From the portable pump that inflates your bicycle tires to the massive systems powering automated factories, compressed air is everywhere, earning it the title of the “fourth utility” in modern industry. At the heart of creating this powerful force is the air compressor. But what physical magic is actually happening inside this essential machine?

If we look past all the complex machinery, the core mission of an air compressor is remarkably pure: it is an efficient “space manager.” The physical principle it relies on is a cornerstone of thermodynamics: Boyle’s Law. This law can be summarized by a simple formula: P₁V₁ = P₂V₂. It states that for a fixed amount of gas at a constant temperature, its pressure (P) and volume (V) have an inverse relationship. What a compressor does is apply mechanical force to do work on the air, forcibly reducing the space it occupies (making V₂ < V₁), thereby creating higher-pressure compressed air (making P₂ > P₁).

Now that we understand this core physical principle, let’s explore the different mechanical designs engineers have created to put it into practice.

Meet the “Space Management Masters”: Four Common Compressor Types

While all compressors obey Boyle’s Law, engineers have devised different mechanical ways to achieve this “space management.” Here are four of the most common types you’ll encounter, each with its own strengths.

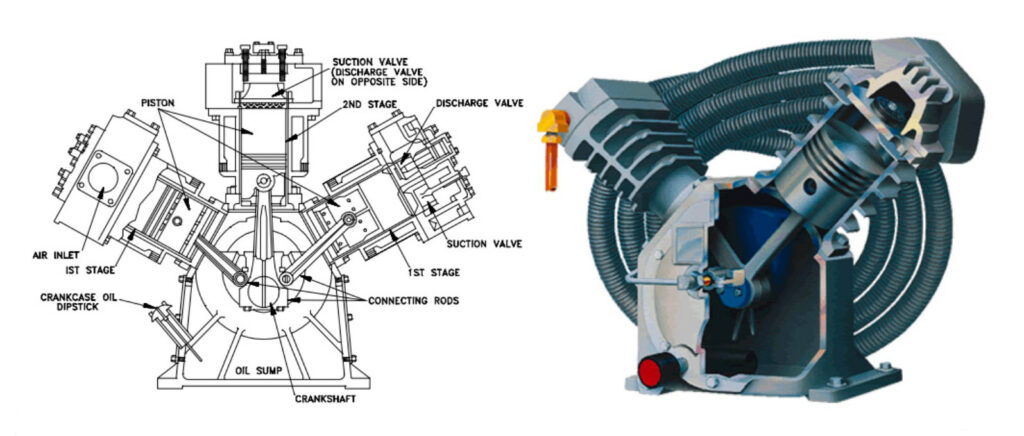

1. The Piston Compressor: The Powerful Puncher

- The Analogy: Think of a heavy-duty, automated bicycle pump. This is the most traditional and recognizable type.

- How it Masters Space: It uses a piston driven by a crankshaft inside a cylinder. On the downstroke, it draws air in. On the upstroke, the piston moves up, drastically reducing the chamber’s volume to compress the air before forcing it out. This is an intermittent process, delivering air in pulses, much like a boxer throwing powerful, repeated jabs.

- Best For: Applications requiring high pressure but not a continuous air supply, such as auto repair shops, small workshops, and gas station tire inflators.

2. The Screw Compressor: The Endurance Runner

- The Analogy: Imagine a continuous, precision “spiral squeezer.” This is the workhorse of modern industry.

- How it Masters Space: Inside a sealed chamber, two intermeshing, helical rotors (one male, one female) spin. As they rotate, air is trapped in the pockets between them. The rotation steadily reduces the volume of these pockets from the intake to the discharge side, smoothly and continuously compressing the air. It’s like a marathon runner, providing a steady, reliable flow over long distances.

- Best For: Industrial applications that demand a continuous, pulsation-free air supply for extended periods, such as manufacturing assembly lines and large-scale processing plants.

