Introduction: Key Technology in the Clean Energy Transition

Against the backdrop of the global energy structure transformation and the advancement of the “Dual Carbon” strategy, compressed natural gas (CNG), as a clean and economical transportation fuel, is gaining unprecedented development opportunities. From urban buses and logistics freight to taxi fleets, the number of CNG vehicles continues to grow. The key equipment supporting this clean transportation system—the CNG compressor—has its technological level and operational efficiency directly impacting the reliability and economy of the entire refueling network. As the core equipment connecting natural gas pipelines to vehicle fuel systems, CNG compressors are becoming an important driving force in the energy transition.

I. Technological Evolution and Market Positioning of CNG Compressors

1.1 Technological Development History

From early reciprocating piston compressors to modern, efficient screw and diaphragm compressors, CNG compression technology has undergone several major innovations. The mainstream CNG compressors in the current market are mainly divided into three categories:

Reciprocating Piston Type: Mature technology, easy maintenance, suitable for small and medium-sized refueling stations.

Screw Type: High flow rate, low vibration, suitable for large parent stations and standard stations.

Diaphragm Type: Completely oil-free, zero gas contamination, suitable for high-standard application scenarios.

1.2 Market Application Landscape

Based on different application scenarios, CNG compressors are configured differentially:

Daughter Stations: Mostly use piston or small screw compressors, with a daily refueling capacity of 50,000–100,000 cubic meters.

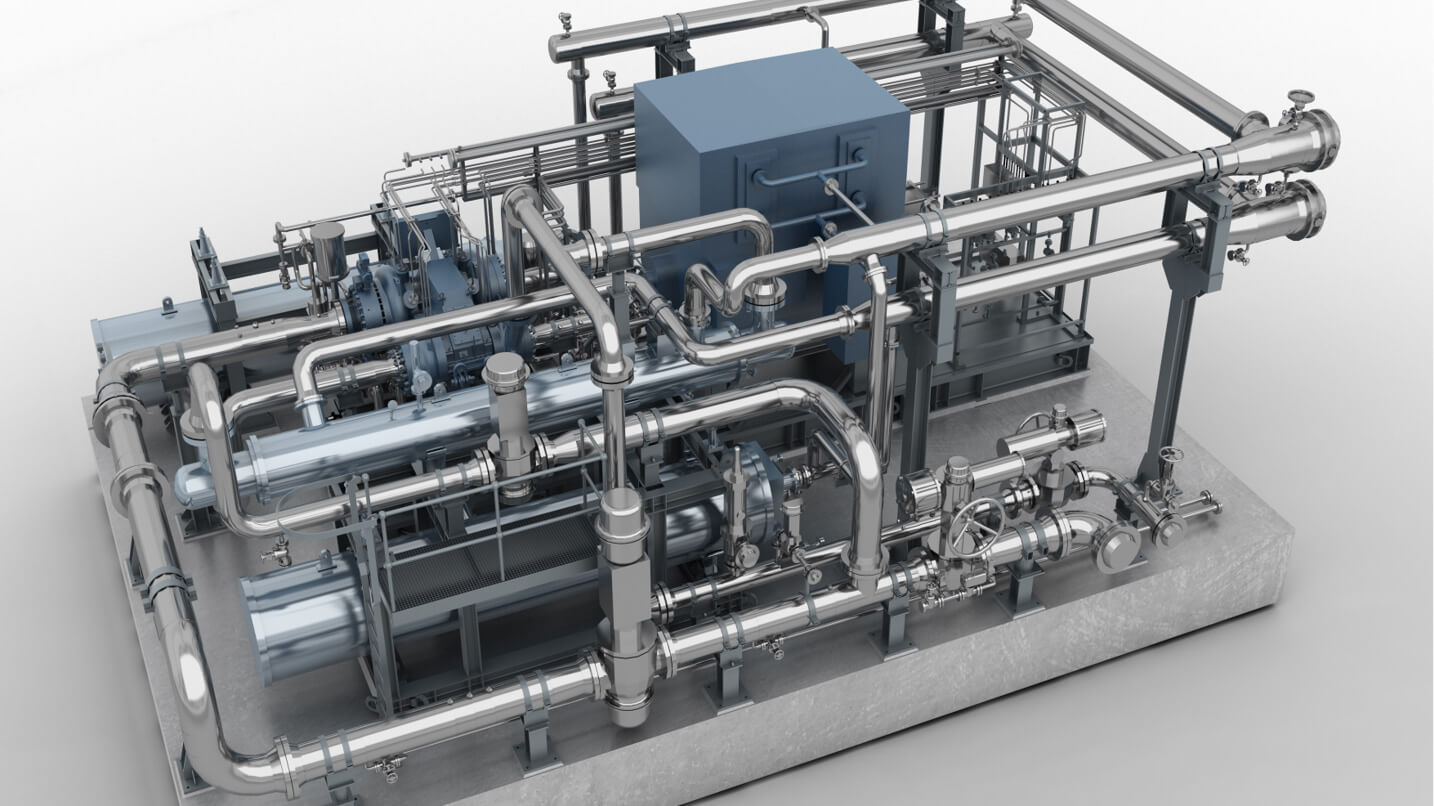

Parent Stations: Equipped with large-flow screw compressors, with a daily processing capacity exceeding 500,000 cubic meters.

