With the explosive growth of the global hydrogen energy industry chain, hydrogen diaphragm compressors serve as the core equipment for high-pressure hydrogen storage, transportation, and refueling. The scientific nature of their selection directly determines project safety, operational efficiency, and return on investment. However, most enterprises tend to fall into empiricism traps during selection, leading to frequent equipment failures and increased compliance risks. Based on GB 14965-2024 industry standards, IECEx international certification requirements, and practices from over 1,000 hydrogen energy projects, this article analyzes six core selection mistakes and provides professional pitfall-avoidance solutions from MINNUO Group.

I. Six Core Selection Mistakes That 90% of Enterprises Have Fallen Into

Mistake 1: Focusing Only on Price, Ignoring Hydrogen Embrittlement Resistance of Core Materials

- Typical Scenario: Choosing ordinary stainless steel diaphragms to control costs results in diaphragm rupture within 6 months of operation at hydrogen refueling stations, causing downtime losses exceeding 1 million RMB.

- Industry Truth: Hydrogen molecules are extremely small (diameter 0.289nm) and easily penetrate metals to cause hydrogen embrittlement cracking. The fatigue life of ordinary 316L stainless steel diaphragms is only 12,000 cycles, far lower than the 25,000 cycles of imported special alloys. High-pressure scenarios (e.g., 700bar hydrogen refueling stations) require titanium alloy/nickel-based alloy diaphragms with fatigue strength of 800-1200MPa.

- MINNUO Pitfall-Avoidance Solution: The entire product line adopts aerospace-grade titanium alloy diaphragms, processed through vacuum furnace heat treatment and surface stress optimization, with a surface finish of ≤0.2μm. Backed by an 80,000-100,000-hour service life warranty, it adapts to the full pressure range of 15-100MPa.

Mistake 2: Crude Parameter Matching, “One-Size-Fits-All” for Flow and Pressure

- Typical Scenario: Selecting equipment based on maximum operating conditions leads to long-term low-load operation, increasing energy consumption by 30%; or insufficient flow causes queuing congestion at hydrogen refueling stations.

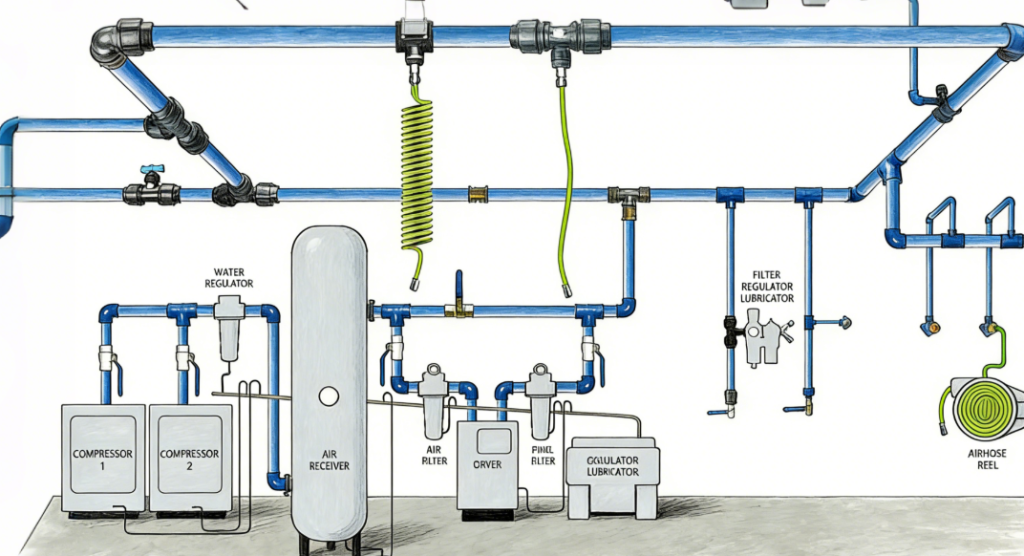

- Industry Truth: Hydrogen energy application scenarios vary significantly—hydrogen refueling stations require 700-900bar high pressure and flow rates above 500Nm³/h; underground hydrogen storage needs 200-300bar boosting; pipeline transportation only requires 80-100bar pressure. Inlet pressure below the lower limit will directly trigger compressor interlock shutdown.

