In modern emergency rescue systems, diesel mobile air compressors, as a key piece of equipment, play an irreplaceable role in all types of major accident rescue operations thanks to their powerful power, ease of mobility, and quick start-up. With the acceleration of China’s industrialization and urbanization, natural disasters and industrial accidents are becoming more frequent, creating a growing demand for efficient rescue equipment. Powered by diesel engines, diesel mobile air compressors are widely used in municipal construction, road maintenance, mining blasting, oil and gas exploration, water well drilling, shipbuilding, and military applications, particularly in emergency rescue scenarios.

This research report focuses on the use of diesel mobile air compressors in major accident rescue in China from 2020 to 2025, and deeply analyzes its specific application, technical characteristics and actual effects in different types of accident rescue, providing reference for relevant departments and enterprises, and promoting the further application and development of diesel mobile air compressors in the field of emergency rescue.

Technical characteristics and advantages of diesel mobile air compressor

1.1 Core Technology Features

A diesel mobile air compressor is an integrated compressed air supply device consisting primarily of a diesel engine, air compressor, control system, air storage device, and mobile chassis. Its operating principle is that the diesel engine drives the air compressor, compressing the air and delivering it through pipelines to the work site for use by various pneumatic equipment. Modern diesel mobile air compressors have the following key technical features:

- Power system : It uses a high-efficiency diesel engine, usually a straight – four-cylinder diesel engine, electric start, with turbocharging, to provide strong power support. MINNUO MN17/14-153 unit uses a Carter twin-turbocharged diesel engine with strong power. Its high-pressure head can provide 40 kg of high pressure, greatly improving drilling efficiency.

- Compression systems : Most utilize screw air compression technology, which is characterized by high efficiency, stability, and low noise. For example, the MINNUO diesel mobile air compressor utilizes independently developed permanent magnet variable frequency air compressor technology and an IoT remote monitoring system, which can reduce energy consumption by over 30%.

- Control systems : These are equipped with a large-screen human-machine interface (HMI) with fault notification and logging capabilities for easy operation and maintenance. Some high-end models also feature intelligent control systems, such as mobile air compressors equipped with AI-driven operating systems. These systems dynamically adjust power output based on actual demand, saving energy and reducing operating costs.

- Mobility : The four-wheel trailer design provides flexible and convenient mobility, with the four-wheel trailer at the bottom, making it easy to maneuver in complex terrain. The equipment’s overall structure is compact, small, and lightweight. For example, the 24-hour company’s portable diesel-driven air compressor weighs only 50kg and can be carried to the rescue site by two people.

1.2 Advantages in emergency rescue

Diesel mobile air compressors have significant advantages in emergency rescue scenarios, mainly in the following aspects:

- Rapid Deployment : With a short startup time, typically within 30 seconds, the system meets the rapid gas supply needs of emergency rescue operations. This feature enables rescue teams to quickly establish a gas source, buying valuable time for rescue efforts.

- Independent Power Supply : Powered by diesel, it’s not restricted by on-site power supply conditions, making it particularly suitable for use at disaster sites where power outages or power outages occur. For example, if a natural disaster like an earthquake or mudslide paralyzes the power system, a diesel mobile air compressor can operate independently to ensure the normal operation of rescue equipment.

- Strong adaptability : It can adapt to various harsh environmental conditions, including high temperature, high humidity, high dust environment and remote areas .MINNUO MN17/14-153 electric-drive mobile air compressor can be placed outdoors to fill work areas that cannot be reached by the air lines in the compressor station within the factory.

- Stable and reliable gas supply : the output pressure is stable and the flow is sufficient. For example, the portable diesel-driven air compressor of 24-hour company can supply gas with a flow rate of 5m³/min. MINNUO MN17/14-153 unit can provide 40 kg high pressure to meet the needs of different rescue equipment.