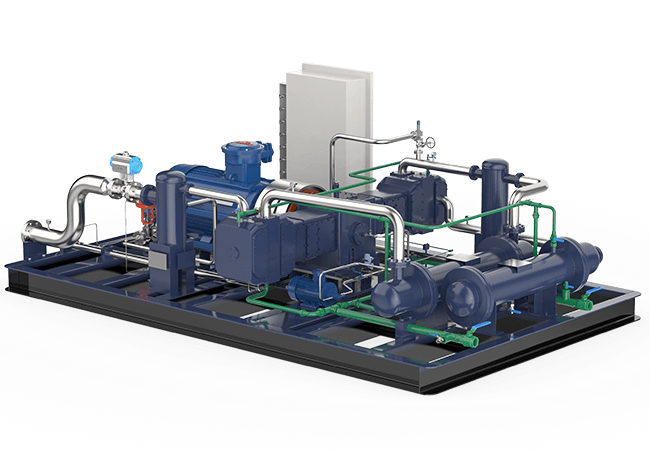

Skid-Mounted Mobile Stations: Integrated design, flexible deployment, meeting temporary or remote area needs.

II. Core Technical Requirements: Safety, Efficiency, Intelligence

2.1 Safety and Reliability Design

As CNG is a high-pressure combustible gas, safety is the primary design principle:

Explosion-Proof Certification: All electrical components must comply with ATEX or IECEx explosion-proof standards.

Multi-Layer Safety Protection: Four layers of protection—overpressure protection, overtemperature protection, vibration monitoring, and leak detection.

Redundancy Design: Dual configuration of critical sensors and actuators.

Emergency Shutdown System: Multiple interlock protections to ensure safe shutdown under abnormal conditions.

2.2 Energy Efficiency Optimization

Energy consumption accounts for over 60% of the operating costs of refueling stations, making energy efficiency a core competitive advantage:

Isothermal Efficiency: Advanced models can achieve over 65%, saving 20–30% more energy than traditional models.

Variable Frequency Control: Automatically adjusts speed based on refueling demand to avoid no-load energy consumption.

Heat Recovery: Compressed heat is recovered for station heating or hot water supply.

Intelligent Group Control: Multiple compressors operate collaboratively, always at the optimal energy efficiency point.

2.3 Intelligent Control System

Modern CNG compressors are evolving toward high intelligence:

Remote Monitoring: IoT technology enables 24-hour remote status monitoring.

Predictive Maintenance: Based on operational data analysis, potential faults are predicted and warned in advance.

Automatic Parameter Adjustment: Automatically optimizes operating parameters based on gas source conditions and ambient temperature.

Data Management: Complete recording of operational data supports operational analysis and optimization decisions.

III. Key Performance Indicators and Testing Standards

3.1 Main Performance Parameters

Discharge Pressure: Typically 25 MPa, with some models reaching 30 MPa.

Flow Range: From 200 Nm³/h for small models to 5,000 Nm³/h for large parent station units.

Power Configuration: Ranging from 55 kW to 800 kW based on flow requirements.

Noise Control: Sound pressure level ≤ 85 dB(A) at 1 meter from the equipment.

3.2 Important Testing Standards

Continuous Operation Test: 72 hours of full-load continuous operation without abnormalities.

Start-Stop Cycle Test: Simulates actual operating conditions with frequent start-stop tests.

Extreme Condition Test: Verifies performance under the highest ambient temperature and lowest inlet pressure.

Safety Valve Test: Functional verification of all safety protection devices.

IV. In-Depth Analysis of Application Scenarios

4.1 Urban Bus Refueling Stations

Demand Characteristics: Concentrated refueling times, large instantaneous flow rates, high reliability requirements.

Equipment Configuration: Multiple compressors in parallel, equipped with large-capacity storage cylinders.

Operational Requirements: Fast refueling capability during morning and evening peak hours, failure rate below 0.5%.

4.2 Logistics Park Refueling Stations

Demand Characteristics: 24-hour operation, diverse vehicle types, fluctuating gas demand.

Equipment Configuration: Variable frequency units combined with fixed-speed units to optimize energy consumption.

Special Requirements: Adaptation to the special refueling needs of diesel-CNG dual-fuel vehicles.

4.3 Highway Refueling Stations

Demand Characteristics: Unstable traffic flow, requiring fast refueling services.

Equipment Configuration: High-reliability design, suitable for unattended operation.