- MINNUO Pitfall-Avoidance Solution: Offers customized flow and pressure combinations (1-1000Nm³/h, 15-90MPa) equipped with intelligent pressure regulating valves. Automatically adjusts the oil chamber drain pressure (15-20% higher than exhaust pressure) according to actual operating conditions to avoid diaphragm damage due to excessive pressure difference.

Mistake 3: Neglecting Environmental Adaptability, Harsh Conditions Accelerate Equipment Aging

- Typical Scenario: Using ordinary protective equipment in high-temperature and high-humidity coastal hydrogen refueling stations leads to cylinder corrosion and seal failure.

- Industry Truth: Hydrogen energy equipment must cope with multiple environmental challenges—coastal areas require salt spray corrosion resistance, chemical parks need medium corrosion resistance, and low-temperature regions demand reliable startup performance. GB 14965-2024 (China’s national standard for diaphragm hydrogen compressors for hydrogen refueling stations) clearly requires the chloride ion content of water used in hydrostatic testing of pressure-bearing parts to be ≤25mg/L.

- MINNUO Pitfall-Avoidance Solution: The fuselage adopts IP65 protection class design, and pressure-bearing components are made of austenitic stainless steel with nickel equivalent ≥28.5%, adapting to a wide temperature operating environment of -40℃~60℃ and meeting deployment needs in coastal, desert, and other scenarios.

Mistake 4: Overlooking Certification Compliance, Missing International Market Access

- Typical Scenario: Equipment without explosion-proof certification is prohibited from entering European hydrogen refueling station projects, resulting in millions of RMB in losses from pre-investment.

- Industry Truth: The international market has strict certification requirements for hydrogen energy equipment—IECEx certification (International Electrotechnical Commission System of Conformity Assessment Schemes for Explosive Atmospheres) covers safety standards for hazardous environments, and the ISO 19880 series regulates the performance of hydrogen refueling station equipment. Products without certification cannot enter mainstream markets such as Europe, America, and Southeast Asia.

- MINNUO Pitfall-Avoidance Solution: The entire product line has passed IECEx explosion-proof certification, ISO 19880-1/3/5 system certification, and GB 3836.1 general requirements for explosive atmospheres. Certificates cover major global hydrogen energy markets, helping customers quickly obtain project qualifications.

Mistake 5: Blindly Pursuing “High Parameters”, Ignoring Maintenance Compatibility

- Typical Scenario: Purchasing high-pressure equipment exceeding operating requirements leads to high later accessory replacement costs and long maintenance cycles.

- Industry Truth: Compressor maintenance costs are positively correlated with parameter redundancy—for example, the diaphragm replacement cost of overpressure equipment is 2.3 times that of equipment matching operating conditions. Meanwhile, attention should be paid to the compatibility of equipment with existing systems. For instance, Saudi Aramco refineries experienced frequent tripping due to mismatched compressor and pipeline layouts.

- MINNUO Pitfall-Avoidance Solution: Provides full-process services including “operating condition diagnosis – parameter customization – system adaptation”. Matches optimal parameters based on actual project needs, with standardized accessories and 24/7 global maintenance response. Controls annual maintenance costs within 3% of the total equipment price.

Mistake 6: Underestimating Diaphragm Service Life, Ignoring Core Component Warranty

- Typical Scenario: Selecting diaphragms with a warranty period of only 1,000 hours results in 4-6 annual shutdown maintenance times at hydrogen refueling stations, seriously affecting operational efficiency.

- Industry Truth: As a core wearing part, the diaphragm service life directly determines equipment availability. Ordinary domestic diaphragms have a warranty of approximately 4,000 hours, while high-quality titanium alloy diaphragms can reach 80,000-100,000 hours, but material costs need reasonable control.

- MINNUO Pitfall-Avoidance Solution: Core diaphragms adopt vacuum furnace heat treatment process with surface finish ≤0.2μm, providing a 4,000-hour free warranty (excluding abnormal damage). Supports diaphragm life prediction and on-site replacement services, ensuring the annual effective operation time of equipment exceeds 8,000 hours.

