In the world of compressed air, one rule seems logical: “When in doubt, size up.” A larger compressor feels like insurance against future expansion and peak demands. It’s a decision made with the best intentions.

But here is the industrial truth no sales brochure highlights: An oversized air compressor is not insurance; it’s a financial leak engineered into your system’s foundation. You pay for it not once at purchase, but every minute it runs, through inflated energy bills, excessive maintenance, and hidden capacity loss.

This is the Sizing Trap. Unlike a sudden breakdown, its cost is silent, sanctioned, and buried within your operational overhead. This guide will help you diagnose if you’re caught in it, quantify the waste, and provide actionable paths to escape.

I. The Anatomy of the Trap: Why Bigger is Infinitely Worse

The core problem is a fundamental mismatch between the machine’s design point and your actual demand profile. A compressor is most efficient near its full load. As load decreases, its efficiency plummets, but your cost doesn’t.

An oversized compressor typically falls into one of two destructive operational modes:

- The Stop-Start Martyr: A moderately oversized fixed-speed machine. It loads quickly, meets demand, unloads, and idles until pressure drops, then restarts. This cycle repeats endlessly, causing excessive wear on starters, motors, and valves from hundreds of unnecessary starts per day.

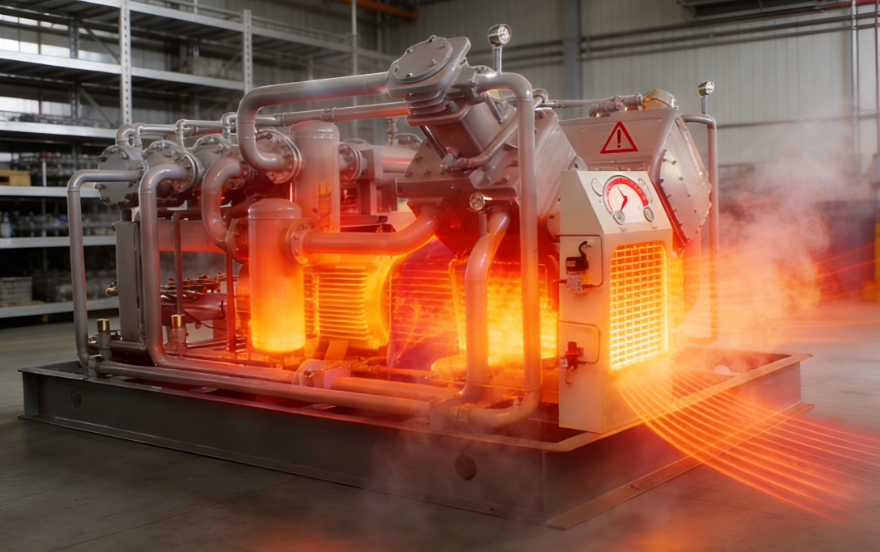

- The Empty Runner: A severely oversized machine. It can’t even start and stop efficiently, so it runs continuously in an unloaded state, consuming 20-40% of its full-load power while producing zero air. This is pure, unadulterated waste.

II. Diagnostic Symptoms: How to Spot the Trap in Your Plant

You don’t need complex audits to suspect a problem. Look for these clear signs:

- The Sound: Listen for the frequent “thump-whirr” of a compressor loading and unloading every few minutes (Symptom of the Stop-Start Martyr).

- The Gauge: An ammeter that shows current dropping to a low, steady value (not zero) for long periods while the compressor runs (Symptom of the Empty Runner).

- The Logbook: Motor starter or belt replacements are unusually frequent.

- The Bill: Your energy cost per unit of production is creeping up, despite no major change in output.

III. The Escape Routes: Three Practical Retrofit Strategies

Replacing the compressor is often not feasible. The good news is that effective, cost-conscious solutions exist.

Route 1: The Control System Overhaul (For the Stop-Start Martyr)

- The Fix: Implement a smart sequencing controller if you have multiple compressors. For a single compressor, optimize the pressure band settings to minimize cycles. Consider adding a small variable speed drive (VSD) compressor to handle base load variations, letting the oversized unit run only at peak.

- The ROI: Fast. Often under 12 months through reduced wear and slightly improved efficiency.

Route 2: The Storage Solution (For Moderate Mismatch)

- The Fix: Dramatically increase your air receiver (storage tank) capacity. A larger tank acts as a buffer, smoothing out short-term demand spikes. This allows the compressor to run in longer, more efficient cycles, reducing start/stop events.

- The ROI: Very fast. One of the highest-return investments in compressed air, with payback often in months.

Route 3: The Hardware Retrofit (For the Empty Runner & Severe Cases)

- The Fix: Retrofitting a VSD onto an existing fixed-speed compressor. This allows the motor speed to precisely match air demand, eliminating unloaded run time and dramatically improving part-load efficiency.

- The ROI: Significant but requires capital. Typically 1-3 years, depending on runtime and energy costs. A professional assessment is crucial to determine viability.

IV. The Decision Framework: Finding Your Path Out

Follow this logic to determine your best first step:

- Log Your Data: For one week, record your compressor’s load/unload cycles or power profile.

- Characterize the Trap: Are you a Martyr (frequent cycles) or an Empty Runner (long unloaded periods)?

- Evaluate the Routes:

- If cycles are frequent → Start with Route 1 (Control) or Route 2 (Storage).

- If unloaded run time is high → Seriously investigate Route 3 (VSD Retrofit).

- Run the Numbers: Use a simple formula:

Annual Waste = (Unloaded Power kW) x (Unloaded Hours/Year) x (Energy Cost $/kWh)

This number quantifies the trap and justifies the investment.

V. Conclusion: From Trapped to Optimized

The Sizing Trap is a legacy of an old mindset that prioritized upfront safety over lifetime cost. Modern compressed air philosophy is about precision matching: delivering the right air, at the right pressure, with the least energy.

Escaping the trap isn’t just about saving money; it’s about reclaiming control over a critical utility. It reduces mechanical stress, improves system reliability, and frees up capital for productive investments.

At MINNUO, we approach compressed air as an integrated system. Whether it’s selecting the right-sized unit for a new project or providing the diagnostic insight and retrofit solutions to fix a legacy sizing error, our goal is the same: to transform your compressed air from a hidden cost center into a model of efficient, predictable operation. The first step out of the trap is recognizing you’re in it. The next step is having a clear map for the way out.

Email

Email sales:+86 15366749631

sales:+86 15366749631