The development of the catering industry has always centered on food safety and operational efficiency. With the tightening of industry supervision and the upgrading of consumer demand, the shortcomings of traditional oil-lubricated compressors have become increasingly prominent—lubricating oil leakage is likely to cause food contamination, and problems such as high energy consumption, high noise, and frequent maintenance also push up operating costs. Against this backdrop, oil-free scroll compressors have become a key equipment for the industry’s upgrading, thanks to their features including Class 0 oil-free standard (oil content ≤ 0.01mg/m³), volumetric efficiency of over 90%, and quiet operation at 55-60 decibels. Their penetration rate in the catering field has risen from 31% in 2021 to 43% in 2024, and the market scale is expected to exceed 12 billion yuan (RMB) by 2030.

Jiangsu Minnuo Group, which has deep experience in the compressor field, accurately adapts to all catering scenarios with more than 50 patents, ISO 8573-1 Class 0 certification, and a “mini-type medium-displacement large-displacement” product matrix. This article will start with the technical principles of oil-free scroll compressors, analyze the adaptation logic between these compressors and catering scenarios, discuss the value of the equipment in scenarios such as baking and cold chain with reference to Jiangsu Minnuo’s application cases, and finally look ahead to the industry’s development trends, providing references for catering enterprises to upgrade their equipment.

1. Technical Principle: Decoding the “Pure Power” Gene of Oil-Free Vortex

1.1 Definition and Characteristics

Oil-free scroll compressors, as efficient and clean compressed air equipment, play a vital role in modern industrial production. They can be defined as equipment capable of producing oil-free compressed air. Through their specific mechanical structure and operating principle, they ensure that the compression process contains no harmful oils, thereby providing pure, dry, and stable compressed air. These devices are widely used in fields such as semiconductor manufacturing, food processing, medical equipment, electronics, and automotive manufacturing, making them an indispensable component of modern industrial production .

The main features of oil-free scroll compressors are reflected in the following aspects:

High efficiency, energy saving and low consumption: The oil-free scroll compressor adopts a unique structure in which the moving scroll and the static scroll are meshed. The moving scroll revolves around the static scroll, forming multiple continuously changing compression chambers to smoothly complete the suction, compression and exhaust processes. This design abandons the impact motion of the traditional reciprocating piston, greatly improving the compression efficiency, and the volumetric efficiency can reach more than 90%. Equipped with permanent magnet frequency conversion technology, it can also intelligently adjust the speed according to the actual gas demand in the catering scene, and the energy efficiency under partial load is more than 30% higher than that of traditional models. According to industry research, the oil-free scroll compressor used in the catering industry in 2025 will have an average annual energy consumption of about 22,000 degrees lower than that of traditional oil-containing compressors. In long-term operation scenarios such as chain central kitchens, the energy-saving advantage is very prominent.

Compact Design and Quiet Operation: Leveraging the inherent advantages of a scroll structure, oil-free scroll compressors achieve an extremely compact design. Compared to traditional piston compressors, these compressors are 40%-50% smaller and approximately 30% lighter, achieving the same displacement. This makes them suitable for installation in limited spaces, such as restaurant kitchens and central kitchens, and can be wall-mounted or nestled in corners between equipment. Furthermore, the compression process eliminates the need for violent mechanical motion, such as piston impact or valve opening and closing. Operating noise is controlled at 55-60 decibels, significantly lower than the 75-90 decibels of traditional models.

Pure compressed air and hygienic assurance: One of the core features of oil-free scroll compressors is their ability to provide oil-free compressed air that complies with ISO 8573-1 Class 0 standards. Carbon fiber-reinforced, self-lubricating, wear-resistant materials in the compression chamber enable oil-free operation, eliminating lubricant contamination of the compressed air at the source. The oil content is ≤ 0.01 mg/m³, and particulate matter and microbiological indicators also meet food processing requirements. In the catering industry, this pure air can be used directly in food-contact processes such as pneumatic beverage filling, bread dough mixing, and cold chain food sorting, effectively mitigating the risk of food contamination.

Long life and easy maintenance: The scroll and other core components of the oil-free scroll compressor are made of wear-resistant, self-lubricating high-end materials. The oil-free design eliminates component wear caused by lubricant aging and carbonization, resulting in a service life of 15-20 years, far exceeding the 8-12 years of traditional oil-containing compressors. Maintenance is also significantly simplified, eliminating the need for frequent lubricant changes and oil-gas separator cleaning. Only consumable parts, such as the air filter, require regular replacement, resulting in an average of only one to two maintenance visits per year, reducing maintenance costs by approximately 30%.