- Multifunctional application : It can drive multiple pneumatic tools at the same time, such as hydraulic demolition tools, pneumatic jacks, drills, pneumatic picks, etc., so that one machine can be used for multiple purposes and improve rescue efficiency.

Specific application of diesel mobile air compressors in major accident rescue in recent years

2.1 Application in mine accident rescue

Mine accidents are a major challenge in China’s production safety sector, including various types such as collapse, water seepage, and explosion. Diesel mobile air compressors play a key role in mine accident rescue and are mainly used in the following aspects:

2.1.1 Underground ventilation and air supply

In mine collapses or explosions, underground ventilation systems are often damaged, leading to the accumulation of toxic and harmful gases and insufficient oxygen, seriously threatening the lives of trapped personnel. Diesel mobile air compressors can quickly establish temporary ventilation systems, providing fresh air and removing harmful gases underground.

Qixia Gold Mine Explosion Case : At 14:00 on January 10, 2021, an explosion occurred at the Wucailong Gold Mine under construction in Xicheng Town, Qixia City. At the time of the accident, 22 workers were trapped underground. Minnuo mobile air compressor participated in the rescue. Its model is MN17/14-153 was responsible for drilling holes in the main tunnel and delivering air underground. Over 320 professional rescue personnel and over 70 sets of various mechanical equipment were deployed on site, including drilling rigs, drill pipes, and other large-scale rescue equipment.

During this rescue operation, a diesel mobile air compressor delivered fresh air to the mine through a drill hole, improving the air quality underground and creating a better living environment for the trapped personnel. This also provided the necessary safety guarantees for rescuers entering the mine. This application fully demonstrates the key role of diesel mobile air compressors in mine rescue.

2.1.2 Driving rescue equipment

Mine rescue operations require a large number of pneumatic tools, such as drills, jackhammers, and rock drills. These devices require a stable supply of compressed air. Diesel mobile air compressors can power these devices and support the smooth progress of rescue operations.

National Emergency Rescue Learning and Exchange Conference Case : At a national emergency rescue learning and exchange conference, Minnuo MN17/14-153 unit demonstrated its powerful performance during a mine rescue drill. Powered by a powerful Carter twin-turbocharged diesel engine, its high-pressure head can deliver 40 kg of pressure, significantly improving drilling efficiency. Sullair’s mobile air compressors quickly responded to rescue needs, providing stable and reliable power support that continuously improves mine rescue capabilities.

In actual mine rescue operations, drills powered by diesel mobile air compressors can quickly open rescue routes, while pneumatic picks and rock drills can clear collapsed debris, paving the way for rescue efforts. This application not only improves rescue efficiency but also reduces the workload and safety risks faced by rescuers.

2.1.3 Drainage and obstacle removal

In mining accidents, especially flooding incidents, large amounts of accumulated water can increase the difficulty of rescue and even threaten the lives of trapped personnel. Diesel mobile air compressors can drive drainage equipment to remove accumulated water underground, creating conditions for rescue.

Furthermore, when clearing collapsed debris and obstacles, tools like pneumatic picks and rock drills driven by diesel mobile air compressors can efficiently break and remove obstacles, opening rescue routes. For example, in mine rescue operations, air compressors provide stable compressed air power for drilling rigs, workover rigs, and other equipment, ensuring smooth mine rescue operations.

