In any industrial facility, the compressed air system is often the largest consumer of electricity, accounting for 10% to 30% of a plant’s total energy bill. For decades, the standard workhorse—the fixed-speed air compressor—operated on a simple but wasteful principle: run at full speed or not at all. This “all-or-nothing” approach creates a significant problem: most plants don’t have a constant air demand. During periods of low usage, these traditional machines cycle on and off inefficiently, burning money even when they’re not producing useful air.

The solution to this pervasive waste is the Variable Speed Drive (VSD) compressor, a smarter technology designed to match air output precisely to demand in real time. But what exactly is a VSD compressor, how does its energy-saving magic work, and is it the right investment for your operation? This guide cuts through the technical jargon to provide clear answers, empowering you to make an informed decision that can dramatically cut your operating costs.

What is a Variable Speed Drive (VSD) Compressor?

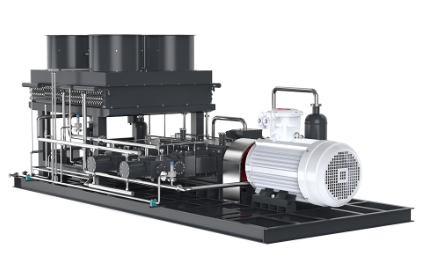

A Variable Speed Drive (VSD) air compressor is an air compressor that dynamically adjusts the speed of its electric motor (and consequently, its air end) to produce exactly the amount of compressed air needed at any given moment.

Think of it this way:

- A fixed-speed compressor is like a car that can only drive at 70 mph. To go slower, you must repeatedly brake and accelerate, which is inefficient and hard on the vehicle.

- A VSD compressor is like a car with cruise control that seamlessly adjusts speed between 20 mph and 70 mph to maintain a set distance, using only the power necessary for the current conditions.

The core innovation is the replacement of a simple starter with an intelligent Variable Frequency Drive (VFD). This drive acts as the machine’s brain, continuously monitoring system pressure. If pressure rises due to dropping demand, it slows the motor. If pressure falls due to increasing demand, it speeds up the motor. This results in a smooth, stepless adjustment of output, eliminating the energy-intensive stop-start cycles of traditional compressors.

How Does a VSD Compressor Work? The Technology Behind the Savings

To appreciate the savings, you must first understand the inefficiency it solves and the mechanism it employs.

The Problem: Inefficiency of Fixed-Speed “Load/Unload” Cycling

A standard fixed-speed compressor operates in a load/unload cycle:

- Load: The motor runs at full speed (e.g., 1800 RPM), the compressor valve is open, and it produces 100% of its rated air.

- Unload: When air demand drops and pressure reaches a high limit, the compressor valve closes. The motor continues to run at full speed, but now it’s only compressing a tiny amount of air internally to overcome mechanical friction. In this state, it can still consume 25-40% of its full load power while producing ZERO useful air.

- This cycle repeats constantly, wasting significant energy during unload periods and causing damaging pressure swings.

The Solution: Core Components of a VSD System

A VSD compressor integrates three key components:

- The Variable Frequency Drive (VFD): This is the power converter. It takes the incoming 50/60 Hz AC power, rectifies it to DC, and then inverts it back to AC at a precisely controlled frequency and voltage. Motor speed is directly proportional to the frequency supplied by the VFD (e.g., 30 Hz = ~900 RPM, 60 Hz = ~1800 RPM).

- A Specialized Motor: Typically, a Permanent Magnet (PM) motor or an optimized induction motor. PM motors are especially efficient because they don’t require electrical current to create a magnetic field, yielding higher efficiency across a wide speed range.

- Advanced Controller: This system brain receives pressure signals from the network. Using a sophisticated algorithm, it calculates the exact motor speed required to maintain the set pressure (e.g., 100 psi) within a very tight tolerance (often ±1 psi).

The Operating Principle: Precision Matching

When your production line slows down and air demand falls, the system pressure begins to rise. The VSD controller detects this increase and immediately signals the VFD to gradually reduce the motor frequency and speed. The air end slows down, producing less air. The power draw drops dramatically and proportionally.

When demand picks up, the process reverses seamlessly. The result is a near-perfect flat line on your system pressure gauge and a power consumption curve that mirrors your actual air usage.

How Much Energy Can a VSD Compressor Actually Save?

The savings are not marginal; they are transformative, governed by a fundamental law of physics.

The Affinity Laws: The Math of Massive Savings

For centrifugal pumps and fans (which includes an air compressor’s air end), the Affinity Laws state:

- Flow (CFM/SCFM) is proportional to speed (RPM).

- Power (kW) is proportional to the cube of the speed (RPM³).

This cubic relationship is the key. A small reduction in speed yields a large reduction in power.

Example Calculation:

If your air demand drops by 20%, the VSD compressor can reduce motor speed by 20%.

- Speed Factor = 0.8 (80% of full speed)

- Power Factor = (0.8)³ = 0.512

This means the compressor now uses only 51.2% of the power it would use at full speed to meet that lower demand. A 20% speed reduction leads to nearly a 50% reduction in energy consumption for that output level.

Real-World Energy Savings Scenarios

Savings depend entirely on your load profile—how your air demand fluctuates over time.

- High Savings (40-50%+): Operations with large swings between high peak demand and long periods of low demand (e.g., batch processing plants, facilities with night/weekend shifts).

- Moderate Savings (25-35%): Facilities with continuous but highly variable demand throughout the day (e.g., automotive assembly, packaging lines).

