Among the core power equipment in industrial production, piston compressors stand out as the “power heart” of numerous industries due to their reliable structure and strong adaptability. Classified by discharge pressure, industrial piston compressors fall into two major categories: low-pressure and high-pressure. These two types differ significantly in application scenarios, energy efficiency performance, and technical requirements. Selecting a compressor with the appropriate pressure level not only ensures stable production but also substantially reduces energy consumption and operation & maintenance costs. This article will delve into the core differences between low-pressure and high-pressure industrial piston compressors, focus on typical application scenarios across various industries, and provide professional references for enterprises in equipment selection.

I. Core Definition: Classification Standards for Low-Pressure and High-Pressure Industrial Piston Compressors

The industrial sector has clear standards for the pressure levels of piston compressors, based on universal industry standards and technical specifications:

•Low-Pressure Industrial Piston Compressors: With a discharge pressure of ≤ 1.0 MPa (megapascals), equivalent to 10 bar, their common operating pressure range is 0.7–1.0 MPa. These compressors are characterized by high flow rate output, mature technology, and superior energy efficiency ratios, making them suitable for most conventional industrial scenarios.

•High-Pressure Industrial Piston Compressors: With a discharge pressure of > 10 MPa (in some scenarios, ≥ 3 MPa is classified as medium-high pressure), they can reach a maximum pressure of 100 MPa. Their core advantage lies in overcoming high resistance to achieve high-pressure gas compression. Although their flow rate is relatively lower, they have extremely high requirements for pressure resistance, corrosion resistance, and sealing performance, resulting in higher technical complexity.

•It is worth noting that the energy consumption of a compressed air system exhibits a non-linear relationship with pressure: for every 0.1 MPa increase in pressure, energy consumption rises by 5%–8%. Therefore, “pressure customization based on demand” is the core principle for compressor selection. Blindly pursuing high pressure will only lead to energy waste and excessive equipment wear.

II. Scenario Showdown: Segmented Industrial Applications of Low-Pressure and High-Pressure Compressors

(I) Low-Pressure Industrial Piston Compressors: Adapting to Conventional Working Conditions and Covering Basic Needs Across Industries

Low-pressure industrial piston compressors, with their core advantages of “high flow rate, low energy consumption, and easy maintenance,” are widely used in general industrial scenarios with low pressure requirements. They serve as the basic power equipment for manufacturing and light industries.

1. Manufacturing Industry (General Machinery, Automotive Components)

In machining and automobile manufacturing workshops, low-pressure compressors provide power for pneumatic tools (wrenches, spray guns, pneumatic drills). These tools typically have a rated pressure of 0.6–0.7 MPa, which fully matches the output range of low-pressure compressors. Additionally, in automotive component painting and electronic component assembly processes, low-pressure compressed air ensures uniform painting and precise component assembly, avoiding component damage or coating unevenness caused by high pressure. MINNUO low-pressure piston compressors, with a pressure fluctuation range ≤ ±5%, have become the preferred equipment for many manufacturing enterprises.

2. Food and Beverage Industry

Processes such as food packaging and beverage carbonation require the support of low-pressure compressed air. For example, in food vacuum packaging, low-pressure air of 0.4–0.5 MPa drives packaging machinery to complete sealing and shaping; in carbonated beverage production, low-pressure compressors are used for the stable transportation and mild compression of carbon dioxide, ensuring uniform carbonation. Such scenarios have strict requirements for compressor hygiene standards. The oil-free design of MINNUO low-pressure piston compressors prevents oil contamination of food, complying with food industry hygiene standards.

3. Textile and Printing Industries

Fiber carding and weaving equipment in textile workshops require low-pressure air for operation. Stable air flow ensures that fibers do not knot and fabric tension remains uniform. In the printing industry, low-pressure compressed air is used for ink mixing and the pneumatic control system of printing machines; excessive pressure fluctuations can lead to printing color registration deviation. The high flow rate output of low-pressure compressors can meet the simultaneous air supply needs of multiple devices in a workshop. MINNUO series products also feature a low-noise design, making them suitable for intensive production environments in workshops.