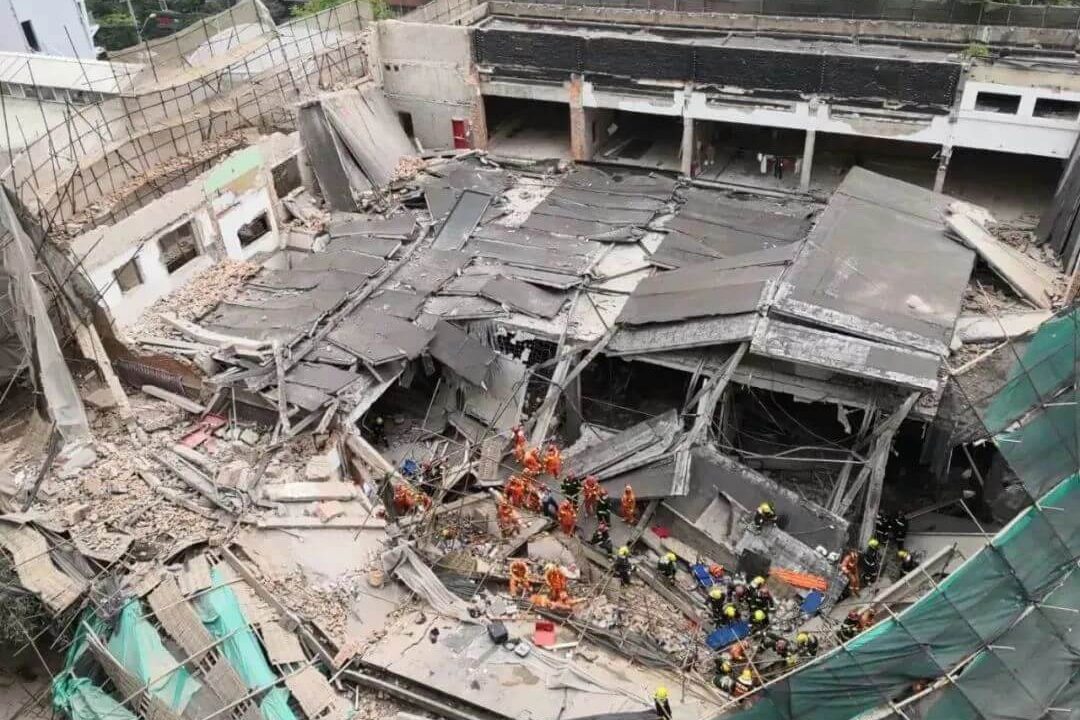

2.2 Application in building collapse accident rescue

Building collapse accidents are another common major safety accident, including building collapse caused by earthquakes and collapse caused by construction accidents. Diesel mobile air compressors are mainly used in the following aspects of building collapse rescue:

2.2.1 Opening rescue channels

In building collapses, rescuers need to quickly clear a path to reach trapped people. Hydraulic demolition tools powered by diesel mobile air compressors can cut through obstacles like rebar and concrete, creating a path for rescuers.

A rescue case study : A portable diesel-driven air compressor provided by 24 Hours (Shanghai) Equipment Leasing Co., Ltd. to emergency rescue agencies played a crucial role in a building collapse rescue operation. Weighing only 50 kg, the compressor could be carried to the rescue site by two people, had a quick startup time (less than 30 seconds), and provided an air flow rate of 5 m³/min. Using this compressor, the rescue team successfully opened a rescue channel within two hours and rescued three trapped people, buying valuable time for the rescue operation.

This case fully demonstrates the efficiency and practicality of diesel mobile air compressors in building collapse rescue operations. Due to their lightweight design and quick startup, they can be put into operation within a short period of time, providing the necessary air supply for rescue operations and significantly improving rescue efficiency.

2.2.2 Lifting and Removing Heavy Objects

In building collapse accidents, trapped people are often buried under heavy objects, requiring the use of equipment such as pneumatic jacks to lift and remove them. Diesel mobile air compressors can provide power for these devices, helping rescue workers lift collapsed objects and rescue trapped people.

In actual rescue operations, pneumatic jacks powered by diesel mobile air compressors have powerful lifting capabilities, can operate in confined spaces, and precisely control the lifting height to avoid secondary injuries to trapped personnel. Furthermore, due to their small size and light weight, they can be easily moved to the required location and adapt to various complex rescue environments.