1.2 Core structure and working principle

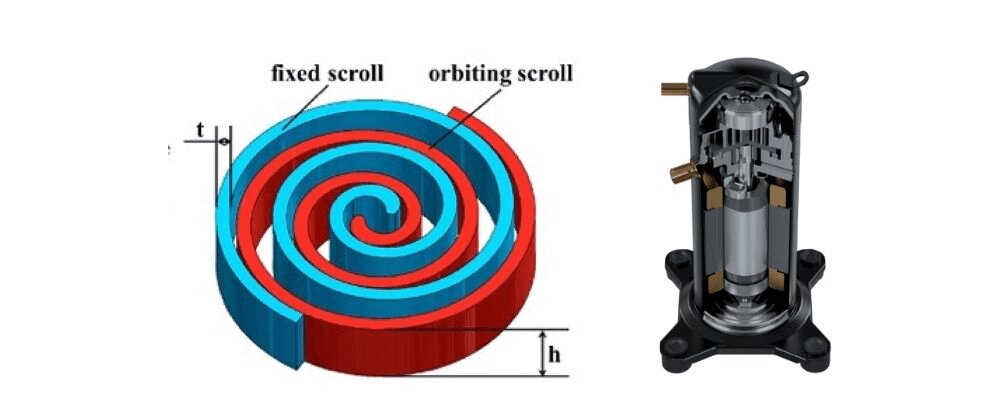

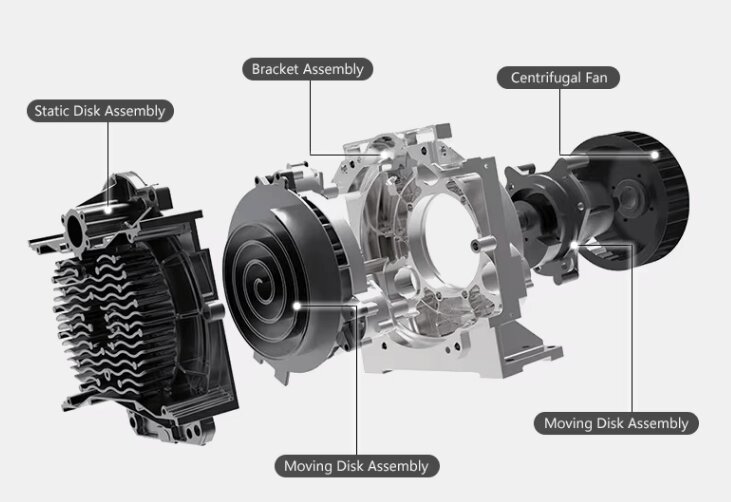

The core structure of the oil-free scroll compressor revolves around two main technologies: “scroll meshing compression” and “oil-free sealing”. Its core components and motion mechanism determine the efficient and clean output characteristics:

(1)Core structure composition

The scroll assembly consists of a fixed scroll (fixed to the engine frame) and an orbiting scroll (a revolving scroll). These two components mesh with high-precision spiral tooth surfaces, achieving tolerances down to the micron level. The scrolls are typically constructed of high-strength die-cast aluminum or engineering ceramics. Adaptive sealing strips (Such as carbon fiber reinforced polytetrafluoroethylene) are embedded in the tooth tips. When the compressor starts, gas pressure expands the sealing strips, creating a dry seal and physically preventing lubricant contamination.

Anti-rotation mechanism: The orbiting scroll is constrained by a cross ring or spherical coupling so that it only orbits around the center of the stationary scroll (rather than rotating), ensuring a stable meshing clearance and controllable changes in the compression chamber volume.

Spindle and bearing system: The spindle is made of stainless steel, and the bearings use self-lubricating materials or permanent magnetic suspension technology to achieve oil-free operation, avoiding the risk of lubricating oil leakage in traditional bearings.

Cooling and sealing system: Rely on forced air cooling (such as Gaoling Technology’s independent wind wheel and heat dissipation duct) or water cooling system to remove compression heat; some models adopt “water lubrication” design, using food-grade pure water as the lubricating medium to further improve air cleanliness.