- Lower Savings: Facilities that run at a consistently high load (e.g., >80% capacity). Here, a fixed-speed machine may be more efficient, as the VSD system itself has a small efficiency loss (~2-3%) at full load due to drive electronics.

The golden rule for VSD savings: The wider and more frequent the fluctuations in your air demand, the greater your potential savings.

Key Benefits Beyond Energy Savings

While energy cost reduction is the primary driver, VSD compressors deliver a powerful suite of additional advantages:

- Extended Equipment Life: By eliminating harsh start-stop cycles (a VSD may only start once per day), wear and tear on motors, contactors, and the air end are drastically reduced. Soft starts also prevent damaging current inrush.

- Unmatched Pressure Stability: Maintaining system pressure within a 1-2 psi band (vs. a 10-20 psi band with load/unload) improves the performance and consistency of pneumatic tools, CNC machines, and automated processes, leading to better product quality.

- Reduced Electrical Demand Charges: Utilities often charge a premium based on your peak 15-minute power draw (demand charge). The soft start and avoidance of high inrush currents from frequent starts can significantly lower this peak, reducing another line item on your electricity bill.

- Lower Operating Temperatures: Running at a slower, partial load generates less heat than a fixed-speed machine cycling between full load and unload. This leads to cleaner, cooler oil and longer lubricant and component life.

- Minimized Impact of Air Leaks: During low-demand periods, a VSD unit will slow down to compensate for leaks. While leaks should always be fixed, this characteristic means leaks are less costly than with a fixed-speed machine that must cycle on and off to feed them.

Is a VSD Compressor Right for Your Operation?

VSD technology is powerful, but it’s not a universal solution for every application.

Ideal Applications for VSD Compressors (Yes!):

- Facilities with a widely varying air demand (shift changes, multiple production lines turning on/off).

- Applications where pressure stability is critical (precision instrumentation, laboratory air, textile manufacturing).

- Plants operating multiple shifts with low overnight or weekend demand.

- As the trim or lead compressor in a multiple-compressor system to handle demand fluctuations efficiently.

Applications to Evaluate Carefully:

- Continuous 100% Load: If your compressor runs at full capacity 24/7 with no variation, a well-maintained fixed-speed machine is simpler and may have a slight full-load efficiency edge.

- Extremely Harsh Environments: Excessive heat, moisture, or conductive dust can challenge the cooling and electronics of a VFD cabinet. Special enclosure ratings (NEMA 4X) may be required.

- Very Small, Intermittent Demand: For tiny workshops, a small fixed-speed or reciprocating compressor may be more cost-effective.

The Essential First Step: An Air Audit.

You cannot guess your savings. A professional compressed air audit uses data loggers to measure your facility’s actual air flow (SCFM) and pressure over 1-2 weeks. The resulting load profile graph is the single most important tool for determining the potential ROI of a VSD compressor. Reputable suppliers like MINNUO offer this service to provide data-driven recommendations.

FAQ

Q1: What is the difference between VSD, VFD, and VS?

A1: These terms are often used interchangeably in the compressor industry. Technically, VFD (Variable Frequency Drive) is the electronic controller that varies motor speed. VSD (Variable Speed Drive) typically refers to the entire drive system (VFD + motor). VS (Variable Speed) is a simpler marketing term for the same technology.

Q2: Are VSD compressors more expensive to maintain?

A2: The maintenance schedule is similar to a fixed-speed machine (oil, filters, separators). The VFD itself requires minimal maintenance—primarily keeping its cooling vents clean and air filters changed. The major cost avoidance is in reduced wear on starters and motors due to soft starts, which can lower long-term maintenance costs.

Q3: Can I retrofit a VSD to my existing fixed-speed compressor?

A3: Retrofits are technically possible but often complex and costly. They require a compatible motor, extensive electrical work, and control integration. The economic and performance outcome is rarely as good as a purpose-built, integrated VSD compressor. A new, optimized system is usually the better investment.

Q4: How do I calculate the ROI for a VSD compressor investment?

A4:

- Determine Annual Energy Cost of Existing Compressor: (Motor kW) x (Operating Hours) x (Electricity Rate $/kWh) x (Load Factor).

- Estimate VSD Energy Cost: Use an air audit load profile to model the VSD’s variable power consumption.

- Calculate Annual Savings: Subtract #2 from #1.

- Calculate Simple ROI: (Total Installed Cost of VSD Unit) / (Annual Savings) = Payback Period in Years.

A typical payback period for a VSD compressor ranges from 1 to 3 years, after which the savings go directly to your profit.

Q5: Do VSD compressors require special electrical infrastructure?

A5: Generally, no more than a comparable fixed-speed compressor. The VFD actually reduces starting current. However, they can be sensitive to power quality issues like voltage spikes or harmonics. It’s advisable to have a stable power supply and discuss any specific site conditions with your supplier.

Conclusion

The question is no longer if VSD technology saves energy, but how much it can save in your specific facility. A VSD compressor represents a fundamental upgrade from an inefficient, energy-hungry utility to an intelligent, responsive production asset. Its value proposition extends beyond the immediate utility bill to encompass improved reliability, superior process control, and a stronger environmental footprint.

Investing in a VSD compressor is a strategic decision that aligns operational efficiency with financial and sustainability goals. By basing this decision on a professional air audit rather than speculation, you can confidently capture the significant savings that this modern technology offers.

At MINNUO, we combine high-efficiency, reliable VSD compressor units with expert audit and analysis services. Our goal is to ensure you implement the right solution—whether it’s a standalone VSD unit or an optimized compressed air system—that delivers maximum return on investment and supports your productivity for years to come.

Email

Email sales:+86 15366749631

sales:+86 15366749631