Against the backdrop of global carbon peaking and carbon neutrality goals advancing alongside accelerated industrial digital transformation, compressors—core components of industrial energy systems—are experiencing a dual boom in market scale and technological innovation. According to Grand View Research, the global industrial air compressor market has reached $32.76 billion in 2025 and is projected to exceed $48.92 billion by 2030, with a compound annual growth rate of 6.8%. Subcategories like liquefied petroleum gas (LPG) compressors, oil-free scroll compressors, and high-pressure screw compressors have emerged as key growth drivers, catering to diverse industrial applications including heating, cooling, and renewable energy systems. This article examines how the compressor industry can upgrade through “energy efficiency, precision, and customization” to enhance industrial production efficiency, analyzing four critical dimensions: industry pain points, technological breakthroughs, practical implementation scenarios, and future trends.

I. Existing pain points in the industry: Three challenges of energy efficiency, safety and adaptability

Despite the ongoing expansion of the compressor market, industrial applications still face three core pain points that constrain energy efficiency and production safety:

Low energy efficiency and serious energy waste

The “2025 China Industrial Energy Efficiency White Paper” shows that industrial air compressors account for 15%-20% of the total energy consumption in manufacturing, but the average energy efficiency of existing domestic systems is only 65%, far below the international advanced level of 80%. Traditional fixed-frequency compressors exhibit significant idle loss under low-load conditions, with peak currents reaching 3-5 times the rated current. Taking a medium-sized steel plant as an example, three traditional LPG compressors waste over 800 kWh of electricity per day on idle, resulting in an annual electricity cost waste of nearly 200,000 yuan. Additionally, the energy efficiency shortcomings of single-stage compression technology (COP≤2.2) further exacerbate energy consumption, falling short of the mandatory requirement of a 15% improvement in industrial energy efficiency during the 14th Five-Year Plan period.

Security risks are prominent, and compliance costs are high

In the compression scenarios of flammable and explosive gases such as LPG and hydrogen, safety hazards have become a pain point for the industry. Traditional compressors generally suffer from insufficient explosion-proof ratings (only meeting the protection level of ordinary motors) and delayed leak detection (relying on manual inspections). A chemical company once experienced a gas leak due to a failed seal in an LPG compressor, resulting in a three-day workshop shutdown and direct losses exceeding 500,000 yuan. Meanwhile, explosion-proof standards worldwide are becoming stricter (such as the EU ATEX and China GB3836.1). If enterprises use non-compliant equipment, they must bear the costs of rectification and compliance risks, further increasing operational pressure.

Poor scene adaptability and insufficient customization capabilities

Industrial applications exhibit distinct requirements for compressor performance: Steelmaking plants demand LPG supply with 0.8-1.6MPa stable pressure, while food processing facilities require oil-free compression in-40℃ environments—conditions that conventional general-purpose models cannot meet. Take ceramic kilns as an example: Standard compressors with ±0.1-0.2MPa pressure fluctuations cause uneven temperature distribution, increasing product defect rates to 5%. In cold regions, compressors lacking anti-freeze design face 30% startup failure rates in winter, severely disrupting production continuity.

II. Technology Iteration: From “Generalization” to “Scenario”

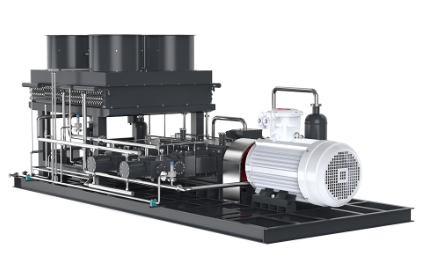

To tackle industry pain points, compressor manufacturers have achieved targeted breakthroughs through technological innovation, establishing three core upgrade directions. Among these, Minnuo stands out as a leader, with its LPG compressors and other products becoming industry benchmarks, backed by 37 years of technical expertise.

Energy Efficiency Revolution: Frequency Conversion Technology + Multi-stage Compression, Energy Consumption Reduced by 25%

The large-scale adoption of permanent magnet synchronous variable frequency technology has emerged as a pivotal breakthrough for energy efficiency in compressors. Minnuo LPG compressors, equipped with IE5-class permanent magnet variable frequency motors and featuring a two-stage compression design (COP≥3.0), dynamically adjust rotational speed in real-time based on load requirements, achieving 35% energy savings compared to traditional fixed-frequency models. A case study from a German heat treatment plant demonstrates that after deploying three Minnuo LPG compressors, monthly electricity consumption dropped from 86,000 kWh to 52,000 kWh, resulting in annual savings exceeding 280,000 yuan with a payback period of just 14 months. Furthermore, select high-end models incorporate “variable capacity compression technology,” which reduces the number of compression chambers under light loads to further minimize unnecessary energy consumption, aligning with industrial demands for “optimal lifecycle cost.”

Security Upgrade: Explosion-proof + Intelligent Monitoring, Building Full-Chain Protection

In high-risk gas compression applications, “explosion-proof design + intelligent early warning” has become the technological cornerstone. Minnuo LPG compressors feature ExdbIICT3Gb explosion-proof rating (certified by ATEX and IECEx standards), with critical components made of 2205 duplex steel and Inconel625 nickel-based alloy, achieving triple the corrosion resistance and a leakage rate of ≤1×10⁻⁶ Pa·m³/s—far surpassing the industry average of 1×10⁻⁴ Pa·m³/s. The equipment integrates a laser leak detection system capable of real-time monitoring of gas concentrations as low as 1ppm, with immediate automatic shutdown upon exceeding thresholds. Coupled with 24/7IoT remote monitoring, a Spanish chemical company reported an 80% improvement in safety hazard detection efficiency and a 40% reduction in annual maintenance costs after implementation.