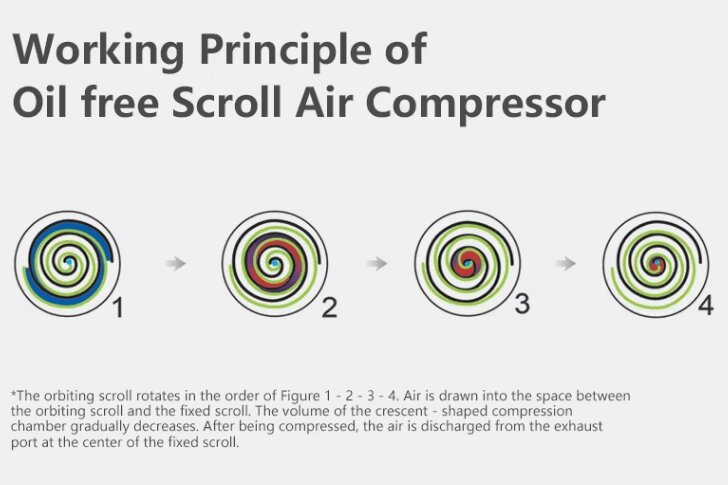

(2) Working principle: continuous progressive compression

The oil-free scroll compressor drives the gas to complete the continuous cycle of “intake → compression → exhaust” through the orbital motion of the orbiting scroll:

Intake phase: The orbiting scroll revolves around the center of the stator, creating multiple crescent-shaped, sealed cavities between the tooth surfaces of the two. External air is drawn into these cavities through the air inlet at the center of the handpiece. As the orbiting scroll rotates, the cavity volume gradually expands, completing the intake process.

Compression phase: The orbiting scroll continuously orbits, pushing the crescent-shaped cavity toward the center. The cavity volume is steadily reduced, and the gas pressure and temperature gradually increase (temperature rise is controlled within 25°C). Due to the scroll’s multi-cavity simultaneous compression characteristics, the airflow pulsation rate is less than 5%, far superior to the 20% or more of traditional piston engines.

Exhaust stage: When the compressed gas reaches the smallest cavity in the center of the scroll, the pressure reaches a peak (usually 0.7-1.0 MPa) and is discharged continuously through the exhaust port at the top of the static scroll without pulse fluctuations.

(3) Technical implementation of oil-free lubrication

Oil-free scroll compressors achieve “zero lubricating oil pollution” through two paths:

Dry friction oil-free: The scroll tooth surface and sealing strip are made of self-lubricating materials (such as polytetrafluoroethylene and engineering ceramics). During operation, the seal is maintained by the wear resistance of the material itself and the “air film” formed by gas pressure, and no lubricating oil is required.

Water-lubricated oil-free: High-power models (such as above 55kW) use food-grade pure water as the lubricating medium. The water can be completely separated through the post-filtration system while cooling and sealing. The final output air oil content is ≤0.001mg/m³, meeting strict food-grade standards.

This “oil-free compression + adaptive sealing” design stabilizes the exhaust oil content of the oil-free scroll compressor at Class 0 (≤0.01mg/m³). At the same time, it improves energy efficiency through “multi-cavity continuous compression”, with a volumetric efficiency of 90%-95%, saving more than 30% energy compared to traditional piston engines.

1.3 Technical Adaptability of Catering Scenarios

The technical characteristics of oil-free scroll compressors are highly compatible with the diverse needs of the catering industry. They precisely meet the requirements of chain store kitchens and central kitchens, from back-of-house kitchens to central kitchens, in terms of hygiene and safety, space utilization, noise control, energy consumption fluctuations, and ease of operation and maintenance. In restaurant refrigeration, packaging, and beverage distribution, where compressed air comes into direct contact with food, oil-free scroll compressors, with their Class 0 oil-free design (oil content ≤ 0.01 ppm), eliminate the risk of lubricant contamination at the source. Their output air meets stringent standards for particulate matter ≤ 0.1 μm, microorganisms ≤ 100 CFU/m³, and a pressure dew point ≤ -40°C . To address the spatial fragmentation of restaurant kitchens and central kitchens, their modular, integrated design makes them 40%-50% smaller and 30% lighter than traditional piston compressors for the same exhaust volume. They also support parallel operation of two to four units, supplying distributed gas points via centralized piping. They can be flexibly wall-mounted or recessed into corners of equipment, significantly simplifying piping layout. Vortex meshing technology achieves inherently low-noise operation, with noise levels ≤65dB (equivalent to the volume of a normal conversation) and vibration levels ≤2.5mm/s. This eliminates the need for additional soundproofing (traditional diesel engines require an investment of 12,000 yuan per unit). To address the significant fluctuations in gas demand in the catering industry (such as full load on pneumatic equipment during the lunch rush hour and low load on refrigerators at night), permanent magnet variable frequency technology dynamically adjusts the motor speed between 300-3000 rpm, improving energy efficiency by over 30% at partial load. Furthermore, pressure recovery time is ≤3 seconds from full to 50% load, preventing equipment downtime caused by pressure fluctuations. Furthermore, since most operation and maintenance personnel in catering companies lack technical expertise, the oil-free design reduces wearing parts by 80%, eliminating the need for lubricant and oil separator replacement, and requiring only one to two maintenance visits per year. Parameters such as pressure, dew point, and filter life can also be intelligently monitored via the display or mobile app, with intuitive and easy-to-understand fault codes. In summary, the oil-free scroll compressor, with its technical combination of “clean air + compact and low noise + variable frequency energy saving + easy maintenance”, has become the core power equipment for the catering industry to ensure food hygiene and safety and improve operational efficiency.

