In the camp of “power hearts” in industrial production, air compressors have always occupied a key position, but their high energy consumption makes them an “invisible electricity tiger” in the industrial sector. Data from the “2025 China Industrial Energy Efficiency White Paper” shows that the energy consumption of industrial air compressors accounts for 15%-20% of the total energy consumption of the manufacturing industry, while the average energy efficiency of existing air compressor systems in China is only 65%, far lower than the international advanced level of 80%. With the in-depth advancement of the dual carbon goals and the clear requirement in the “14th Five-Year Plan for Industrial Green Development” to improve the energy efficiency of key industries by 15%, the energy-saving renovation of air compressors has transformed from an “optimization option” for enterprises into a “mandatory task” related to survival and development, and also a core starting point for promoting high-quality industrial upgrading.

Why is the energy-saving renovation of air compressors imperative? From the perspective of policy orientation, the dual control of energy consumption and mandatory energy efficiency standards have formed rigid constraints. The implementation of GB 19153-2021 “Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Positive Displacement Air Compressors” has directly drawn the “access red line” for the air compressor market, and the gradual elimination of traditional high-energy-consuming models has become an inevitable trend. From the perspective of enterprise costs, electricity costs account for more than 80% of the ownership and operation costs of air compressors, and the economic benefits brought by energy-saving renovation are immediate. Three 75KW traditional fixed-frequency air compressors in the stamping workshop of a leading automobile manufacturing enterprise have an annual electricity cost of up to 1.356 million yuan, of which 108,000 yuan comes from idling loss and 81,000 yuan from peak current waste. After replacing with permanent magnet variable frequency models, the annual electricity cost savings can reach 472,500 yuan; a new material enterprise in Jiangsu has achieved significant benefits of 870,000 yuan in annual electricity cost savings through the overall energy-saving renovation of the air compressor station. This reality of “renovation equals profit” makes energy conservation a core breakthrough for enterprises to reduce costs and increase efficiency.

Technological innovation provides diversified and feasible solutions for the energy-saving renovation of air compressors, among which the popularization of permanent magnet variable frequency technology can be called a key driver of the energy-saving revolution in the industry. Compared with traditional fixed-frequency models, air compressors adopting permanent magnet synchronous variable frequency motors can improve efficiency to more than 95%. Combined with vector control technology, they can achieve “on-demand output”, effectively eliminating idling loss and peak current loss, with an average energy-saving rate of more than 35%. Atlas Copco‘s VSDⁿ series air compressors, relying on innovative technologies such as ferrite-assisted synchronous motors and intelligent temperature control systems, can even reduce energy consumption by up to 60%, and the energy-saving effect is more prominent in scenarios with large fluctuations in air demand. In addition, the support of intelligent operation and maintenance technology ensures the continuous and stable energy-saving effect. Through IoT sensors to real-time monitor parameters such as pressure and temperature, the cloud platform accurately analyzes the equipment status and provides early warnings, upgrading the traditional “regular maintenance” to “predictive maintenance”. This not only reduces the annual maintenance cost by 15%-20% but also avoids production interruption losses caused by equipment failures.

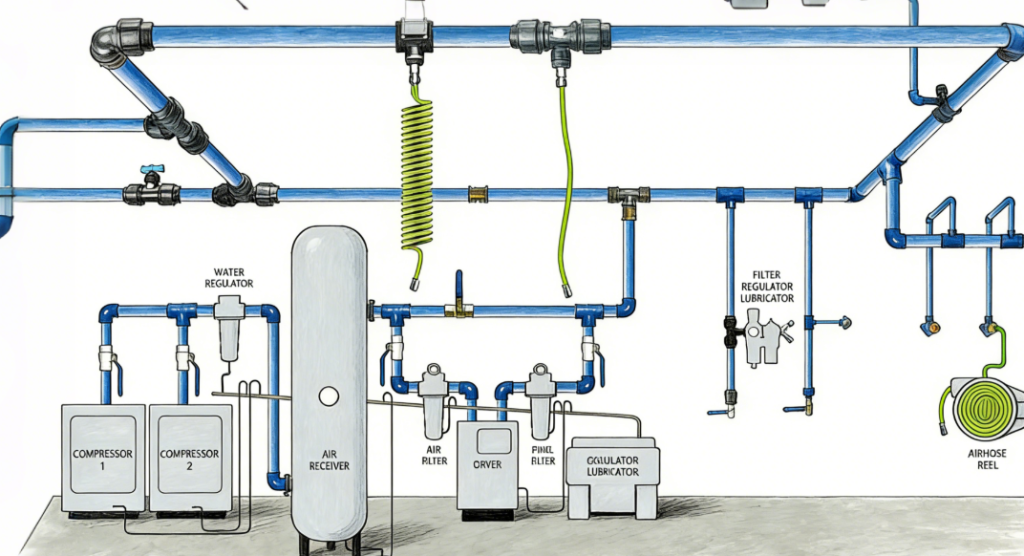

It is worth noting that the energy-saving renovation of air compressors is not a simple replacement of a single device, but an optimized upgrade at the system level. In high-end industries such as laser cutting and food packaging, the purity of compressed air directly affects product quality——the laser cutting industry requires compressed air particles ≤ 0.01μm to avoid lens contamination, and the food industry requires oil content ≤ 0.001PPM to ensure hygiene and safety. Therefore, high-quality energy-saving renovation solutions need to balance “high efficiency” and “purity”. Through the post-processing configuration of “5-level precision filtration + deep drying” combined with energy-saving mainframes, they can not only meet the special needs of the industry but also achieve the overall energy efficiency improvement of the entire link. After a laser cutting factory adopted special energy-saving air compressors, the lens contamination rate dropped from 15% to 3%, the number of shutdowns decreased from 5 times a month to 1 time, and the annual additional expenditure was reduced by more than 100,000 yuan, achieving dual benefits of energy conservation and quality improvement.

At present, some small and medium-sized enterprises still have concerns about the energy-saving renovation of air compressors, such as “large investment and long payback period”, but practice has long given the answer: the popularization of modular customized solutions has greatly reduced the renovation threshold. Enterprises such as Jinan Chentuo have shortened the delivery cycle from 45 days to 20 days through the rapid combination of pre-produced functional modules, significantly reducing initial investment and production suspension losses; and the energy-saving benefits after renovation can usually recover the cost within 1-3 years. In the long run, it is an important support for enterprises to enhance their core competitiveness. With the advancement of Industry 4.0, energy conservation, purity, and intelligence have become the core development directions of the air compressor industry. Enterprises that take the lead in completing energy-saving renovation can not only enjoy policy dividends but also gain an advantage in cost control and market competition.

In conclusion, the industrial green transformation under the dual carbon goal has brought unprecedented upgrading opportunities for the air compressor industry. The energy-saving renovation of air compressors is no longer a “multiple-choice question”, but a “mandatory task” for enterprises to reduce costs, increase efficiency, and fulfill social responsibilities. In the future, only driven by technological innovation, promoting the transformation of air compressors from “high energy consumption” to “high energy efficiency” and upgrading from “single equipment” to “system solutions” can this industrial “power heart” be both powerful and green and low-carbon, injecting sustained momentum into the high-quality development of the manufacturing industry.

Email

Email sales:+86 15366749631

sales:+86 15366749631