In a globalized supply chain, a high-efficiency and reliable air compressor is the “heart” of many manufacturing plants. It drives the production line, controls pneumatic components, and affects the quality of the final product. Improper selection can lead not only to energy waste and production interruptions, but also to high maintenance costs and downtime losses.

As international trade experts, we have handled countless air compressor procurement cases. This article will share our core evaluation framework used internally to help you navigate the complexities and make the smartest investment.

Step 1: Accurately assess your core needs (Know yourself)

Before choosing any brand, you must first understand yourself. This is the foundation of all decisions.

1. Air demand (flow rate and pressure):

Pressure (Bar/PSI): Determine the **maximum operating pressure** required for all gas-using equipment in your plant, and add 1-2 Bar to this as a margin for pipeline pressure loss. Blindly choosing excessively high pressures will result in significant energy waste.

Flow rate (cubic meters per minute or CFM): This is the most critical parameter. Calculate or measure the **total gas consumption** when all gas-consuming equipment is operating simultaneously. A common mistake is estimating based only on existing equipment without considering future capacity expansion. It is recommended to allow for a 10%-20% margin.

2. Air quality requirements:

Dryness: Does your process require absolutely dry compressed air? Choose a refrigerated dryer or an adsorption dryer based on your needs.

Cleanliness: Is oil-free compressed air required? The food, pharmaceutical, and electronics industries typically require 100% oil-free air compressors. For other industries, an oil-injected screw compressor with a high-efficiency filter can be chosen based on product quality requirements, resulting in a lower cost.

3. Operating environment and power supply:

Is your factory located in an area with stable voltage (e.g., 380V/50Hz) or is it subject to greater voltage fluctuations?

What are the ambient temperature, ventilation conditions, and size of the air compressor room? These factors will affect the selection and performance of the machine.

Step 2: Choose the appropriate air compressor type and technology (Know Your Enemy)

After understanding the needs, we will match the technology.

Piston air compressor:

Advantages: Low initial investment, suitable for intermittent, low-volume operating conditions.

Disadvantages: High energy consumption, high noise, low reliability, and frequent maintenance.

International trade advice: It may be considered for small workshops or as a backup gas source, but we generally do not recommend it as a main model for modern, continuous production plants.

Screw air compressor (mainstream in the market):

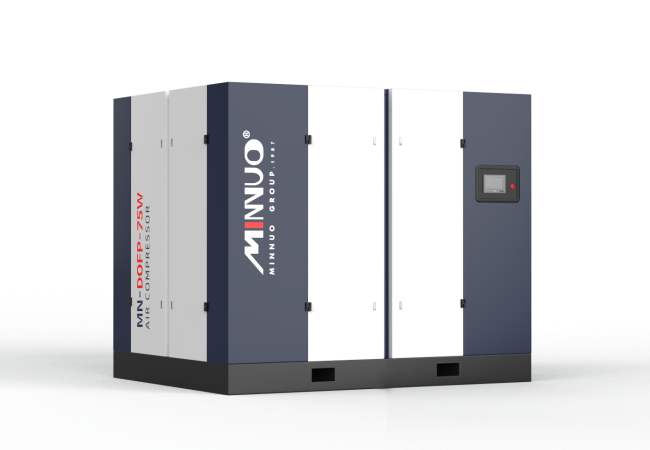

Oil-injected screws: These are technologically mature, highly efficient, and easy to maintain, making them the preferred choice for the vast majority of industrial applications. Their core advantages lie in their stability and economy.

Oil-free screw: Provides 100% oil-free air, but has extremely high initial investment and maintenance costs, and is only suitable for industries with stringent requirements for oil content.

