0.6 | 1.092 | 1.92 | 3.12 | 3.72 | 5.16 | 6.6 | 8.28 | 9.84 | 12.96 | 16.32 | 19.2 | 22.6 | 25.4 | 28.9 | 31.8 | 38.2 | |||

| Power supply voltage | 1PH-220V 50HZ(60HZ) (110V 50HZ/60HZ) | 3PH-380V-50HZ(200V/220V/415V50HZ/60HZ) | ||||||||||||||||||

| Compressor | Type | Hermetic rotating type | Hermetic scroll type (Piston) | |||||||||||||||||

| Start-up mode | Sequential start | |||||||||||||||||||

| Power(kW) | 0.45 | 0.95 | 1.73 | 2.3 | 3.8 | 5.1 | 5.6 | 7.5 | 9.4 | 11.3 | 15.0 | 18.8 | 22.5 | 26.3 | 30.0 | 33.8 | 37.5 | 45.0 | ||

| Refrigerant | Type | R-22(R407c/R134a) | ||||||||||||||||||

| Control mode | Capillary | Expansion valve | ||||||||||||||||||

| Filling amount(kg) | 0.36 | 0.6 | 1.2 | 2.0 | 3.6 | 4.3 | 5.1 | 6.5 | 8.2 | 9.6 | 13.3 | 15.8 | 20.4 | 23.6 | 27.8 | 30.3 | 33.6 | 40.2 | ||

| Evaporator | Type | Water tank with coil | Shell and Tube(Water tank with coil) Shell and Tube(Water tankwith coil) | Shell and Tube | ||||||||||||||||

| Pipe | B | PT 1/2″ | PT 1″ | PT 1-1/2″ | PT 2″ | PT 2″ | PT 2-1/2″ | PT 3″ | ||||||||||||

| Condenser | Type | High efficient finned copper tube | ||||||||||||||||||

| Surface area/row(M2) | 0.5/2R | 0.5/2R | 0.62/3R | 0.62/3R | 0.62/4R | 0.62/4R | 1.16/3R | 1.16/4R | 1.92/3R | 2.28/3R | 3.06/3R | 3.80/3R | 4.52/3R | 5.36/3R | 6.08/3R | 6.82/3R | 7.54/3R | 9.02/3R | ||

| Cooling fan | Type | Low noise axial flow(Low noise outer rotor fan) | ||||||||||||||||||

| Air volume(CMM) | 9 | 17 | 35 | 65 | 110 | 126 | 150 | 195 | 220 | 265 | 390 | 440 | 530 | 620 | 760 | 820 | 880 | 1060 | ||

| Power(kW) | 0.12 | 0.18 | 0.21 | 0.25 | 0.37 | 0.42 | 0.55 | 0.55 | 0.75 | 1.1 | 0.55×2 | 0.75×2 | 1.1×2 | 1.1×2 | 1.5×2 | 2.2×2 | 0.75×4 | 1.1×4 | ||

| Tank volume | L | 16 | 20 | 25 | 50 | 70 | 70 | 120 | 130 | 130 | 180 | 180 | 180 | 220 | 220 | 220 | 280 | 280 | 280 | |

| Water pump power | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 3.0 | 3.0 | 3.0 | |

| Protective device | Compressor overheating, over current, high and low pressure, over temperature, flow switch, phasesequence, phase-missing, exhaust overheating, anti-freezing protection | |||||||||||||||||||

| Dimension | L | mm | 580 | 550 | 600 | 930 | 1140 | 1140 | 1200 | 1300 | 1500 | 1600 | 1900 | 1900 | 2200 | 2300 | 2300 | 2300 | 2500 | 2300 |

| W | mm | 530 | 440 | 500 | 520 | 560 | 560 | 740 | 780 | 780 | 900 | 990 | 990 | 1110 | 1110 | 1110 | 1110 | 1110 | 2100 | |

| H | mm | 680 | 750 | 850 | 975 | 1040 | 1040 | 1370 | 1530 | 1600 | 1640 | 1660 | 1800 | 1810 | 1850 | 2010 | 2100 | 2210 | 2050 | |

| Weight | kg | 51 | 72 | 100 | 150 | 170 | 190 | 370 | 400 | 450 | 540 | 760 | 810 | 1000 | 1050 | 1200 | 1350 | 1350 | 1650 | |

