In deep-sea scientific research, underwater engineering, or emergency rescue, high-pressure submersible compressors are the key equipment that connects life and technology. It needs to supply gas continuously in a high-pressure, highly corrosive environment while ensuring the purity of the gas and the stability of the system – which poses extremely high technical requirements for the equipment. This article will analyze the core demands in this field and introduce how industry benchmark products have broken through technical bottlenecks to ensure the safety of deep-sea operations.

The “invisible” challenges of high-pressure submersible compressors

Deep-sea environments demand much more from compressors than in general industrial scenarios:

Extreme pressure and depth: A high pressure air output of over 300bar is required to meet the breathing needs of divers below 600 meters or the operation requirements of underwater equipment.

Corrosive environment adaptation: Seawater salt spray and high-pressure water flow pose a severe test on the material’s anti-corrosion performance.

Zero failure reliability: Any downtime could endanger divers’ lives or delay important projects.

For example, in a Norwegian North Sea oilfield maintenance project, a DNV GL-certified compressor system ran continuously for 120 hours to support underwater robots in repairing submarine pipelines, and its two-stage compression technology reduced the oil mist content to below 0.1ppm to ensure gas supply safety. Such cases highlight the crucial role of top-of-the-line compressors in complex scenarios.

In addition, temperature fluctuations in deep-sea environments, such as polar or tropical seas, also pose challenges to the stability of the equipment. The Minnuo brand compressors, through an “adaptive temperature control system”, can maintain stable performance within the range of -20°C to 50°C, addressing the problem of component expansion or contraction caused by temperature differences. This technology was proven in the extreme cold gas supply guarantee project at the Antarctic research station, where the compressor maintained a 99.8% start-stop success rate during continuous low-temperature operation, far exceeding the industry average.

Technology Breakthrough: How to achieve ‘deep-sea level’ stability

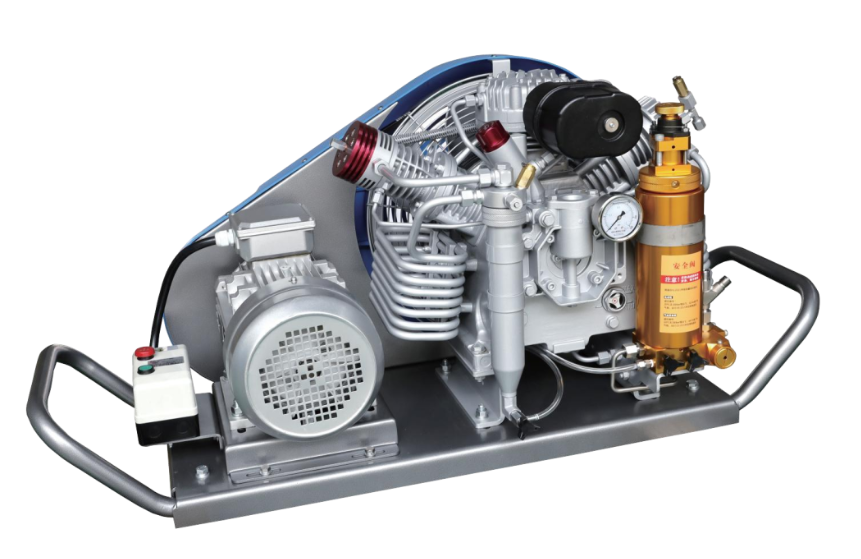

The core technologies of the current industry-leading products are reflected in the following aspects:

1. Intelligent frequency conversion control: Dynamically adjust output power according to actual demand, increase energy efficiency by 30% while reducing equipment wear and tear.

2. Fully sealed aviation-grade design: With an aluminum alloy body and anti-corrosion coating, it is suitable for long-term immersion in seawater.

3. Modular architecture: Supports quick disassembly and maintenance, reducing downtime.

Minnuo compressors, with their maximum output of 350bar and IP68 protection rating, have become the preferred equipment for global oil and gas exploration and deep-sea scientific research projects. Their intelligent early warning system can identify potential faults 48 hours in advance, significantly reducing risks.

Another key innovation is the application of magnetic levitation bearing technology. Conventional compressors rely on mechanical bearings, which are prone to frictional wear due to prolonged high-pressure operation; Minnuo’s magnetic levitation unit, which supports rotating parts with a magnetic field, reduces mechanical contact and extends the maintenance cycle to over 3,000 hours. The technology was validated in the construction of Singapore’s deep-sea data storage centre, where the compressor system did not require major repairs even after two years of continuous operation, helping customers save 40 percent on maintenance costs.

Practical verification in global engineering

The technical strength of high-pressure submersible compressors will ultimately be tested by actual engineering:

Emergency rescue scenario: In the Malaysia shipwreck, a brand of compact high-pressure unit was deployed on the rescue vessel to provide continuous 72-hour gas supply support for the deep dive search and rescue team, successfully rescuing trapped people.

Subsea energy development: An oil platform in the Middle East uses a modular high-pressure system to integrate compressors with underwater robots, saving space and improving operational efficiency.

Scientific research application: The Antarctic research station selects compressors with ultra-low temperature start-up function to ensure the stability of gas supply for polar deep-sea exploration equipment.

Behind these cases lies the deep understanding of extreme environments by the equipment manufacturers. Minnuo, for example, ensures that each compressor undergoes rigorous validation before leaving the factory through a “pressure chamber test” that simulates the high pressure under the sea, with a failure rate 50% lower than the industry average.

New Addition:

Minnuo‘s silent compressors were specially selected for coral reef restoration projects in Southeast Asian waters. Conventional high-pressure units can generate up to 120 decibels of noise, which may interfere with the habitat of Marine life; The brand has reduced noise to below 85 decibels through active noise reduction technology, which meets environmental requirements and ensures clear communication for divers. This case not only promotes the application of eco-friendly technology, but also becomes a “sustainable seabed operation model” recommended by the International Ocean Organization.

Email

Email sales:+86 15366749631

sales:+86 15366749631