2.2.3 Life detection and medical support

During the later stages of building collapse rescue operations, diesel mobile air compressors can also provide air source support for life detection equipment and medical rescue equipment. For example, during prolonged rescue operations, compressed air can be used to power equipment such as respirators and medical air pumps, providing necessary medical support to trapped personnel.

2.3 Application in earthquake disaster relief

Earthquake disasters often lead to large-scale building collapse and infrastructure damage, and rescue work faces huge challenges. Diesel mobile air compressors play an important role in earthquake disaster relief:

2.3.1 Demolition and search and rescue support

After the earthquake, numerous buildings collapsed, burying trapped people in the rubble. Hydraulic demolition tools powered by diesel mobile air compressors can efficiently cut through obstacles such as steel and concrete, clearing paths for rescue workers and conducting search and rescue operations.

In earthquake rescue operations, time is of the essence. The rapid deployment and stable air supply of diesel mobile air compressors ensures the continuous and efficient operation of rescue tools, significantly improving rescue efficiency. For example, during earthquake rescue operations, diesel mobile air compressors drive hydraulic rescue tools to cut through rebar and concrete, opening rescue routes and buying valuable time to free trapped personnel.

2.3.2 Temporary gas and electricity supply support

Earthquake disasters often paralyze power systems, impacting the normal operation of rescue equipment. Diesel mobile air compressors, as independent power sources, can provide power for various pneumatic equipment and can also provide temporary power support in conjunction with generators.

For example, diesel generators are extremely useful in earthquake relief efforts. Without electricity, disaster relief efforts are difficult, making mobile power stations a crucial option for emergency response. These mobile power stations typically feature a 50-kilowatt generator set, powered by an inline four-cylinder diesel engine with electric start and turbocharging, a copper-core generator, and a push-button start function. The unit also comes with a four-wheel trailer, making it flexible and easy to move, allowing for rapid deployment wherever needed.

2.3.3 Post-disaster reconstruction support

Post-earthquake reconstruction efforts also require significant compressed air support. Diesel mobile air compressors can power various construction equipment, supporting debris removal, temporary building construction, and infrastructure repair.

During the post-disaster reconstruction phase, the mobility and adaptability of diesel mobile air compressors are fully utilized, allowing them to be quickly deployed at different construction sites to meet various construction needs. For example, Xinran diesel mobile air compressors are widely used in municipal engineering construction, landscaping projects, water pipe dredging, communication cable systems, road traffic management and other fields, providing strong support for post-disaster reconstruction.

2.4 Application in Chemical Accident Rescue

Chemical accidents include chemical leaks, explosions, fires, etc., which are often accompanied by the release of toxic and harmful gases, posing special challenges to rescue work. Diesel mobile air compressors are mainly used in chemical accident rescue:

2.4.1 Leakage control and plugging

In the event of a chemical pipeline leak, the source must be quickly controlled to prevent the spread of hazardous substances. Diesel portable air compressors can drive pneumatic tools, such as pneumatic wrenches, to quickly remove and install pipeline flanges, allowing leaks to be repaired promptly and reducing the amount of hazardous chemicals released.

For example, in the synthesis of chemical products, the pressure and flow of the reaction gas need to be precisely controlled. Diesel mobile air compressors can provide stable and precise compressed air according to process requirements, helping the smooth progress of chemical reactions and leakage control.

2.4.2 Ventilation and gas treatment

Chemical accident sites often contain toxic and hazardous gases, requiring effective ventilation and gas treatment. Diesel mobile air compressors can power ventilation equipment, helping to disperse leaked toxic and hazardous gases and protect the safety of on-site rescue workers.

In practical applications, ventilation equipment powered by diesel mobile air compressors can quickly improve air quality at accident sites, reduce toxic gas concentrations, and create a safe working environment for rescue workers. Compressed air can also be used to power gas detection equipment, helping rescue workers understand on-site gas conditions and develop effective rescue plans.

