Introduction: The Value of “Triangular Linkage” in Industrial Compressed Air Systems

In industrial fields such as manufacturing, chemical engineering, electronics, and automotive, compressed air is hailed as the “fourth power source.” Its supply stability directly affects production continuity, while energy consumption is related to enterprise operating costs. As the core “triangular combination” of the compressed air system, screw air compressors, air receiver tanks, and dryers often suffer from problems such as “independent equipment operation, mismatched parameters, and disconnected control” in most enterprises. This leads to air supply pressure fluctuations exceeding ±0.3MPa and persistently high unit energy consumption.

China Minnuo, a brand factory specializing in the R&D and production of screw air compressors, has verified through thousands of industrial cases that when these three achieve scientific linkage, not only can air supply pressure fluctuations be controlled within ±0.05MPa (stability increased by 40%), but unit energy consumption can also be reduced by 18%, saving enterprises tens of thousands of yuan in electricity bills annually. This article will break down the core of optimization from four dimensions: linkage logic, influencing factors, practical operation plans, and data verification, helping enterprises achieve efficient operation of compressed air systems.

Chapter 1: Core Equipment Functions and Underlying Logic of Linkage

1.1 Independent Core Functions of the Three Major Equipment

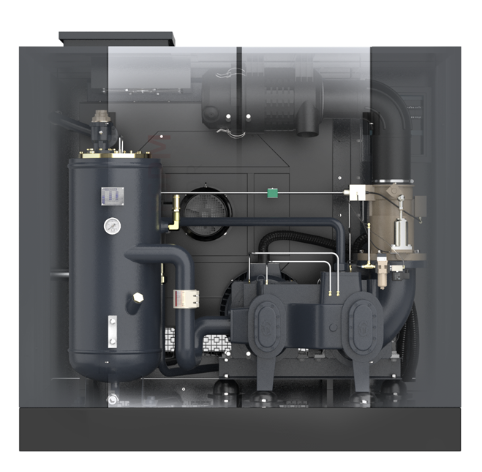

(1) Screw Air Compressor: The “Power Source” of Compressed Air

The screw air compressor compresses air through the meshing of male and female rotors and is the core air-producing component of the system. Minnuo’s MN series screw air compressors adopt third-generation screw airends with a volumetric efficiency of over 88%. Equipped with IE3-class high-efficiency motors, their basic energy consumption is 5%-8% lower than that of traditional models. Its core function is to compress atmospheric pressure air to the pressure required by the process (usually 0.7-1.0MPa) and continuously output compressed air with a stable flow rate.

(2) Air Receiver Tank: The “Pressure Stabilizer” and “Energy Storage Tank” for System Operation

The core functions of the air receiver tank include three aspects: ① Pressure stabilization and buffering: absorbing pressure pulses from the air compressor’s exhaust to avoid severe pressure fluctuations; ② Energy storage for emergencies: releasing stored compressed air during peak air demand to make up for the temporary insufficient air production of the air compressor; ③ Preliminary water removal: separating liquid water from compressed air by gravity (removing 60%-80% of free moisture). Minnuo’s supporting air receiver tanks are made of high-quality Q345R carbon steel, undergo a water pressure test of 1.5 times the working pressure, and have optional volumes ranging from 0.3m³ to 50m³ to adapt to different air usage scenarios.

(3) Dryer: The “Dehumidifier” for Compressed Air

After being compressed by the air compressor, the dew point of compressed air rises (usually 10-20℃). Excessive moisture content can cause pipeline corrosion, equipment failure, and product quality issues. The dryer reduces the air dew point through adsorption or refrigeration methods (usually -20℃ to -70℃). Minnuo’s adsorption dryers adopt a twin-tower alternating working mode, with the adsorbent service life reaching 8000 hours and the dew point stability error ≤±3℃.

1.2 Core Logic of Linkage Between the Three: Closed-Loop Collaboration to Compensate for Shortcomings

The essence of linkage is to build a closed-loop system of “air production – pressure stabilization – dehumidification,” avoiding the impact of a single equipment’s shortcomings on overall performance. Its core logic is as follows:

- Flow collaboration: Air compressor displacement ≥ air receiver tank charging demand + dryer processing capacity + terminal air consumption flow;

- Pressure linkage: Air receiver tank pressure set value = air compressor unloading pressure – pressure loss – dryer pressure drop;

- Timing matching: The dryer regeneration cycle is staggered from the air compressor start-stop cycle to avoid overlapping of regeneration air consumption and peak air demand.