2. Core application scenarios of Jiangsu Minnuo oil-free scroll compressor

Jiangsu Minnuo Group’s oil-free scroll compressors, with their clean output, intelligent control, and stable operation, demonstrate precise adaptation value across the entire catering chain. Their core applications cover key links such as baking processing, cold chain warehousing, and distribution.

In chain restaurant baking lines, this equipment utilizes an ISO 8573-1 Class 0 certified, oil-free pure air source, fundamentally eliminating the risk of compressed air contamination. Its output air has an extremely low oil content, allowing direct contact with sensitive ingredients such as coffee beans and flour, fully meeting food processing hygiene requirements. Operating noise is controlled to a level comparable to a normal conversation, ensuring a quiet operating environment even when installed in the baking area of a shopping mall or near an R&D laboratory. A built-in intelligent monitoring system tracks key parameters such as pressure and temperature in real time, providing predictive warnings to mitigate malfunctions. The main unit achieves 25,000 hours of maintenance-free operation, reducing downtime and maintenance by 180 hours annually. Combined with the store management system’s coordinated adjustment function, the air supply pressure is automatically increased during peak baking hours and reduced during off-peak hours. This can save a single store 42,000 yuan in electricity bills annually and reduce maintenance costs by over 30%.

In the cold chain storage system of the central kitchen, Jiangsu Minnuo’s oil-free scroll compressor solves the industry problem of reduced refrigeration efficiency in low-temperature environments. In cold storage conditions at minus 25 degrees Celsius, the equipment can still stably output strong refrigeration capacity, and through precise temperature control technology, the temperature fluctuation in the box is controlled within the range of ±0.5°C, extending the shelf life of pre-prepared dishes, fresh food and other ingredients to 120 days, and reducing the food loss rate from 8% to 3%. The waste heat generated during equipment operation can be converted into 85°C hot water through a recovery system to directly meet the needs of tableware disinfection. A single factory can save more than 150,000 yuan in natural gas costs each year. At the same time, the optimized noise reduction design completely solves the noise nuisance problem in traditional cold storage machine rooms, creating a more comfortable working environment for warehouse operators .

In catering distribution center scenarios, this oil-free scroll compressor unit outputs air without contact with lubricating oil, eliminating the risk of contamination of cold chain ingredients and successfully passing the latest food safety standards. Its multi-unit intelligent joint control system can dynamically adjust its operating status according to the delivery volume: during the daily delivery peak period from 6:00 to 10:00 a.m., multiple units work together at full capacity to ensure air supply; during low-load periods at night, it automatically switches to single-unit operation mode. This flexible and adaptable operating mode enables the equipment to achieve Class A energy efficiency standards, saving over 30% compared to traditional oil-containing compressors, reducing annual electricity consumption by 220,000 kWh for a single distribution center, and keeping order delays due to equipment failures below 0.3%.

These application scenarios together confirm that Jiangsu Minnuo’s oil-free scroll compressor provides safe and efficient power solutions for the entire chain of the catering industry from production and processing to warehousing and distribution through the technical combination of “clean air source + intelligent energy saving + low-consumption maintenance”. Its average investment recovery period of 1.8 years and energy savings of more than 600,000 yuan in a 15-year cycle further highlight its long-term application value.