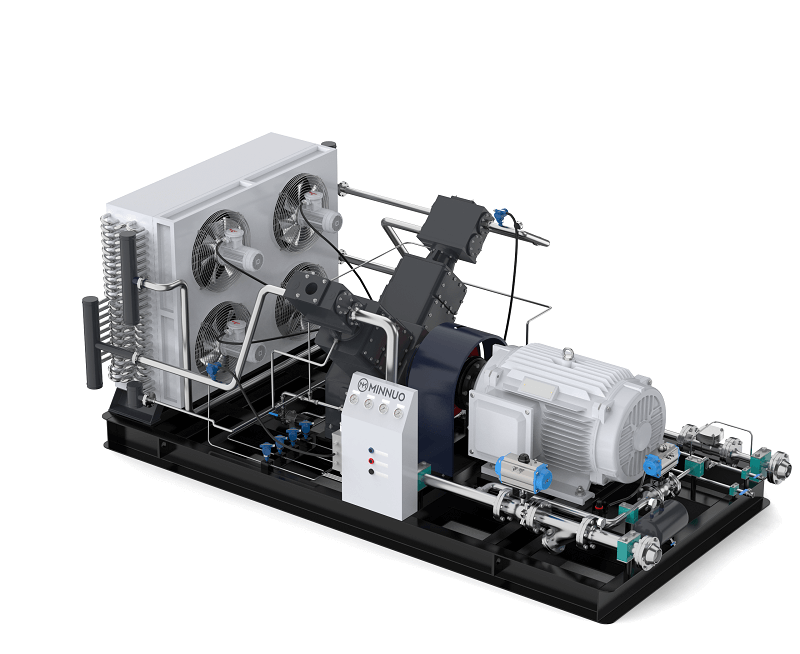

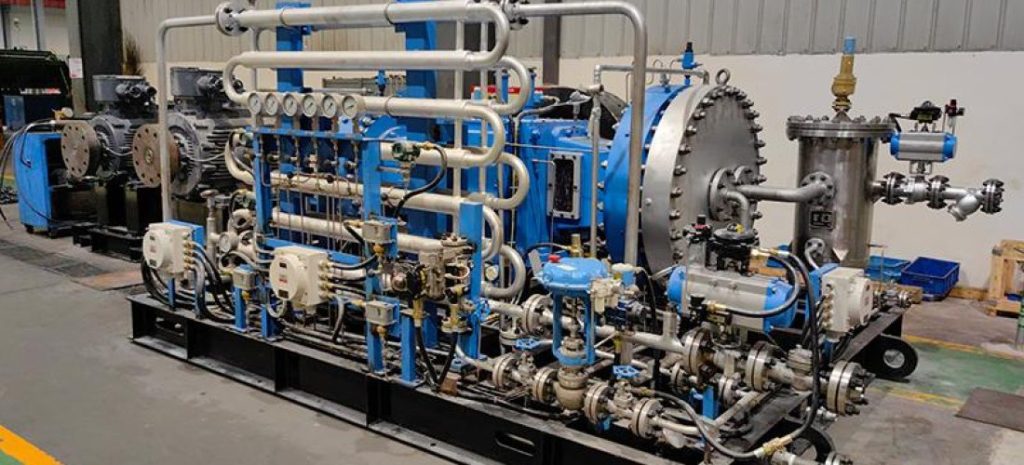

Centrifugal air compressor:

Advantages: Ultra-large flow rate, absolutely oil-free output air, and extremely high energy efficiency under specific high flow conditions.

Disadvantages: Requires huge investment and is not suitable for operating conditions with large fluctuations in traffic flow.

Suitable for: large-scale petrochemical, metallurgical, pharmaceutical and other ultra-large factories.

Step 3: Evaluate Brands and Suppliers (Global Perspective)

In international trade, choosing a brand is choosing a long-term partner.

1. Top international brands vs. high-quality domestic brands:

Top-tier brands (such as Atlas Copco, Ingersoll Rand, and Sullair) offer advanced technology, superior energy efficiency, extremely high reliability, and a comprehensive global warranty network. However, they are expensive, and parts and maintenance costs are high.

High-quality domestic brands (such as Minnuo, Kaishan, Baosi, Hanbell Precision Machinery, etc.): outstanding cost performance, rapid technological progress, fast local service response, convenient and low-cost parts supply.

2. The supplier’s professionalism and service capabilities:

Does your supplier have expertise in air compressor technology and can provide professional selection advice?

Can they provide localized installation, commissioning, and after-sales service? A fast response time is key to minimizing downtime losses.

International trade reminder: Be sure to confirm whether the supplier can provide genuine original spare parts and understand the certification qualifications of its technical team.

Step 4: Focus on total cost of ownership, not just the purchase price.

Savvy international buyers don’t look at the price, but rather at the total cost of ownership.

Initial purchase cost: The price at which the machine was purchased.

Energy costs (accounting for 70%-80% of TCO): This is the largest expense. It is essential to choose high-efficiency models (such as those with Level 1 energy efficiency) and pay attention to the key parameter of specific power; the lower the value, the more energy-efficient the appliance.

Maintenance costs: The cost of regularly replacing consumables (air filter, oil filter, oil separator, lubricating oil) and labor costs.

Downtime costs: Losses incurred due to production stoppages caused by equipment failure. Reliable equipment and services can minimize these costs.

A simple TCO calculation will show you that an air compressor that is slightly more expensive but 10% more energy efficient can recoup the price difference within 1-2 years.

Step 5: Finalize details and complete the procurement

1. Request a detailed configuration list: specify the brand and model of the main unit, the brand of the motor, the control system, and which post-processing equipment is included, etc.

2. Review the after-sales service terms: clarify the warranty period, response time, and whether it includes free initial commissioning and training.

3. Consider intelligent control: In scenarios where multiple air compressors are connected to the grid, the central control system can automatically schedule the machines to achieve optimal energy saving globally.

4. Arrange professional installation and training : Ensure that the installation is carried out by professional personnel and provide basic training to your operators.

Conclusion

Choosing the best air compressor for your factory is a systematic strategic decision. It requires you to start from your actual needs and comprehensively consider technology, brand, service, and total cost of ownership.

In global sourcing, a reliable supplier that provides full lifecycle support is far more valuable than a cheap machine. Don’t try to save a few cents today, only to pay several dollars tomorrow.

Email

Email sales:+86 15366749631

sales:+86 15366749631