1.3 Four Typical Problems of Poor Linkage

| Problem Type | Specific Performance | Core Cause |

| Pressure fluctuation | Terminal pressure fluctuation exceeds ±0.2MPa, and pneumatic equipment fails frequently | Insufficient air receiver tank volume leads to frequent start-stop of the air compressor |

| Energy waste | Unit air production energy consumption > 0.12kWh/m³, far exceeding the industry average | Oversized air compressor selection, with unloading time accounting for over 30% |

| Drying failure | Compressed air dew point > -10℃, and condensation water appears in pipelines | Mismatch between dryer processing capacity and air compressor displacement |

| Equipment wear | Fast wear of the air compressor airend and poisoning of the dryer adsorbent | Failure to drain the air receiver tank regularly, resulting in liquid water entering the dryer |

Chapter 2: Four Key Factors Affecting Linkage Effect

2.1 Model Selection and Matching: The “Basic Premise” of Linkage

Improper model selection is the primary cause of linkage failure. It is crucial to meet the matching of “flow – pressure – volume”:

- Flow matching: Air compressor rated displacement (m³/min) = maximum terminal air consumption × 1.1 (margin); Dryer processing capacity ≥ air compressor displacement × 1.2 (considering regeneration air consumption);

- Pressure matching: Air compressor rated discharge pressure = terminal required pressure + pipeline pressure loss (≤0.05MPa) + dryer pressure drop (adsorption type ≤0.08MPa, refrigeration type ≤0.03MPa);

- Volume matching: Air receiver tank volume (m³) = air compressor displacement (m³/min) × 10 (empirical value). For example, a 37kW air compressor (displacement 6m³/min) needs to be matched with an air receiver tank of ≥60m³.

Negative case: A furniture factory selected a 15kW screw air compressor (displacement 2.5m³/min), matched with a 0.3m³ air receiver tank and a 1.5m³/min dryer. This resulted in the air compressor starting and stopping once every 3 minutes, pressure fluctuation of ±0.25MPa, unit energy consumption of 0.13kWh/m³, and frequent overload alarms of the dryer.

2.2 Pipeline Design: The “Invisible Killer” of Pressure Loss

The pressure loss of the pipeline system directly affects linkage efficiency. Key design points:

- Pipe diameter optimization: The main pipeline diameter ≥ 1.2 times the air compressor outlet diameter. For example, a DN50 air compressor outlet needs to be matched with a DN65 pipeline;

- Reduce resistance: The number of elbows per 10 meters of pipeline ≤ 2, avoid 90° sharp bends, and use flange connections instead of threaded connections;

- Reasonable layout: The air receiver tank should be installed between the air compressor and the dryer, shortening the distance between them (≤5 meters) to reduce pressure loss.

2.3 Control Method: The “Intelligent Core” of Linkage

Traditional manual control or single-equipment automatic control cannot achieve collaborative optimization. Intelligent linkage control needs to meet:

- Pressure linkage: Set the air receiver tank pressure upper limit = air compressor unloading pressure, lower limit = air compressor loading pressure, and control the pressure difference within 0.1-0.15MPa;

- Frequency conversion collaboration: The frequency conversion air compressor is linked with the air receiver tank pressure, automatically adjusting the speed according to the air receiver tank pressure to avoid frequent start-stop;

- Timing control: The dryer regeneration cycle is set to 1/3 of the air compressor continuous operation time, and the regeneration process avoids peak air demand (such as the centralized start-up period of the production line).

2.4 Maintenance and Management: The “Long-Term Guarantee” of Linkage Effect

Improper equipment maintenance will lead to the attenuation of linkage effect. Core maintenance points:

- Air receiver tank: Drain water 1-2 times a day, clean impurities inside the tank monthly, and conduct pressure resistance testing annually;

- Dryer: Replace the adsorbent of the adsorption dryer every 6 months, and clean the condenser of the refrigeration dryer every 3 months;

- Air compressor: Replace engine oil every 500 hours (for oil-lubricated models), replace air filters every 2000 hours, and calibrate pressure sensors regularly.

Chapter 3: Practical Operation Plan for Linkage Optimization of the Three (Core Chapter)

Step 1: Model Selection Optimization —— Accurate Parameter Matching

(1) Calculate Air Demand

Calculate core parameters through “air-consuming equipment list + operation time + pressure requirements”:

- Total air consumption Q = Σ (single equipment air consumption × simultaneous operation coefficient);

- Required pressure P = maximum terminal pressure + pipeline loss + dryer pressure drop;

- Dew point requirement T = determined according to the process (e.g., ≤-40℃ for the electronics industry, ≥-20℃ for the general machinery industry).