3. Jiangsu Minnuo Oil-free Scroll Compressor’s Product Matrix and Deep Adaptation to Catering Scenarios

Jiangsu Minnuo Group has been deeply engaged in the field of air compressors. With more than 50 invention and utility model patents, TUV and ISO 8573-1 Class 0 certifications, it has built an oil-free scroll compressor product matrix covering “mini-medium displacement-large displacement”, which accurately matches the full-scene needs of the catering industry from single-store operations to central kitchen large-scale production.

3.1 Power-based models adapted to different dining scenarios

Mini (1.5-3.7 kW): Space-friendly for chain stores. Designed for space-constrained locations like shopping mall coffee shops and community bakeries, Jiangsu Minnuo’s 1.5-3.7 kW oil-free scroll compressors are incredibly compact . Measuring just 540 x 540 x 770 mm (roughly equivalent to a double-door refrigerator), and weighing a minimum of 110 kg, they can be mounted directly on kitchen walls or recessed under countertops, eliminating valuable floor space. Operating noise levels are controlled at 51-56 dB, quieter than background music in shopping malls. Even in kitchens adjacent to customer dining areas, they avoid noise complaints.

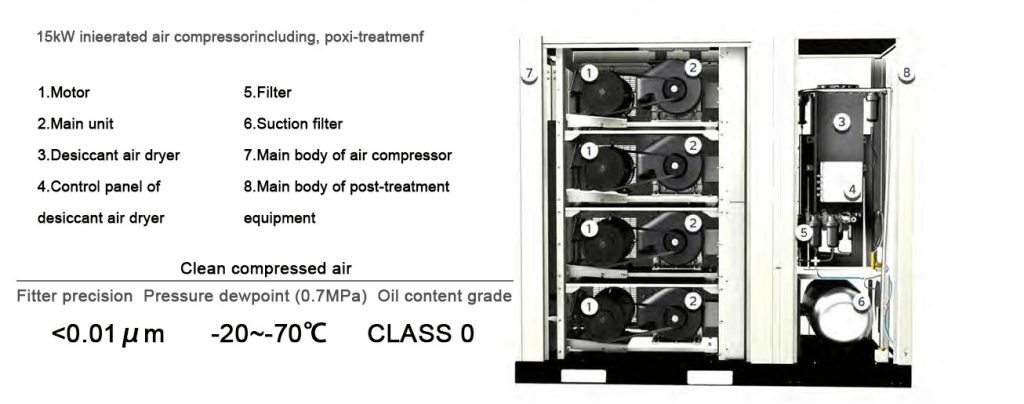

Medium-displacement (7.5-18.5 kW): A highly efficient and adaptable solution for regional central kitchens. For chain brands with regional central kitchens serving 10-20 stores, these 7.5-18.5 kW mid-displacement models meet the centralized air supply needs for dough mixing, pneumatic food sorting, and small cold storage cooling. These models integrate a dryer and precision filter, maintaining a stable dew point of -20°C to -70°C after compressed air conditioning, effectively preventing condensation from breeding bacteria in pipelines. These units are suitable for applications requiring high air dryness, such as dough fermentation and dairy product filling.

Large-displacement (22-37 kW): Core equipment for stable operation in central kitchens. To meet the demands of 24-hour continuous production and simultaneous gas consumption for multiple production lines in pre-prepared food central kitchens, large-displacement 22-37 kW models, featuring intelligent control and a long-life design, are the core power source. Their main engine offers 25,000 hours of maintenance-free operation, extending the maintenance interval three times that of traditional diesel engines, significantly reducing unplanned downtime .

3.2 One-stop supporting services: lowering the threshold for catering enterprises to establish themselves

Jiangsu Minnuo does not simply provide compressor equipment, but has created a one-stop solution of “compressor + supporting equipment + installation service” based on the needs of catering scenarios to solve the pain points of catering companies such as “difficult equipment selection, complex installation, and poor later adaptation”.

Supporting equipment adapted to the unique characteristics of the catering environment. Designed for the humid and greasy environment of restaurant kitchens, the accompanying air storage tanks are constructed of 304 stainless steel, with a thickness of 4-6mm, effectively preventing rust and boasting a service life of up to 20 years. A precision air filter can filter out particles and microorganisms larger than 0.1μm. Combined with a refrigerated air dryer, the water content of the compressed air is controlled below 3ppm, preventing food contamination caused by water accumulation in the pipes. Furthermore, Jiangsu Minnuo’s aluminum alloy pipes utilize quick-connect connections, increasing installation efficiency by 50% compared to traditional galvanized pipes. Their smooth inner surface resists grease accumulation, reducing cleaning frequency from quarterly to semi-annual, saving 12,000 yuan in annual maintenance costs for a single kitchen pipe.

