A well-designed compressor room is the foundation of an efficient, reliable, and safe compressed air system. Too often, the compressor room is an afterthought—a hot, noisy closet where equipment is crammed together. This leads to premature failures, excessive energy consumption, and costly emergency repairs.

Getting the layout right from the start avoids these hidden costs. This guide exposes the five most common and expensive mistakes in compressor room design and provides engineering-backed solutions to ensure your system delivers peak performance for years to come.

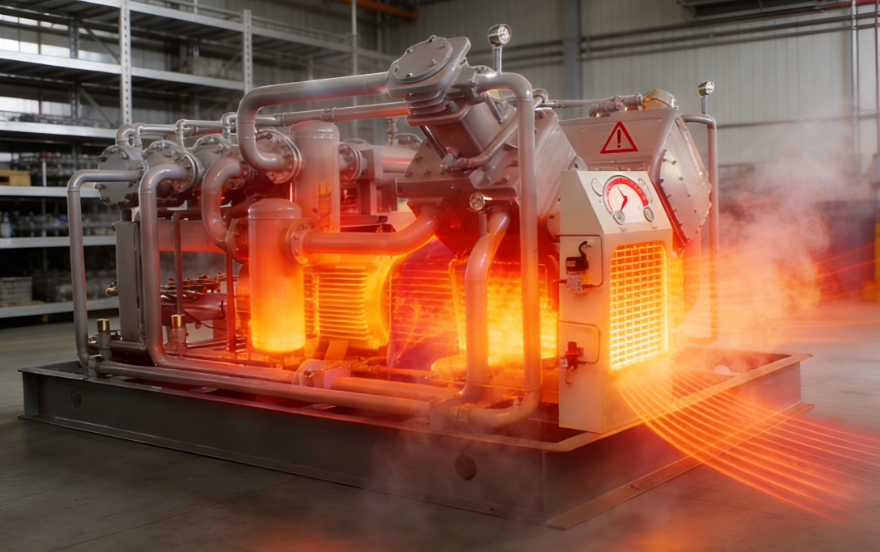

Mistake #1: Inadequate Ventilation & Heat Management

The Problem: Compressors generate immense heat. Trapping this heat in a small room causes chronic overheating, which forces the compressor to work harder, increases oil degradation, and drastically shortens component life. For every 10°C (18°F) above design inlet temperature, compressor efficiency drops by about 2%.

The Solution:

- Calculate Required Airflow: Provide enough cool, clean air for both combustion (if diesel) and cooling. A simple rule: Supply airflow (m³/h) should be at least 3 to 4 times the compressor’s motor kW rating.

- Use Separate Inlet & Exhaust: Create a cross-flow pattern. Place low-level louvres or vents on one wall for cool air intake. Install high-level exhaust fans or ducts on the opposite wall to eject hot air directly from the compressor coolers. Never recirculate hot air.

- Consider Make-Up Air Units: For large systems or sealed rooms, install a powered make-up air system with filters to guarantee sufficient clean, cool air supply.

Mistake #2: Ignoring Accessibility for Maintenance

The Problem: Placing compressors, dryers, and filters against walls or in corners turns routine maintenance into a major ordeal. This leads to skipped maintenance, longer downtime, and increased labor costs.

The Solution:

- Follow the “Service Clearance” Rule: Maintain a minimum clearance of 1 meter (3 feet) on all sides of each major component (compressor, dryer, receiver tank).

- Plan for Component Removal: Ensure there is a straight, unobstructed path to remove the air-oil separator, cooler bundle, or motor for major service. Consider ceiling hoists or rolling beams for heavy equipment.

- Label and Zone: Clearly label all valves, filters, and drains. Create dedicated zones for maintenance activities.

Mistake #3: Poor Pipework Layout Inside the Room

The Problem: Chaotic, undersized, or sloped piping inside the room creates pressure drops, traps condensate, and makes the system impossible to drain or troubleshoot.

The Solution:

- Install a Proper Drip Leg and Main Header: Immediately after the compressor and dryer, pipe upward into a drip leg (condensate drop) before entering the main header. The main header should slope 1-2% downward in the direction of airflow to guide condensate to drainage points.

- Use Swept Elbows, Not Sharp 90°s: Use long-radius elbows to minimize turbulent flow and pressure loss at the very start of your system.

- Size for Velocity, Not Just Flow: For the main header, size pipes so air velocity is below 6 m/s (20 ft/s) to allow water droplets to fall out of the airstream.

Mistake #4: Incorrect Receiver Tank Placement and Sizing

The Problem: The receiver tank is placed too far from the compressor or is too small, failing to stabilize pressure, capture condensate, and reduce compressor cycling.

The Solution:

- Place the Tank Before the Dryer (Wet Tank): For the most common setup, place the receiver immediately after the compressor’s aftercooler. This allows air to cool further, dropping more condensate into the tank, and provides a buffer of stable, pre-dried air for the dryer, improving its efficiency.

- Right-Size the Tank: A common rule is 10-20 liters of tank capacity per CFM of compressor output (e.g., a 100 CFM compressor needs a 1,000-2,000 liter tank). Larger tanks are better for systems with high intermittent demand.