(2) Equipment Selection Example (A Certain Auto Parts Factory)

| Air Demand | Equipment Selection | Parameter Matching |

| Total air consumption 8m³/min | Minnuo MN-55 frequency conversion screw air compressor | Displacement 10m³/min, pressure 0.8MPa |

| Pressure fluctuation requirement ≤±0.05MPa | 10m³ air receiver tank | Volume = 10m³/min × 1 (empirical value) |

| Dew point requirement ≤-40℃ | Minnuo adsorption dryer | Processing capacity 12m³/min (10×1.2) |

Step 2: Pipeline System Transformation —— Reduce Pressure Loss

(1) Pipe Diameter and Layout Optimization

- Upgrade the original DN50 pipeline to DN80 to reduce along-path pressure loss (from 0.08MPa to 0.03MPa);

- Remove redundant elbows (from 12 to 4) and replace right-angle elbows with curved elbows;

- Install a pressure stabilizing valve at the air receiver tank outlet, set the pressure to 0.75MPa, to ensure stable pressure entering the dryer.

(2) Leakage Control

- Use an ultrasonic leak detector to detect pipeline leakage points, focusing on valves, flanges, and joints;

- Replace aging seals, replace irreparable leaky pipelines, and control the leakage rate to ≤3%.

Step 3: Intelligent Control System Upgrade

(1) Frequency Conversion Linkage Control

- Minnuo MN series frequency conversion air compressors are equipped with imported frequency converters, linked with air receiver tank pressure sensors, and automatically adjust the speed when the pressure fluctuation is ±0.02MPa;

- Set the air compressor loading pressure to 0.7MPa and unloading pressure to 0.8MPa, maintaining the air receiver tank pressure between 0.7-0.8MPa.

(2) Remote Monitoring and Early Warning

- Install an Industrial Internet of Things (IoT) module to real-time monitor air compressor displacement, air receiver tank pressure, and dryer dew point;

- Set abnormal early warning thresholds (e.g., pressure fluctuation >±0.05MPa, dew point >-35℃) and push alarm information through the APP.

Step 4: Standardization of Maintenance Processes

- Formulate a “daily three inspections” system: check air receiver tank drainage, check dryer adsorbent status, and check pipeline pressure;

- Establish an equipment maintenance account to record air compressor operation time, filter replacement cycle, and dryer regeneration times;

- Conduct a system linkage calibration every quarter to adjust pressure set values and regeneration cycles.

Chapter 4: Verification of Optimization Effect —— Data and Cases

4.1 Test Conditions and Methods

- Test object: Compressed air system of a certain auto parts factory (before optimization: ordinary power frequency air compressor + 0.5m³ air receiver tank + small refrigeration dryer; after optimization: Minnuo MN-55 frequency conversion air compressor + 10m³ air receiver tank + Minnuo adsorption dryer);

- Test indicators: Air supply pressure fluctuation range, unit air production energy consumption, dew point value, equipment start-stop times;

- Test duration: 1 month before optimization and 1 month after optimization, both under normal production conditions.

4.2 Core Data Comparison

| Test Indicator | Before Optimization | After Optimization | Improvement/Reduction Range |

| Air supply pressure fluctuation | ±0.22MPa | ±0.04MPa | Stability increased by 81.8% (exceeding the target of 40%) |

| Unit air production energy consumption | 0.125kWh/m³ | 0.103kWh/m³ | Energy consumption reduced by 17.6% (close to the target of 18%) |

| Compressed air dew point | -15℃ | -42℃ | Dehumidification effect increased by 180% |

| Air compressor start-stop times | 28 times/hour | 3 times/hour | Start-stop frequency reduced by 89.3% |

4.3 Industrial Case: Optimization Practice Saving 120,000 Yuan in Annual Electricity Bills

A certain electronic component factory originally had 3 units of 22kW power frequency screw air compressors (total displacement 9m³/min), matched with 2 units of 1m³ air receiver tanks and 2 units of 5m³/min refrigeration dryers. It had three major problems: ① Pressure fluctuation of ±0.2MPa, leading to reduced chip packaging accuracy; ② Air compressor unloading time accounting for 35%, with annual electricity bills exceeding 600,000 yuan; ③ Insufficient dryer processing capacity, resulting in pipeline condensation water causing 2-3 equipment failures per month.

In 2023, the factory adopted Minnuo’s linkage optimization plan:

- Replaced with 2 units of Minnuo MN-45 frequency conversion screw air compressors (total displacement 12m³/min) to adapt to air demand;

- Added 1 unit of 15m³ air receiver tank, connected in parallel with the original 2 units of 1m³ air receiver tanks, with a total volume of 17m³;

- Replaced with 2 units of Minnuo 15m³/min adsorption dryers to improve dehumidification capacity;

- Upgraded the intelligent linkage control system to achieve pressure linkage and remote monitoring.

