Introduction: Why the Right High Pressure Compressor is a Strategic Investment

In industrial operations, a high pressure compressor is more than just a piece of equipment; it’s the beating heart of critical processes. From inflating life-saving airbags and manufacturing PET bottles to driving water jets that cut through titanium and enabling deep-well natural gas extraction, the demands placed on these machines are immense.

Selecting the wrong compressor isn’t merely an inconvenience—it’s a direct threat to your bottom line. The consequences manifest as crippling energy bills, unplanned downtime that halts production lines, premature component failure, and an inability to meet quality standards. This comprehensive guide is designed to empower engineers, plant managers, and procurement specialists with a detailed, step-by-step framework for selecting a high pressure compressor that delivers optimal performance, reliability, and value over its entire lifecycle.

Step 1: Defining Your Core Performance Specifications (The Non-Negotiables)

A precise understanding of your application’s requirements is the cornerstone of a successful selection. Vague specifications are the primary cause of underperformance.

- Discharge Pressure (PSI/Bar):

- Be Precise: Don’t just state a maximum (e.g., 5000 PSI). Define the stable operating pressure required and any acceptable fluctuation range. For test bench applications, specify if the pressure needs to be variable and controllable.

- Consider Future Needs: Is there a possibility your process will require higher pressures in the future? Some compressor designs can be upgraded with additional stages.

- Flow Rate (CFM or l/min):

- Calculate Total Demand: Sum the air consumption of all tools, machines, or processes that will run simultaneously. For intermittent uses, calculate the average and peak demands.

- Factor in Leakage and Aging: A good practice is to add a 10-15% safety margin to your calculated flow rate to account for system leaks and future, unaccounted-for uses.

- Gas Medium:

- Critical for Material Selection: The gas being compressed dictates everything. Standard air? Inert Nitrogen? Highly flammable Hydrogen? Corrosive Chlorine?

- Purity & Compatibility: Oxygen service demands strict cleanliness and oil-free operation to prevent fire hazards. Aggressive gases require specialized seals and stainless steel or nickel-alloy components.

- Duty Cycle:

- Intermittent Duty: (e.g., 30% on, 70% off). Ideal for reciprocating piston compressors, which are designed for stop-start operation.

- Continuous Duty: (e.g., 24/7 operation). Rotary screw, centrifugal, or lubricated, industrial-grade piston compressors are built for this demanding regime. Using an intermittent-duty compressor for continuous operation will lead to rapid failure.

Step 2: A Deep Dive into High Pressure Compressor Technologies

Understanding the core technologies is key to matching the machine to your application.

- Reciprocating Piston Compressors: The High-Pressure Titans

- How They Work: A piston is driven by a crankshaft within a cylinder, drawing in gas on the downstroke and compressing it on the upstroke. Multi-stage models cool the gas between stages for higher efficiency.

- Ideal For: Pressure ranges from 1,000 to 50,000+ PSI. Perfect for lower flow rates, intermittent duty, gas boosting, and breathing air systems.

- Pros: Unmatched high-pressure capability, relatively simple technology, cost-effective for small-to-medium capacities.

- Cons: Significant vibration and noise, higher number of wearing parts (valves, piston rings), pulsating flow requires a damping receiver tank.

- Diaphragm Compressors: The Purity Champions

- How They Work: A hydraulic fluid pushes a flexible, metallic diaphragm to compress the gas. This creates a hermetic seal, completely isolating the gas from the hydraulic system and the environment.

- Ideal For: Ultra-high-purity, toxic, or expensive gases. Essential in pharmaceuticals, semiconductor manufacturing, and hydrogen fuel stations. Pressures up to 30,000 PSI.

- Pros: 100% oil-free and leak-proof, guarantees maximum gas purity, safe for hazardous gases.

- Cons: Generally lower flow rates than piston compressors, diaphragms have a finite lifecycle and represent a planned maintenance item.

- Multi-Stage Centrifugal Compressors: The Continuous Flow Powerhouses

- How They Work: Gas is accelerated by a high-speed impeller and then diffused in a volute, converting velocity into pressure. Multiple stages are used to achieve high overall pressures.

- Ideal For: Massive, continuous flow rates in large industrial plants (e.g., oil refineries, chemical processing, air separation units). Pressures typically up to 10,000 PSI.

- Pros: Smooth, completely pulsation-free flow, exceptional reliability and longevity when run continuously, high efficiency at full load.

- Cons: Very high capital cost, poor efficiency at part-load, complex control systems, not suitable for low-flow applications.

Step 3: Critical Evaluation Factors for Long-Term Success

- Oil-Free vs. Lubricated (Oil-Flooded):

- Class 0 Oil-Free: Mandatory for food & beverage, pharmaceuticals, semiconductors, and breathing air. Prevents product contamination and safety risks. Achieved with Teflon-coated or stainless steel components in piston compressors, or via diaphragm technology.

- Lubricated: Generally more robust, efficient, and cost-effective for non-critical industrial applications (e.g., plant air, some manufacturing). The trade-off is the risk of oil carryover and the need for downstream filtration.

- Cooling Systems:

- Air-Cooling: Simpler, more self-contained. Ideal for smaller units and locations where water is scarce. Can be less effective in very hot ambient conditions.