Taking into account the differences in layout between restaurant outlets and central kitchens, Jiangsu Minnuo provides on-site surveys and customized installation services. To accommodate the height restrictions of shopping malls, the compressor and dryer can be stacked one above the other. To meet the multi-story gas requirements of central kitchens, a vertical piping system is designed to minimize pressure loss. Furthermore, with over 200 service locations nationwide, Minnuo promises a response time of two hours for fault reports and on-site repairs within 48 hours, addressing restaurant operators’ concerns about equipment breakdowns and lack of repair services.

3.3 Compliance and Global Advantages: Helping Catering Companies Expand Their Boundaries

Jiangsu Minnuo’s oil-free scroll compressors offer dual guarantees for catering companies in terms of policy compliance and international presence. Firstly, they are ISO 9001:2015 certified and SGS-tested, fully complying with the 2025 “Hygiene Standard for Compressed Air for Food Processing,” enabling companies to pass regulatory reviews without requiring additional modifications. Secondly, their products are exported to over 150 countries and comply with international standards such as the EU CE and the US FDA, facilitating international expansion for catering companies. A frozen food company successfully obtained EU food contact material certification using Jiangsu Minnuo’s Class 0 compressors, reducing tariffs on their European exports by 5% and increasing their annual export value by 20 million yuan.

4. Development trend of oil-free scroll compressors in the catering industry (based on Jiangsu Minnuo’s technical direction)

Judging from Jiangsu Minnuo’s technology research and development and product iteration, the application of oil-free scroll compressors in the catering industry will show three major trends in the future:

4.1 Intelligent Upgrade: Adapting to Digital Management of Catering

Jiangsu Minnuo has integrated a “touch-controlled computer + remote monitoring module” into some of its models, allowing users to view equipment operating data and receive maintenance reminders via a mobile app. In the future, Minnuo will integrate with the ERP systems of catering companies to achieve integrated management of “gas demand, equipment operation, and energy consumption statistics.” For example, the system can predict the next day’s baking output based on store sales data and adjust the compressor’s air supply pressure and duration in advance, further reducing energy consumption.

4.2 Deepening Greening: From “Oil-free” to “Low Carbon Throughout the Life Cycle”

In addition to its oil-free design, Jiangsu Minnuo is promoting low-carbon development throughout its equipment lifecycle through innovative materials (such as a recyclable aluminum alloy body) and upgraded heat recovery technology (increasing waste heat recovery from 94% to 98%). In the future, its oil-free scroll compressors will be integrated with catering businesses’ solar power systems, achieving a “green energy + clean air supply” combination, helping catering brands achieve carbon neutrality goals.

4.3 Scenario-based Segmentation: Customized Solutions for New Catering Businesses

With the rise of new business formats such as pre-prepared meals and community group meals , Jiangsu Minnuo plans to launch a “mobile oil-free scroll compressor” – drawing on its design experience in mobile electric two-wheel/four-wheel compressors, it will create a small, flexible and movable oil-free model to meet the temporary gas supply needs of community group meals; at the same time, in response to the development of hydrogen energy catering equipment, it will develop oil-free compression technology that is suitable for hydrogen environments to seize the initiative in emerging scenarios.

Conclusion

Jiangsu Minnuo Group has transformed oil-free scroll compressors from “industrial equipment” to “infrastructure for the catering industry” through a model of “product matrix adaptation to specific scenarios, one-stop service to lower barriers to entry, and compliance advantages to expand boundaries.” Its 32 years of technological accumulation and scenario-based innovation have not only addressed core pain points for catering companies, such as hygiene compliance, energy consumption control, and convenient operation and maintenance, but have also driven the transformation of oil-free scroll technology from “optional equipment” to “standard equipment.” With the implementation of the new hygiene standards in 2025 and the intelligent upgrade of the catering industry, companies like Jiangsu Minnuo, with both technical strength and service capabilities, will become a key force in driving the catering industry’s “clean, low-carbon, and digital” transformation. The above content combines Jiangsu Minnuo’s product characteristics with the needs of catering scenarios, supplemented by product adaptation details and future trends. If you would like to highlight the application of a certain type of catering format (such as pre-prepared meals or chain coffee shops), or add more practical value of technical parameter conversion, please feel free to let me know for further adjustments.

Email

Email sales:+86 15366749631

sales:+86 15366749631