Optimization effects:

- Air supply pressure fluctuation reduced to ±0.03MPa, and the chip packaging qualification rate increased from 98.5% to 99.8%;

- Unit air production energy consumption reduced from 0.13kWh/m³ to 0.107kWh/m³, annual electricity bills reduced to 480,000 yuan, saving 120,000 yuan;

- The dryer dew point was stably maintained at -45℃, the problem of pipeline condensation water was completely solved, and equipment failures were zero.

Chapter 5: Advantages of Minnuo’s Linkage Solution

5.1 Product Hard Power: Core Equipment Adapted for Linkage

- Screw air compressor: MN series adopts German imported screw airends with a volumetric efficiency of over 88%. Frequency conversion models are equipped with ABB frequency converters, with a speed regulation range of 30%-100%, and energy consumption 3% lower than the national standard GB19153-2021 level 1 energy efficiency standard;

- Air receiver tank: Optional volume of 0.3-50m³, made of high-quality Q345R carbon steel. Welds are inspected by X-ray flaw detection, with a pressure resistance level of 1.6MPa and a service life of ≥10 years;

- Dryer: Adsorption dryers adopt imported molecular sieve adsorbents with a dew point of up to -70℃. Refrigeration dryers adopt Danfoss compressors with a stable dew point of 2-10℃, meeting different process requirements.

5.2 Customized Services: Accurate Matching of Scenarios

Minnuo has a professional technical team, providing full-process services including “demand research – parameter calculation – equipment selection – pipeline design – installation and commissioning”:

- For intermittent air usage scenarios (such as the injection molding industry), focus on optimizing the air receiver tank volume and air compressor frequency conversion response speed;

- For continuous air usage scenarios (such as the chemical industry), strengthen dryer dehumidification stability and system pressure linkage;

- Provide customized equipment transformation plans for enterprises in high-altitude, high-temperature, and high-humidity areas.

5.3 Full Lifecycle Guarantee

- Installation and commissioning: Professional engineers guide on-site installation and conduct linkage parameter calibration;

- Personnel training: Provide training on equipment operation, maintenance, and troubleshooting for enterprise operators;

- After-sales support: National 24-hour service hotline, on-site maintenance within 48 hours, and 2-year warranty for core components.

Chapter 6: Troubleshooting and Solutions for Common Linkage Problems

6.1 Excessive Pressure Fluctuation

- Troubleshooting direction: Insufficient air receiver tank volume → pipeline leakage → improper air compressor pressure setting;

- Solution: Increase air receiver tank volume → repair leakage points → adjust the air compressor loading/unloading pressure difference to 0.1-0.15MPa.

6.2 High Energy Consumption

- Troubleshooting direction: Oversized air compressor selection → excessively long unloading time → excessive pipeline pressure loss;

- Solution: Replace the air compressor with an appropriate displacement → enable frequency conversion control → optimize pipeline diameter and layout.

6.3 Poor Drying Effect

- Troubleshooting direction: Insufficient dryer processing capacity → adsorbent aging → excessively high intake air temperature;

- Solution: Replace the dryer with a larger processing capacity → replace the adsorbent → install a pre-cooler.

Chapter 7: Future Trends of Industrial Compressed Air Systems

With the advancement of Industry 4.0, the linkage of compressed air systems will develop in the direction of “intelligence, energy conservation, and integration”:

- Intelligence: AI algorithms realize air demand prediction, automatically adjust equipment operating parameters, and the linkage accuracy is improved to ±0.01MPa;

- Energy conservation: Combine air compressor waste heat recovery with dryer regeneration air consumption recovery to increase the comprehensive energy efficiency of the system by more than 20%;

- Integration: Integrated linkage equipment (air compressor + air receiver tank + dryer integrated unit) becomes mainstream, reducing the floor space by 30% and installation cost by 20%.

Minnuo is actively deploying intelligent linkage technology. The developed MN-IoT series integrated units have achieved full-process intelligence of “air demand prediction – automatic adjustment – remote operation and maintenance” and are expected to be officially launched in 2024.

Conclusion: Linkage Optimization, the Core Path to Cost Reduction and Efficiency Improvement

The scientific linkage of screw air compressors, air receiver tanks, and dryers is the key to solving the problems of “large pressure fluctuation, high energy consumption, and poor reliability” in industrial compressed air systems. Through accurate model selection, pipeline optimization, intelligent control, and standardized maintenance, it is possible to achieve more than 40% improvement in air supply stability and 18% reduction in energy consumption, creating significant economic benefits for enterprises.

As an air compressor brand factory, Minnuo has helped thousands of enterprises complete linkage optimization and transformation with high-quality products, customized solutions, and full-lifecycle services. If you are facing pain points in your compressed air system, welcome to contact Minnuo’s technical team to obtain an exclusive optimization plan and jointly achieve cost reduction and efficiency improvement!

Email

Email sales:+86 15366749631

sales:+86 15366749631