2.4.3 Firefighting and cooling support

In chemical fire accidents, diesel mobile air compressors can provide power support for fire-fighting equipment, such as driving fire pumps, foam generators and other equipment to perform fire extinguishing and cooling work.

In high-temperature environments, diesel mobile air compressors can still operate stably, providing a continuous air supply for firefighting equipment. Compressed air can also be used to drive cooling equipment, lowering both equipment and ambient temperatures, preventing the spread of fire and secondary explosions.

2.4 Other Application Scenarios

In addition to the above-mentioned major accident types, diesel mobile air compressors also play an important role in many other emergency rescue scenarios:

2.4.1 Oil and gas pipeline leak rescue

In the event of an oil or gas pipeline leak, a diesel mobile air compressor can provide power for leak-proofing equipment, ventilation equipment, and firefighting equipment. For example, at an oil extraction site, air compressors provide stable compressed air power to drilling rigs, workover rigs, and other equipment, ensuring smooth oil extraction operations and leak control.

2.4.2 Water conservancy project emergency rescue

During water conservancy project rescue operations, diesel portable air compressors can provide power for drainage equipment, grouting equipment, and demolition tools. For example, during dam rescue operations, diesel portable air compressors can drive drainage pumps to remove accumulated water and grouting equipment to plug leaks, providing strong support for rescue efforts.

2.4.3 Road and bridge emergency repairs

During emergency road and bridge repairs, diesel mobile air compressors can power crushing equipment, drilling equipment, and concrete vibrating equipment. For example, during emergency road repairs, crushing equipment driven by diesel mobile air compressors can quickly clear damaged road surfaces, while drilling equipment can perform anchoring operations, providing support for emergency road repairs.

Technical development trend of diesel mobile air compressor in major accident rescue

With the continuous advancement of science and technology and the increasing demand for emergency rescue, diesel mobile air compressors have shown the following development trends in technology and application:

3.1 Improvement in intelligence and automation

Modern diesel mobile air compressors are increasingly using intelligent and automated technologies to improve the performance and usability of the equipment:

- Intelligent control systems : Mobile air compressors equipped with AI-driven operating systems can dynamically adjust power output based on actual demand, saving energy and reducing operating costs. For example, Xinran air compressors utilize an IoT-enabled remote monitoring system, which reduces energy consumption by over 30% and supports real-time data monitoring and fault warnings.

- Remote monitoring technology : Through a remote platform, you can view air compressor parameters such as pressure, flow, and energy consumption in real time, optimizing equipment efficiency and reducing operating costs. This technology makes equipment management more convenient and improves equipment reliability and safety.

- Automated operation : Some high-end models have achieved automated operation, such as automatic startup, automatic loading/unloading, automatic protection and other functions, which greatly simplifies the operation process and reduces the skill requirements for operators.

3.2 Energy-saving and environmental protection technology innovation

Against the backdrop of increasingly stringent environmental protection requirements, diesel mobile air compressors are constantly innovating in energy-saving and environmentally friendly technologies:

- High-efficiency and energy-saving design : Utilizing efficient screw compression technology and energy-saving motors, energy consumption is reduced.

- New energy applications : Some manufacturers are beginning to explore the use of alternative fuels, such as hydrogenated vegetable oil (HVO), a renewable energy source, to provide cleaner exhaust and reduce environmental impact. This fuel is carbon-neutral and provides cleaner exhaust, thereby reducing environmental impact.

- Low-noise design : Optimized structural design and the use of sound-insulating materials reduce equipment operating noise.

3.3 Lightweight and Portable Development

In order to adapt to complex rescue environments, diesel mobile air compressors are developing towards lightweight and portability:

- Lightweight material application : High-strength, lightweight materials are used to manufacture equipment housings and components to reduce equipment weight. For example, the use of aluminum alloy in the air compressor housing ensures sufficient strength while also providing good heat dissipation.