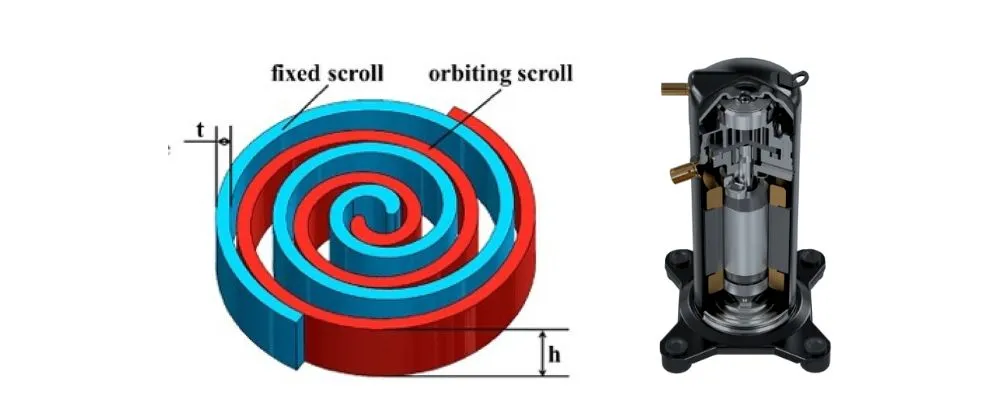

3. The Scroll Compressor: The Silent Dancer

- The Analogy: Picture two spiral-shaped scrolls—one fixed, one orbiting—elegantly nested together, like partners in a silent, precise waltz.

- How it Masters Space: The orbiting motion of one scroll against the stationary other creates a series of crescent-shaped gas pockets. These pockets are continuously pushed toward the center of the scrolls, steadily decreasing in volume and compressing the gas. This process is remarkably quiet, smooth, and efficient.

- Best For: Environments where noise and vibration are critical concerns, such as hospitals, laboratories, HVAC systems, and residential air conditioning units.

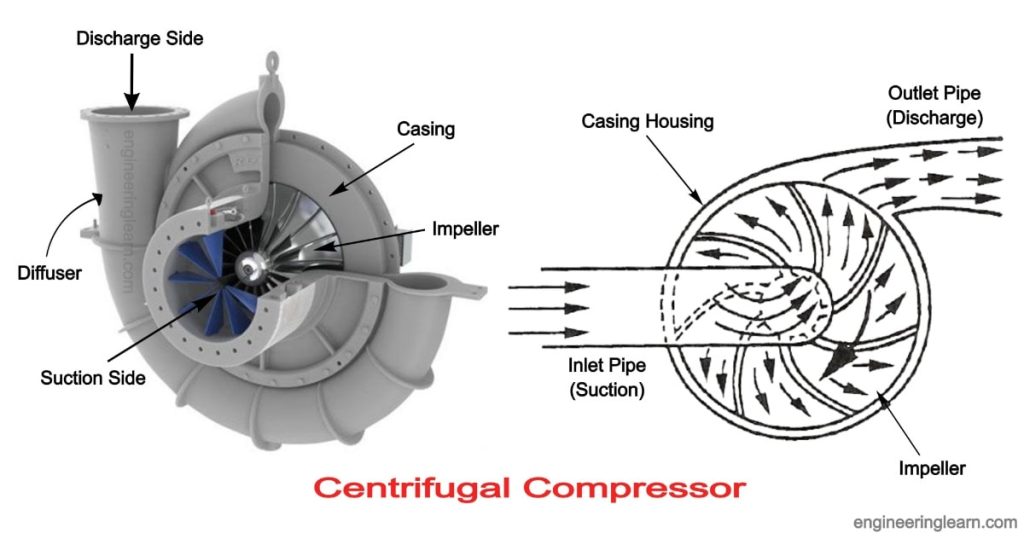

4. The Centrifugal Compressor: The Speed King

- The Analogy: Visualize a high-speed “centrifugal slinger.” It works more like a turbocharger than a pump.

- How it Masters Space: This is a dynamic compressor. It uses a high-speed rotating impeller (like a sophisticated fan) to transfer kinetic energy to the air, flinging it outward at high velocity. This high-speed air then passes through a diffuser, which slows it down, converting the velocity into high pressure. It’s all about using immense speed to achieve compression.

- Best For: Extremely large-scale applications requiring massive volumes of clean, oil-free air, such as in large chemical plants, steel mills, and offshore platforms.

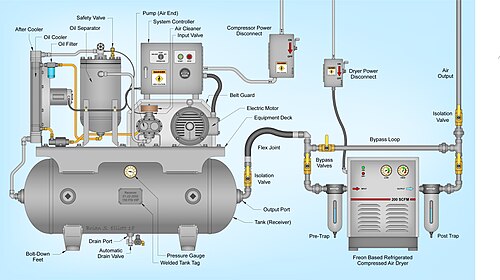

Beyond the Core: The Essential Support Team

A reliable compressor is more than just a compression chamber; it’s an integrated system. Just like a champion athlete needs a skilled support team, the “space management masters” rely on several critical subsystems to perform efficiently, reliably, and for the long haul.