- Water-Cooling: Superior cooling efficiency for large, high-heat load compressors on continuous duty. Results in a more compact design and stable operating temperatures but requires a reliable cooling water source and infrastructure.

- Control Systems & Energy Efficiency:

- On/Off Control: Basic and suitable for small compressors with very stable demand.

- Load/Unload: More efficient than on/off, but still cycles the motor.

- Variable Speed Drive (VSD): The gold standard for efficiency in applications with fluctuating demand. The motor speed varies to match the output exactly, eliminating unloaded cycles and saving 20-35% in energy costs. Crucial for reducing the largest portion of your TCO.

Step 4: Common Costly Mistakes and How to Avoid Them

- The “Sticker Price” Trap: The purchase price is a fraction of the Total Cost of Ownership (TCO). A cheaper, less efficient compressor can cost tens of thousands more in electricity over its life. Always calculate the 5-year TCO.

- Ignoring Air Preparation: A high pressure compressor is only part of the system. Failing to budget for and specify adequate filtration, dryers, and air receivers will lead to moisture, particulates, and oil damaging your process and the compressor itself.

- Underestimating Installation & Environment: Does your site have adequate power, ventilation, and space? High-pressure systems often require specific foundations to manage vibration. Factor these costs in early.

- Overlooking Service and Support: A compressor is a long-term asset. Choose a supplier with a proven track record, readily available spare parts, and responsive technical support. A machine down for lack of a simple valve can cost thousands per hour in lost production.

Step 5: Key Applications and Technology Pairing

- PET Bottle Blowing & Plastic Forming: Requires clean, dry, high-pressure air (typically 800-1000 PSI). Oil-free piston compressors are the industry standard to prevent bottle contamination.

- Waterjet Cutting: Demands ultra-high pressure (60,000-90,000 PSI) for cutting. Uses intensifier-style piston pumps which are specifically designed for these extreme pressures with water as the medium.

- Industrial Cleaning & Testing: High-pressure air or water for tube cleaning, pressure testing vessels, and parts drying. Robust multi-stage piston compressors are commonly used.

- Gas Transmission & Storage: Boosting natural gas into pipelines or compressing hydrogen for storage. Large reciprocating piston compressors or multi-stage centrifugals are used, depending on the scale and gas.

Conclusion: Partner for Performance and Uptime

Selecting a high pressure compressor is a complex but critical engineering decision. By methodically working through your specifications, understanding the technological trade-offs, and planning for the total lifecycle cost, you can make an investment that powers your productivity for years to come.

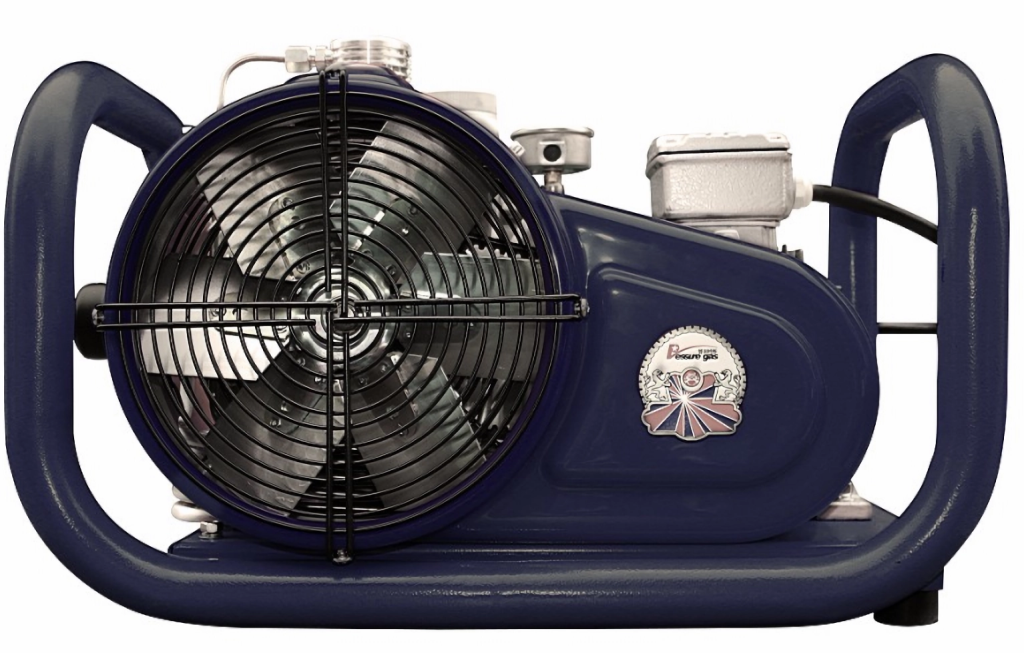

At MINNUO, we engineer reliability into every high pressure compressor we build. Our product range includes heavy-duty oil-lubricated piston compressors for demanding industrial applications, 100% oil-free piston and diaphragm compressors for critical processes, and custom-configured systems with advanced VSD controls and integrated air treatment.

Don’t leave your critical processes to chance. Contact MINNUO‘s application engineering team today for a free, in-depth analysis of your requirements and a compressor recommendation tailored for your performance and budget goals.

Email

Email sales:+86 15366749631

sales:+86 15366749631