- Compact design : Optimize internal structure layout and reduce equipment size. For example, Minnuo ‘s portable diesel-driven air compressor weighs only 50kg and can be carried to the rescue site by two people. It has a fast startup time (within 30 seconds) and an air flow rate of 5m³/min.

- Modular Design : A modular design concept facilitates equipment transportation, installation, and maintenance. For example, the newly upgraded 250kW vehicle-mounted air compressor, installed on a vehicle chassis, consumes over 23% less electricity than traditional twin-screw air compressors. It can be moved to supply air over short distances, reducing energy consumption, pipeline requirements, and gas tank usage.

3.4 Multifunctional Integration

Modern diesel mobile air compressors are increasingly focusing on multi-functional integration to improve the adaptability and utilization of equipment:

- Multi-source integration : Able to simultaneously provide compressed air at a variety of pressures and flow rates to meet the needs of different equipment. For example, some high-end models can simultaneously provide low-pressure, high-flow and high-pressure, low-flow compressed air to adapt to different application scenarios.

- Multi-device integration : Integrating air compressors with other equipment, such as generators and hydraulic systems, creates multifunctional rescue equipment. For example, a new vehicle-mounted air compressor combines the functions of an air compressor and a generator, providing power support for multiple devices.

- Multi-scenario adaptability : Through optimized design and the selection of appropriate materials, the equipment’s adaptability to diverse environmental conditions is enhanced. For example, the diesel-driven, oil-free PTS1600 air compressor, featuring a diesel-driven, oil-free design, helps customers quickly obtain high-quality, ISO 8573/1 Class 0-certified oil-free compressed air in remote, power-limited, and harsh environments.

Evaluation of the application effect of diesel mobile air compressor in major accident rescue

4.1 Improved rescue efficiency

The application of diesel mobile air compressors has significantly improved the efficiency of major accident rescue:

- Rapid Response : Diesel-powered portable air compressors start quickly, typically within 30 seconds, allowing them to be put into operation quickly, buying valuable time for rescue efforts. For example, during a building collapse rescue operation, Minnuo ‘s portable diesel-driven air compressors helped the rescue team open a rescue channel within two hours and rescue three trapped people.

- Continuous working ability : Diesel mobile air compressor has strong continuous working ability and can provide stable air source support during long-term rescue operations. The MN17/14-153 air compressor has been running for 7,200 hours and still maintains stable and reliable performance.

- Multi-device coordination : A single diesel mobile air compressor can simultaneously provide air supply support for multiple pneumatic devices, improving rescue equipment utilization and coordination efficiency. For example, the XAS 88KD, equipped with a highly efficient integrated power source, delivers up to 5.0 m³/min of air pressure, enough to power three pneumatic tools, ensuring maximum hourly construction efficiency.

4.2 Improved rescue safety

The application of diesel mobile air compressors also significantly improves the safety of rescue work:

- Reduce the risk of secondary injury : Pneumatic tools driven by diesel mobile air compressors are precise in operation and can work in confined spaces, reducing the risk of secondary injury to trapped personnel.

- Adapt to dangerous environments : Diesel mobile air compressors can work stably in harsh environments such as high temperature, high humidity, and high dust, providing rescue workers with necessary air source support and ensuring the safety of rescue work.

- Reduce the labor intensity of rescue workers : Pneumatic tools driven by diesel mobile air compressors have powerful working capabilities and can complete many tasks that are difficult to complete by manpower, reducing the labor intensity and safety risks of rescue workers.

4.3 Economic Benefit Analysis

From the perspective of economic benefits, the application of diesel mobile air compressors also brings significant value:

- Equipment leasing reduces costs : Equipment leasing eliminates the need for large investments in equipment, reducing emergency response costs. For example, the air compressor leasing service provided by 24 Hours (Shanghai) Equipment Leasing Co., Ltd. helps businesses avoid wasted equipment and lower operating costs.