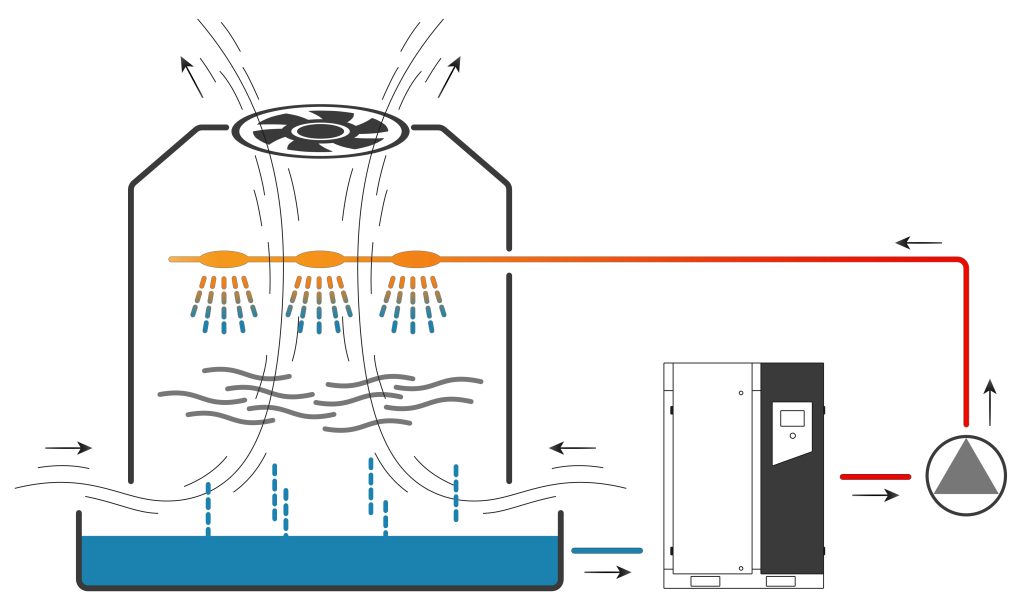

The Cooling System: The Thermal Manager

- The Challenge: According to the laws of thermodynamics, compressing gas inevitably generates intense heat (the heat of compression). If left unchecked, this heat can damage components, degrade lubricants, and drastically reduce efficiency.

- The Solution: The cooling system, which may use air, water, or oil as a coolant, acts as the compressor’s radiator. It works to dissipate this excess heat, maintaining a safe operating temperature. This is crucial for protecting the machine and ensuring consistent volumetric efficiency—meaning the compressor actually delivers the amount of air it’s designed to.

The Drive System: The Power Transmitter

- The Challenge: The rotational power from the electric motor must be efficiently transferred to the compression element (the pistons, screws, or impeller).

- The Solution: This is the role of the drive system, typically using a direct coupling or a belt drive. A well-engineered drive system ensures that minimal power is lost between the motor and the compressor element, maximizing the overall transmission efficiency of the unit.

The Control & Air Treatment System: The Brain and Purifier

- The Challenge: First, the compressor’s output must intelligently match the air demand to save energy. Second, the “raw” compressed air exiting the core is hot, humid, and contains contaminants that can damage downstream equipment.

- The Solution:

- Intelligent Control (The Brain): Modern compressors often feature sophisticated controls, with Variable Speed Drive (VSD) being the pinnacle of efficiency. A VSD compressor adjusts its motor speed in real-time to meet exact air demand, much like a car’s cruise control, avoiding the energy waste of constantly stopping and starting.

- Air Treatment (The Purifier): A series of components—including aftercoolers, air dryers, and filters—work together to remove heat, moisture, oil, and particles. This process delivers clean, dry, stable compressed air, which is essential for protecting valuable tools and ensuring product quality in processes like painting or food packaging.

Conclusion: From Principle to Reliable Power

Understanding the journey of air—from the fundamental certainty of Boyle’s Law (P₁V₁=P₂V₂) to the distinct roles of piston, screw, scroll, and centrifugal compressors, and finally to the critical support of cooling, drive, and control systems—provides more than just knowledge. It empowers you with the insight to appreciate the engineering behind reliable industrial power and to make informed decisions for your operations.

This commitment to demystifying core principles and transforming them into tangible performance and efficiency is at the heart of what we do at Minnuo Group. We believe that true reliability is engineered into every component, and we are dedicated to being your trusted partner in delivering that unwavering power to your business.

Email

Email sales:+86 15366749631

sales:+86 15366749631