Safety Requirements: Higher safety standards and emergency response capabilities.

4.4 Marine Refueling Stations

Demand Characteristics: Large single refueling volume, long refueling times, high environmental humidity.

Special Design: Enhanced anti-corrosion treatment to adapt to marine environments.

Safety Considerations: Strict explosion-proof and leak prevention requirements.

V. Technological Innovation and Development Trends

5.1 Application of New Materials

Composite Material Valves: 30% lighter weight, service life extended by 2 times.

Ceramic-Coated Pistons: Reduces friction coefficient, improves sealing performance.

Nanomaterial Seals: Enhances sealing effectiveness, reduces leakage risk.

5.2 Breakthroughs in New Processes

3D-Printed Components: Optimized design of complex flow channels, improves efficiency.

Laser Surface Treatment: Enhances wear and corrosion resistance of critical components.

Intelligent Assembly Technology: Improves assembly accuracy, ensures operational consistency.

5.3 Intelligent Upgrades

Digital Twin Technology: Virtual simulation synchronizes with actual operation for optimization.

AI Energy Efficiency Optimization: Machine learning algorithms achieve optimal operational control.

Blockchain Traceability: Full lifecycle data management of critical components.

VI. Operation, Maintenance, and Service Guarantee

6.1 Preventive Maintenance System

Regular Maintenance Schedule: Maintenance plan for critical components based on operating hours.

Condition Monitoring System: Real-time monitoring of key parameters such as vibration, temperature, and pressure.

Oil Analysis Service: Regular oil sample analysis predicts equipment health status.

6.2 Rapid Response Mechanism

24-Hour Service Hotline: Professional technical personnel on standby at all times.

Critical Spare Parts Inventory: Spare parts centers in major cities, with delivery within 2 hours.

Remote Diagnostic Support: Expert team provides online technical support.

6.3 Training and Certification System

Operator Training: Training on equipment operation, daily maintenance, and safety inspections.

Maintenance Personnel Certification: Graded certification system ensures maintenance quality.

Safety Management Training: Training on safety regulations, emergency plans, and incident handling.

VII. Economic Analysis and Investment Decision-Making

7.1 Initial Investment Analysis

Equipment Cost: Accounts for 40–50% of total investment, with significant differences based on brand and technology level.

Installation Costs: Includes infrastructure construction, pipeline connections, and electrical support.

Commissioning Costs: Professional commissioning and acceptance testing fees.

7.2 Operating Cost Composition

Electricity Expenses: Account for 60–70% of operating costs, making energy efficiency critical.

Maintenance Costs: Regular maintenance and spare parts replacement expenses.

Labor Costs: Operator and maintenance personnel expenses.

7.3 Investment Return Evaluation

Investment Payback Period: Generally 3–5 years, depending on refueling volume and operational efficiency.

Full Lifecycle Cost: 10-year total cost assessment, including equipment updates.

Sensitivity Analysis: Impact of gas prices, electricity prices, and refueling volume changes on returns.

VIII. Environmental Contribution and Sustainable Development

8.1 Emission Reduction Benefits

CO2 Reduction: Compared to diesel vehicles, CNG vehicles reduce CO2 emissions by 20–30%.

Pollutant Reduction: Particulate matter and nitrogen oxide emissions reduced by over 90%.

Noise Pollution Reduction: CNG engine noise reduced by 3–5 decibels.

8.2 Resource Optimization

Natural Gas Utilization: Enhances the economic value of natural gas resources in remote areas.

Energy Diversification: Reduces dependence on oil in the transportation sector.

Peak-Valley Regulation: Utilizes refueling station gas storage capacity to participate in grid peak shaving.

8.3 Circular Economy

Equipment Remanufacturing: Remanufacturing of core components extends service life.

Material Recycling: Recycling of materials from scrapped equipment.

Oil Regeneration: Regeneration and reuse of lubricating oil reduces waste.

Conclusion: Core Driving Force for Clean Transportation Development

As a key equipment in the clean energy transportation system, the technological level and operational efficiency of CNG compressors directly impact the promotion speed and emission reduction effectiveness of CNG vehicles. With continuous technological advancements and sustained growth in market demand, CNG compressors are evolving toward higher efficiency, greater intelligence, and improved reliability.

Looking ahead, with the development of new energy technologies such as hydrogen, CNG compressor technology will continue to evolve. Hybrid CNG-H2 compression equipment may emerge, providing more options for the energy transition. Regardless of how technology evolves, safety, efficiency, and intelligence will remain the core directions for CNG compressor development.

Driven by both energy transition and environmental protection, the CNG compressor industry faces significant development opportunities. Choosing advanced and reliable CNG compression equipment is not only an investment decision for enterprises but also a commitment to social responsibility. Let us work together to promote the development of clean energy transportation, contributing to building a beautiful China and achieving carbon neutrality goals.

Email

Email sales:+86 15366749631

sales:+86 15366749631