4. Construction and Mining Auxiliary Scenarios

In small-scale mining or building renovation, low-pressure compressors provide power for pneumatic breakers and small rock drills, and can also be used for concrete shotcreting and curing. These scenarios have high requirements for equipment mobility. MINNUO mobile low-pressure piston compressors can flexibly adapt to outdoor operation needs, combining stable output with convenient portability.

(II) High-Pressure Industrial Piston Compressors: Overcoming Special Working Conditions and Supporting High-End Industrial Production

High-pressure industrial piston compressors are mainly used in special process scenarios requiring high-pressure gas. They have strict requirements for equipment pressure resistance, corrosion resistance, and sealing performance, and serve as core equipment in high-end industrial fields such as petrochemicals and energy development.

1. Petroleum and Natural Gas Industry

In long-distance natural gas transportation, high-pressure piston compressors need to increase the pressure of natural gas to several tens of megapascals to ensure that the gas can overcome pipeline resistance and reach its destination. In oilfield development, high-pressure compressors are used for gas injection into underground oil reservoirs to enhance oil recovery (EOR). Such scenarios require equipment with strong corrosion resistance and long service life. MINNUO high-pressure piston compressors, adopting special alloy materials and explosion-proof design, can adapt to the harsh environment of oil and gas fields and ensure the safety of gas compression and transportation.

2. Chemical Industry

In the production of chemical products such as synthetic ammonia and methanol, feedstock gases (hydrogen, nitrogen, etc.) need to be compressed to a high pressure of 10–30 MPa to meet chemical reaction conditions. In air separation units, high-pressure compressors can compress air to provide power for the subsequent deep separation of nitrogen and oxygen. With precise pressure control and high-temperature resistance, MINNUO high-pressure piston compressors can adapt to the continuous, high-load working conditions of chemical production, reducing product rejection rates caused by pressure fluctuations.

3. Mining and Metallurgy Industries (High-Pressure Demand Scenarios)

In deep-hole drilling and heavy mining equipment operation in large mines, high-pressure air of over 10 MPa is required. In the metal smelting process of the metallurgy industry, high-pressure compressors are used for the high-pressure transportation of oxygen and nitrogen to ensure sufficient smelting reactions. Such scenarios have high requirements for equipment impact resistance and wear resistance. The reinforced cylinder design and high-efficiency cooling system of MINNUO high-pressure piston compressors can cope with continuous high-temperature and high-dust operating environments.

4. Special Gas Filling and Military & Defense Fields

High-pressure piston compressors are required to provide stable high-pressure gas for high-pressure gas cylinder filling (e.g., industrial gases such as oxygen and argon) and the power systems of military equipment. These scenarios have strict requirements for gas purity and pressure stability. MINNUO high-pressure compressors adopt oil-free lubrication and precision filtration design to ensure that the output gas is free of impurities. At the same time, they are equipped with multiple safety protection devices to eliminate the risk of high-pressure leakage.

III. Core Difference Comparison Table: Understand the Key Differences at a Glance

| Comparison Dimension | Low-Pressure Industrial Piston Compressors | High-Pressure Industrial Piston Compressors |

| Discharge Pressure | ≤ 1.0 MPa (10 bar) | > 10 MPa (up to 100 MPa) |

| Core Advantages | High flow rate, low energy consumption, low maintenance cost | Stable high-pressure output, strong pressure resistance, good sealing performance |

| Energy Consumption Performance | High energy efficiency ratio; 5%–8% energy saving per 0.1 MPa pressure reduction | High energy consumption; increased energy consumption due to intense compression process |

| Typical Industries | Manufacturing, food & beverage, textile & printing, construction auxiliary | Petroleum & natural gas, chemical industry, large-scale mining & metallurgy, special gas filling |

| Technical Requirements | Mature technology; moderate requirements for sealing and pressure resistance | Complex technology; requires high-temperature resistance, corrosion resistance, and explosion-proof design |

IV. Core Selection Recommendations: Match Needs, Choose Appropriately Not “Expensively”

When enterprises select low-pressure or high-pressure industrial piston compressors, the core principle is to be “production demand-oriented,” avoiding blind pursuit of high pressure or large flow rate:

- Clarify core parameters first: Prioritize confirming the discharge pressure and flow rate required for production, and select the model based on the rated pressure requirements of the equipment. For example, conventional equipment such as pneumatic tools and packaging machinery can meet their needs with MINNUO low-pressure piston compressors; high-pressure synthesis reactions and long-distance gas transportation require matching high-pressure models.