- Improve equipment utilization : Through the leasing model, diesel mobile air compressors can be reused in multiple projects and rescue operations, improving equipment utilization and return on investment.

- Reduced energy consumption and maintenance costs : Modern diesel mobile air compressors utilize advanced energy-saving technologies and intelligent control systems, reducing energy consumption and maintenance costs. For example, Minnuo air compressors utilize independently developed permanent magnet variable frequency air compressor technology and an Internet of Things (IoT) remote monitoring system, reducing energy consumption by over 30%.

Conclusions and Recommendations

5.1 Research Conclusions

Through the study of the application and performance of diesel mobile air compressors in major accident rescue in China in recent years, we can draw the following conclusions:

- Widely used and effective : Diesel mobile air compressors have been widely used in the rescue of major accidents such as mining accidents, building collapses, and earthquake disasters in China in recent years, playing a key role and significantly improving rescue efficiency and success rate.

- Outstanding technical features : Diesel portable air compressors are characterized by quick start-up, strong power, easy mobility, and adaptability to harsh environments, making them particularly suitable for emergency rescue scenarios. These features make them an indispensable and important equipment in emergency rescue.

- Rapid technological development : In recent years, diesel mobile air compressors have made significant progress in intelligence, energy saving and environmental protection, lightweight and multi-functional integration, and the performance of equipment has been continuously improved.

- Significant economic benefits : Through the leasing model and the application of advanced technology, diesel mobile air compressors not only improve rescue efficiency but also reduce the cost of emergency rescue, with significant economic benefits.

5.2 Application Recommendations

Based on the research conclusions, we put forward the following application suggestions:

- Strengthen equipment deployment and layout : It is recommended that emergency rescue agencies at all levels reasonably deploy diesel mobile air compressors based on the characteristics of local accidents and rescue needs, and establish a regional linkage mechanism to ensure that the equipment can be quickly deployed and used.

- Strengthen operator training : The efficient use of diesel mobile air compressors is inseparable from professional operators. It is recommended to strengthen the training of rescue personnel to improve their operating skills and emergency response capabilities to ensure that the equipment can perform at its maximum efficiency at critical moments.

- Establish an equipment maintenance and update mechanism : To ensure that the diesel mobile air compressor is always in good working condition, it is recommended to establish a complete equipment maintenance and update mechanism, perform regular maintenance, and update old equipment in a timely manner.

- Promote advanced technology and application experience : It is recommended that relevant departments and industry associations regularly organize technical exchanges and experience sharing activities to promote advanced diesel mobile air compressor technology and application experience and improve the overall rescue level.

- Strengthen industry-university-research cooperation : Encourage enterprises, universities and research institutions to strengthen cooperation, jointly carry out diesel mobile air compressor technology research and development and application research, and promote technological innovation and industrial upgrading.

5.3 Future Outlook

Looking into the future, diesel mobile air compressors have broad application prospects in major accident rescue:

- The degree of intelligence will be further improved : With the development of technologies such as artificial intelligence and the Internet of Things, the intelligence level of diesel mobile air compressors will be further improved, achieving more precise control and more efficient operation.

- Energy-saving and environmental protection performance will continue to improve : Against the backdrop of increasingly stringent environmental protection requirements, diesel mobile air compressors will pay more attention to energy conservation and environmental protection, and develop more efficient and clean technologies and products.

- Multifunctional integration will become a trend : Future diesel mobile air compressors will pay more attention to multifunctional integration, and integrate with more rescue equipment and technologies to form a more complete emergency rescue solution.

- The application areas will continue to expand : With the advancement of technology and the accumulation of application experience, the application areas of diesel mobile air compressors will continue to expand, providing support for more types of accident rescue.

In short, as an important equipment for emergency rescue, diesel mobile air compressors will play a more important role in major accident rescue in the future and make greater contributions to protecting people’s lives and property.

Email

Email sales:+86 15366749631

sales:+86 15366749631