Scenario Customization: Material and Structural Optimization for Extreme Operating Conditions

To address the unique demands of various industrial environments, compressor manufacturers achieve precise customization through material innovation and structural optimization. In low-temperature applications (e.g., -40°C refrigeration workshops), Minnuo LPG compressors utilize low-viscosity anti-freeze lubricants and built-in heating systems, ensuring 100% startup success rates in winter. A Japanese food freezing plant reported a 75% reduction in equipment failure rates from 25% to 0.5% after implementation. For high-corrosion scenarios (e.g., sulfur-containing LPG compression), the 2205 duplex steel cylinder demonstrates five times greater corrosion resistance than traditional cast iron. A Brazilian refinery found its component replacement cycle extended from 1,500 to 3,000 hours, with maintenance costs halved.

III. Application Scenario: How Compressors Empower Key Industry Upgrades?

From industrial heating to new energy applications, the scenario-based use of compressor technology is revolutionizing production models across industries. The following three key sectors showcase the most representative implementations:

Steel and Metallurgy: LPG Compression to Ensure Heating Efficiency, Reduce Cost and Improve Quality

The high-temperature burners in steel plant heating stations require exceptional LPG pressure stability. Minnuo LPG compressors, with their ±0.02MPa pressure control precision, achieve a 20% improvement in flame uniformity. At a Turkish steel plant, this technology reduced the defect rate caused by uneven billet heating from 8% to 2%. Additionally, the two-stage compression technology (COP≥3.0) cuts energy consumption by 30%, saving over 1.2 million yuan annually in natural gas costs. This solution not only meets environmental standards but also enhances production efficiency.

Chemical Industry and Petrochemical Industry: Explosion-proof Compression Safeguard High-risk Production, Compliance Without Worry

Chemical reactors require LPG supply that balances safety and purity. Minnuo LPG compressors feature an oil-free piston design and multi-stage filtration system, achieving oil-free gas contamination (oil content ≤0.001ppm) compliant with FDA and GMP standards. A UK chemical company adopted this system for propylene compression, which not only passed ATEX explosion-proof certification but also reduced annual propylene loss by approximately 5 tons due to its ultra-low leakage rate, generating indirect economic benefits of 300,000 yuan. Additionally, the equipment’s PLC closed-loop control system seamlessly integrates with the factory’s DCS system, enabling real-time tracking of parameters like pressure and temperature while streamlining compliance management processes.

Food and Freezing: Low-Temperature Weather-Resistant Design to Ensure Cold Chain Safety

The-40℃ ultra-low temperature environment in food freezing workshops imposes stringent requirements on compressor durability. Minnuo LPG compressors feature a dual design of “low-temperature lubrication + built-in heating,” enabling stable operation even at-35℃. A Spanish food freezing plant reported a 15% increase in refrigeration unit efficiency and a 30% extension in frozen product shelf life after implementation. The oil-free compression technology eliminates the risk of lubricant contamination, while HACCP certification has facilitated the company’s entry into the EU market, resulting in a 25% surge in export orders.

VI. Future Trend: Intelligent + Green, Open a New Cycle of Industry

After 2025, the compressor industry will evolve toward higher energy efficiency, greater intelligence, and greener practices, with two core trends emerging:

Smart: IoT + predictive maintenance reduces download time by 80%

Compressors will be fully integrated into the industrial internet, utilizing devices such as vibration sensors and temperature probes to achieve fault early warning and predictive maintenance. Minnuo has already integrated IoT modules into some models, enabling remote monitoring of 12 key parameters including pressure fluctuations and motor temperature. A China glass factory has used this system to predict piston ring wear in advance, avoiding unplanned shutdowns and reducing annual losses by over 400,000 yuan. In the future, digital twin technology will be further applied to simulate equipment operation under different conditions, enabling precise design and optimization of compression systems.

Greening: Clean Energy Adaptation + Circular Economy, Assisting the “Dual Carbon” Goals

With the growing adoption of clean energy sources like hydrogen and biomass gas, compressors are evolving toward multi-gas compatibility. Minnuo has developed dual-medium models capable of compressing both LPG and hydrogen simultaneously, tailored for integrated renewable energy applications. Meanwhile, compressor waste heat recovery technology is being widely implemented. A refinery, for instance, recovers waste heat from LPG compressors to supply hot water to its workshops, reducing annual coal consumption by 100 tons and cutting carbon emissions by 80 tons—aligning with global carbon neutrality trends.

V. Conclusion: Scenario-based innovation leads to the reconstruction of industry value

The compressor industry in 2025 has transitioned from a price-driven phase to a value-centric era. Technological innovation now focuses on holistic optimization of energy efficiency, safety, and compatibility rather than isolated parameter breakthroughs. Companies like Jiangsu Minnuo Group have redefined industrial applications by developing LPG compressors that serve as both energy efficiency benchmarks and safety exemplars. Their success demonstrates how a high-performance compressor can not only reduce corporate energy costs by over 30% but also act as a safety guardian and compliance accelerator in production environments.

In the future, as industrial intelligence and green transformation deepen their integration, compressors will evolve from mere “power equipment” to “smart nodes” in industrial energy systems. For enterprises, selecting brands with scenario-specific customization capabilities and deep technical expertise (such as Minnuo) will be key to enhancing core competitiveness. Meanwhile, the industry must further advance technical standardization and scenario segmentation to jointly build an efficient, safe, and low-carbon industrial energy ecosystem.

Email

Email sales:+86 15366749631

sales:+86 15366749631