- Ensure Proper Draining: Install an automatic zero-loss drain valve at the tank bottom and ensure access for maintenance.

Mistake #5: Neglecting Noise Control and Vibration Isolation

The Problem: Excessive noise is a health hazard and indicates energy waste from vibration. Unisolated vibration transmits into the building structure, causing noise complaints and potential damage.

The Solution:

- Isolate Vibration at Source: Never bolt a compressor directly to the floor. Always use vibration isolation pads or spring mounts specifically rated for the machine’s weight and frequency.

- Use Flexible Connectors: Install braided flexible hoses on all air and water connections to the compressor to prevent vibration from being transmitted into the rigid piping.

- Consider Acoustic Enclosures or Room Treatment: For installations near offices or in noise-sensitive areas, specify factory-built acoustic enclosures or add sound-absorbing panels to the room walls and ceiling.

FAQ: Compressor Room Design

Q1: What is the ideal ambient temperature for a compressor room?

A1: The compressor inlet air temperature should ideally be below 25°C (77°F). The room ambient should be maintained well within the compressor manufacturer’s specified limits, typically a maximum of 40°C (104°F) to prevent overheating and capacity loss.

Q2: Can I install my air dryer in a separate, cooler room?

A2: Yes, and it can be beneficial. Installing a refrigerated dryer in a cooler location improves its efficiency. However, ensure the piping between compressor and dryer is as short as possible, properly sloped, and insulated to prevent premature condensation before the dryer.

Q3: How important is floor drainage?

A3: Critical. Compressor rooms will have water spills from maintenance and emergency drains. The floor should have a chemical-resistant, non-slip coating and slope towards a central floor drain to manage water and oil spills safely.

Q4: We have multiple compressors. How should they be arranged?

A4: Arrange them in parallel with sufficient space between for airflow and access. Connect them to a common header that is sized for the combined flow. Ensure controls are sequenced properly to optimize efficiency, and that intake air is not drawn from the exhaust of another unit.

Conclusion: Good Design is a High-ROI Investment

A compressor room is not just a storage space; it is the functional heart of your plant’s pneumatic power. Investing time in proper design—prioritizing cooling air, maintenance access, logical piping, and vibration control—pays back continuously through lower energy bills, reduced downtime, longer equipment life, and safer operations.

Avoiding these five common mistakes is the most cost-effective “insurance policy” you can buy for your compressed air system.

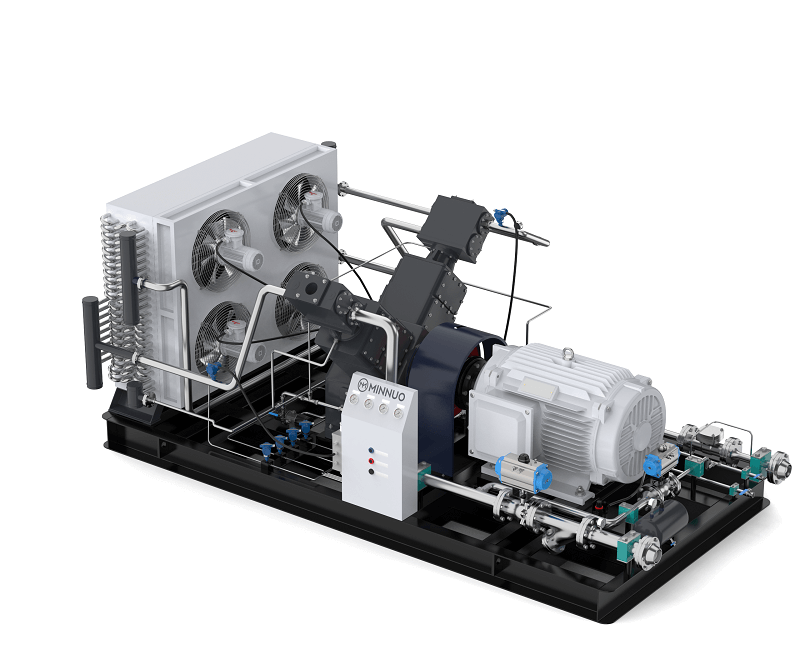

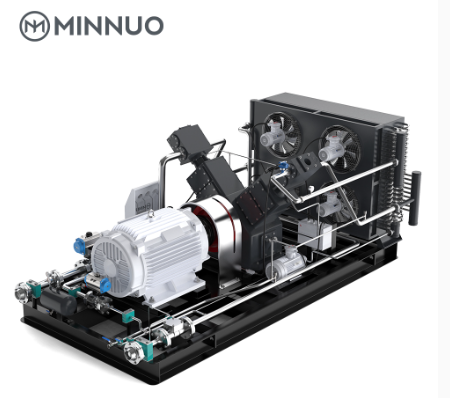

Planning a new compressor room or retrofitting an existing one? MINNUO’s system engineering team can provide layout reviews, ventilation calculations, and detailed plans to optimize your space for efficiency, reliability, and safety. Contact us for a consultation.

Email

Email sales:+86 15366749631

sales:+86 15366749631