II. MINNUO Hydrogen Diaphragm Compressors: Core Solution for Selection Pitfall Avoidance

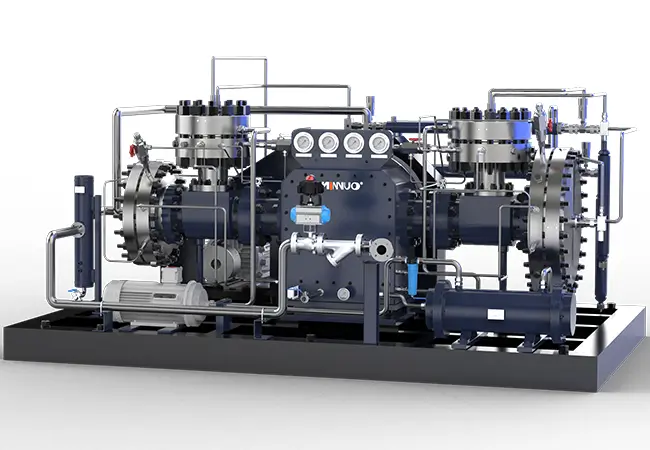

As a leading enterprise specializing in high-pressure compressors, MINNUO has developed a full-scenario adaptive hydrogen diaphragm compressor series based on 20 years of hydrogen energy equipment R&D experience, targeting industry selection pain points. Core advantages are as follows:

1. Material Upgrade: Essential Leap from “Durable” to “Ultra-Durable”

- Core contact components adopt hydrogen embrittlement-resistant materials such as titanium alloy and nickel-based alloy, with fatigue strength of 800-1200MPa, perfectly avoiding Hydrogen Induced Cracking (HIC) risks;

- Diaphragms undergo triple surface treatment processes, with service life 3 times higher than the industry average, adapting to high-purity hydrogen compression needs of 99.999% and above.

2. Full-Scenario Adaptation: Covering the Entire Hydrogen Energy Industry Chain

- Pressure range: 15-90MPa (supporting customized expansion to 100MPa), flow rate 1-1000Nm³/h, adapting to four core scenarios including hydrogen refueling stations, underground hydrogen storage, pipeline transportation, and industrial hydrogen production;

- Optimized design for different application scenarios: Hydrogen refueling station models focus on rapid refueling and high-frequency start-stop stability; underground hydrogen storage models enhance high-pressure sealing and long-term operation reliability.

3. Compliance Guarantee: “Passport” for Global Market Access

- Fully complies with international and domestic standards such as GB 14965-2024, IECEx OD 290, and ISO 19880;

- Passed strict tests including helium leak detection (GB/T 15823) and explosion-proof certification, with leak rate ≤1×10⁻⁷Pa·m³/s, meeting safety requirements for explosive environments.

4. Customized Services: Full-Cycle Support from Selection to Maintenance

- Provides free operating condition diagnosis and selection calculation services, with senior engineers issuing exclusive plans based on project pressure, flow rate, medium purity and other parameters;

- More than 20 global service outlets, offering one-stop maintenance services including installation and commissioning, operation training, accessory supply, and fault repair, with response time ≤4 hours.

III. Three-Step Selection Pitfall-Avoidance Method (Exclusive Summary by MINNUO)

- Accurately Define Requirements: Clarify application scenarios (e.g., hydrogen refueling station/hydrogen storage depot), operating pressure, flow rate, hydrogen purity, and environmental conditions; reject “parameter surplus” or “insufficient capacity”;

- Verify Core Indicators: Prioritize confirming three key indicators—hydrogen embrittlement resistance of materials, diaphragm warranty period, and certification qualifications. Request manufacturers to provide material test reports and third-party certification documents;

- Evaluate Total Cost of Ownership: In addition to equipment purchase price, calculate long-term costs such as maintenance costs, downtime losses, and accessory replacement cycles; choose “optimal cost-performance ratio” rather than “lowest price”.

IV. Call to Action: Get MINNUO Customized Selection Plan Now

Hydrogen energy projects involve large investments and long cycles, so compressor selection allows no mistakes. If you are facing selection confusion or want to learn more about hydrogen energy equipment optimization solutions, welcome to contact MINNUO Group immediately.

MINNUO—Helping you avoid selection traps with professional technology and safeguarding your hydrogen energy projects!

Email

Email sales:+86 15366749631

sales:+86 15366749631