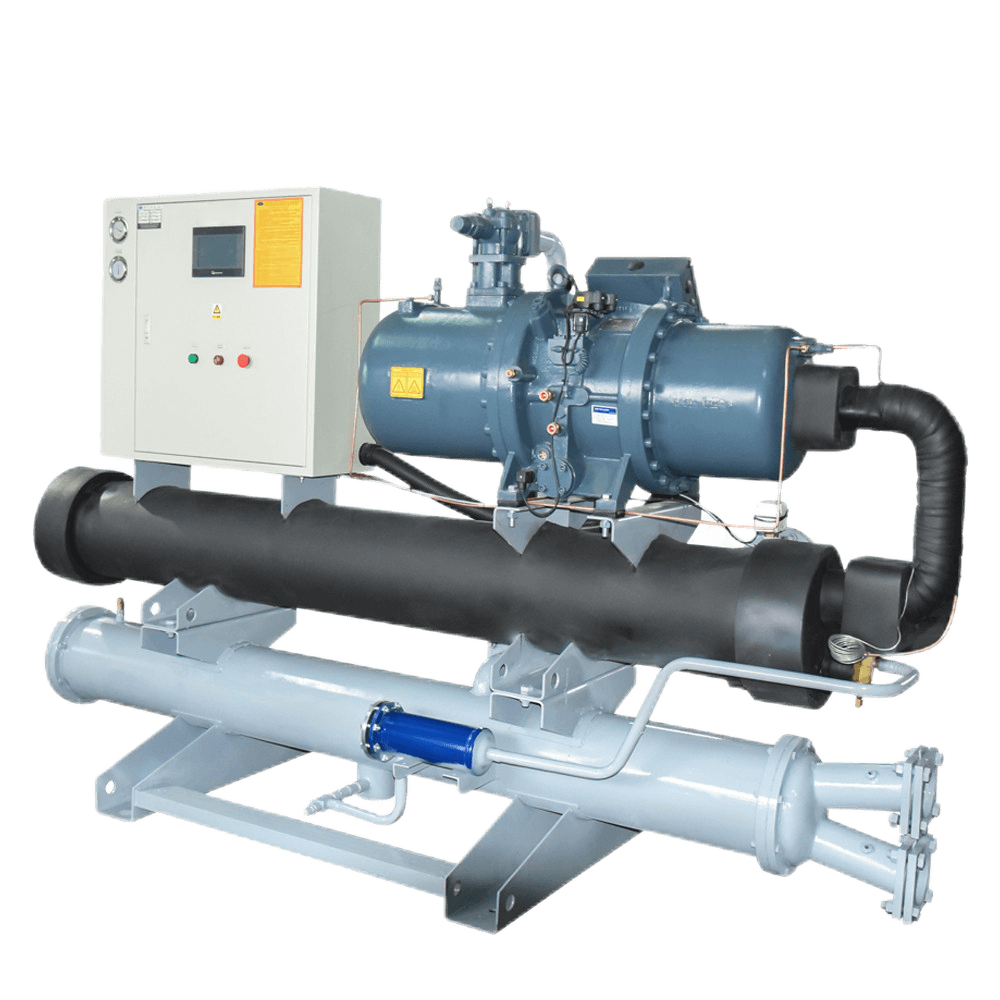

Water-cooled chiller

- Ergonomic panel, full automatic control, equipped with precision electric temperature controller, can run smoothly for a long time.