- Balance energy efficiency and cost: On the premise of meeting pressure requirements, prioritize models with high energy efficiency ratios. In low-pressure scenarios, the energy-saving design of MINNUO low-pressure compressors can significantly reduce long-term operating costs; in high-pressure scenarios, focus on the compression efficiency of the equipment to avoid increased production costs due to excessive energy consumption.

- Consider scenario adaptability: For outdoor operations, prioritize mobile models; for the food and pharmaceutical industries, select oil-free and hygienic models; for the petrochemical industry, choose models with explosion-proof and corrosion-resistant properties. MINNUO can provide customized piston compressor solutions based on different industrial scenarios.

V. MINNUO Industrial Piston Compressors: Full-Scenario Adaptation to Steadily Empower Industrial Production

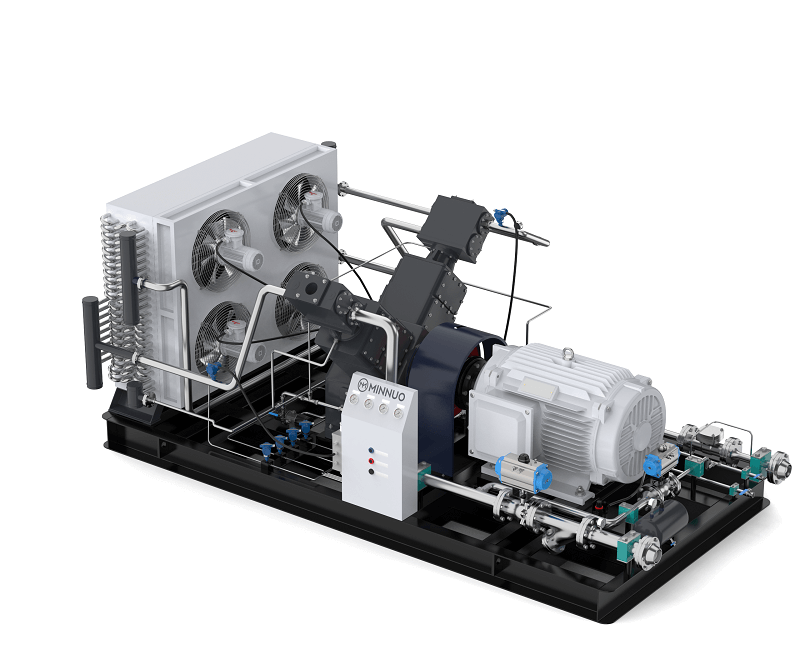

As a brand focusing on the industrial compressor field, MINNUO is deeply engaged in the R&D and production of low-pressure and high-pressure piston compressors. Leveraging years of industry experience, it creates dedicated products for different scenario needs:

- Low-Pressure Series: Adopting high-efficiency motors and optimized cylinder design, with a pressure fluctuation range ≤ ±5% and noise as low as 75 dB. These compressors adapt to the continuous production needs of industries such as manufacturing, food and beverage, and combine energy-saving and stability advantages.

- High-Pressure Series: Using special alloy materials and precision sealing technology, equipped with multiple safety protection devices. They can achieve stable output within a pressure range of 10–100 MPa, meeting the strict requirements of high-end industries such as petroleum & natural gas and chemical engineering.

Whether you are a manufacturing enterprise in need of high-flow low-pressure gas sources or an energy enterprise pursuing stable high-pressure output, MINNUO can provide professional selection guidance and customized solutions. Contact our online customer service now to obtain your exclusive industrial piston compressor selection plan!

Email

Email sales:+86 15366749631

sales:+86 15366749631