- Adopt high efficiency heat transfer heat exchanger, less cold loss, easy to return to the oil, the heat transfer tube does not freeze advantages.

- Adopt high performance compressor imported from Japan and America, high EER value, low noise, stable operation.

Model | KDS-030S | KDS-040S | KDS-050S | KDS-060S | KDS-080S | KDS-090S | KDS-100S | KDS-120S | KDS-150S | KDS-180S | KDS-200S | KDS-220S | KDS-240S | KDS-260S | ||

Power supply voltage | 3φ-50Hz-380V | |||||||||||||||

cooling capacity | kw | 108 | 148 | 173 | 198 | 260 | 293 | 335 | 409 | 480 | 572 | 638 | 715 | 805 | 866 | |

kcal/h | 92,880 | 127,280 | 148,780 | 170,280 | 223,600 | 251,980 | 288,100 | 351,740 | 412,800 | 491,920 | 548,680 | 614,900 | 692,300 | 744,760 | ||

Input power | kw | 22.0 | 30 | 36.0 | 41 | 55.2 | 61.0 | 64.8 | 79.0 | 100.0 | 110.5 | 121.8 | 137.0 | 154.5 | 166.8 | |

Chilled fluid flow | m3/h | 18 | 24 | 29 | 33 | 46 | 50 | 54 | 68 | 80 | 95 | 106 | 122 | 132 | 140 | |

Cooling fluid flow | m3/h | 22 | 29 | 35 | 40 | 55 | 62 | 68 | 82 | 98 | 116 | 129 | 148 | 155 | 172 | |

Power supply voltage | 3PH-380V-50HZ (200V/220V/415V50HZ/60HZ) | |||||||||||||||

Compressor | Type | Semi-Hermetic screw type | ||||||||||||||

Number | 1 | |||||||||||||||

Starting method | Y-△ | |||||||||||||||

Capacity control type(%) | 0,33,66,100 | 0,25,50,75,100 | ||||||||||||||

Power(kw) | 22 | 30 | 36 | 41 | 55.2 | 61 | 64.8 | 79 | 100 | 119 | 132 | 148 | 167 | 180 | ||

Refrigeration oil | Type | SUNISO 4GS | ||||||||||||||

Charge | L | 7 | 7 | 7 | 8 | 12 | 16 | 16 | 16 | 18 | 23 | 23 | 28 | 28 | 28 | |

Refrigerant | Type | R-22 | ||||||||||||||

Control mode | Thermostatic expansion valve | |||||||||||||||

Charge | kg | 16 | 21 | 27 | 32 | 42 | 48 | 54 | 64 | 73 | 92 | 103 | 116 | 122 | 131 | |

Evaporator | Type | Shell and Tube | ||||||||||||||

Pipe | B | PT 2-1/2″ | PT 3″ | PT4″ | PT 5″ |

| PT 6″ |

| PT 8″ | |||||||

Condenser | Type | Shell and Tube | ||||||||||||||

Pipe | B | PT 3″ | PT 4″ | PT 5″ |

| PT 6″ |

| PT 8″ | ||||||||

Protective device | Compressor overheating, over current, high and low pressure, over temperature, flowswitch, phase sequence, phase-missing, exhaust overheating, anti-freezing protection. | |||||||||||||||

Dimension | L | mm | 2500 | 2500 | 2500 | 2500 | 3100 | 3100 | 3100 | 3200 | 3500 | 3500 | 3650 | 3650 | 3950 | 3950 |

w | mm | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 1100 | 1200 | 1200 | 1300 | 1350 | 1400 | 1400 | |

H | mm | 1450 | 1500 | 1600 | 1700 | 1750 | 1860 | 1860 | 1500 | 1550 | 1600 | 1600 | 1650 | 1650 | 1700 | |

Weight | kg | 1020 | 1150 | 1350 | 1500 | 1680 | 1800 | 1930 | 2250 | 2500 | 2650 | 2850 | 3000 | 3350 | 3600 | |

Important parts

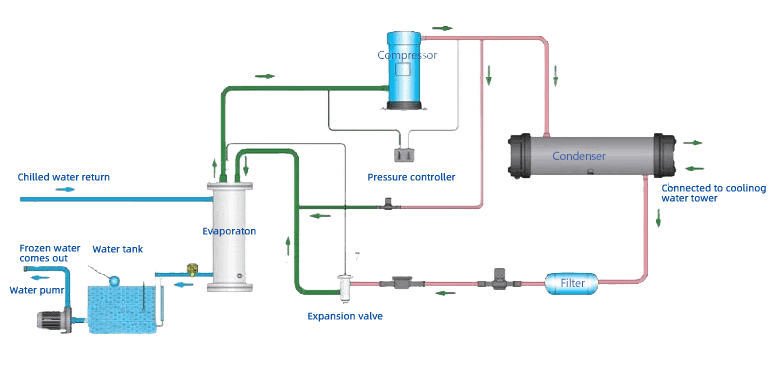

Working Principle

- Compression: low temperature and low pressure refrigerant is sucked into the compressor, and through the compression process inside the compressor, the refrigerant is compressed into high temperature and high pressure gas.

- Condensation: the high temperature and high pressure gas through the condenser exothermic condensation into high pressure liquid, at this time the heat will be released by the radiator heat dissipation into the air, so that the refrigerant cooling.

- Expansion: After the expansion valve, the high pressure liquid flows into the low pressure area, the pressure decreases, while the flow rate is accelerated, the refrigerant expands and the temperature decreases.

- Evaporation: After expansion, the refrigerant enters the evaporator, absorbs the heat in the environment, evaporates into a low-temperature, low-pressure refrigerant, forming a refrigeration cycle.

- Chiller mainly through these four steps to achieve the cooling effect, the high temperature and high pressure gas condensation into a high pressure liquid, and then through the throttling expansion so that the refrigerant evaporates and cools down, so as to achieve the purpose of refrigeration.0

WHY CHOOSE US

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

Real Feedback From Whatsapp

Frequently Asked Questions

The energy efficiency ratio (COP) of chiller units varies according to models and configurations, generally between 3.0 and 6.0. You can refer to the product specifications or consult the supplier for specific values.

Our chiller units offer a wide range of cooling capacities, from tens of kilowatts to thousands of kilowatts, to meet the needs of different sizes.

Installation of chiller units requires consideration of space, ventilation, power and water sources. Maintenance includes regular inspection, cleaning of filters, replacement of lubricating oil and refrigerant, etc.

Under normal use and maintenance, the service life of a chiller plant is usually around 15 to 20 years.

The noise level of a chiller unit is usually between 70 and 85 dB, depending on the model and size of the unit.

Yes, many chiller units are equipped with remote monitoring and control features that allow real-time monitoring and control via the internet.

Buyer Guide

- Select the cooling capacity according to the need. The cooling capacity is the most important parameter of the chiller, and the selection should be based on the size of the area to be cooled and the heat load. If not selected properly, the whole system may fail due to insufficient cooling.

- Consider the ease of maintenance, cleaning and upkeep of the unit. Maintenance and cleaning of the unit is a very important maintenance task during the use of the chiller, as dust and dirt will affect the performance of the cooling system.

- Choose energy-saving chillers. Energy-saving chillers can not only reduce energy use, but also save costs in the long-term use of the process.

- Consider factors such as the noise and appearance of the unit. For water chillers that need to be installed in public places, factors such as noise and appearance are important factors to consider.

In short, if you want to select a cost-effective chiller, there is no way to choose by yourself, you can contact our professional sales staff to assist in the selection.

Fill Form Get Our Compelete price list

Your email address will not be published. Required fields are marked *

Email

Email sales:+86 15366749631

sales:+86 15366749631